INSPECTION

VALVE CLEARANCE ADJUSTMENT

Measure valve clearance in the following procedure.

Check and adjust the valve clearance with the timing chain installed.

| caution | Always rotate the crankshaft clockwise. |

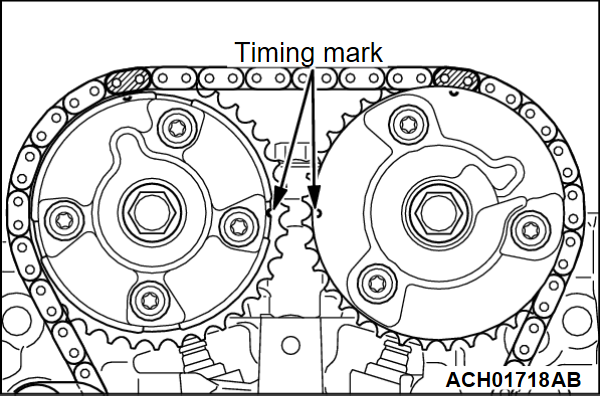

1. Rotate the crankshaft clockwise to align the timing mark of the inlet V.V.T. sprocket and the exhaust camshaft sprocket with the top surface of the cylinder head as illustrated. (Set the No. 1 piston at top dead center on the compression stroke.)

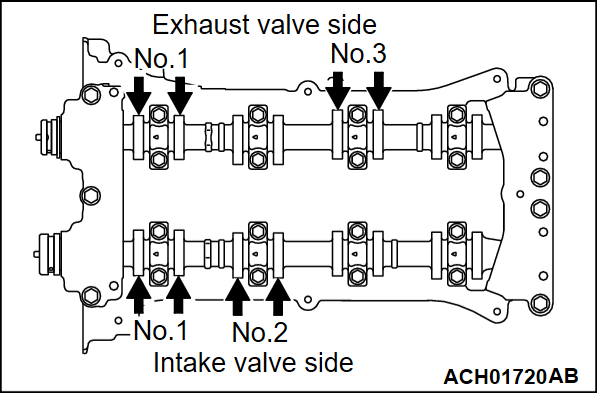

2. Valve clearance can be measured at the illustrated location in this condition.

3. Use a thickness gauge to measure clearance between the camshaft and valve tappet.

Standard value (cold engine)

- Inlet side: 0.22 ± 0.04 mm (0.009 ± 0.002 inch)

- Exhaust side: 0.30 ± 0.04 mm (0.012 ± 0.002 inch)

4. If measured values are out of the standard value, record measured values.

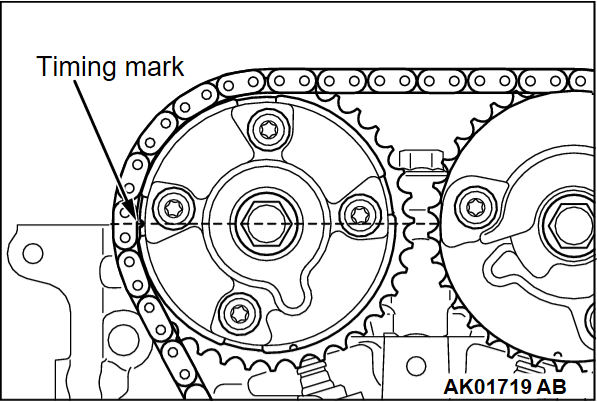

5. Rotate the crankshaft by one turn clockwise to set the No. 4 piston at top dead center on the compression stroke.

| note | The timing mark of the exhaust camshaft sprocket must be at the illustrated position. |

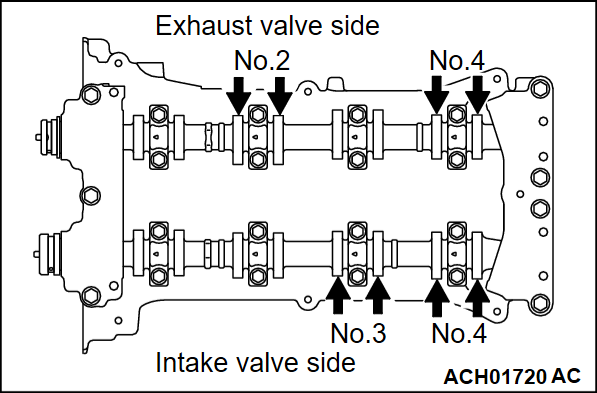

6. Valve clearance can be measured at the illustrated location in this condition.

7. If measured values are out of the standard value, record measured values.

8. If the measured value is out of the standard value, replace the valve tappet.

| note | There are 31 kinds of valve tappets at intervals of 0.020 mm (0.0008 inch) in the range between 5.100 (0.2008 inch) and 5.700 mm(0.2244 inch). |

9. Select a valve tappet in the following procedure.

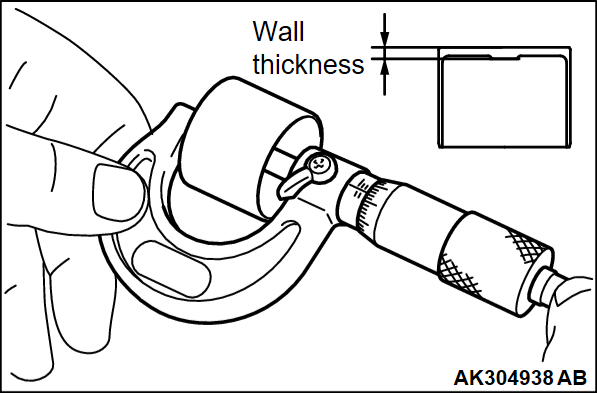

(1) Measure thickness of a removed valve tappet.

(2) Calculate thickness of a valve tappet so that valve clearance meets the standard value.

A: Thickness of valve tappet to be selected

B: Thickness of removed valve tappet

C: Measured valve clearance

Formula

Inlet side: A = B + [C - 0.22 mm(0.009 inch)]

Exhaust side: A = B + [C - 0.30 mm(0.012 inch)]

Refer to "Removal and installation of camshaft" for removal, installation and inspection procedure of valve tappets.

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)