![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)

Inspection Procedure 11: ASC-ECU power supply circuit system

|

|

| caution |

- When the ASC-ECU power supply voltage becomes 9.7 ± 0.3 V or less, the ABS warning light, ASC warning display, and ASC OFF display illuminate, and the ABS, stability control, and TCL controls are prohibited.

- If the battery terminal is not tightened properly, a dump surge may occur and the power supply voltage may become abnormally high for a short period of time.

- If there is any problem in the CAN bus lines, an incorrect diagnostic trouble code may be set. Prior to this diagnosis, diagnose the CAN bus lines.

- Whenever the ECU is replaced, ensure that the CAN bus lines are normal.

- When the hydraulic unit (integrated with ASC-ECU) is replaced, always perform the calibration of steering wheel sensor, G and yaw rate sensor, brake fluid pressure sensor, cut valve, and inlet valve.(Refer to

, ,  , ,  , and , and  .) .)

|

|

|

|

- ASC-ECU contains the power supply circuit (terminal No. 32) for the solenoid valve. The solenoid valve is energized by the valve relay, which is incorporated in ASC-ECU.

- ASC-ECU contains the power supply circuit (terminal No. 1) for the pump motor. The pump motor is energized by the motor relay, which is incorporated in ASC-ECU.

- ASC-ECU contains the power supply circuit (terminal No. 2) for ASC-ECU, and the power is supplied from the fusible link No. 34 through the multi-purpose fuse No. 17.

- If a malfunction occurs in the ASC-ECU power supply, the communication with scan tool becomes unavailable.

|

|

|

- Damaged wiring harness and connectors

- Malfunction of fuse or fusible link

- Improper tightening of battery terminal

- Improper tightening of grounding bolt

- Battery failure

- Charging system failed

- ASC-ECU malfunction

|

|

|

Required Special Tools:

- MB991958 Scan Tool (M.U.T.-III Sub Assembly)

- MB991824: Vehicle Communication Interface (V.C.I.)

- MB991827 M.U.T.-III USB Cable

- MB991910 M.U.T.-III Main Harness A

- MB991997: ASC check harness

|

|

|

Refer to GROUP 54A - Battery Test  . .

|

|

|

Q.

Is the battery in good condition?

|

|

|

Go to Step 3. Go to Step 3.

|

|

|

|

|

|

Charge or replace the battery. Then, go to Step 2. Charge or replace the battery. Then, go to Step 2.

|

|

|

|

|

|

STEP 2. Charging system check

|

|

|

Refer to GROUP 16 - Output Current Test  . .

|

|

|

Q.

Is the charging system in good condition?

|

|

|

Go to Step 3. Go to Step 3.

|

|

|

|

|

|

Repair or replace the charging system component(s). Repair or replace the charging system component(s).

|

|

|

|

|

|

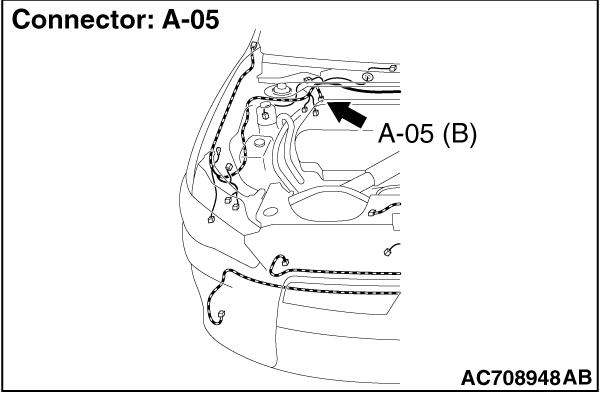

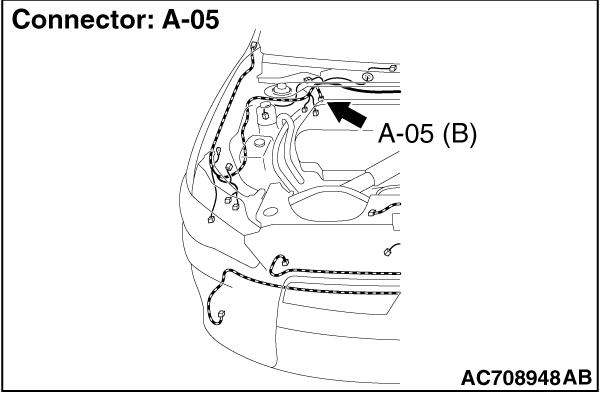

STEP 3. Connector check: A-05 ASC-ECU connector

|

|

|

Q.

Is the check result normal?

|

|

|

Go to Step 4. Go to Step 4.

|

|

|

|

|

|

NO : Repair the defective connector.

|

|

|

|

|

|

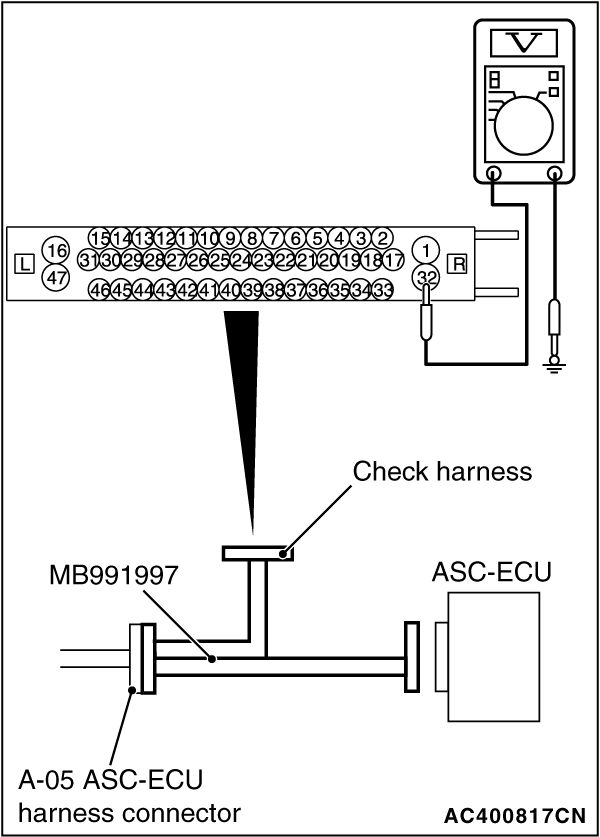

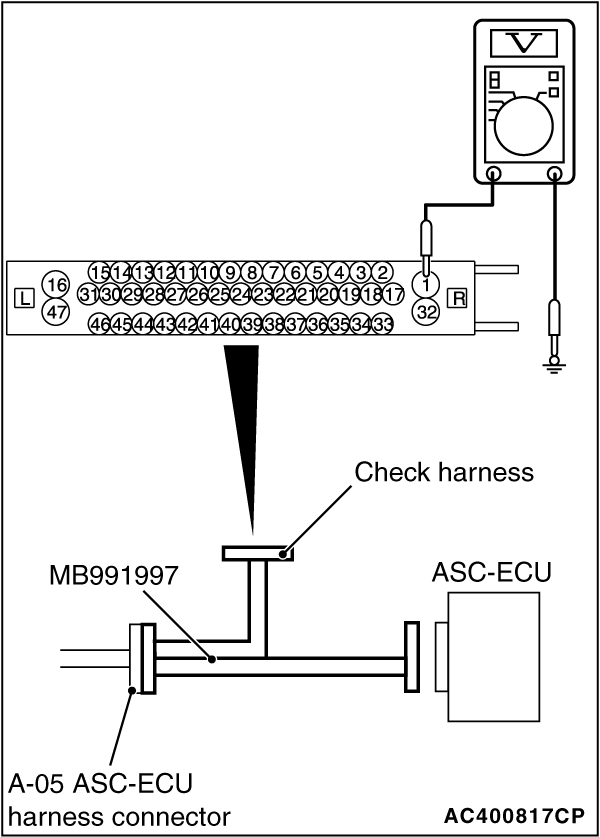

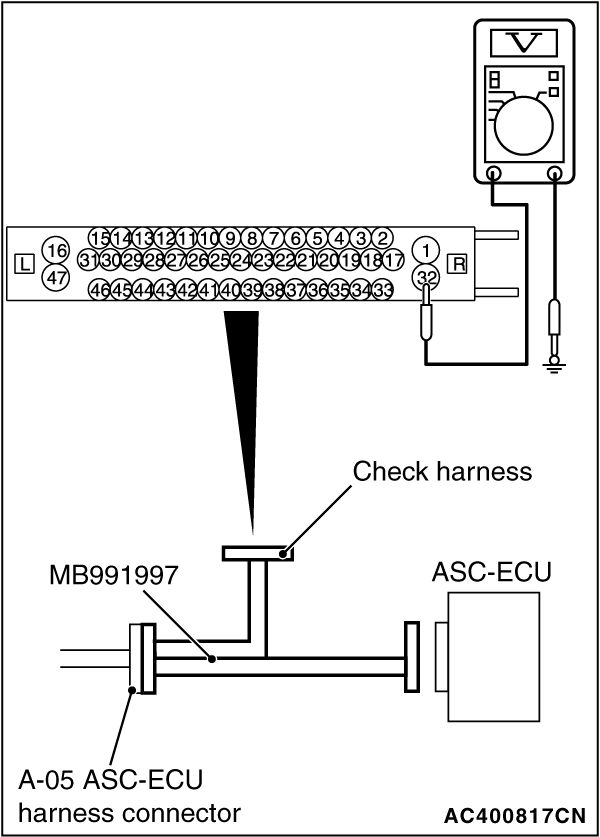

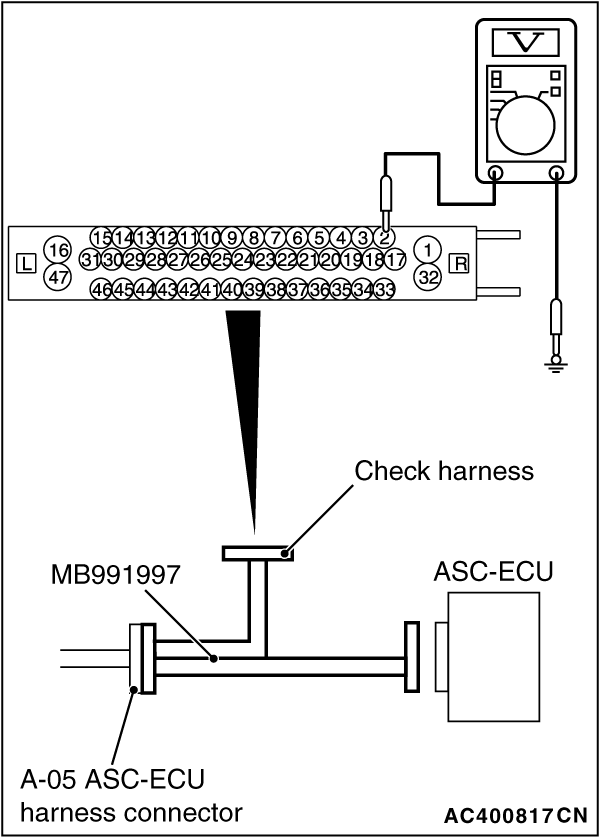

STEP 4. Voltage measurement at A-05 ASC-ECU connector

|

|

(1)Disconnect the connector, connect the ASC check harness (Special tool: MB991997) to the wiring harness-side connector, and measure the voltage at the special tool connector side.

| note |

Do not connect the special tool to ASC-ECU.

|

(2)Measure the voltage between the terminal No. 32 and the body ground.

OK: Battery positive voltage

Q.

Is the check result normal?

Go to Step 7. Go to Step 7.

Go to Step 5. Go to Step 5.

|

|

|

STEP 5. Fusible link check: Check the fusible link No. 27.

|

|

|

Q.

Is the check result normal?

|

|

|

An open circuit may be present in the power supply circuit. Repair the wiring harness between A-05 ASC-ECU connector terminal No. 32 and the fusible link No. 27. An open circuit may be present in the power supply circuit. Repair the wiring harness between A-05 ASC-ECU connector terminal No. 32 and the fusible link No. 27.

|

|

|

|

|

|

Go to Step 6. Go to Step 6.

|

|

|

|

|

|

STEP 6. Wiring harness check between A-05 ASC-ECU connector and fusible link No. 27.

|

|

|

(1)Disconnect ASC-ECU connector A-05.

|

|

|

(2)Remove fusible link No. 27.

|

|

|

(3)Check the continuity (short to ground) between A-05 ASC-ECU connector terminal No. 32 and the ground.

OK: No continuity

|

|

|

Q.

Is the check result normal?

|

|

|

Replace the fusible link No.27. Replace the fusible link No.27.

|

|

|

|

|

|

Short circuit may be present in the power supply circuit. Repair the wiring harness between A-05 ASC-ECU connector terminal No. 32 and fusible link No. 27. Short circuit may be present in the power supply circuit. Repair the wiring harness between A-05 ASC-ECU connector terminal No. 32 and fusible link No. 27.

|

|

|

|

|

|

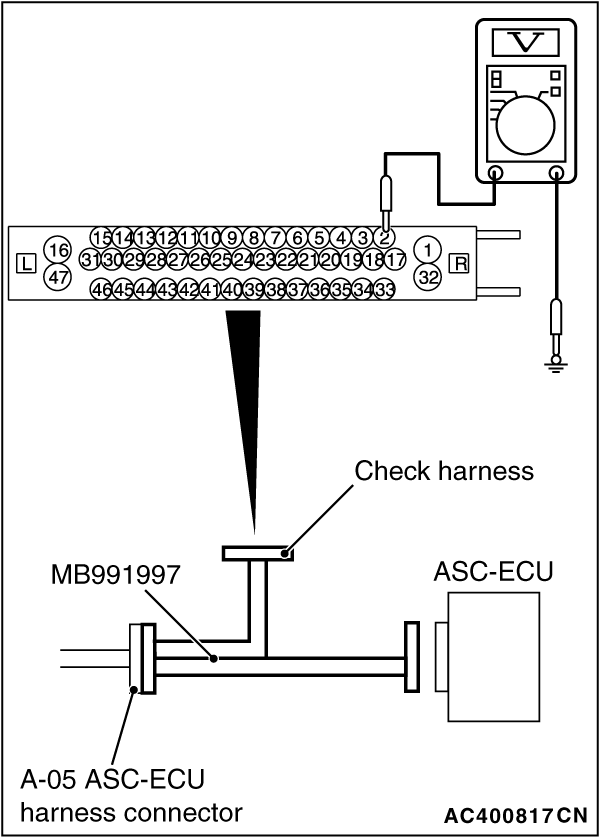

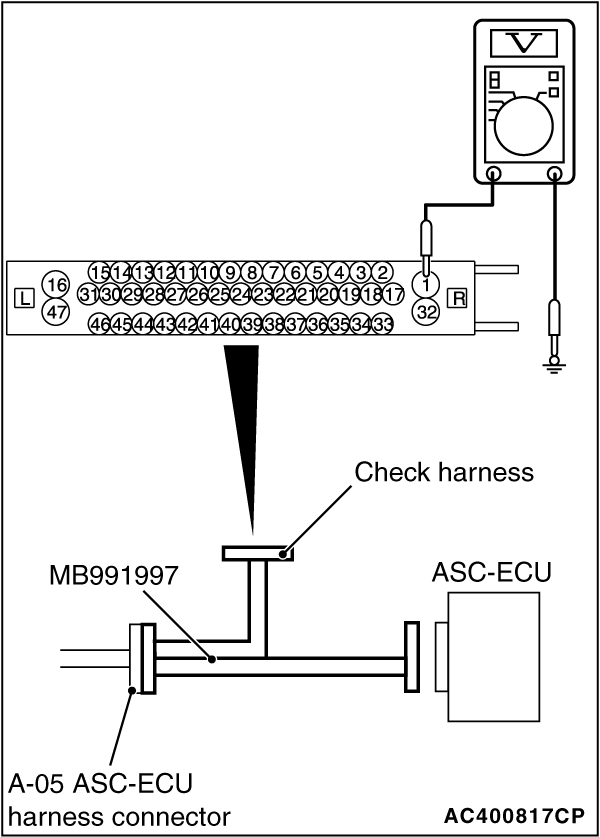

STEP 7. Voltage measurement at A-05 ASC-ECU connector

|

|

(1)Disconnect the connector, connect the ASC check harness (Special tool: MB991997) to the wiring harness-side connector, and measure the voltage at the special tool connector side.

| note |

Do not connect the special tool to ASC-ECU.

|

(2)Measure the voltage between the terminal No. 1 and the body ground.

OK: Battery positive voltage

Q.

Is the check result normal?

Go to Step 10. Go to Step 10.

Go to Step 8. Go to Step 8.

|

|

|

STEP 8. Fusible link check: Check the fusible link No.26.

|

|

|

Visually check for open circuit in the fusible link No.26.

|

|

|

Q.

Is the check result normal?

|

|

|

An open circuit may be present in the pump motor power supply circuit. Repair the wiring harness between A-05 ASC-ECU connector terminal No. 1 and the fusible link No. 26. An open circuit may be present in the pump motor power supply circuit. Repair the wiring harness between A-05 ASC-ECU connector terminal No. 1 and the fusible link No. 26.

|

|

|

|

|

|

Go to Step 9. Go to Step 9.

|

|

|

|

|

|

STEP 9. Wiring harness check between A-05 ASC-ECU connector and fusible link No. 26.

|

|

|

(1)Disconnect ASC-ECU connector A-05.

|

|

|

(2)Remove fusible link No. 26.

|

|

|

(3)Check the continuity (short to ground) between A-05 ASC-ECU connector terminal No. 1 and the ground.

OK: No continuity

|

|

|

Q.

Is the check result normal?

|

|

|

Replace the fusible link No.26. Replace the fusible link No.26.

|

|

|

|

|

|

Short circuit may be present in the power supply circuit. Repair the wiring harness between A-05 ASC-ECU connector terminal No. 1 and fusible link No. 26. Short circuit may be present in the power supply circuit. Repair the wiring harness between A-05 ASC-ECU connector terminal No. 1 and fusible link No. 26.

|

|

|

|

|

|

STEP 10. Check of fuse No. 17 and fusible link No. 34

|

|

|

Visually check for open circuit in the fuse No. 17 and the fusible link No. 34.

|

|

|

Q.

Is the check result normal?

|

|

|

Go to Step 16. Go to Step 16.

|

|

|

|

|

|

Go to Step 11. Go to Step 11.

|

|

|

|

|

|

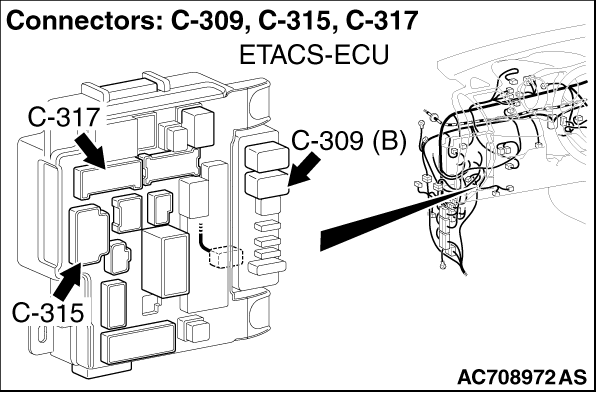

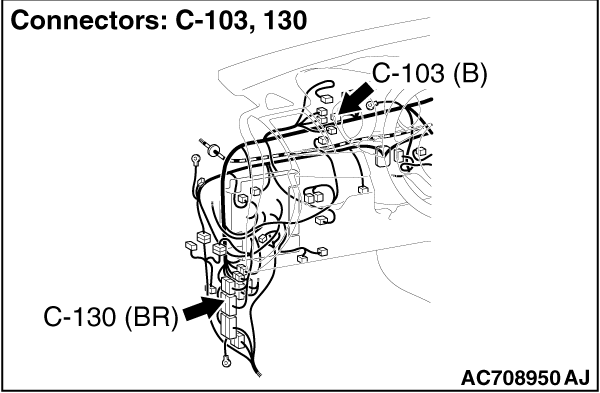

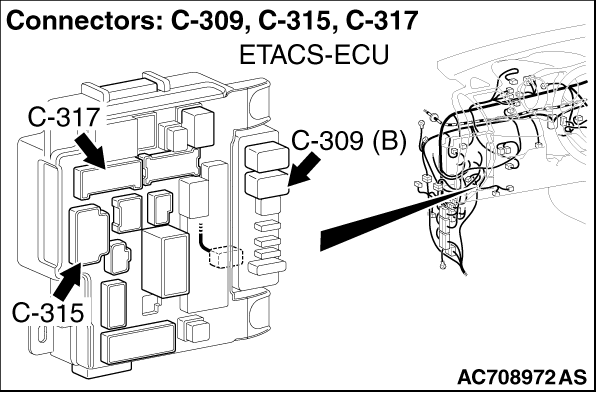

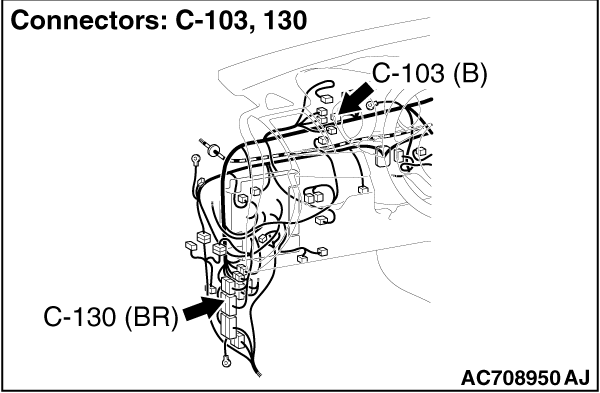

STEP 11. Connector check: C-41 intermediate connector, C-43 joint connector, C-46 ETACS-ECU connector, C-103 joint connector, C-130 intermediate connector, C-309 ETACS-ECU connector and C-315 ETACS-ECU connector

|

|

|

Q.

Is the check result normal?

|

|

|

Go to Step 12. Go to Step 12.

|

|

|

|

|

|

Repair the connector. Then, replace fuse No. 17 or fusible link No. 34. Repair the connector. Then, replace fuse No. 17 or fusible link No. 34.

|

|

|

|

|

|

STEP 12. Wiring harness check between C-309 ETACS-ECU connector and fusible link No. 34.

|

|

|

(1)Remove fusible link No. 34.

|

|

|

(2)Disconnect ETACS-ECU connector C-309, and measure at the wiring harness side.

|

|

|

(3)Check the continuity (short to ground) between terminal No. 1 and the ground.

OK: No continuity

|

|

|

Q.

Is the check result normal?

|

|

|

Go to Step 13. Go to Step 13.

|

|

|

|

|

|

Repair the wiring harness between C-309 ETACS-ECU connector terminal No. 1 and fusible link No. 34. Then, replace fuse No. 17 or fusible link No. 34. Repair the wiring harness between C-309 ETACS-ECU connector terminal No. 1 and fusible link No. 34. Then, replace fuse No. 17 or fusible link No. 34.

|

|

|

|

|

|

STEP 13. Wiring harness check between C-315 ETACS-ECU connector and C-103 joint connector.

|

|

|

(1)Disconnect the C-103 joint connector.

|

|

|

(2)Disconnect ETACS-ECU connector C-315, and measure at the wiring harness side.

|

|

|

(3)Check the continuity (short to ground) between terminal No. 4 and the ground.

OK: No continuity

|

|

|

Q.

Is the check result normal?

|

|

|

Go to Step 14. Go to Step 14.

|

|

|

|

|

|

Repair the wiring harness between C-315 ETACS-ECU connector terminal No. 4 and C-103 joint connector terminal No.18. Then, replace fuse No. 17 or fusible link No. 34. Repair the wiring harness between C-315 ETACS-ECU connector terminal No. 4 and C-103 joint connector terminal No.18. Then, replace fuse No. 17 or fusible link No. 34.

|

|

|

|

|

|

STEP 14. Wiring harness check between the C-103 joint connector and the C-46 AWC-ECU connector.

|

|

|

(1)Disconnect the C-46 AWC-ECU connector.

|

|

|

(2)Disconnect the C-103 joint connector, and measure at the wiring harness side.

|

|

|

(3)Check the continuity (short to ground) between terminal No. 16 and the ground.

OK: No continuity

|

|

|

Q.

Is the check result normal?

|

|

|

Go to Step 15. Go to Step 15.

|

|

|

|

|

|

Repair the wiring harness between C-103 joint connector terminal No.16 and C-46 AWC-ECU connector terminal No.12. Then, replace fuse No. 17 or fusible link No. 34. Repair the wiring harness between C-103 joint connector terminal No.16 and C-46 AWC-ECU connector terminal No.12. Then, replace fuse No. 17 or fusible link No. 34.

|

|

|

|

|

|

STEP 15. Wiring harness check between the C-103 joint connector and the A-05 ASC-ECU connector.

|

|

|

(1)Disconnect ASC-ECU connector A-05.

|

|

|

(2)Disconnect the C-103 joint connector, and measure at the wiring harness side.

|

|

|

(3)Check the continuity (short to ground) between terminal No.17 and the ground.

OK: No continuity

|

|

|

Q.

Is the check result normal?

|

|

|

Replace the fuse No. 17 or the fusible link No. 34. Then, go to Step 20. Replace the fuse No. 17 or the fusible link No. 34. Then, go to Step 20.

|

|

|

|

|

|

Repair the wiring harness between C-103 joint connector terminal No.17 and A-05 ASC-ECU connector terminal No.2. Then, replace fuse No. 17 or fusible link No. 34. Repair the wiring harness between C-103 joint connector terminal No.17 and A-05 ASC-ECU connector terminal No.2. Then, replace fuse No. 17 or fusible link No. 34.

|

|

|

|

|

|

STEP 16. Voltage measurement at A-05 ASC-ECU connector

|

|

(1)Disconnect the connector, connect the ASC check harness (Special tool: MB991997) to the wiring harness-side connector, and measure the voltage at the special tool connector side.

| note |

Do not connect the special tool to ASC-ECU.

|

(2)Measure the voltage between the terminal No. 2 and the body ground.

OK: Battery positive voltage

Q.

Is the check result normal?

Go to Step 20. Go to Step 20.

Go to Step 17. Go to Step 17.

|

|

|

STEP 17. Measure the voltage at the C-309 ETACS-ECU connector.

|

|

|

(1)Disconnect the connector, and measure at the wiring harness-side connector.

|

|

|

(2)Measure the voltage between the terminal No. 1 and the body ground.

OK: Battery positive voltage

|

|

|

Q.

Is the check result normal?

|

|

|

Go to Step 18. Go to Step 18.

|

|

|

|

|

|

Repair the wiring harness between C-309 ETACS-ECU connector terminal No. 1 and the fusible link No. 34. Repair the wiring harness between C-309 ETACS-ECU connector terminal No. 1 and the fusible link No. 34.

|

|

|

|

|

|

STEP 18. Measure the voltage at the C-315 ETACS-ECU connector.

|

|

|

(1)Without disconnecting the connector, measure by backprobing.

|

|

|

(2)Measure the voltage between the terminal No. 4 and the body ground.

OK: Battery positive voltage

|

|

|

Q.

Is the check result normal?

|

|

|

Go to Step 20. Go to Step 20.

|

|

|

|

|

|

Go to Step 19. Go to Step 19.

|

|

|

|

|

|

STEP 19. Wiring harness check between A-05 ASC-ECU connector terminal No. 2 and C-315 ETACS-ECU connector terminal No. 4

|

|

|

Q.

Is the check result normal?

|

|

|

Go to Step 20. Go to Step 20.

|

|

|

|

|

|

NO : Repair the wiring harness.

|

|

|

|

|

|

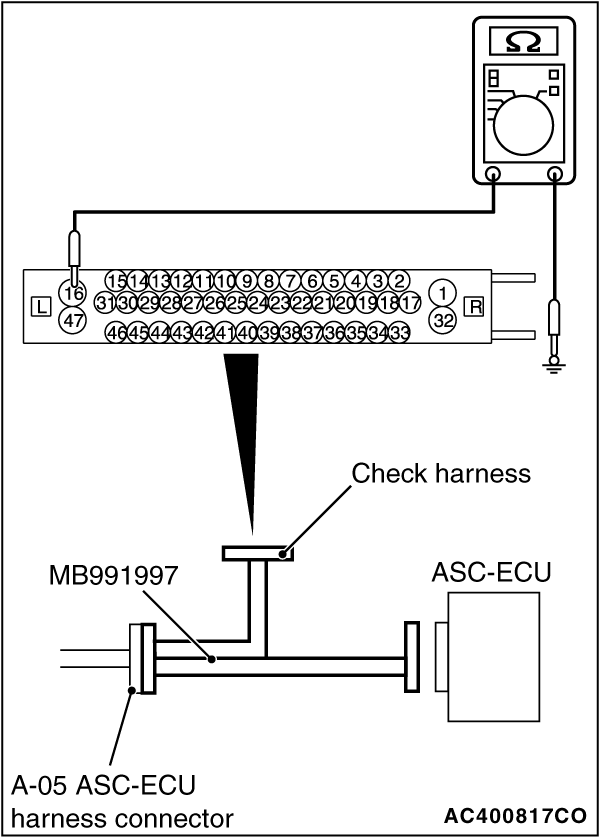

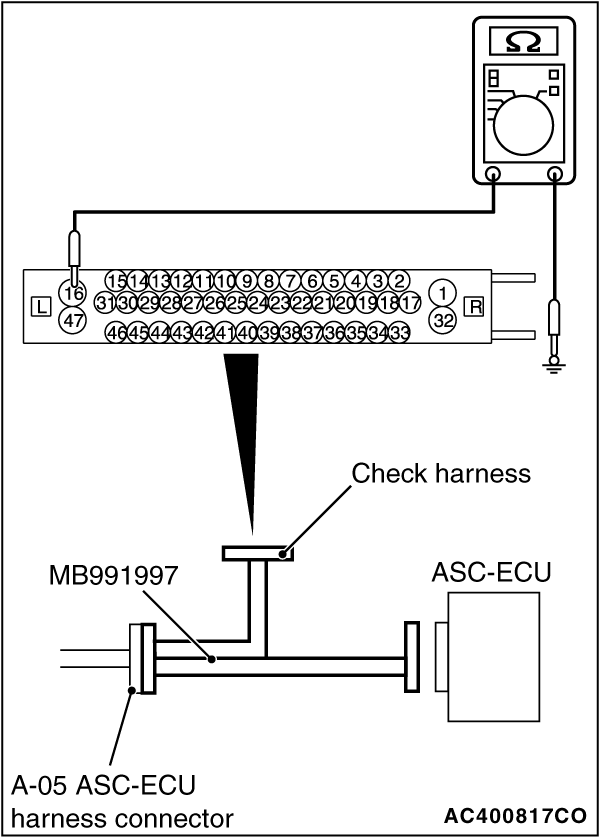

STEP 20. Resistance measurement at A-05 ASC-ECU connector

|

|

(1)Disconnect the connector, connect the ASC check harness (Special tool: MB991997) to the wiring harness-side connector, and measure the voltage at the special tool connector side.

| note |

Do not connect the special tool to ASC-ECU.

|

(2)Measure the resistance between the terminal No. 16 and the body ground as well as between the terminal No. 47 and the body ground.

OK: Continuity exists (2 Ω or less)

Q.

Is the check result normal?

Go to Step 21. Go to Step 21.

NO : Repair the wiring harness.

|

|

|

STEP 21. Retest the system.

|

|

|

Q.

Is the communication with scan tool MB991958 possible?

|

|

|

Intermittent malfunction. (Refer to GROUP 00 - How to Cope with Intermittent Malfunction Intermittent malfunction. (Refer to GROUP 00 - How to Cope with Intermittent Malfunction  .) .)

|

|

|

|

|

|

Check that the scan tool connection cable is properly connected, and that the V.C.I. switch is turned ON. Then, replace the hydraulic unit (integrated with ASC-ECU).(Refer to Check that the scan tool connection cable is properly connected, and that the V.C.I. switch is turned ON. Then, replace the hydraulic unit (integrated with ASC-ECU).(Refer to  .) Then go to Step 22. .) Then go to Step 22.

|

|

|

|

|

|

STEP 22. Retest the system.

|

|

|

Q.

Is the communication with scan tool MB991958 possible?

|

|

|

Return to Step 1. Return to Step 1.

|

|

|

|

|

|

This diagnosis is complete. This diagnosis is complete.

|

|

|

|

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)

.

. Go to Step 3.

Go to Step 3. Charge or replace the battery. Then, go to Step 2.

Charge or replace the battery. Then, go to Step 2. .

. Go to Step 3.

Go to Step 3. Repair or replace the charging system component(s).

Repair or replace the charging system component(s). Go to Step 4.

Go to Step 4.

Go to Step 7.

Go to Step 7. Go to Step 5.

Go to Step 5. An open circuit may be present in the power supply circuit. Repair the wiring harness between A-05 ASC-ECU connector terminal No. 32 and the fusible link No. 27.

An open circuit may be present in the power supply circuit. Repair the wiring harness between A-05 ASC-ECU connector terminal No. 32 and the fusible link No. 27. Go to Step 6.

Go to Step 6. Replace the fusible link No.27.

Replace the fusible link No.27. Short circuit may be present in the power supply circuit. Repair the wiring harness between A-05 ASC-ECU connector terminal No. 32 and fusible link No. 27.

Short circuit may be present in the power supply circuit. Repair the wiring harness between A-05 ASC-ECU connector terminal No. 32 and fusible link No. 27.

Go to Step 10.

Go to Step 10. Go to Step 8.

Go to Step 8. An open circuit may be present in the pump motor power supply circuit. Repair the wiring harness between A-05 ASC-ECU connector terminal No. 1 and the fusible link No. 26.

An open circuit may be present in the pump motor power supply circuit. Repair the wiring harness between A-05 ASC-ECU connector terminal No. 1 and the fusible link No. 26. Go to Step 9.

Go to Step 9. Replace the fusible link No.26.

Replace the fusible link No.26. Short circuit may be present in the power supply circuit. Repair the wiring harness between A-05 ASC-ECU connector terminal No. 1 and fusible link No. 26.

Short circuit may be present in the power supply circuit. Repair the wiring harness between A-05 ASC-ECU connector terminal No. 1 and fusible link No. 26. Go to Step 16.

Go to Step 16. Go to Step 11.

Go to Step 11. Go to Step 12.

Go to Step 12. Repair the connector. Then, replace fuse No. 17 or fusible link No. 34.

Repair the connector. Then, replace fuse No. 17 or fusible link No. 34. Go to Step 13.

Go to Step 13. Repair the wiring harness between C-309 ETACS-ECU connector terminal No. 1 and fusible link No. 34. Then, replace fuse No. 17 or fusible link No. 34.

Repair the wiring harness between C-309 ETACS-ECU connector terminal No. 1 and fusible link No. 34. Then, replace fuse No. 17 or fusible link No. 34. Go to Step 14.

Go to Step 14. Repair the wiring harness between C-315 ETACS-ECU connector terminal No. 4 and C-103 joint connector terminal No.18. Then, replace fuse No. 17 or fusible link No. 34.

Repair the wiring harness between C-315 ETACS-ECU connector terminal No. 4 and C-103 joint connector terminal No.18. Then, replace fuse No. 17 or fusible link No. 34. Go to Step 15.

Go to Step 15. Repair the wiring harness between C-103 joint connector terminal No.16 and C-46 AWC-ECU connector terminal No.12. Then, replace fuse No. 17 or fusible link No. 34.

Repair the wiring harness between C-103 joint connector terminal No.16 and C-46 AWC-ECU connector terminal No.12. Then, replace fuse No. 17 or fusible link No. 34. Replace the fuse No. 17 or the fusible link No. 34. Then, go to Step 20.

Replace the fuse No. 17 or the fusible link No. 34. Then, go to Step 20. Repair the wiring harness between C-103 joint connector terminal No.17 and A-05 ASC-ECU connector terminal No.2. Then, replace fuse No. 17 or fusible link No. 34.

Repair the wiring harness between C-103 joint connector terminal No.17 and A-05 ASC-ECU connector terminal No.2. Then, replace fuse No. 17 or fusible link No. 34.

Go to Step 20.

Go to Step 20. Go to Step 17.

Go to Step 17. Go to Step 18.

Go to Step 18. Repair the wiring harness between C-309 ETACS-ECU connector terminal No. 1 and the fusible link No. 34.

Repair the wiring harness between C-309 ETACS-ECU connector terminal No. 1 and the fusible link No. 34. Go to Step 20.

Go to Step 20. Go to Step 19.

Go to Step 19. Go to Step 20.

Go to Step 20.

Go to Step 21.

Go to Step 21. Intermittent malfunction. (Refer to GROUP 00 - How to Cope with Intermittent Malfunction

Intermittent malfunction. (Refer to GROUP 00 - How to Cope with Intermittent Malfunction  .)

.) Check that the scan tool connection cable is properly connected, and that the V.C.I. switch is turned ON. Then, replace the hydraulic unit (integrated with ASC-ECU).(Refer to

Check that the scan tool connection cable is properly connected, and that the V.C.I. switch is turned ON. Then, replace the hydraulic unit (integrated with ASC-ECU).(Refer to  .) Then go to Step 22.

.) Then go to Step 22. Return to Step 1.

Return to Step 1. This diagnosis is complete.

This diagnosis is complete.