REMOVAL AND INSTALLATION

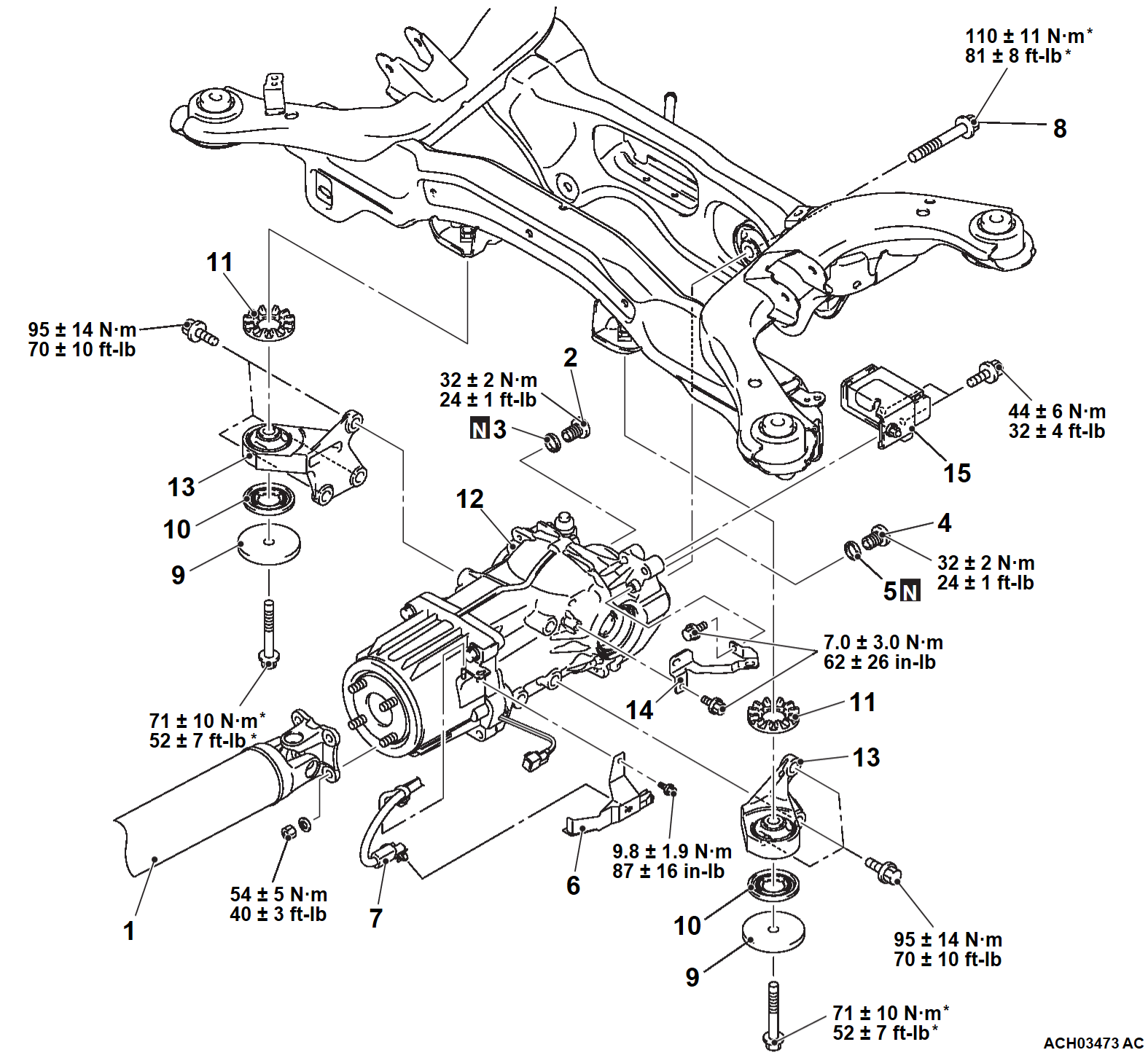

| caution | The parts indicated by * are the bolts with friction coefficient stabilizer. In removal, ensure there is no damage, clean dust and soiling from the bearing and thread surfaces, and tighten them to the specified torque. |

Pre-removal operation | Post-installation operation |

REMOVAL SERVICE POINT

INSTALLATION SERVICE POINT

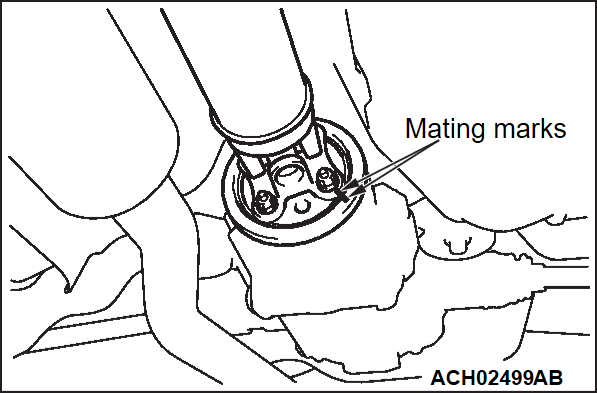

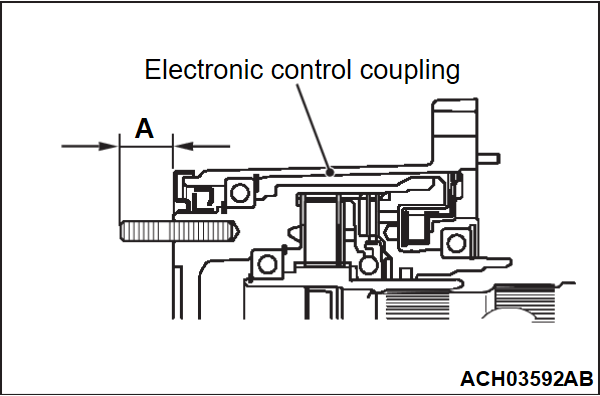

>>A<< DIFFERENTIAL CARRIER ASSEMBLY INSTALLATION

1. Check that the length of the electronic control coupling stud bolt (A) is within the standard value range.

Standard value: 22.3 - 25.1 mm (0.88 - 0.99 inch)

2. If the length exceeds the standard value, replace the stud bolt.

Tightening torque: 15 ± 3 N·m (11 ± 2 ft-lb)

| note | When replacing the stud bolts, always clean the stud bolt threaded holes. |

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)