![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)

DTC P0442: Evaporative

Emission Control System Leak Detected (Small Leak)

TECHNICAL DESCRIPTION

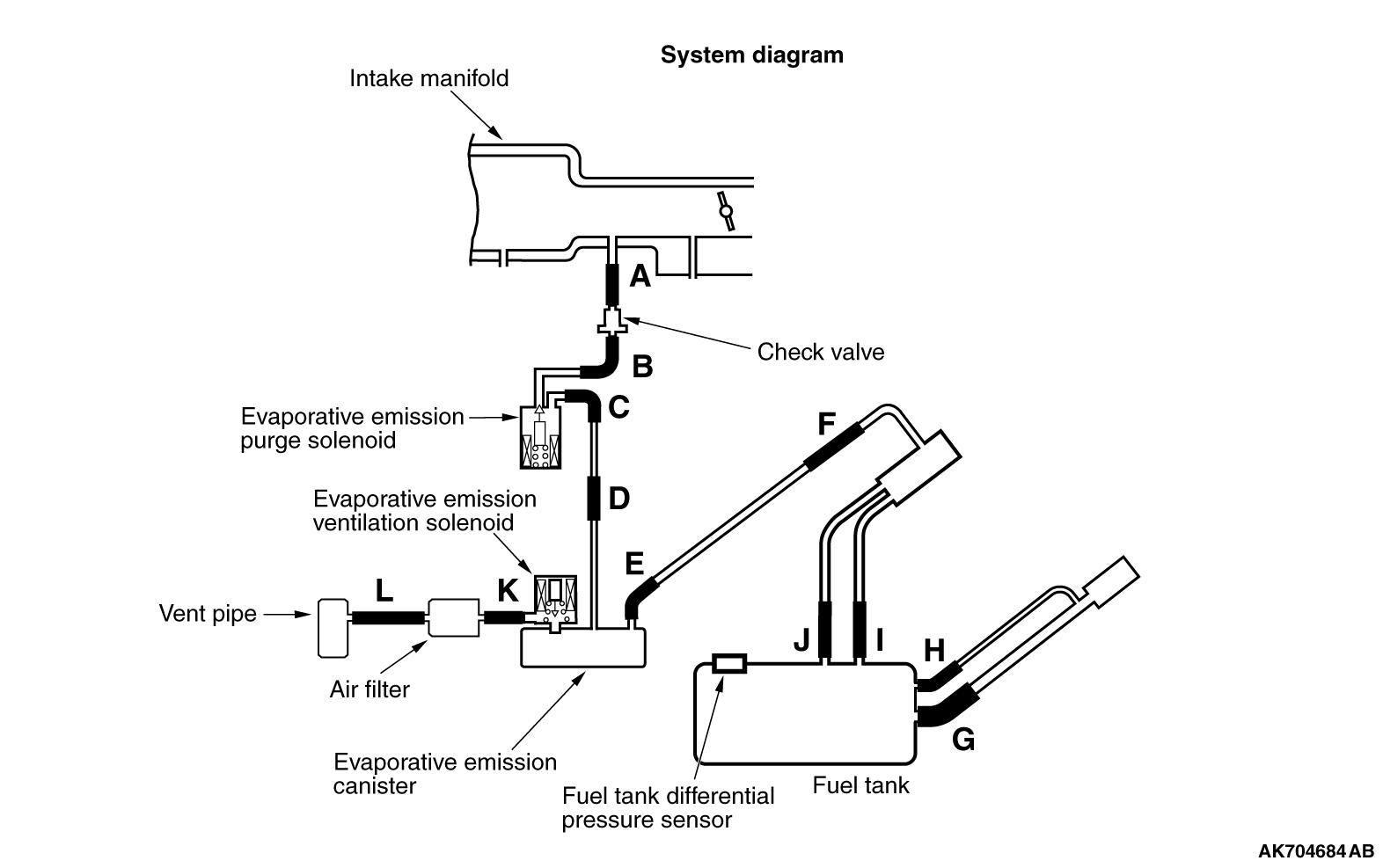

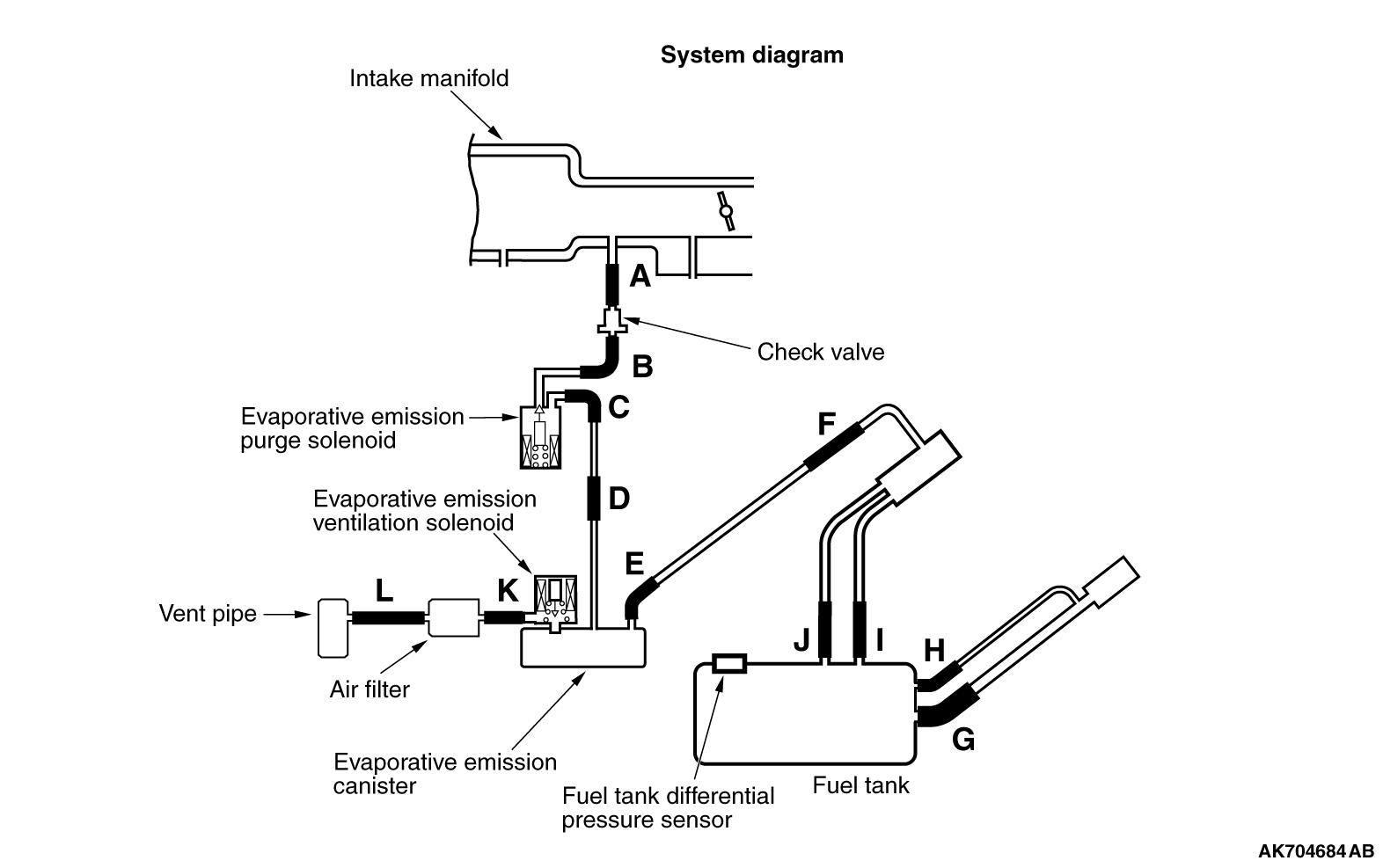

- The ECM monitors the Evaporative Emission (EVAP) System

pressure.

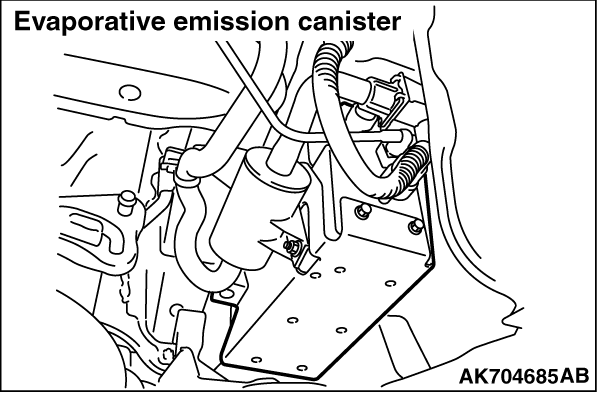

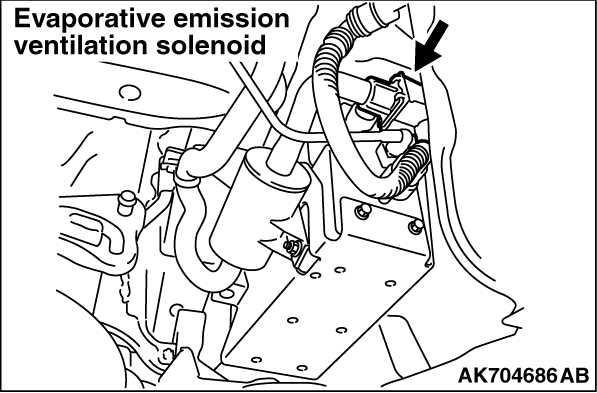

- The ECM controls the evaporative emission ventilation solenoid. It closes the evaporative emission

ventilation solenoid to seal the evaporative emission canister side of the system.

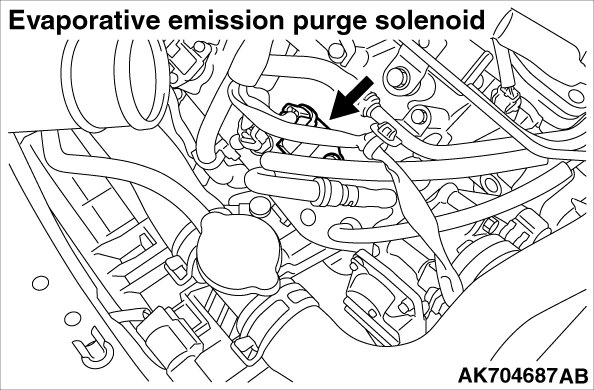

- The evaporative emission purge solenoid is opened to allow manifold vacuum to create

low pressure (vacuum) in the EVAP system.

- When the EVAP system develops a vacuum of 2 kPa (0.29 psi), the evaporative emission

purge solenoid is closed and the fuel system vacuum is maintained at 2 kPa (0.29 psi).

- The ECM determines whether there is a leak in the EVAP system by monitoring the

vacuum inside the fuel tank.

- The test is stopped when fuel vapor pressure exceeds predetermined limits.

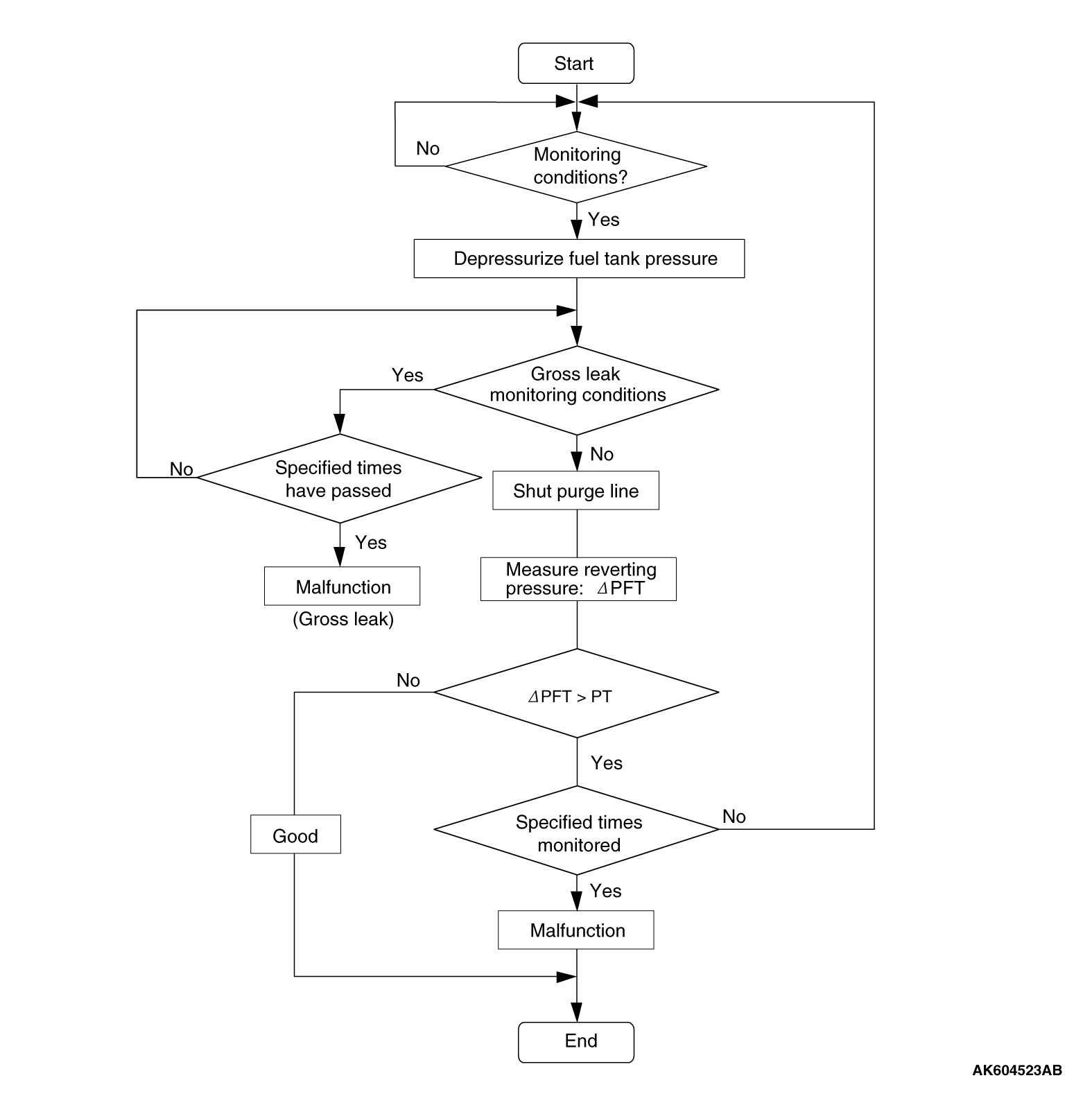

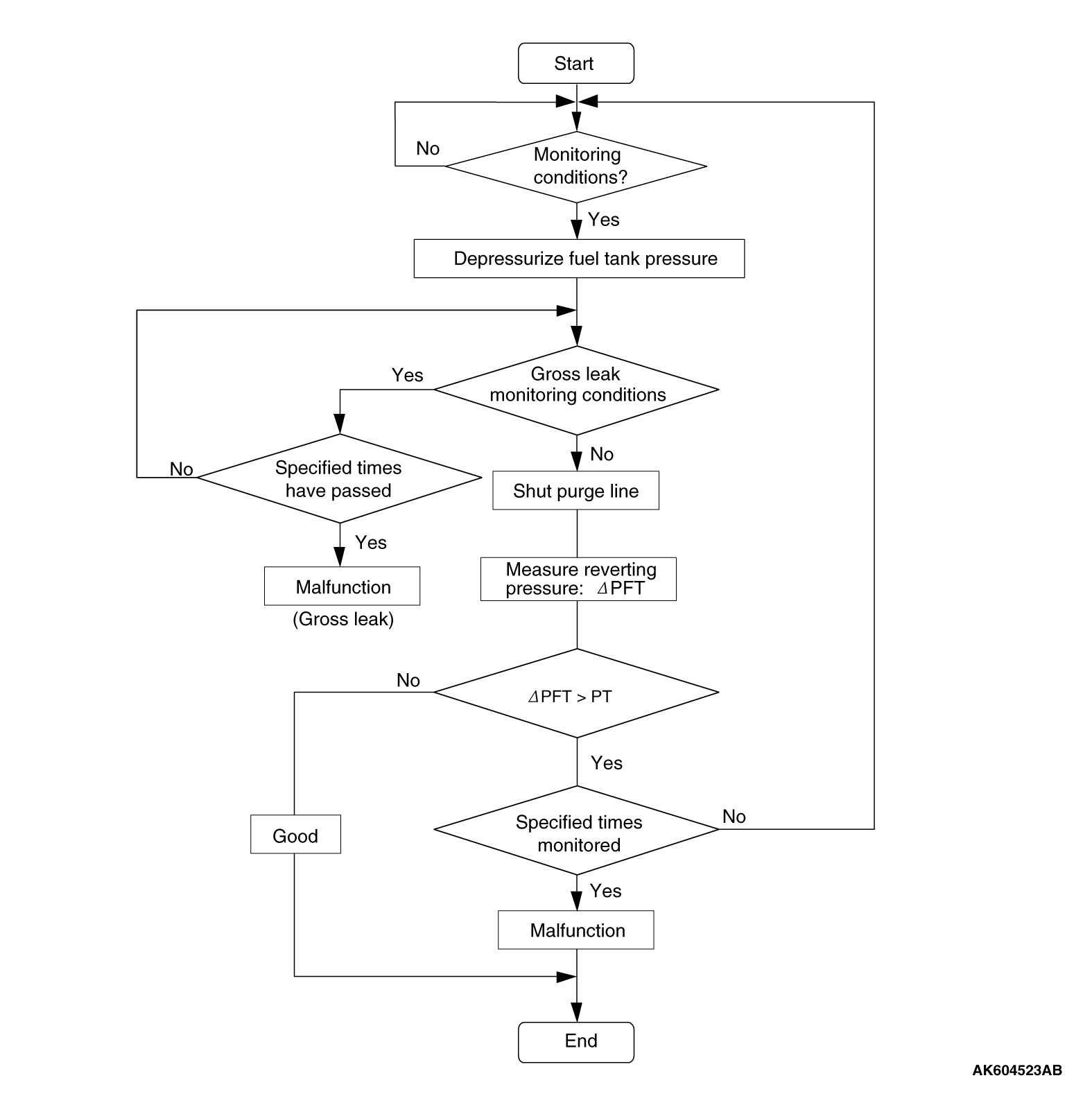

DESCRIPTIONS OF MONITOR METHODS

Measure reverting pressure after depressurizing by intake manifold negative pressure and

detect malfunction if reverting pressure rises largely.

MONITOR EXECUTION

Once per driving cycle

MONITOR EXECUTION CONDITIONS (OTHER MONITOR AND SENSOR)

Other Monitor (There is no temporary DTC stored in memory for the item monitored

below)

- Evaporative emission purge solenoid monitor

- Evaporative emission purge system monitor

- Fuel tank differential pressure sensor monitor

- Evaporative emission ventilation solenoid monitor

- Fuel level sensor monitor

- Fuel tank temperature sensor monitor

Sensor (The sensors below are determined to be normal)

- Mass airflow sensor

- Barometric pressure sensor

- Intake air temperature sensor

- Engine coolant temperature sensor

DTC SET CONDITIONS

Logic Flow Chart (Monitor Sequence)

Check Conditions

- Amount of remaining fuel is 15 - 40 percent of capacity when the engine

is started.

- Engine coolant temperature is less than 36°C (97°F) when the engine

is started.

- Intake air temperature is less than 36°C (97°F) when the engine

is started.

- Engine coolant temperature is more than 60°C (140°F).

- Intake air temperature is more than -10°C (14°F).

- Fuel temperature is less than 36°C (97°F).

- Power steering pressure switch: "OFF"

- When the evaporative emission purge solenoid and evaporative emission ventilation

solenoid are closed, the change of the pressure in the fuel tank is less than 451 Pa (0.13 in.Hg).

- The pressure fluctuation is less than 647 Pa (0.19 in.Hg).

- Barometric pressure is more than 76 kPa (22.4 in.Hg).

- Vehicle speed is more than 20 km/h (12 mph).

- Fuel tank differential pressure sensor output voltage is between 1.0 and 4.0 volts.

- At least 10 seconds have passed since the last monitor was complete.

- Monitoring time: 75 - 125 seconds

Judgement Criterion

- Internal pressure of the fuel tank has changed more than 1,010 Pa (0.29 in.Hg) in

20 seconds after the tank and vapor lines were closed.

| note |

- The monitoring time (75 - 125 seconds) depends on the fuel level and the temperature

in the fuel tank.

- The next monitoring occurs at least 10 seconds later.

|

Check Conditions

- Amount of remaining fuel is 40 - 85 percent of capacity when the engine

is started.

- Engine coolant temperature is less than 36°C (97°F) when the engine

is started.

- Intake air temperature is less than 36°C (97°F) when the engine

is started.

- Engine coolant temperature is more than 20°C (68°F).

- Intake air temperature is more than -10°C (14°F).

- Fuel temperature is less than 36°C (97°F).

- When the evaporative emission purge solenoid and evaporative emission ventilation

solenoid are closed, the change of the pressure in the fuel tank is less than 324 Pa (0.09 in.Hg).

- Barometric pressure is more than 76 kPa (22.4 in.Hg).

- Fuel tank differential pressure sensor output voltage is between 1.0 and 4.0 volts.

- At least 10 seconds have passed since the last monitor was complete.

- Monitoring time: 10 - 14 minutes

Judgement Criterion

- Internal pressure of the fuel tank has changed more than 1,922 Pa (0.56 in.Hg) in

88 seconds after the tank and vapor lines were closed.

| note |

- The monitoring time (10 - 14 minutes) depends on the fuel level and the

temperature in the fuel tank.

- The next monitoring occurs at least 10 seconds later.

|

FAIL-SAFE AND BACKUP FUNCTION

OBD-II DRIVE CYCLE PATTERN

Refer to Diagnostic Function - OBD-II Drive Cycle - Pattern 4  .

.

TROUBLESHOOTING HINTS (THE MOST LIKELY CAUSES FOR THIS CODE TO BE SET ARE:)

- Loose fuel cap.

- Fuel cap relief pressure is incorrect.

- Evaporative emission canister seal is leaking.

- Fuel tank, purge line or vapor line seal is leaking.

- Evaporative emission ventilation solenoid does not seal.

|

|

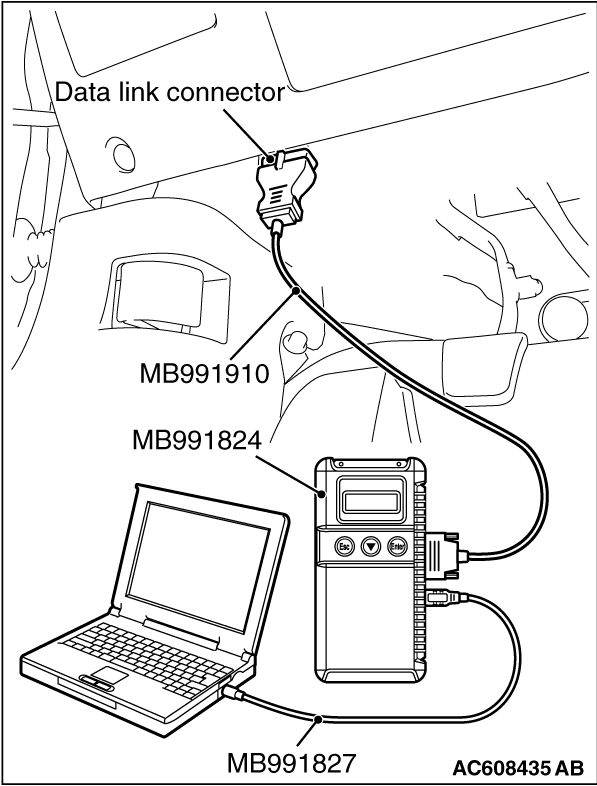

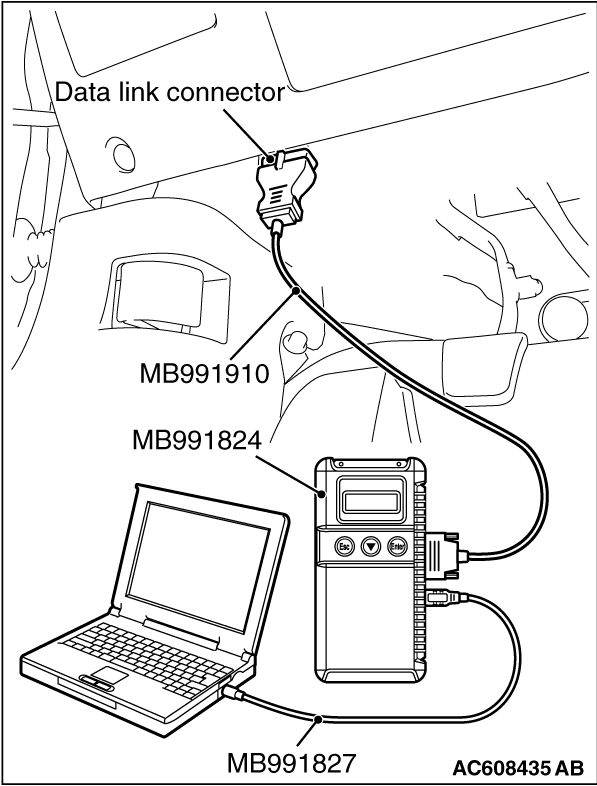

Required Special Tools:

- MB991958: Scan Tool (M.U.T.-III Sub Assembly)

- MB991824: V.C.I.

- MB991827: M.U.T.-III USB Cable

- MB991910: M.U.T.-III Main Harness A

|

|

|

STEP 1. Using scan tool MB991958, check the evaporative emission

system monitor test.

|

|

| caution |

- To prevent damage to scan tool MB991958, always turn the ignition switch

to the "LOCK" (OFF) position before connecting or disconnecting scan tool MB991958.

- During this test, the ECM will automatically increase the engine speed to 1,600

r/min or greater. Check that the transaxle is set to "P" position.

|

(1)Connect scan tool MB991958 to the data link connector.

(2)Turn the ignition switch to the "ON" position.

(3)Erase the DTCs using scan tool MB991958.

(4)Check that the fuel cap is securely closed (Tighten until three clicks are heard).

(5)Start the engine.

(6)Select "Special Function"

(7)Select "Evap Leak Monitor"

(8)During this test, keep the accelerator pedal at the idle position.

(9)Keep the engine speed and engine load within the specified range. When the monitor

test starts, the "In Progress" item on scan tool MB991958 will change from "NO" to "YES".

(10) Turn the ignition switch to the "LOCK" (OFF) position, and disconnect scan tool

MB991958.

Q.

Is "Evap Leak Mon. Completed. Test Failed and DTCs Set" displayed on scan tool MB991958?

A malfunction has been detected during the monitor test. Refer to the Diagnostic

Trouble Code Chart and diagnose any other DTCs that are set A malfunction has been detected during the monitor test. Refer to the Diagnostic

Trouble Code Chart and diagnose any other DTCs that are set  .

If no other DTC’s have been set, go to Step 2 . .

If no other DTC’s have been set, go to Step 2 .

NO <"Evap Leak Mon. Completed. Test Passed" is displayed on scan tool MB991958.> : The evaporative emission system is working properly at this time. Explain to the

customer that an improperly tightened fuel cap can cause the MIL to illuminate. Return the vehicle

to the customer.

NO <"Evap Leak Mon. Discontinued. Retest again from the first" is displayed on scan

tool MB991958.> : The EVAP monitor has been interrupted during the test. Turn the ignition switch

to the "LOCK" (OFF) position once, and repeat the monitoring.

|

|

|

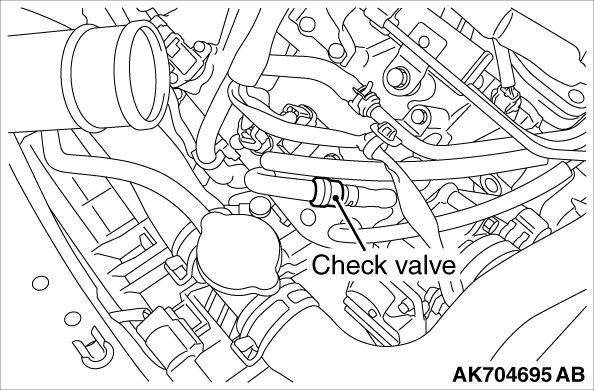

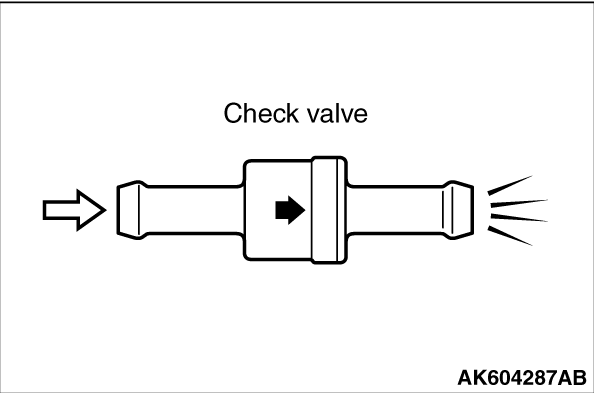

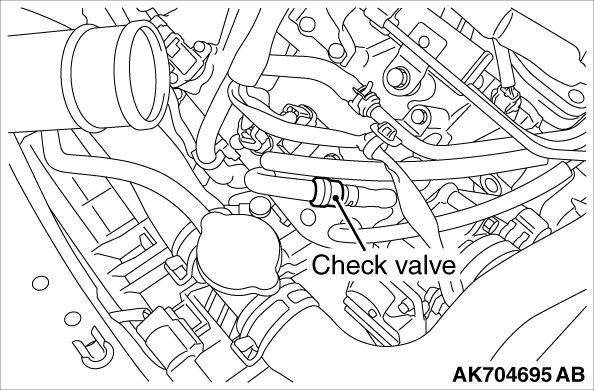

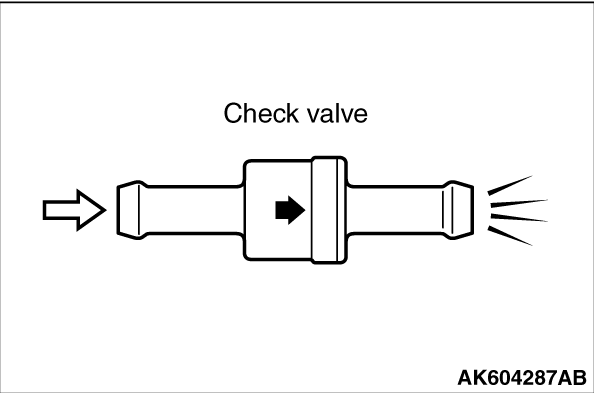

STEP 2. Test check valve.

|

|

(1)Check valve is a one-way check valve.

|

|

(2)Check valve should allow air to flow in only one direction.

Q.

Does check valve allow air to pass in one direction only?

Go to Step 3 . Go to Step 3 .

Replace check valve. Then go to Step 14 . Replace check valve. Then go to Step 14 .

|

|

|

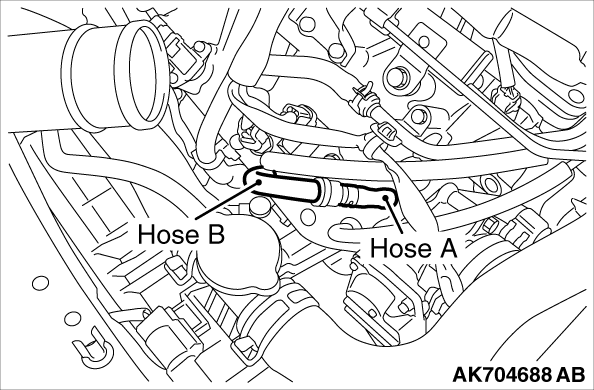

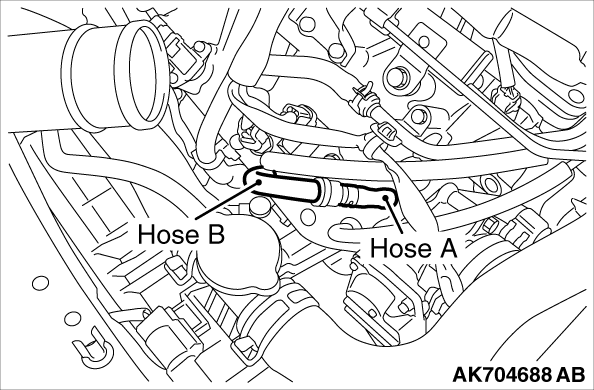

STEP 3. Check for leaks in evaporative emission hoses

A and B.

|

|

Use a hand vacuum pump to test each hose A and B.

Q.

Do the hoses hold vacuum?

Go to Step 4 . Go to Step 4 .

Replace any damaged hose. Then go to Step 14 . Replace any damaged hose. Then go to Step 14 .

|

|

|

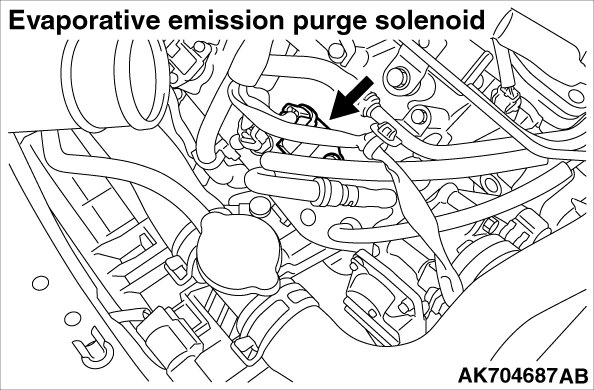

STEP 4. Check the evaporative emission purge solenoid for leaks.

|

|

|

Refer to GROUP 17, Emission Control - Evaporative Emission Control System - Evaporative

Emission Purge Solenoid Check  . .

|

|

|

Q.

Is the evaporative emission purge solenoid operating properly?

|

|

|

Go to Step 5 . Go to Step 5 .

|

|

|

|

|

|

Replace the evaporative emission purge solenoid. Then go to Step 14 . Replace the evaporative emission purge solenoid. Then go to Step 14 .

|

|

|

|

|

|

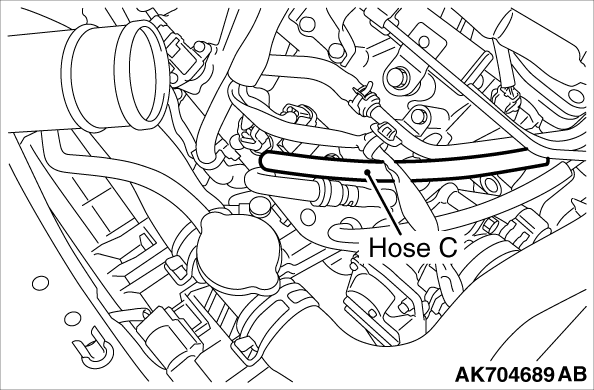

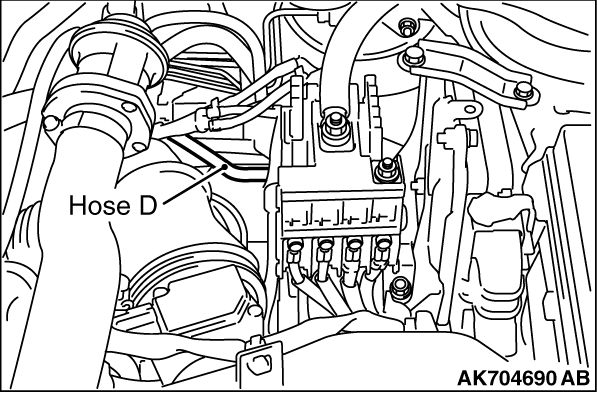

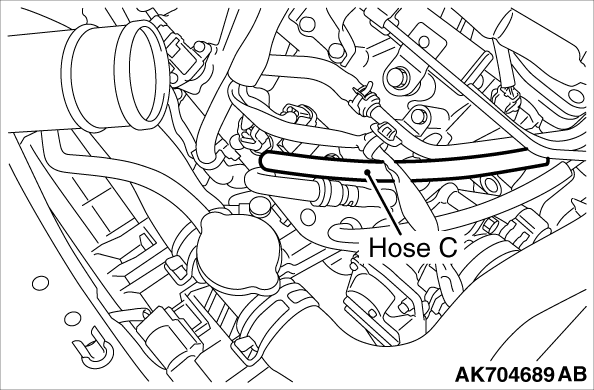

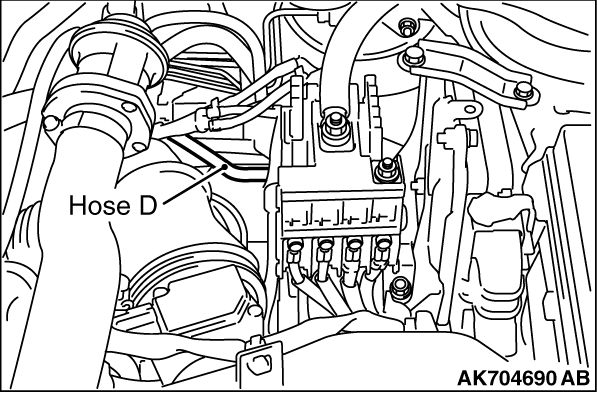

STEP 5. Check for leaks in evaporative emission hoses

C and D.

|

|

Use a hand vacuum pump to test each hose C and D.

Q.

Do the hoses hold vacuum?

Go to Step 6 . Go to Step 6 .

Replace any damaged hose. Then go to Step 14 . Replace any damaged hose. Then go to Step 14 .

|

|

|

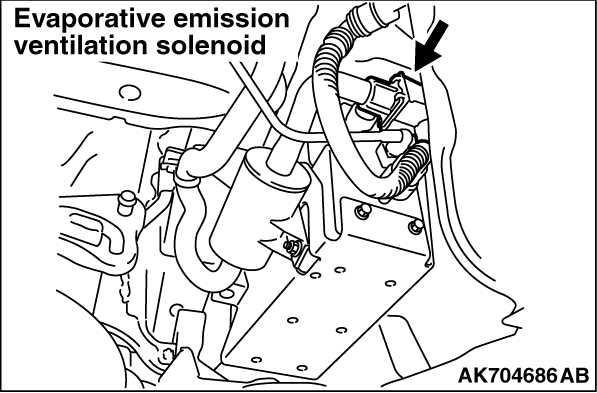

STEP 6. Using scan tool MB991958, check actuator test item 15: Evaporative

emission ventilation solenoid.

|

|

|

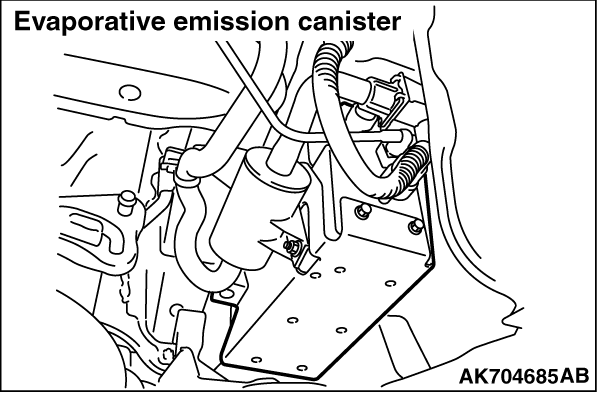

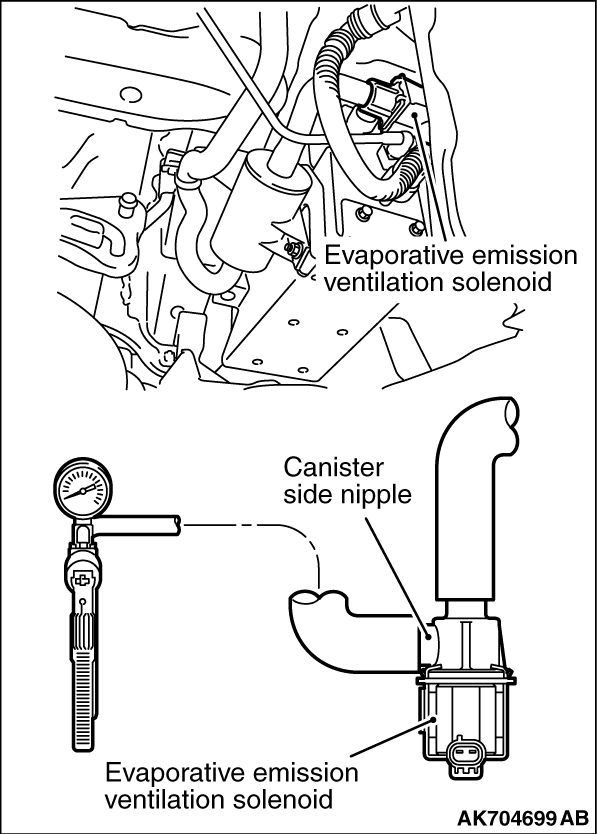

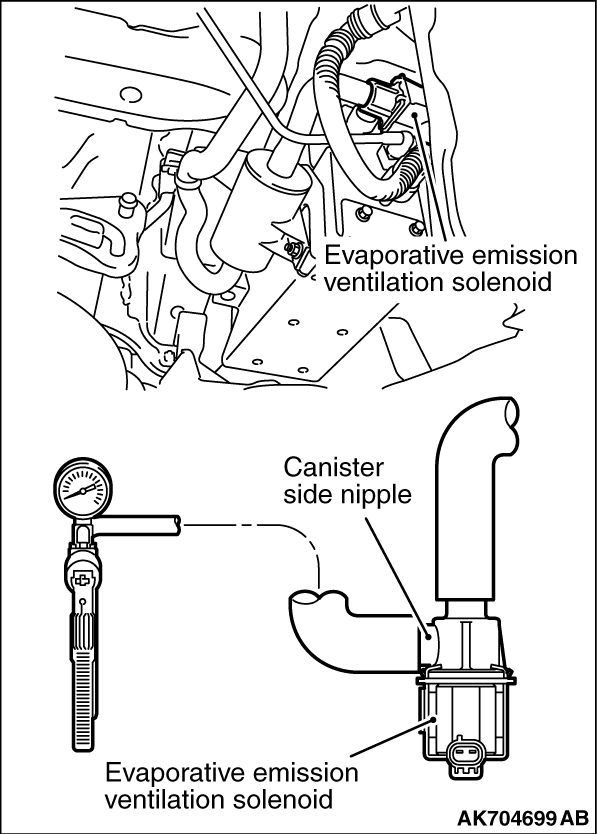

(1)Remove the canister cover.

|

|

|

(2)Remove the evaporative emission ventilation solenoid. Do not disconnect the connector.

|

|

(3)Connect the hose of the hand vacuum pump to the canister side nipple of the evaporative

emission ventilation solenoid.

(4)Turn the ignition switch to the "ON" position.

(5)Set scan tool MB991958 to actuator test mode.

- Item 15: Evaporative Emission Ventilation Solenoid.

- While the evaporative emission ventilation solenoid is energized, operate

the hand vacuum pump and confirm that the solenoid holds vacuum.

(6)Turn the ignition switch to the "LOCK" (OFF) position.

(7)Disconnect the hand vacuum pump, and reinstall the evaporative emission ventilation

solenoid.

(8)Reinstall the canister cover.

Q.

Did the evaporative emission ventilation solenoid hold vacuum?

Go to Step 7 . Go to Step 7 .

Replace the evaporative emission ventilation solenoid. Then go to Step 14 . Replace the evaporative emission ventilation solenoid. Then go to Step 14 .

|

|

|

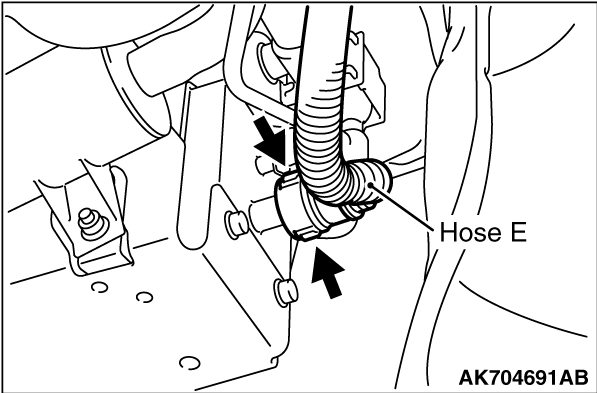

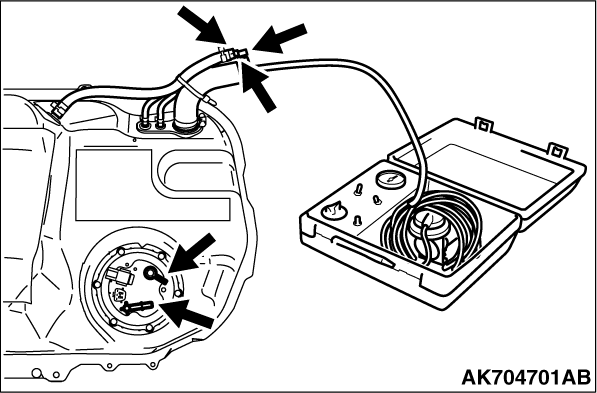

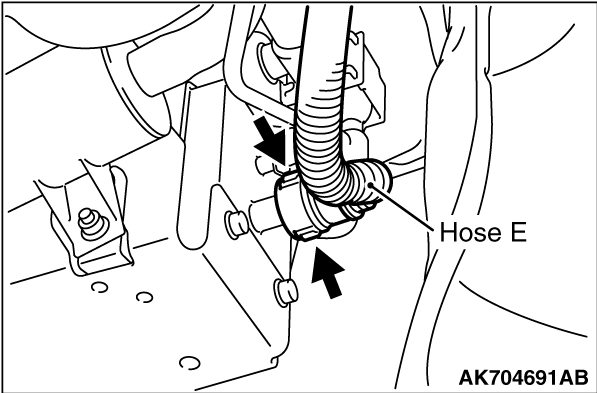

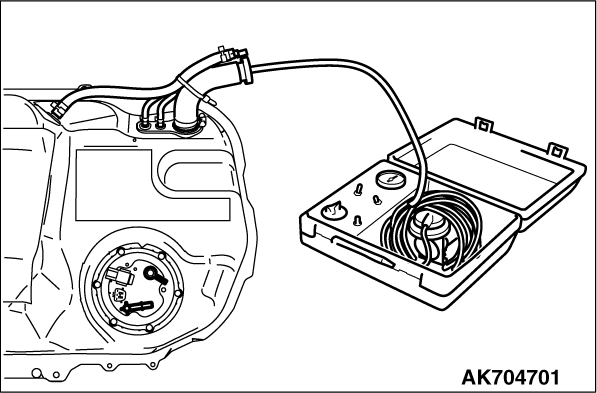

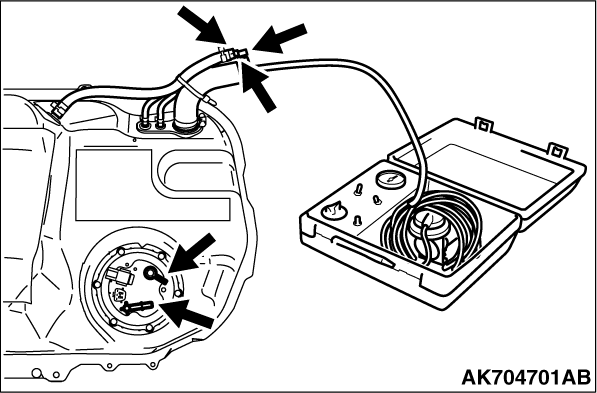

STEP 7. Perform the pressure test on the evaporative emission system.

|

|

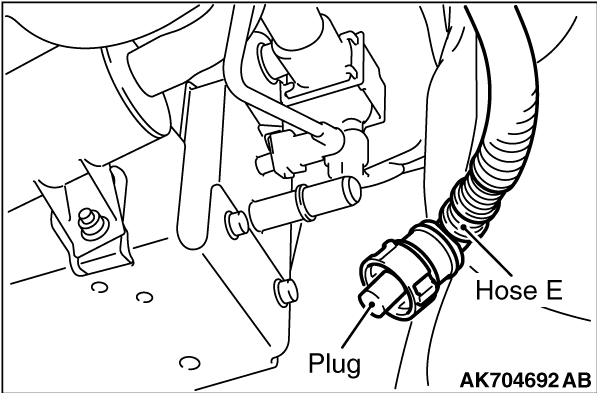

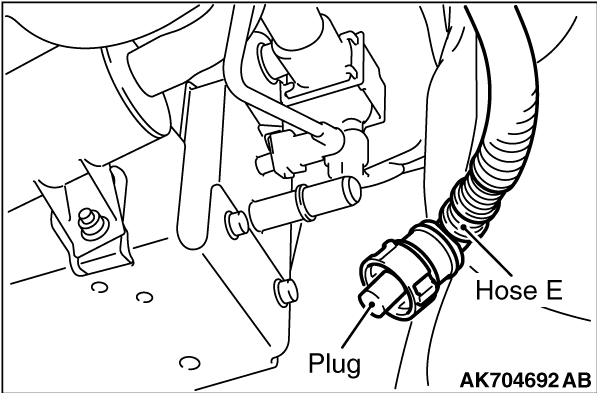

(1)Disconnect hose E from the canister while holding the release buttons indicated in the

illustration pressed by fingers.

|

|

(2)Plug the disconnected end of hose E.

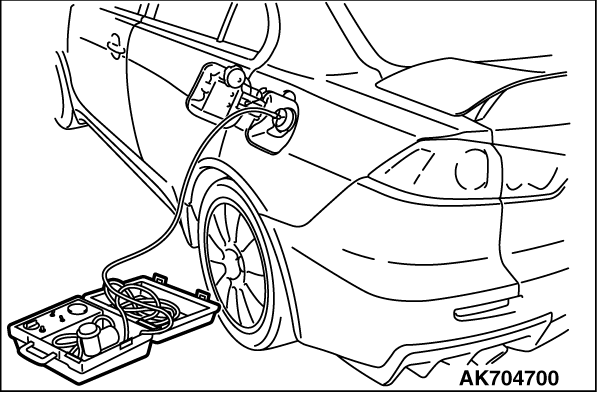

(3)Confirm that the evaporative emission system pressure pump (Miller number 6872A)

is operating properly. Perform the self-test as described in the pump manufacturer’s instructions.

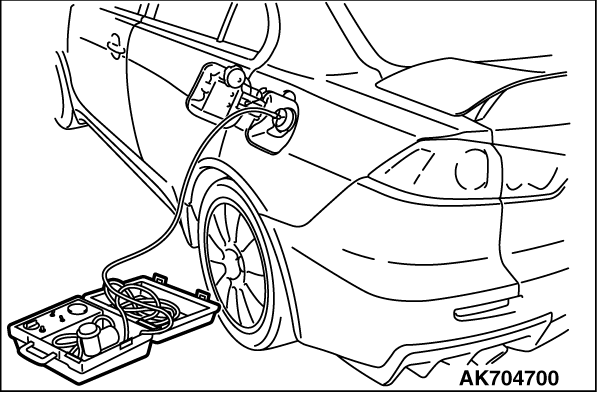

(4)Remove the fuel cap.

|

|

(5)Connect the evaporative emission system pressure pump (Miller number 6872A) to the fuel

tank filler tube by using fuel tank adapter (MLR-8382).

(6)Pressure test the system to determine whether any leaks are present.

| note |

The "Pressure test" in this procedure refers to the I/M240 Simulation Test. The

eight steps of this test are described in the manufacturer’s instructions for the evaporative

emission system pressure pump, Miller number 6872A.

|

(7)Remove the evaporative emission system pressure pump (Miller number 6872A) and

the fuel tank adapter (MLR-8382), and reinstall the fuel cap.

(8)Connect hose E to the evaporative emission canister.

Q.

Is the evaporative emission system line free of leaks?

Go to Step 12 . Go to Step 12 .

Go to Step 8 . Go to Step 8 .

|

|

|

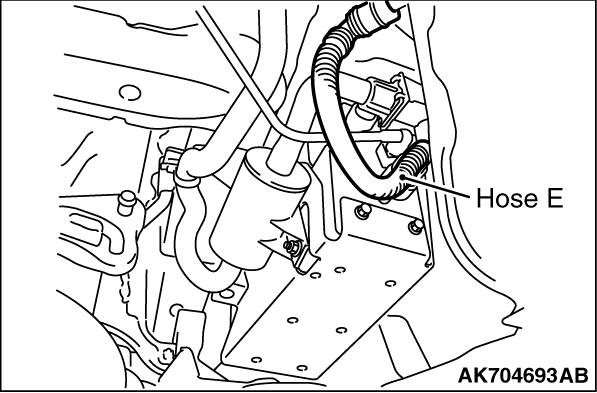

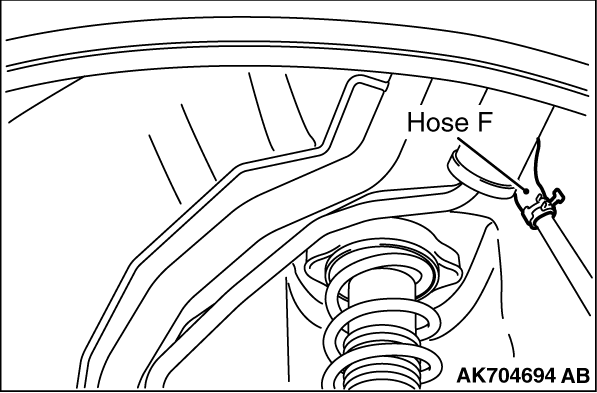

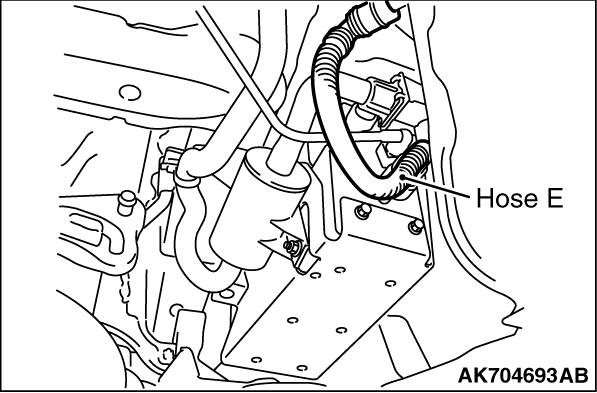

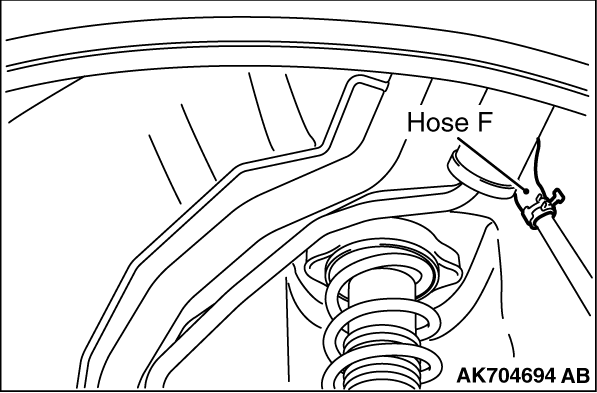

STEP 8. Check for leaks in evaporative emission hoses E and F.

|

|

(1)Use a hand vacuum pump to test each hose E and F.

Q.

Do the hoses hold vacuum?

Go to Step 9 . Go to Step 9 .

Replace any damaged hose. Then go to Step 14 . Replace any damaged hose. Then go to Step 14 .

|

|

|

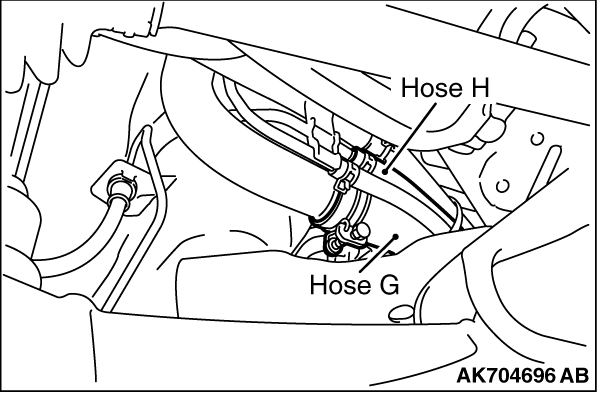

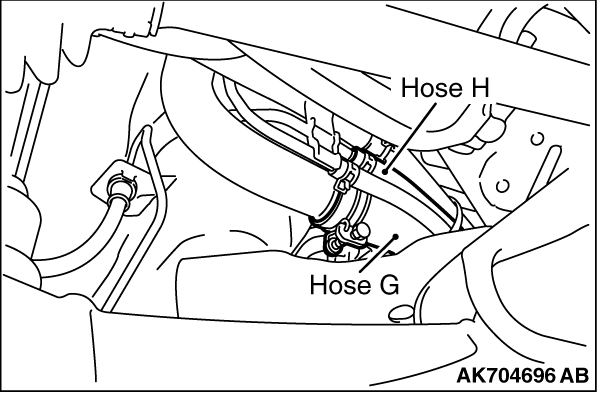

STEP 9. Check for leaks in evaporative emission hoses G and H.

|

|

|

(1)Remove the fuel tank assembly.

|

|

(2)Use a hand vacuum pump to test each hose G and H.

Q.

Do the hoses hold vacuum?

Go to Step 10. Go to Step 10.

Replace any damaged hose and reinstall the fuel tank assembly. Then go to Step

14 . Replace any damaged hose and reinstall the fuel tank assembly. Then go to Step

14 .

|

|

|

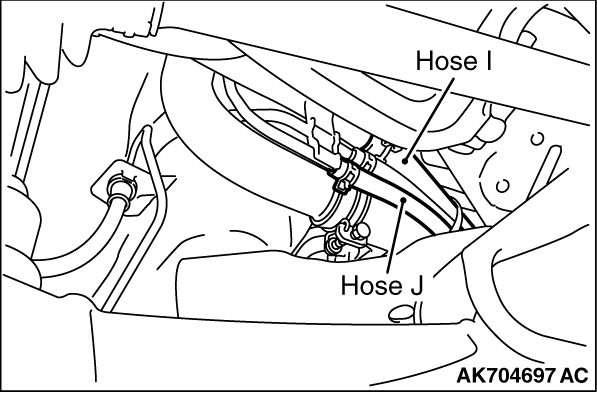

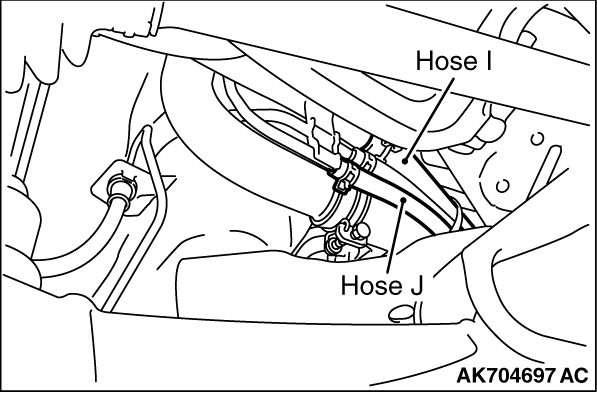

STEP 10. Check for leaks in evaporative emission hoses I and J.

|

|

|

(1)Remove the fuel tank assembly.

|

|

(2)Use a hand vacuum pump to test each hose I and J.

Q.

Do the hoses hold vacuum?

Go to Step 11 . Go to Step 11 .

Replace any damaged hose and reinstall the fuel tank assembly. Then go to Step

14 . Replace any damaged hose and reinstall the fuel tank assembly. Then go to Step

14 .

|

|

|

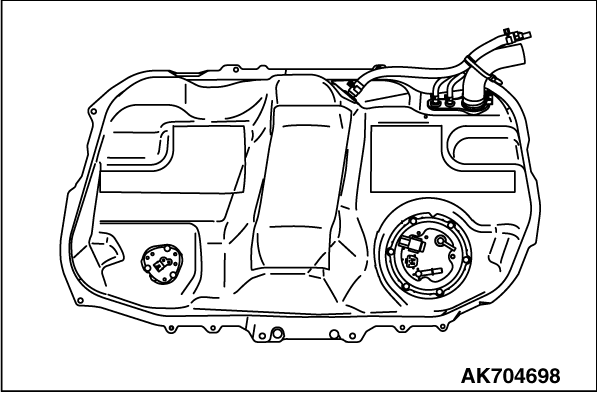

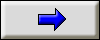

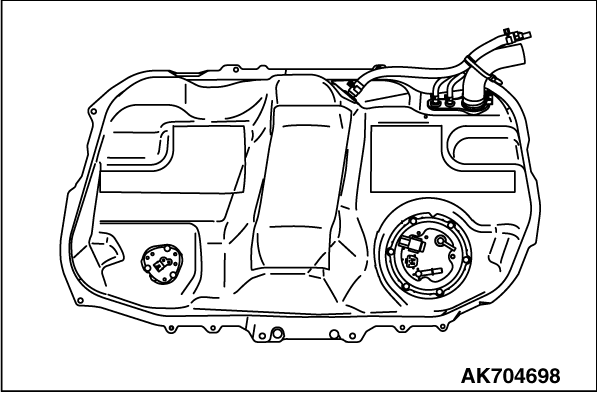

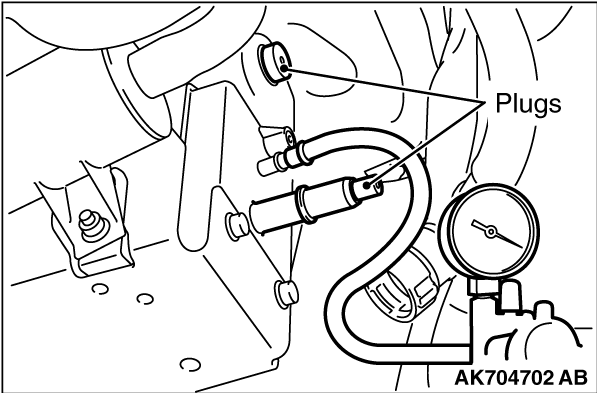

STEP 11. Check for leaks in the fuel tank.

|

|

(1)Visually check for cracks or other leaks in the fuel tank.

| note |

Carefully check the fuel pump module and the fuel tank differential pressure sensor installation

in the fuel tank.

|

|

|

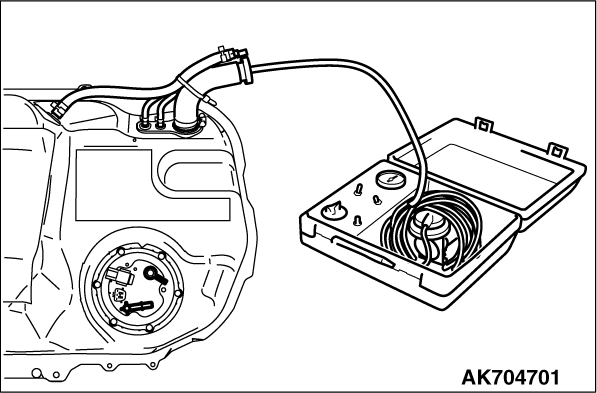

(2)Connect the evaporative emission system pressure pump (Miller number 6872A) to the fuel

filler hose.

|

|

(3)Plug the hose and the nipple shown in the illustration.

| note |

If these items are not securely plugged now, the fuel could leak in the next step.

|

(4)Pressurize the fuel tank with the evaporative emission system pressure pump.

(5)In the pressurized state, check for leaks by applying a soapy water solution to

each section and look for bubbles.

Q.

Are any leaks found?

YES <When there is a leak from the attachment points of the fuel pump module, fuel

tank differential pressure sensor, fuel level sensor or leveling valve.> : Reassemble the leaked parts and check again that there are no leaks. Then reinstall

the fuel tank. Then go to Step 14 . : Reassemble the leaked parts and check again that there are no leaks. Then reinstall

the fuel tank. Then go to Step 14 .

YES <When there is a leak from the fuel tank.> : Replace the fuel tank. Then go to Step 14 . : Replace the fuel tank. Then go to Step 14 .

When there is no leak, reinstall the fuel tank. Then go to Step 13 . When there is no leak, reinstall the fuel tank. Then go to Step 13 .

|

|

|

STEP 12. Check the evaporative emission canister for vacuum leaks.

|

|

(1)Connect a hand vacuum pump to the evaporative emission canister and plug the other nipples.

(2)Apply a pressure on the hand vacuum pump, and confirm that air is maintained.

(3)Disconnect the hand vacuum pump and remove the plugs.

Q.

Is the evaporative emission canister in good condition?

Go to Step 13 . Go to Step 13 .

Replace the evaporative emission canister. Then go to Step 14 . Replace the evaporative emission canister. Then go to Step 14 .

|

|

|

STEP 13. Using scan tool MB991958, check the evaporative emission

system monitor test.

|

|

|

| caution |

- During this test, the ECM automatically increases

the engine speed to 1,600 r/min or greater. Check that the transaxle is set to "P"

position.

|

|

|

|

(1)Turn the ignition switch to the "ON" position.

|

|

|

(2)Erase the DTCs using scan tool MB991958.

|

|

|

(3)Check that the fuel cap is securely closed (Tighten until three clicks are heard).

|

|

|

(5)Select "Special Function"

|

|

|

(6)Select "Evap Leak Monitor"

|

|

|

(7)During the test, keep the accelerator pedal at the idle position.

|

|

|

(8)Keep the engine speed and engine load within the specified range. When the monitor

test starts, the "In Progress" item on scan tool MB991958 will change from "NO" to "YES".

|

|

|

(9)Turn the ignition switch to the "LOCK" (OFF) position.

|

|

|

Q.

Is "Evap Leak Mon. Completed. Test Failed and DTCs Set" displayed on scan tool MB991958?

|

|

|

Replace the ECM. When the ECM is replaced, register the ID code. Refer to GROUP

42B, ID Code Registration Judgment Table <Vehicles with KOS> Replace the ECM. When the ECM is replaced, register the ID code. Refer to GROUP

42B, ID Code Registration Judgment Table <Vehicles with KOS>  or

GROUP 42C, ID Code Registration Judgment Table <Vehicles with WCM> or

GROUP 42C, ID Code Registration Judgment Table <Vehicles with WCM>  .

Then go to Step 14 . .

Then go to Step 14 .

|

|

|

|

|

|

NO <"Evap Leak Mon. Completed. Test Passed" is displayed on scan tool MB991958.> : The evaporative emission system is working properly at this time. Go to Step 14

. : The evaporative emission system is working properly at this time. Go to Step 14

.

|

|

|

|

|

|

NO <"Evap Leak Mon. Discontinued. Retest again from the first" is displayed on scan

tool MB991958.> : The EVAP monitor has been interrupted during the test. Turn the ignition switch

to the "LOCK" (OFF) position once, and repeat the monitoring.

|

|

|

|

|

|

STEP 14. Test the OBD-II drive cycle.

|

|

|

(1)Carry out a test drive with the drive cycle pattern. Refer to Diagnostic Function - OBD-II

Drive Cycle - Pattern 4  . .

|

|

|

(2)Check the diagnostic trouble code (DTC).

|

|

|

Retry the troubleshooting. Retry the troubleshooting.

|

|

|

|

|

|

The inspection is complete. The inspection is complete.

|

|

|

|

A malfunction has been detected during the monitor test. Refer to the Diagnostic

Trouble Code Chart and diagnose any other DTCs that are set

A malfunction has been detected during the monitor test. Refer to the Diagnostic

Trouble Code Chart and diagnose any other DTCs that are set  .

If no other DTC’s have been set, go to Step 2 .

.

If no other DTC’s have been set, go to Step 2 .![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)