DTC U0100: CAN time-out error (Engine)

DIAGNOSTIC FUNCTION

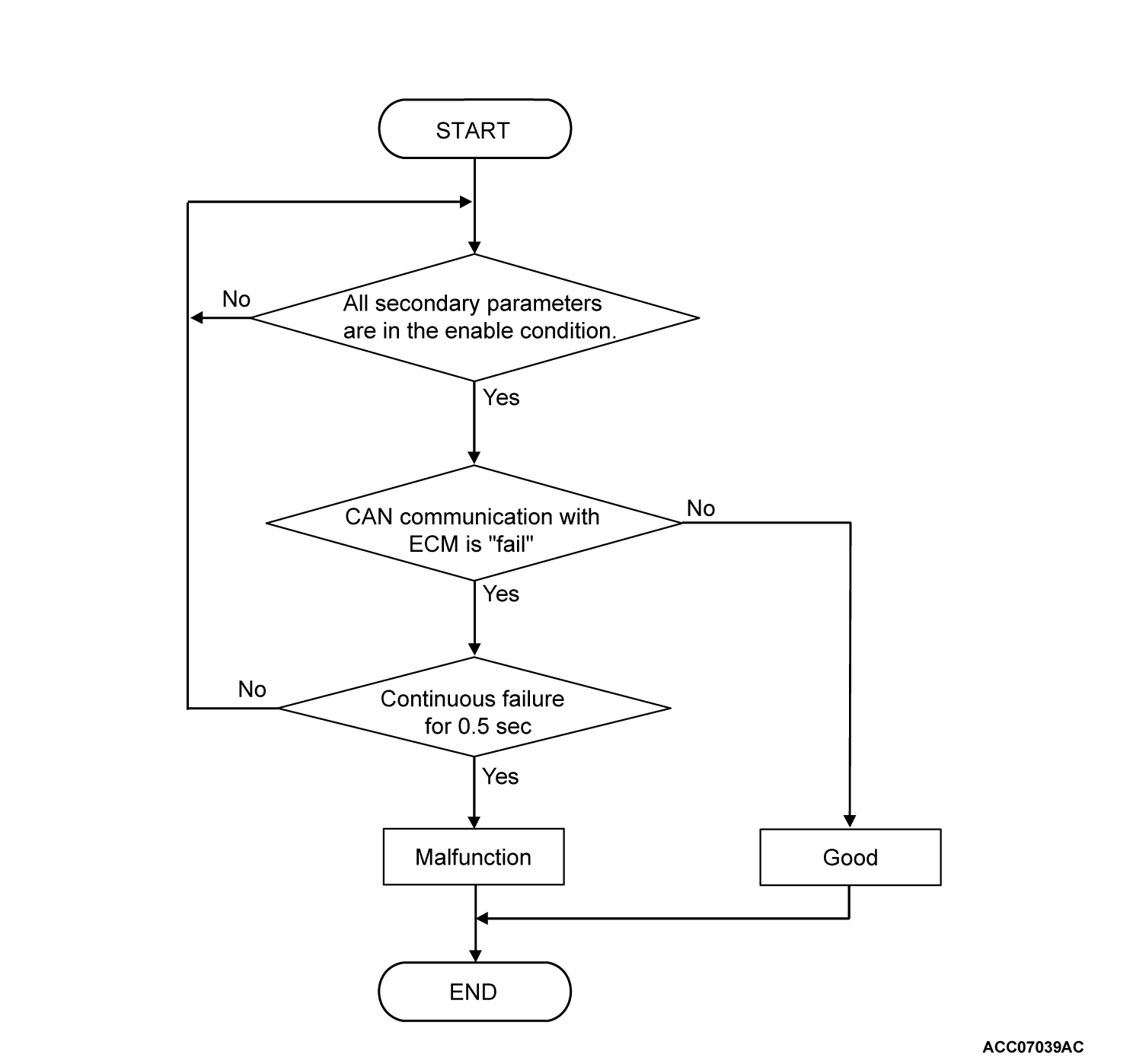

The TCM determines that the system is defective if the TCM can receive no CAN communication information from the ECM.

DESCRIPTIONS OF MONITOR METHODS

No information is received from the ECM for 0.5 seconds.

MONITOR EXECUTION

- When 1.05 seconds have elapsed after TCM started.

MONITOR EXECUTION CONDITIONS (OTHER MONITOR AND SENSOR)

Other Monitor (There is no temporary DTC stored in memory for the item monitored below)

- P0712, P0713: Malfunction of the transmission fluid temperature sensor

- P0715: Malfunction of primary pulley speed sensor

- P0720: Malfunction of secondary pulley speed sensor

- P0730: Incorrect gear ratio

- P0966, P0967: Malfunction of secondary pressure solenoid valve

- P0970, P0971: Malfunction of primary pressure solenoid valve

- P2720, P2721: Malfunction of select pressure solenoid valve

- P2763, P2764: Malfunction of lock-up solenoid valve

- P2765: Malfunction of turbine speed sensor

Sensor (The sensor below is determined to be normal)

- Transmission fluid temperature sensor

- Primary pulley speed sensor

- Secondary pulley speed sensor

- Turbine speed sensor

DTC SET CONDITIONS

Check Conditions

- Voltage of battery: 10 volts or more.

- Time after TCM start: More than 1.05 seconds.

Judgment Criteria

- CAN communication with ECM: fail (0.5 second).

OBD-II DRIVE CYCLE PATTERN

Ignition switch: ON (start the engine and keep it for 10 seconds or more).

PROBABLE CAUSES

- Malfunction of the CAN bus line

- Malfunction of ECM

- Malfunction of TCM

DIAGNOSIS

STEP 1. Scan tool (M.U.T.-IIISE) CAN bus diagnostics.

Use scan tool (M.U.T.-IIISE) to perform the CAN bus diagnosis.

Is the check result normal?

STEP 2. Scan tool (M.U.T.-IIISE) diagnostic trouble code.

Check if the engine-related diagnostic trouble code is set. Carry out the appropriate troubleshooting.

Carry out the appropriate troubleshooting.

Is the engine-related diagnostic trouble code set?

Carry out the appropriate troubleshooting.

Carry out the appropriate troubleshooting.STEP 3. Scan tool (M.U.T.-IIISE) diagnostic trouble code.

Is diagnostic trouble code No. U0100 set in the other ECU, which communicates with the ECM via CAN?

Is the diagnostic trouble code set?

STEP 4. Symptom recheck after erasing diagnostic trouble code.

Is the diagnostic trouble code set?

Replace ECM.

Replace ECM.![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)