DTC P011B: Engine Coolant Temperature /Intake Air Temperature Correlation

CIRCUIT OPERATION

TECHNICAL DESCRIPTION

MONITOR EXECUTION

- Once per driving cycle

MONITOR EXECUTION CONDITIONS (Other monitor and Sensor)

Other Monitor (There is no temporary DTC set in memory for the item monitored below)

- Fuel tank temperature sensor monitor

Sensor (The sensor below is determined to be normal)

- Mass airflow sensor

- Engine coolant temperature sensor

- Intake air temperature sensor 1

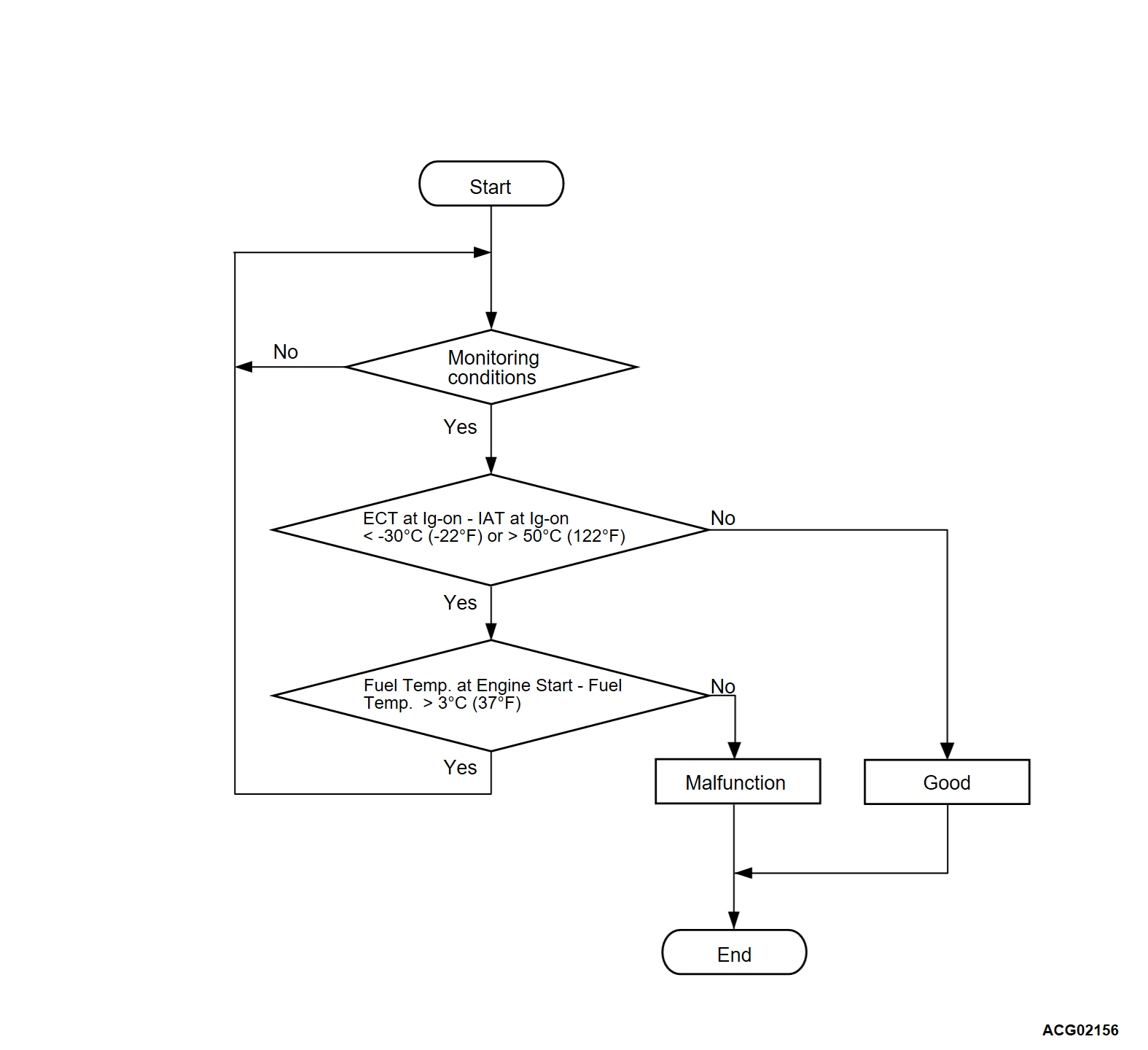

Check Conditions

- The engine coolant temperature is higher than 78°C (172°F) engine stop in previous Drive Cycle <Up to 18 Model year>

- The engine coolant temperature is higher than 77°C (171°F) engine stop in previous Drive Cycle <From 19 Model year>

- The engine coolant temperature - fuel tank temperature is between -5°C (23°F) and 5°C (41°F) when the ignition on.

- Battery positive voltage is higher than 10 volts.

Judgment Criterion

- The engine coolant temperature - intake air temperature is less than -30°C (-22°F) or higher than 50°C (122°F) when the ignition on.

| note |

|

FAIL-SAFE AND BACKUP FUNCTION

- None.

TROUBLESHOOTING HINTS (The most likely causes for this code to be set are:)

- Engine coolant temperature sensor failed.

- Engine coolant temperature sensor circuit harness damage, or connector damage.

- Intake air temperature sensor 1 failed.

- Intake air temperature sensor 1 circuit harness damage, or connector damage.

- ECM failed.

DIAGNOSIS

STEP 1. Using scan tool (M.U.T.-IIISE), check data list item 5: Intake Air Temperature Sensor 1.

| caution | To prevent damage to scan tool (M.U.T.-IIISE), always turn the ignition switch to the "LOCK" (OFF) position before connecting or disconnecting scan tool (M.U.T.-IIISE). |

(2) Remove the mass airflow sensor from the air cleaner cover.

(3) Turn the ignition switch to the "ON" position.

(4) Set scan tool (M.U.T.-IIISE) to the data reading mode for item 5, Intake Air Temperature Sensor 1.

(5) Heating the sensor using a hair drier.

- The indicated temperature increases.

note Do not allow it to increase over 80°C (176°F).

(6) Turn the ignition switch to the "LOCK" (OFF) position.

(7) Attach the mass airflow sensor.

Is the sensor operating properly?

STEP 2. Using scan tool (M.U.T.-IIISE), check data list item 6: Engine Coolant Temperature Sensor.

(1) Turn the ignition switch to the "ON" position.

(2) Set scan tool (M.U.T.-IIISE) to the data reading mode for item 6, Engine Coolant Temperature Sensor.

- The engine coolant temperature and temperature shown with the scan tool should approximately match.

(3) Turn the ignition switch to the "LOCK" (OFF) position.

Is the sensor operating properly?

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)