Diagnostic Item 24: Diagnose shorts between CAN_H and L lines (CAN-C-Mid).

| caution | When servicing a CAN bus line, ground yourself by touching a metal object such as an unpainted water pipe. If you fail to do, a component connected to the CAN bus line may be broken. |

TROUBLE JUDGMENT

When all of the following conditions are met, the scan tool (M.U.T.-IIISE) determines that a short circuit is present between CAN_L and CAN_H lines.

- The scan tool (M.U.T.-IIISE) cannot receive the periodic transmission data from any ECUs.

- The voltage between CAN-C-Mid (CAN_L and CAN_H lines) is 1.0 volt or more, 4.0 volts or less.

- The resistance at CAN-C-Mid (CAN_L and CAN_H lines) is 2 ohms or less.

TROUBLESHOOTING HINTS

- Malfunction of the wiring harness

- Malfunction of the connector

- Malfunction of the ETACS-ECU

- Malfunction of the KOS&OSS-ECU <Vehicles with KOS>

- Malfunction of the camera-ECU <Vehicles with multi around monitor>

- Malfunction of the HUD <Vehicles with HUD>

- Malfunction of the A/C controller assembly

- Malfunction of the multivision display <Vehicles with smartphone link display audio>

- Malfunction of the combination meter

- Malfunction of the TCU <Vehicles with TCU>

DIAGNOSIS

Required Special Tools:

- MB991223: Harness Set

- MB992006: Extra Fine Probe

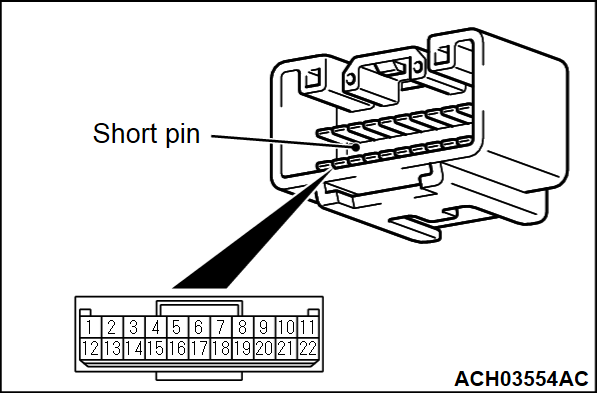

STEP 1. Connector check: joint connector (CAN5)

| caution | The strand end of the twist wire should be within 10 cm (3.9 inches) from the connector. For details refer to  . . |

When checking the joint connector, ensure that its wiring harness side and its short pins are not damaged.

Is the check result normal?

Repair a defective connector or replace the joint connector.

Repair a defective connector or replace the joint connector.STEP 2. Resistance measurement at joint connector (CAN5).

| caution | A digital multimeter should be used. For details refer to  . . |

| caution | The test wiring harness should be used. For details refer to  . . |

(1) Disconnect the connector, and measure at the wiring harness side.

(2) Turn the ignition switch to the "LOCK" (OFF) position.

(3)

| caution | When measuring the resistance, disconnect the negative battery terminal. For details refer to  . . |

Ensure that the negative battery terminal is disconnected.

(4) Resistance between joint connector (CAN5) terminal Nos.11 and 22

OK: 120 ± 20 ohms

Is the check result normal?

STEP 3. Resistance measurement at ETACS-ECU connector.

| caution | A digital multimeter should be used. For details refer to  . . |

(1) Remove the ETACS-ECU, and measure at the equipment side.

(2) Resistance between ETACS-ECU connector terminal Nos.17 and 16

OK: 120 ± 20 ohms

| caution | Strictly observe the specified wiring harness repair procedure. For details refer to  . . |

Is the check result normal?

<Within 120 ± 20 ohms> Repair the wiring harness between joint connector (CAN5) and the ETACS-ECU connector.

<Within 120 ± 20 ohms> Repair the wiring harness between joint connector (CAN5) and the ETACS-ECU connector. <Not within 120 ± 20 ohms> Check the ETACS-ECU connector, and repair if necessary. If the ETACS-ECU connector is in good condition, replace the ETACS-ECU.

<Not within 120 ± 20 ohms> Check the ETACS-ECU connector, and repair if necessary. If the ETACS-ECU connector is in good condition, replace the ETACS-ECU.STEP 4. Resistance measurement at joint connector (CAN5).

| note | Steps 4 and 5 are only for vehicles with KOS. On vehicles without it, go to Step 6 . . |

| caution | A digital multimeter should be used. For details refer to  . . |

| caution | The test wiring harness should be used. For details refer to  . . |

(1) Disconnect the connector, and measure at the wiring harness side.

(2) Turn the ignition switch to the "LOCK" (OFF) position.

(3)

| caution | When measuring the resistance, disconnect the negative battery terminal. For details refer to  . . |

Ensure that the negative battery terminal is disconnected.

(4) Resistance between joint connector (CAN5) terminal Nos.6 and 17

OK: 1 kΩ or more

Is the check result normal?

STEP 5. Resistance measurement at KOS&OSS-ECU connector.

| caution | A digital multimeter should be used. For details refer to  . . |

(1) Remove the KOS&OSS-ECU, and measure at the equipment side.

(2) Resistance between KOS&OSS-ECU connector terminal Nos.35 and 51

OK: 1 kΩ or more

| caution | Strictly observe the specified wiring harness repair procedure. For details refer to  . . |

Is the check result normal?

<1 kΩ or more> Repair the wiring harness between joint connector (CAN5) and the KOS&OSS-ECU connector.

<1 kΩ or more> Repair the wiring harness between joint connector (CAN5) and the KOS&OSS-ECU connector. <Less than 1 kΩ> Check the KOS&OSS-ECU connector, and repair if necessary. If the KOS&OSS-ECU connector is in good condition, replace the KOS&OSS-ECU.

<Less than 1 kΩ> Check the KOS&OSS-ECU connector, and repair if necessary. If the KOS&OSS-ECU connector is in good condition, replace the KOS&OSS-ECU.STEP 6. Resistance measurement at joint connector (CAN5).

| note | Steps 6 and 7 are only for vehicles with multi around monitor. On vehicles without it, go to Step 8 . . |

| caution | A digital multimeter should be used. For details refer to  . . |

| caution | The test wiring harness should be used. For details refer to  . . |

(1) Disconnect the connector, and measure at the wiring harness side.

(2) Turn the ignition switch to the "LOCK" (OFF) position.

(3)

| caution | When measuring the resistance, disconnect the negative battery terminal. For details refer to  . . |

Ensure that the negative battery terminal is disconnected.

(4) Resistance between joint connector (CAN5) terminal Nos.4 and 15

OK: 1 kΩ or more

Is the check result normal?

STEP 7. Resistance measurement at camera-ECU connector.

| caution | A digital multimeter should be used. For details refer to  . . |

(1) Remove the camera-ECU, and measure at the equipment side.

(2) Resistance between camera-ECU connector terminal Nos.1 and 21

OK: 1 kΩ or more

| caution | Strictly observe the specified wiring harness repair procedure. For details refer to  . . |

Is the check result normal?

<1 kΩ or more> Check the intermediate connector, and repair if necessary. If the intermediate connector is in good condition, repair the wiring harness between joint connector (CAN5) and the camera-ECU connector.

<1 kΩ or more> Check the intermediate connector, and repair if necessary. If the intermediate connector is in good condition, repair the wiring harness between joint connector (CAN5) and the camera-ECU connector. <Less than 1 kΩ> Check the camera-ECU connector, and repair if necessary. If the camera-ECU connector is in good condition, replace the camera-ECU.

<Less than 1 kΩ> Check the camera-ECU connector, and repair if necessary. If the camera-ECU connector is in good condition, replace the camera-ECU.STEP 8. Resistance measurement at joint connector (CAN5).

| note | Steps 8 and 9 are only for vehicles with HUD. On vehicles without it, go to Step 10 . . |

| caution | A digital multimeter should be used. For details refer to  . . |

| caution | The test wiring harness should be used. For details refer to  . . |

(1) Disconnect the connector, and measure at the wiring harness side.

(2) Turn the ignition switch to the "LOCK" (OFF) position.

(3)

| caution | When measuring the resistance, disconnect the negative battery terminal. For details refer to  . . |

Ensure that the negative battery terminal is disconnected.

(4) Resistance between joint connector (CAN5) terminal Nos.5 and 16

OK: 1 kΩ or more

Is the check result normal?

STEP 9. Resistance measurement at HUD connector.

| caution | A digital multimeter should be used. For details refer to  . . |

(1) Remove the HUD, and measure at the equipment side.

(2) Resistance between HUD connector terminal Nos.6 and 18

OK: 1 kΩ or more

| caution | Strictly observe the specified wiring harness repair procedure. For details refer to  . . |

Is the check result normal?

<1 kΩ or more> Repair the wiring harness between joint connector (CAN5) and the HUD connector.

<1 kΩ or more> Repair the wiring harness between joint connector (CAN5) and the HUD connector. <Less than 1 kΩ> Check the HUD connector, and repair if necessary. If the HUD connector is in good condition, replace the HUD.

<Less than 1 kΩ> Check the HUD connector, and repair if necessary. If the HUD connector is in good condition, replace the HUD.STEP 10. Resistance measurement at joint connector (CAN5).

| caution | A digital multimeter should be used. For details refer to  . . |

| caution | The test wiring harness should be used. For details refer to  . . |

(1) Disconnect joint connector (CAN5), and measure at the wiring harness side.

(2) Turn the ignition switch to the "LOCK" (OFF) position.

(3)

| caution | When measuring the resistance, disconnect the negative battery terminal. For details refer to  . . |

Ensure that the negative battery terminal is disconnected.

(4) Resistance between joint connector (CAN5) terminal Nos.8 and 19

OK: 1 kΩ or more

Is the check result normal?

STEP 11. Resistance measurement at A/C controller assembly connector.

| caution | A digital multimeter should be used. For details refer to  . . |

(1) Remove the A/C controller assembly, and measure at the equipment side.

(2) Resistance at A/C controller assembly connector terminal Nos.32 and 31

OK: 1 kΩ or more

| caution | Strictly observe the specified wiring harness repair procedure. For details refer to  . . |

Is the check result normal?

<1 kΩ or more> Repair the wiring harness between joint connector (CAN5) and the A/C controller assembly connector.

<1 kΩ or more> Repair the wiring harness between joint connector (CAN5) and the A/C controller assembly connector. <Less than 1 kΩ> Check the A/C controller assembly connector, and repair if necessary. If the A/C controller assembly connector is in good condition, replace the A/C controller assembly.

<Less than 1 kΩ> Check the A/C controller assembly connector, and repair if necessary. If the A/C controller assembly connector is in good condition, replace the A/C controller assembly.STEP 12. Resistance measurement at joint connector (CAN5).

| note | Steps 12 and 13 are only for vehicles with smartphone link display audio. On vehicles without it, go to Step 14 . . |

| caution | A digital multimeter should be used. For details refer to  . . |

| caution | The test wiring harness should be used. For details refer to  . . |

(1) Disconnect joint connector (CAN5), and measure at the wiring harness side.

(2) Turn the ignition switch to the "LOCK" (OFF) position.

(3)

| caution | When measuring the resistance, disconnect the negative battery terminal. For details refer to  . . |

Ensure that the negative battery terminal is disconnected.

(4) Resistance between joint connector (CAN5) terminal Nos.7 and 18

OK: 1 kΩ or more

| caution | Strictly observe the specified wiring harness repair procedure. For details refer to  . . |

Is the check result normal?

STEP 13. Resistance measurement at multivision display connector.

| caution | A digital multimeter should be used. For details refer to  . . |

(1) Remove the multivision display, and measure at the equipment side.

(2) Resistance at multivision display connector terminal Nos.3 and 13

OK: 1 kΩ or more

Is the check result normal?

<1 kΩ or more> Repair the wiring harness between joint connector (CAN5) and the multivision display connector.

<1 kΩ or more> Repair the wiring harness between joint connector (CAN5) and the multivision display connector. <Less than 1 kΩ> Check the multivision display connector, and repair if necessary. If the multivision display connector is in good condition, replace the multivision display.

<Less than 1 kΩ> Check the multivision display connector, and repair if necessary. If the multivision display connector is in good condition, replace the multivision display.STEP 14. Resistance measurement at joint connector (CAN5).

| note | Steps 14 and 15 are only for vehicles with TCU. On vehicles without it, go to Step 16  . . |

| caution | A digital multimeter should be used. For details refer to  . . |

| caution | The test wiring harness should be used. For details refer to  . . |

(1) Disconnect joint connector (CAN5), and measure at the wiring harness side.

(2) Turn the ignition switch to the "LOCK" (OFF) position.

(3)

| caution | When measuring the resistance, disconnect the negative battery terminal. For details refer to  . . |

Ensure that the negative battery terminal is disconnected.

(4) Resistance between joint connector (CAN5) terminal Nos.2 and 13

OK: 1 kΩ or more

Is the check result normal?

STEP 15. Resistance measurement at TCU connector.

| caution | A digital multimeter should be used. For details refer to  . . |

(1) Remove the TCU, and measure at the equipment side.

(2) Resistance at TCU connector terminal Nos.33 and 13

OK: 1 kΩ or more

| caution | Strictly observe the specified wiring harness repair procedure. For details refer to  . . |

Is the check result normal?

<1 kΩ or more> Repair the wiring harness between joint connector (CAN5) and the TCU connector.

<1 kΩ or more> Repair the wiring harness between joint connector (CAN5) and the TCU connector. <Less than 1 kΩ> Check the TCU connector, and repair if necessary. If the TCU connector is in good condition, replace the TCU.

<Less than 1 kΩ> Check the TCU connector, and repair if necessary. If the TCU connector is in good condition, replace the TCU.STEP 16. Resistance measurement at joint connector (CAN5).

| caution | A digital multimeter should be used. For details refer to  . . |

| caution | The test wiring harness should be used. For details refer to  . . |

(1) Disconnect joint connector (CAN5), and measure at the wiring harness side.

(2) Turn the ignition switch to the "LOCK" (OFF) position.

(3)

| caution | When measuring the resistance, disconnect the negative battery terminal. For details refer to  . . |

Ensure that the negative battery terminal is disconnected.

(4) Resistance between joint connector (CAN5) terminal Nos.10 and 21

OK: 120 ± 20 ohms

Is the check result normal?

STEP 17. Resistance measurement at combination meter connector.

| caution | A digital multimeter should be used. For details refer to  . . |

(1) Remove the combination meter, and measure at the equipment side.

(2) Resistance at combination meter connector terminal Nos.14 and 15

OK: 120 ± 20 ohms

| caution | Strictly observe the specified wiring harness repair procedure. For details refer to  . . |

Is the check result normal?

<Within 120 ± 20 ohms> Repair the wiring harness between joint connector (CAN5) and the combination meter connector.

<Within 120 ± 20 ohms> Repair the wiring harness between joint connector (CAN5) and the combination meter connector. <Not within 120 ± 20 ohms> Check the combination meter connector, and repair if necessary. If the combination meter connector is in good condition, replace the combination meter.

<Not within 120 ± 20 ohms> Check the combination meter connector, and repair if necessary. If the combination meter connector is in good condition, replace the combination meter.![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)