|

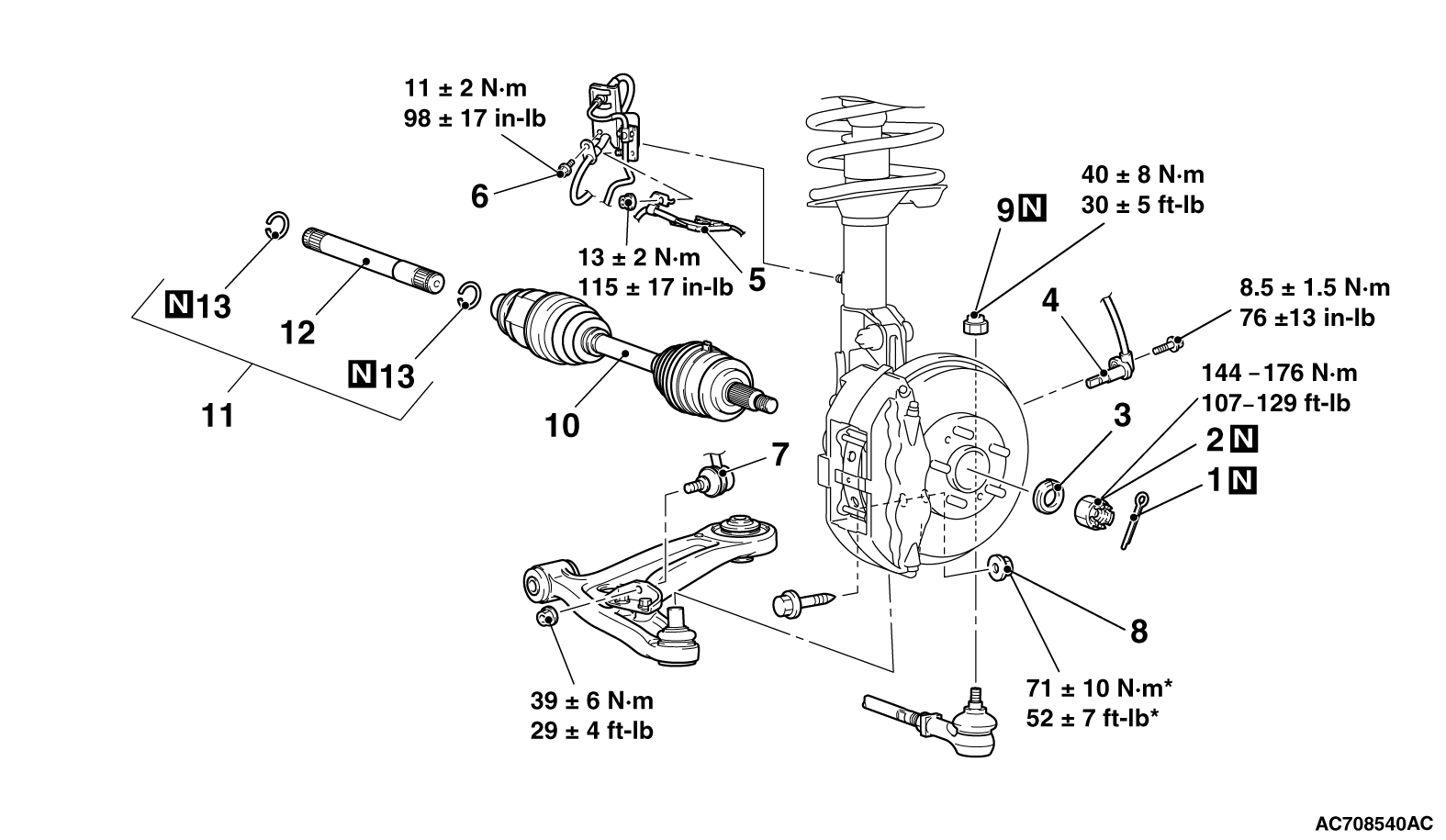

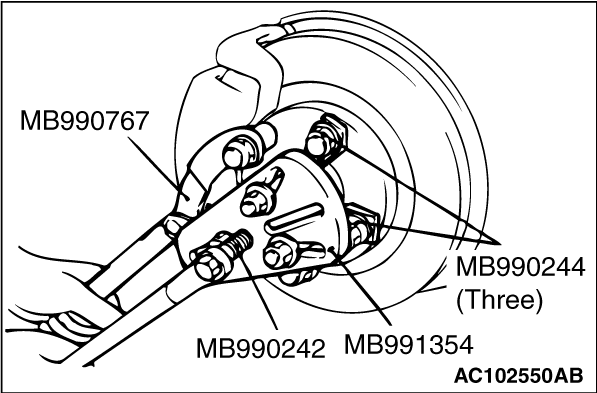

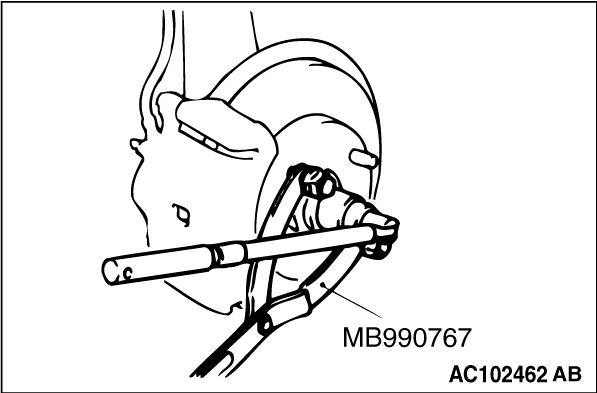

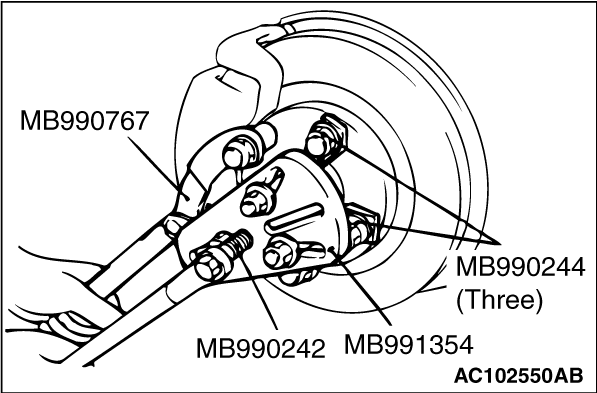

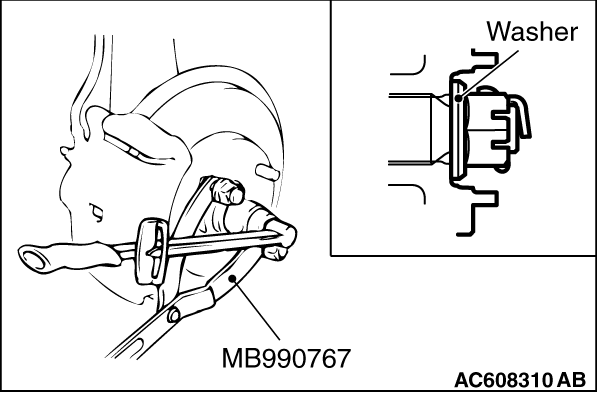

Use special tool MB990767 to counter the hub as shown in the figure to remove the front driveshaft nut.

|

|

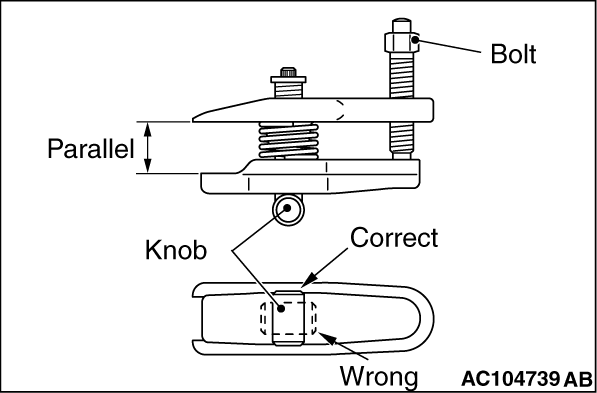

1.

| caution |

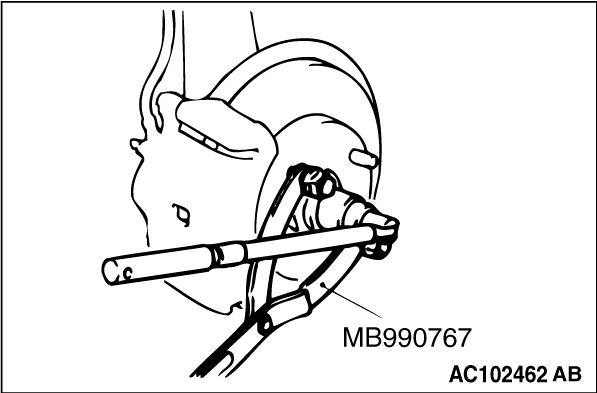

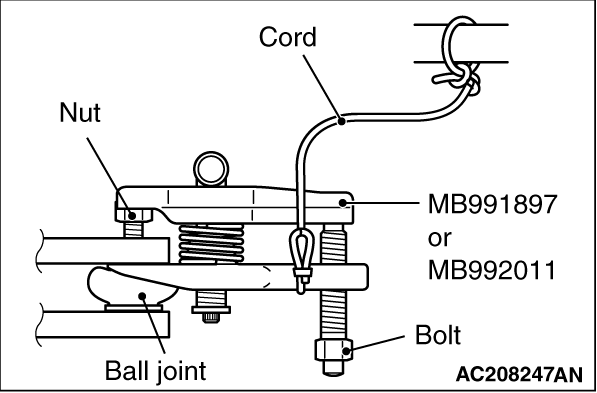

- Loosen the self-locking nut (tie-rod end connection) from the ball joint, but do not remove here. Use the special tool.

- To prevent the special tool from dropping off, suspend it with a cord.

- If the dust cover is damaged during operation, replace the tie-rod end. (Refer to GROUP 37 - Power Steering Gear and Linkage Disassembly and Reassembly

.) .)

|

Install special tool MB991897 or MB992011 as shown in the figure.

|

|

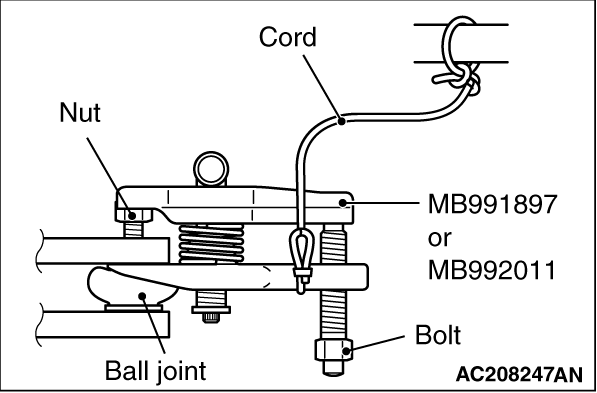

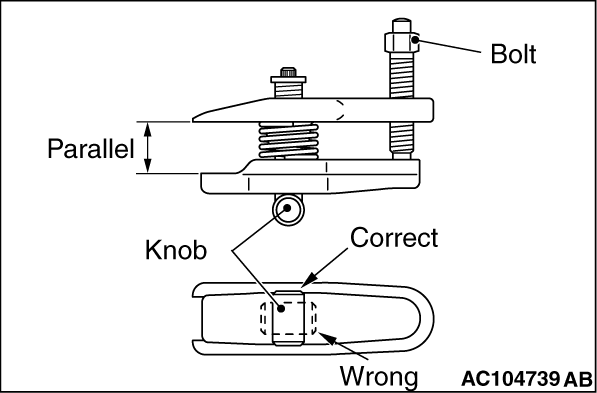

2.Turn the bolt and knob to make the special tool jaws parallel, then hand-tighten the bolt. After tightening, check that the jaws are still parallel.

| note |

To adjust the special tool jaws to be parallel, set the orientation of the knob as shown in the figure.

|

3.Tighten the bolt with a wrench to disconnect the tie rod end.

|

|

1.

| caution |

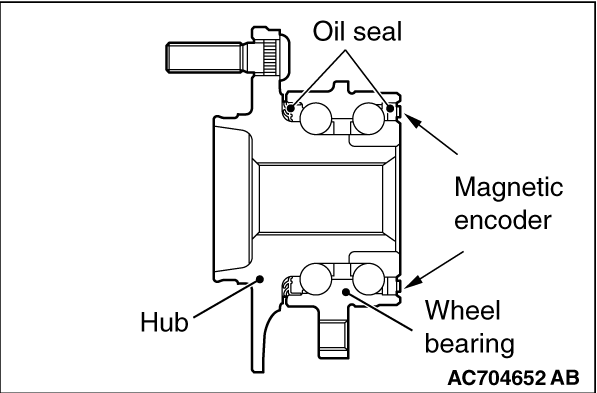

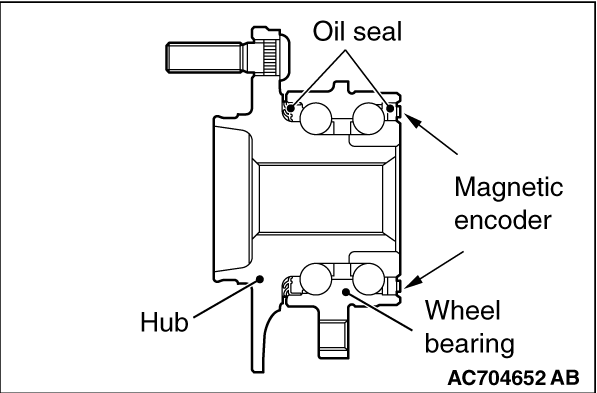

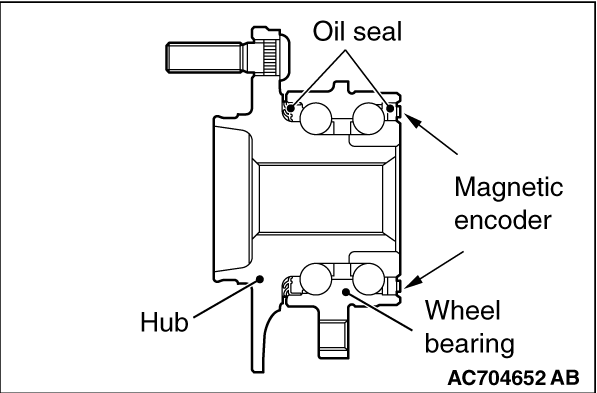

- The magnetic encoder collects metallic particles easily, because it is magnetized. Make sure that the magnetic encoder does not collect metallic particles.

- When removing the front driveshaft, make sure that it does not contact with the magnetic encoder (integrated with the inner oil seal) to avoid damage.

|

If the driveshaft is seized with the hub, use special tools MB990242 and MB990244, MB990767 and MB991354 to push the driveshaft assembly out from the hub.

|

|

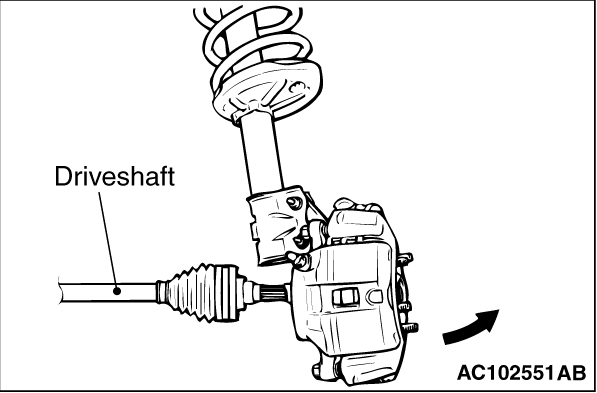

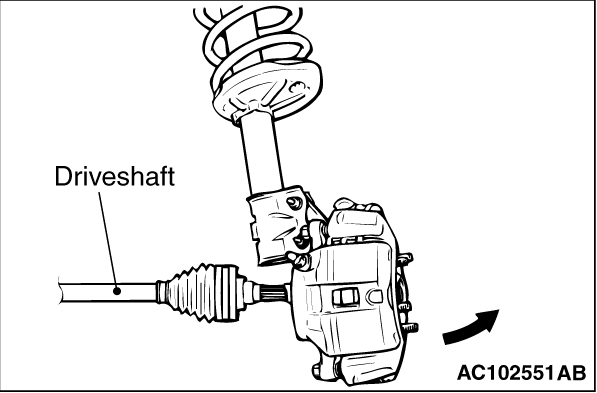

2.While pulling the lower side of the brake disk toward you, remove the driveshaft assembly from the hub.

| caution |

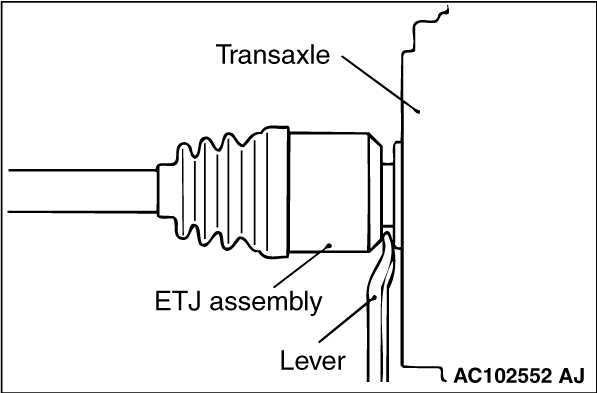

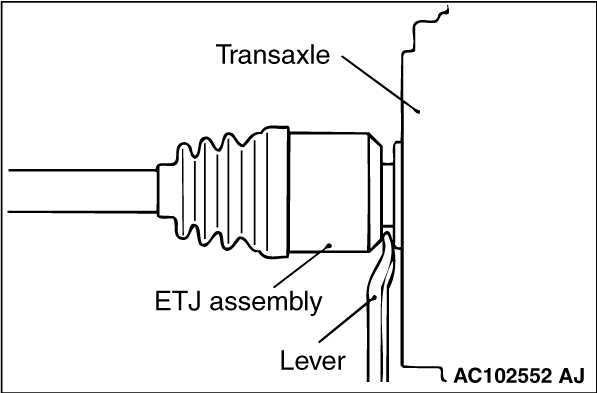

- Never pull out the front driveshaft assembly from the EBJ assembly side. Otherwise, the ETJ assembly may be damaged. Always pull out from the ETJ side with a lever.

- Care must be taken to ensure that the oil seal of the transaxle is not damaged by the spline part of the front driveshaft assembly.

|

|

|

3.Insert a lever between the transaxle case or transfer and front driveshaft assembly, and then pull the front driveshaft assembly out from the transaxle.

|

|

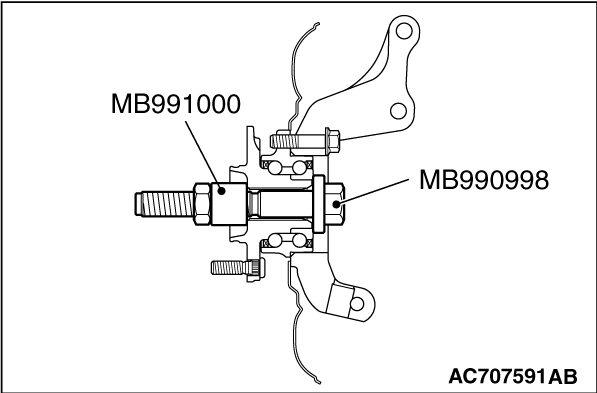

| caution |

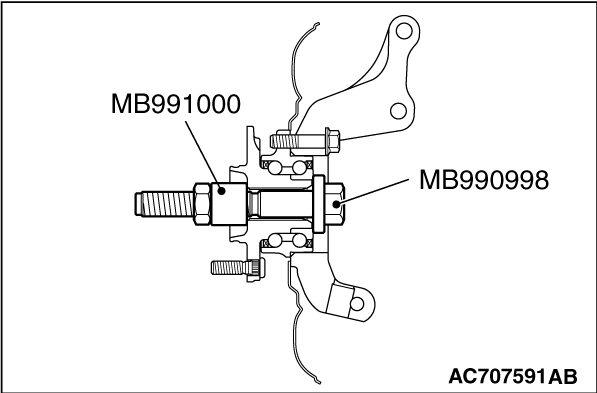

Do not apply the vehicle weight to the wheel bearing with the front driveshaft assembly removed. If, however, the vehicle weight shall be applied to the bearing (in order to move the vehicle), tighten the following special tools MB991000 and MB990998 to the specified torque 144 - 176 N·m (107 - 129 ft-lb).

|

|

|

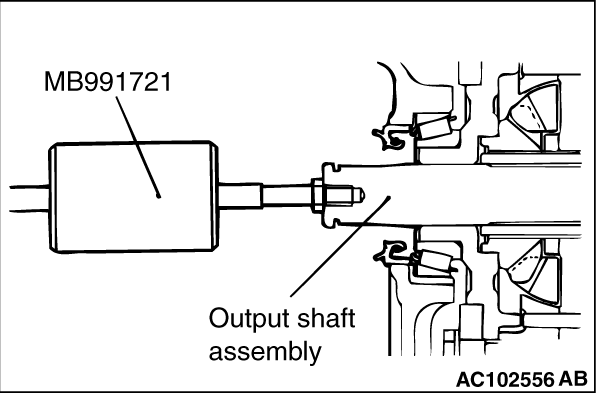

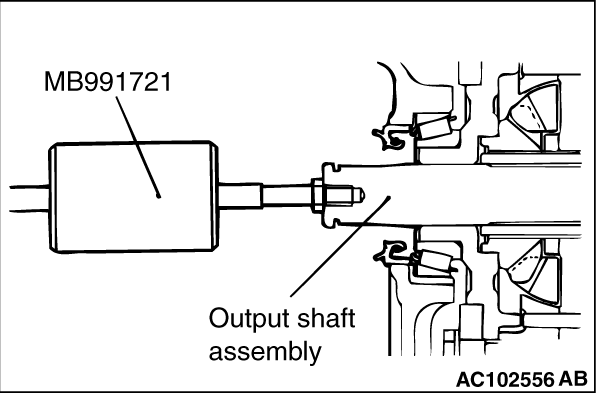

Use special tool MB991721 to remove the output shaft assembly.

|

|

| caution |

- The magnetic encoder collects metallic particles easily, because it is magnetized. Make sure that the magnetic encoder should not collect metallic particles. Check that there is not any trouble prior to reassembling it.

- When installing the front driveshaft, make sure that it does not contact with the magnetic encoder (integrated with the inner oil seal) to avoid damage.

- Care must be taken to ensure that the oil seal of the transaxle is not damaged by the spline part of the output shaft assembly or front driveshaft assembly.

|

|

|

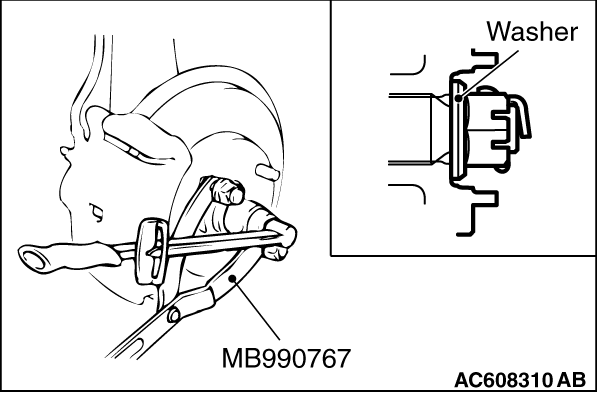

1.Be sure to install the front driveshaft washer in the illustrated direction.

2.Using special tool MB990767, tighten the driveshaft nut. At this time, tighten the nut to the specified lower limit torque so that the pin hole may align with cotter pin.

Tightening torque: 144 - 176 N·m (107 - 129 ft-lb)

3.If the pin hole does not align with the pin, tighten the driveshaft nut [less than 176 N·m (129 ft-lb)] and find the nearest hole, then fit the cotter pin.

|

.)

.) .)

.) .)

.) .)

.)![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)