REMOVAL AND INSTALLATION

Pre-removal Operation | Post-installation Operation |

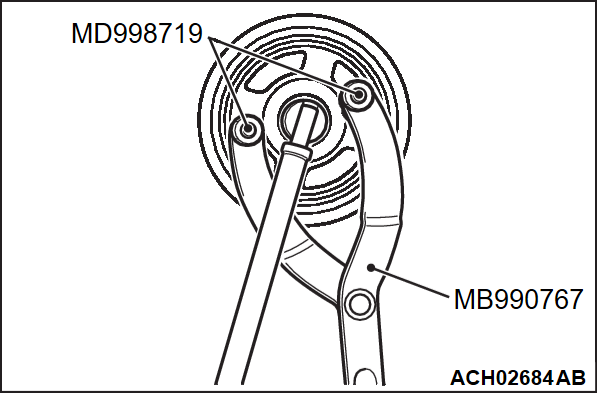

- MB990767: Front hub and flange yoke holder

- MD998719: Pin

Required Special Tools:

REMOVAL SERVICE POINTS

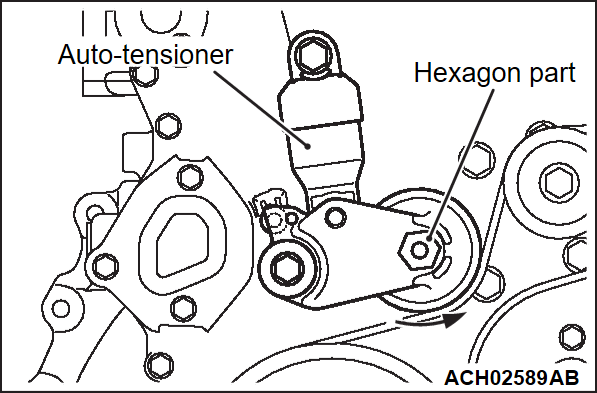

<<A>> DRIVE BELT REMOVAL

To introduce the serpentine drive system with the auto-tensioner, the following operations will be required.

1.

Securely set the tool to the hexagonal part of the auto-tensioner.

| warning | Be sure to set the tool to the hexagonal part securely to prevent the tool from falling off because the tension of the auto-tensioner is high. |

2. Rotate the auto-tensioner counterclockwise.

3. Insert the L-shaped hexagon wrench into the auto-tensioner hole to fix the auto-tensioner.

4.

| caution | To reuse the drive belt, draw an arrow indicating the rotating direction on the back of the belt using chalk to install the same direction. |

Remove the drive belt.

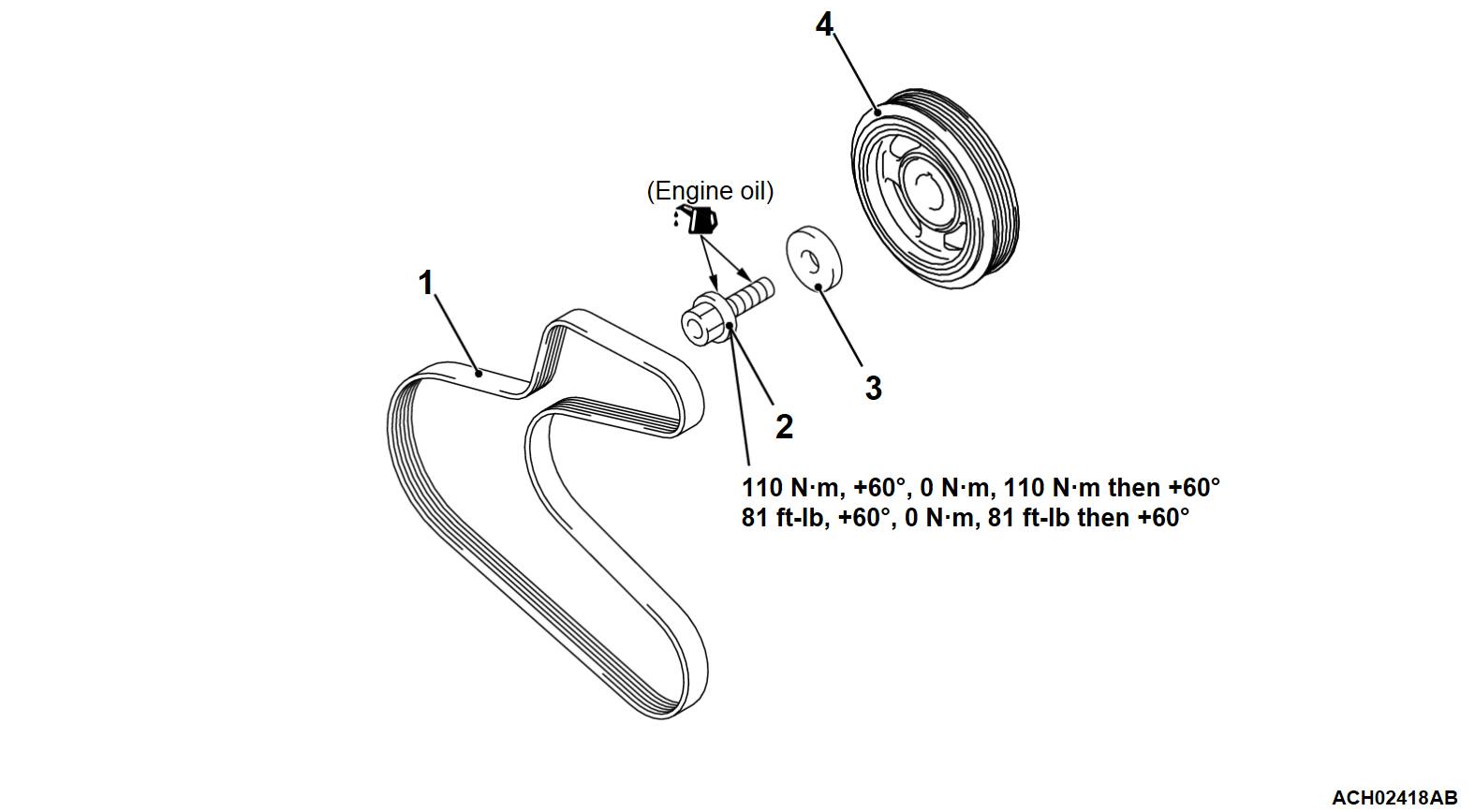

<<B>> CRANKSHAFT PULLEY CENTER BOLT/CRANKSHAFT PULLEY WASHER/CRANKSHAFT PULLEY REMOVAL

1. Use the following special tools to support the crankshaft pulley:

- Front hub and flange yoke holder (MB990767)

- Pin (MD998719)

2. Loosen the crankshaft pulley center bolt and remove the crankshaft pulley washer and crankshaft pulley.

INSTALLATION SERVICE POINTS

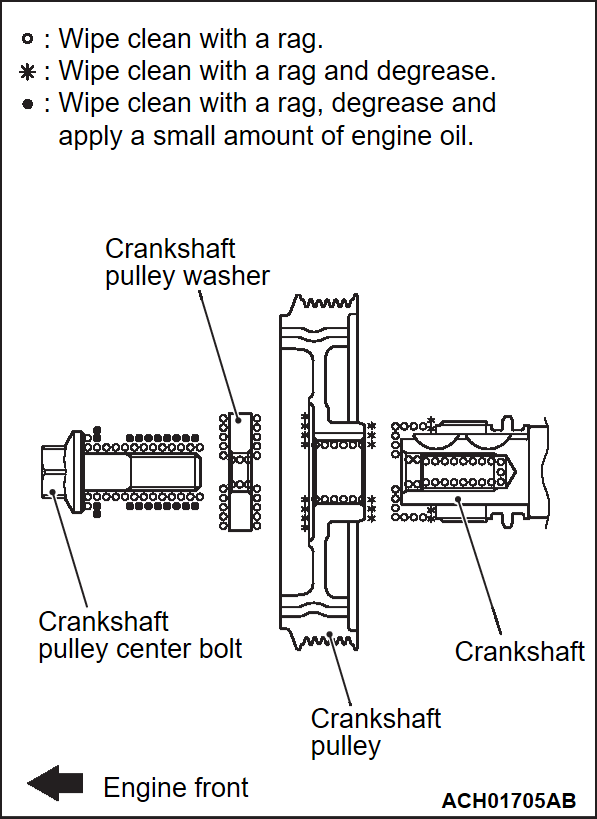

>>A<< CRANKSHAFT PULLEY/CRANKSHAFT PULLEY WASHER/CRANKSHAFT PULLEY CENTER BOLT INSTALLATION

1. Wipe off the dirt on the crankshaft sprocket, crankshaft and crankshaft pulley as shown in the figure using a rag, and then degrease the areas.

| note | Degrease them to prevent drop in the friction coefficient of the pressed area which is caused by oil adhesion. |

2. Install the crankshaft pulley.

3. Wipe off the dirt on the crankshaft pulley washer and the crankshaft pulley center bolt as shown in the figure using a rag.

4. Apply an adequate and minimum amount of engine oil to the thread of the crankshaft pulley center bolt and the lower area of the flange.

5. Use the following special tools as during removal to support the crankshaft pulley:

- Front hub and flange yoke holder (MB990767)

- Pin (MD998719)

6. Tighten the crankshaft pulley center bolt to the specified torque.

Tightening torque: 110 N·m (81 ft-lb)

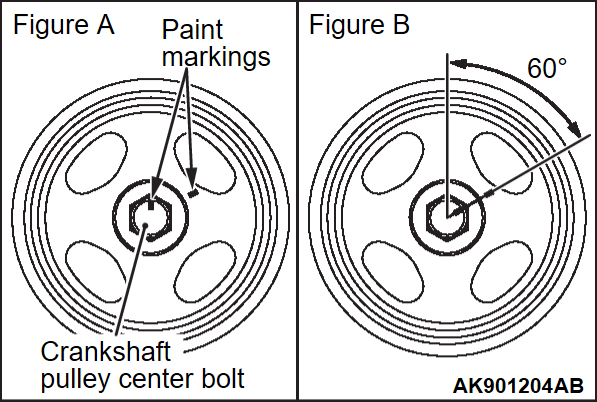

7. As shown in figure A, put a paint mark on one angle of the crankshaft pulley center bolt. Then, put a paint mark on the crankshaft pulley on the extended line of the angle next to the marked angle.

8.

| caution |

|

Tighten the crankshaft pulley center bolt in a 60°, and check that the paint mark on the crankshaft pulley center bolt aligns with the paint mark on the crankshaft pulley as shown in figure B.

9. Loosen the crankshaft pulley center bolt completely after steps 6 to 8, and then repeat steps 6 to 8.

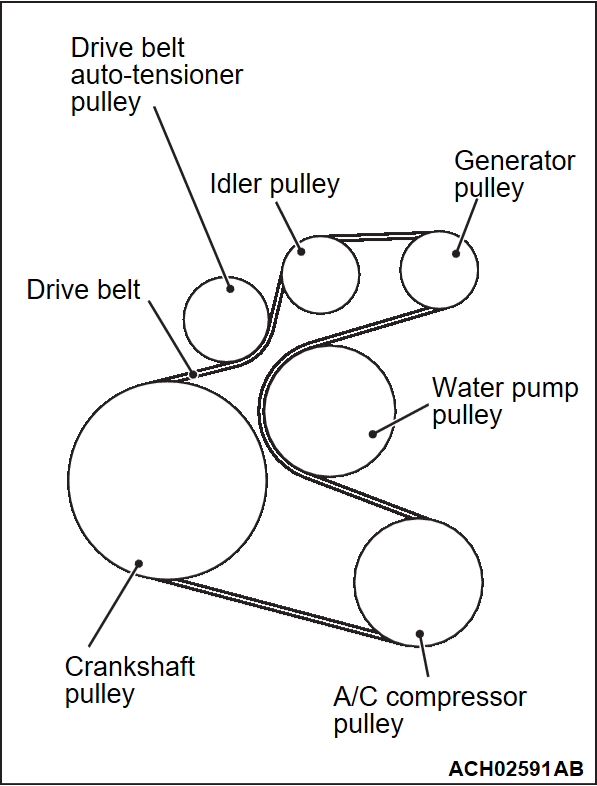

>>B<< DRIVE BELT INSTALLATION

1.

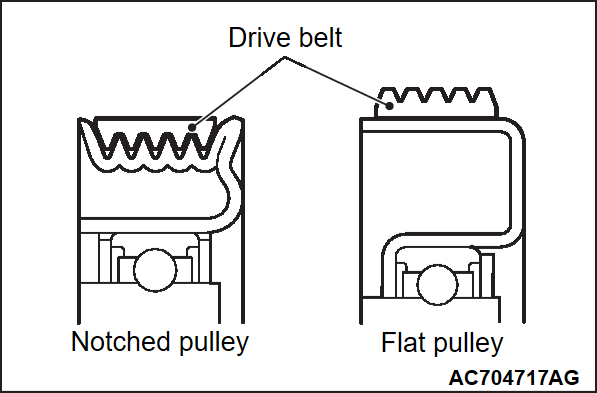

Install the drive belt to each pulley as shown in the figure.

| caution |

|

2.

Securely set the tool to the hexagonal part of the auto-tensioner.

| warning | Be sure to set the tool to the hexagonal part securely to prevent the tool from falling off because the tension of the auto-tensioner is high. |

3. Rotate the auto-tensioner counterclockwise and remove the L-shaped hexagon wrench fixing the auto-tensioner.

4. Apply tension to the drive belt while slowly turning the auto-tensioner clockwise.

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)