![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)

DTC P0133: Heated

Oxygen Sensor (front) Circuit Slow Responce

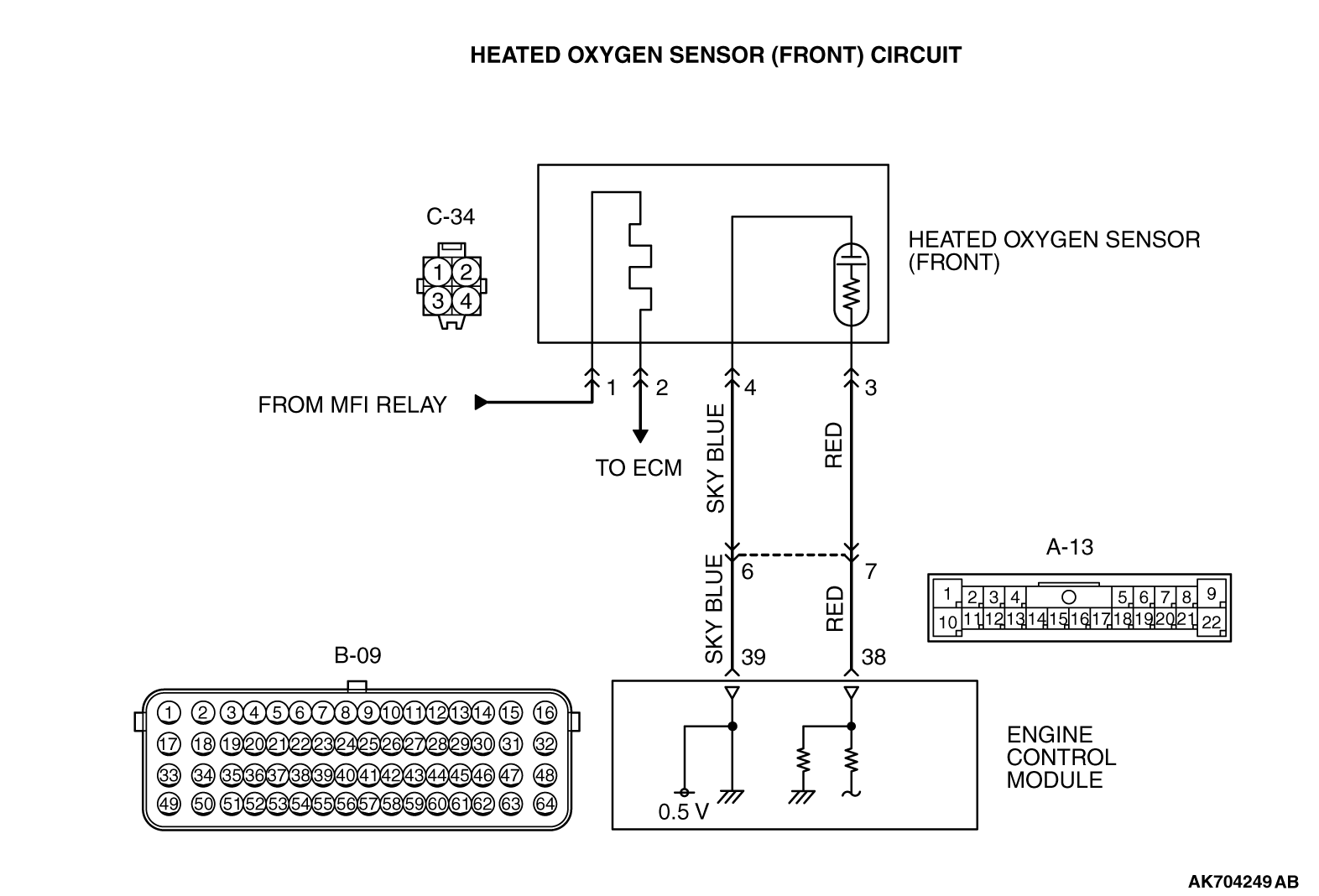

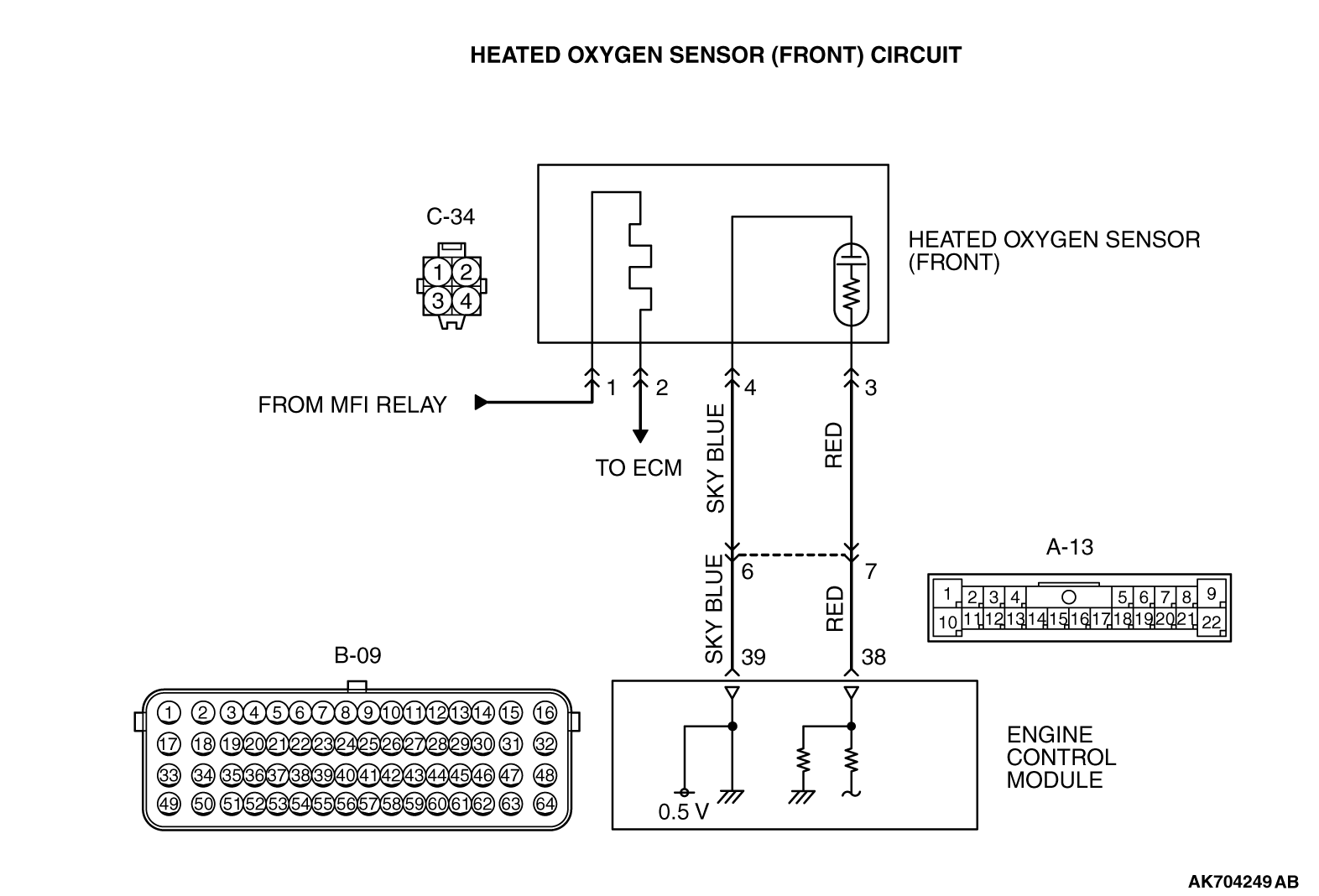

CIRCUIT OPERATION

- A voltage corresponding to the oxygen concentration in

the exhaust gas is sent to the ECM (terminal No. 38) from the output terminal (terminal No.

3) of the heated oxygen sensor (front).

- Terminal No. 4 of the heated oxygen sensor (front) is grounded with ECM (terminal

No. 39).

- The ECM applies an offset voltage of 0.5 volt to terminal No. 4 of the heated oxygen

sensor (front).

TECHNICAL DESCRIPTION

- The heated oxygen sensor (front) detects the concentration

of oxygen in the exhaust gas; it converts those data to voltage, and inputs the resulting signals

to the ECM.

- When the heated oxygen sensor (front) begins to deteriorate, the heated oxygen sensor

signal response becomes poor.

- The ECM checks for the heated oxygen sensor (front) rich/lean switching frequency.

DESCRIPTIONS OF MONITOR METHODS

Heated oxygen sensor (front) rich/lean switching frequency

is under specified value.

MONITOR EXECUTION

MONITOR EXECUTION CONDITIONS (Other monitor and Sensor)

Other Monitor (There is no temporary DTC stored in memory

for the item monitored below)

- Heated oxygen sensor (front) heater monitor

- Misfire monitor

- Fuel system monitor

- Heated oxygen sensor (rear) feedback control system monitor

Sensor (The sensor below is determined to be normal)

- Mass airflow sensor

- Engine coolant temperature sensor

- Intake air temperature sensor

- Barometric pressure sensor

- Throttle position sensor

- Accelerator pedal position sensor

DTC SET CONDITIONS

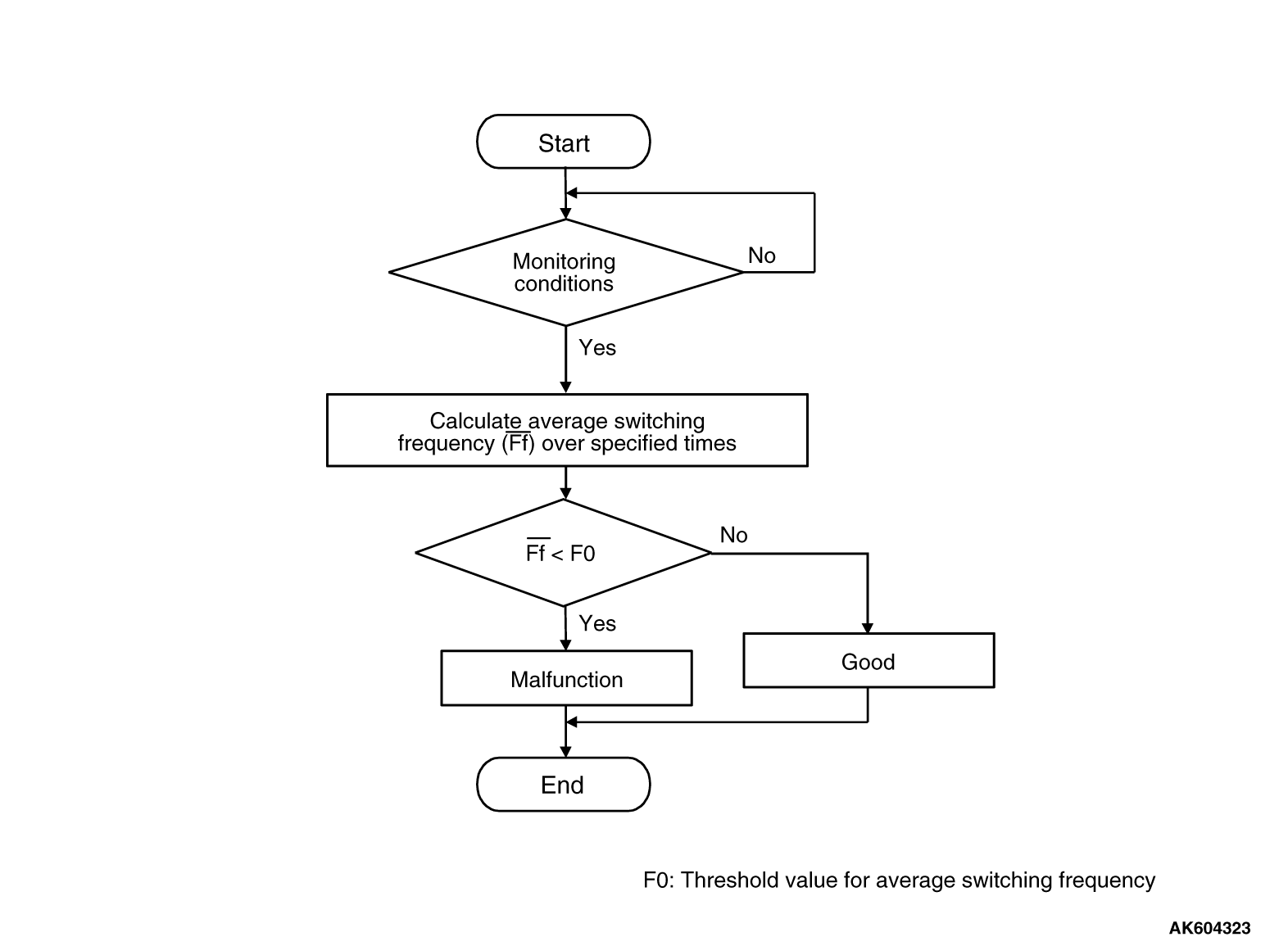

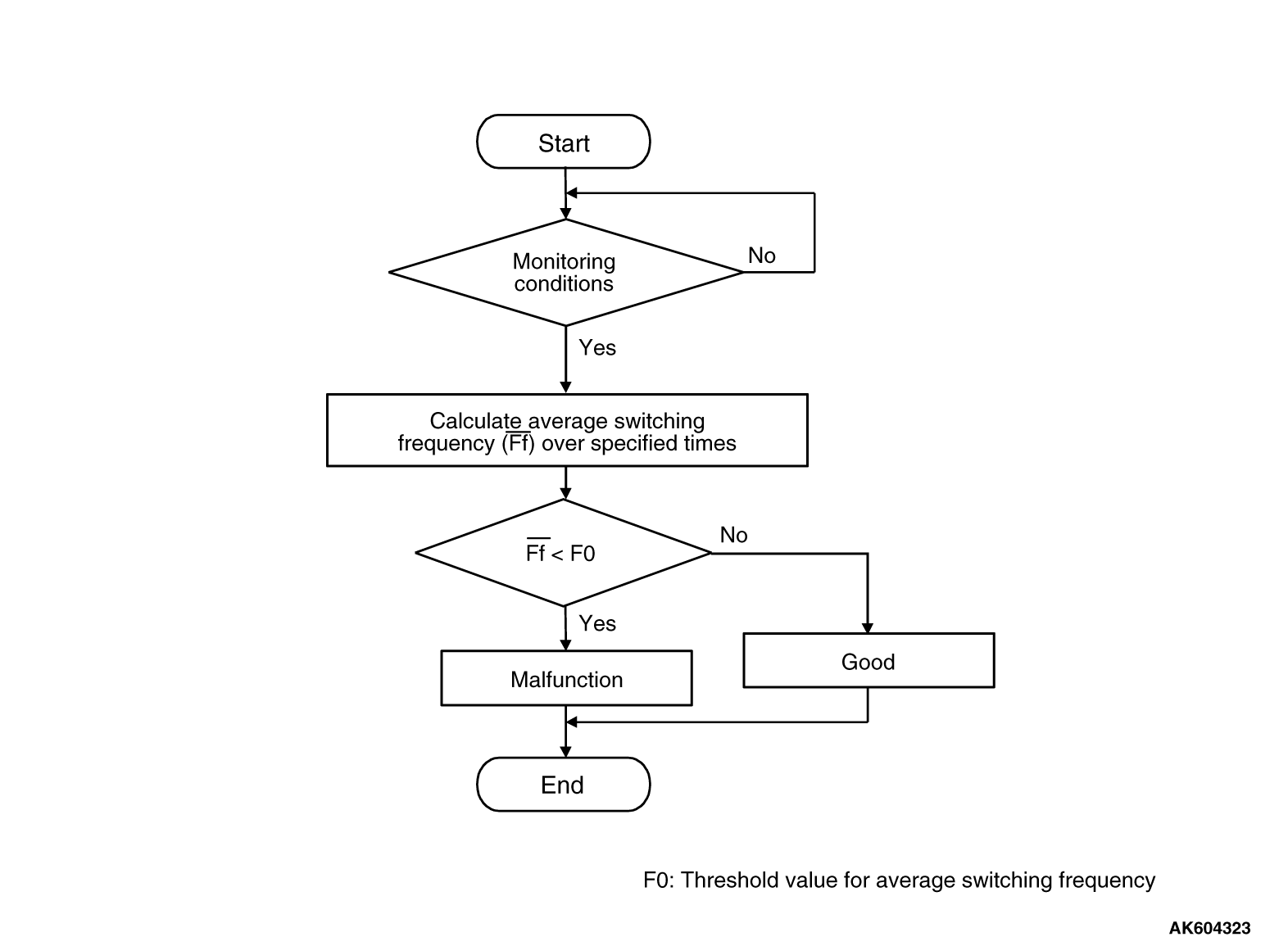

Logic Flow Chart

Check Conditions

- Engine coolant temperature is higher than 60°C (140°F).

- Engine speed is between 1,406 and 3,500 r/min.

- Volumetric efficiency is between 20 and 65 percent.

- Under the closed loop air/fuel control.

- The accelerator pedal is depressed.

- Short-term fuel trim is between -20 and +17 percent.

- More than 3.5 seconds have elapsed after the above mentioned conditions have been

met.

- During the drive cycle, the ECM performs monitoring with the accumulated total time

of 10 seconds, 5 times.

Judgement Criteria

- The average of the heated oxygen sensor (front) rich/lean switching frequency is

less than 9 times <M/T> or 8 times <TC-SST> for the accumulated time of 10 seconds.

- The heated oxygen sensor (front) rich/lean switching frequency is less than 20 times <M/T> or

16 times <TC-SST> for the accumulated time of 10 seconds.

| note |

If the sensor switching frequency is lower than the Judgement Criteria due to the M.U.T.-III OBD-II

test Mode - HO2S Test Results, it is assumed that the heated oxygen sensor has deteriorated.

If it is higher, it is assumed that the harness is damaged or has a short circuit.

If the heated oxygen sensor signal voltage has not changed even once (lean/rich)

after the DTC was erased, the sensor switch time will display as 0 second.

|

FAIL-SAFE AND BACKUP FUNCTION

OBD-II DRIVE CYCLE PATTERN

Refer to Diagnostic Function - OBD-II Drive Cycle - Pattern

1  .

.

TROUBLESHOOTING HINTS (The most likely causes for this code to be set are:)

- Heated oxygen sensor (front) deteriorated.

- Connector damage.

- ECM failed.

|

|

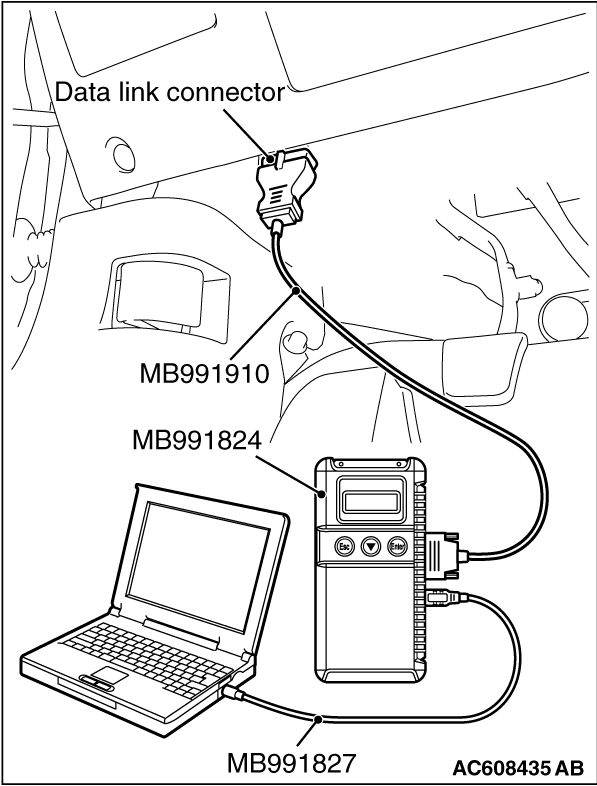

Required Special Tools:

- MB991958: Scan Tool (M.U.T.-III Sub Assembly)

- MB991824: V.C.I.

- MB991827: USB Cable

- MB991910: Main Harness A

- MB991658: Test Harness

|

|

|

STEP 1. Using scan tool MB991958, check data list item AC:

Heated Oxygen Sensor (front).

|

|

| caution |

To prevent damage to scan tool MB991958, always turn the ignition switch to the "LOCK"

(OFF) position before connecting or disconnecting scan tool MB991958.

|

(1)Connect scan tool MB991958 to the data link connector.

(2)Start the engine and run at idle.

(3)Set scan tool MB991958 to the data reading mode for item AC, Heated Oxygen Sensor

(front).

(4)Warm up the engine, 2,500 r/min.

- Output voltage repeats 0.4 volt or less and 0.6 to 1.0

volt 9 times <M/T> or 8 times <TC-SST> or more within 10 seconds.

(5)Turn the ignition switch to the "LOCK" (OFF) position.

Q.

Is the sensor operating properly?

It can be assumed that this malfunction is intermittent. Refer to GROUP 00, How

to Use Troubleshooting/Inspection Service Points - How to Cope with Intermittent

Malfunctions It can be assumed that this malfunction is intermittent. Refer to GROUP 00, How

to Use Troubleshooting/Inspection Service Points - How to Cope with Intermittent

Malfunctions  . .

Go to Step 2. Go to Step 2.

|

|

|

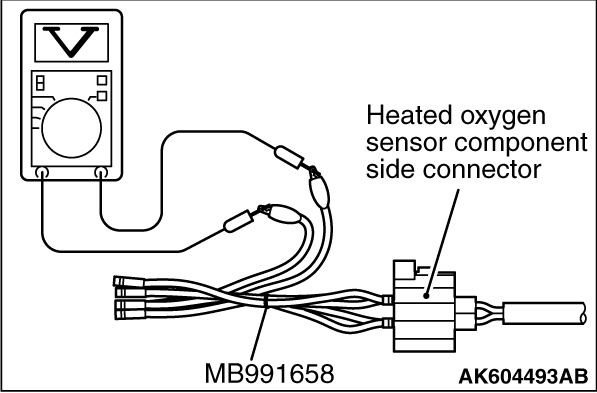

STEP 2. Check the heated oxygen sensor (front).

|

|

|

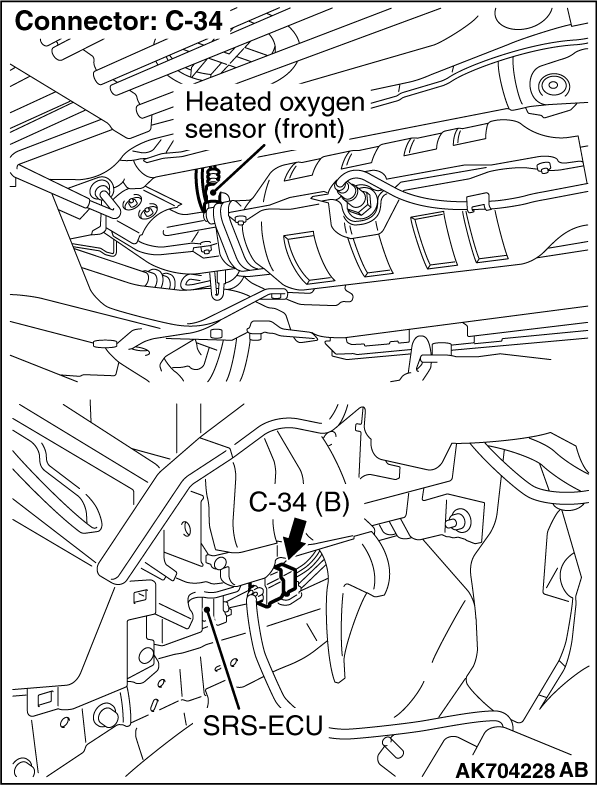

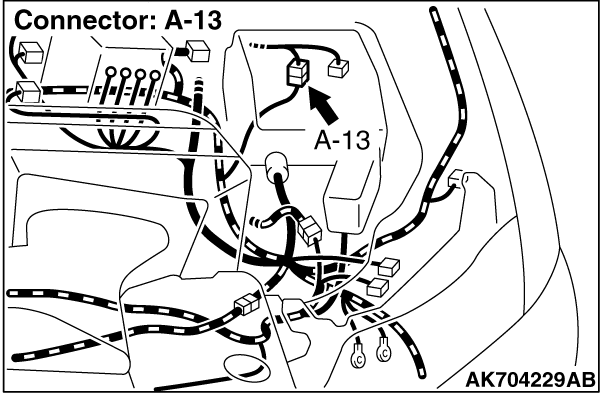

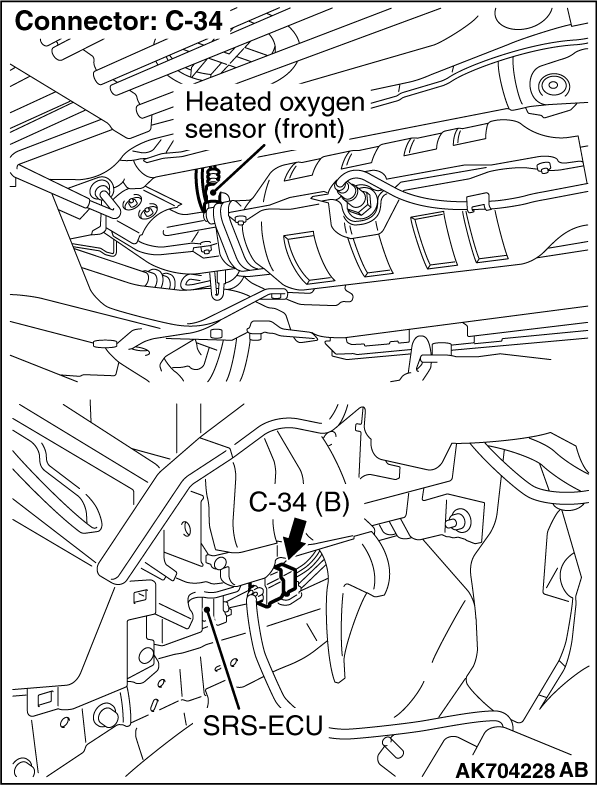

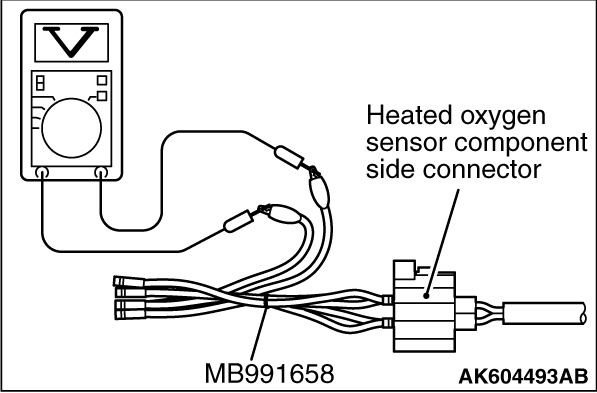

(1)Disconnect the heated oxygen sensor (front) connector C-34 and connect test harness

special tool MB991658 to the connector on the heated oxygen sensor (front) side.

|

|

|

(2)Warm up the engine until engine coolant temperature reaches 80°C (176°F)

or higher.

|

|

|

(3)Rev the engine for 5 minutes or more with the engine speed of 2,000 r/min.

|

|

(4)Connect a digital voltage meter between terminal No. 3 and terminal No. 4.

(5)Warm up the engine, 2,500 r/min

- Output voltage repeats 0.4 volt or less and 0.6 to 1.0 volt 9 times <M/T>

or 8 times <TC-SST> or more within 10 seconds.

| caution |

- Be very careful when connecting

the jumper wires; incorrect connection can damage the heated oxygen sensor.

- Be careful the heater can be damaged if a voltage beyond 8 volts is applied to the

heated oxygen sensor heater.

|

| note |

If the temperature of sensing area does not reach the high temperature [of approximately

400°C (752°F) or more] even though the heated oxygen sensor is normal,

the output voltage would be possibly low in spite of the rich air/fuel ratio. Therefore, if

the output voltage is low, use a jumper wire to connect the terminal No. 1 and the terminal

No. 2 of the heated oxygen sensor with the positive terminal and the negative terminal of 8

volts power supply respectively, then check again.

|

Q.

Is the sensor operating properly?

Go to Step 3. Go to Step 3.

Replace the heated oxygen sensor (front). Then go to Step 4. Replace the heated oxygen sensor (front). Then go to Step 4.

|

|

|

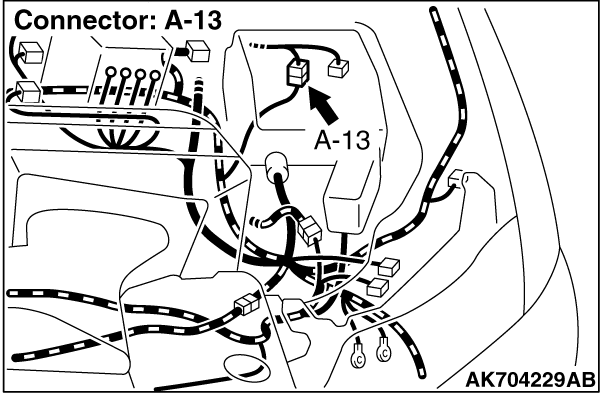

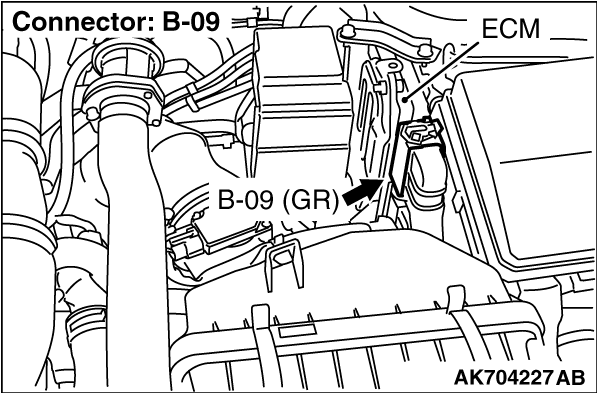

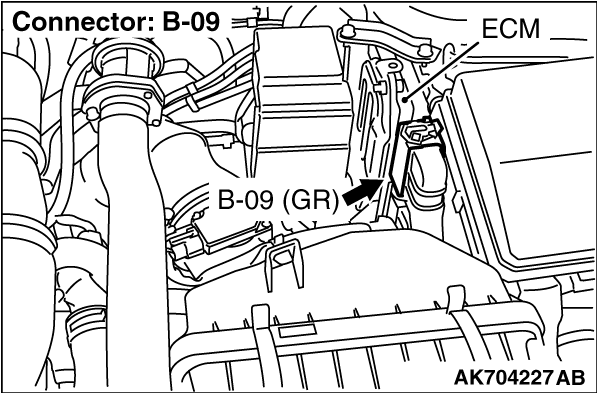

STEP 3. Check harness connector C-34 at heated oxygen sensor (front)

and harness connector B-09 at ECM for damage.

|

|

|

Q.

Is the harness connector in good condition?

|

|

|

Replace the ECM. When the ECM is replaced, register the ID code. Refer to GROUP

42B, ID Code Registration Necessity Judgment Table <Vehicles with KOS> Replace the ECM. When the ECM is replaced, register the ID code. Refer to GROUP

42B, ID Code Registration Necessity Judgment Table <Vehicles with KOS>  or

GROUP 42C, ID Codes Registration Judgment Table <Vehicles with WCM> or

GROUP 42C, ID Codes Registration Judgment Table <Vehicles with WCM>  .

Then go to Step 4. .

Then go to Step 4.

|

|

|

|

|

|

Repair or replace it. Refer to GROUP 00E, Harness Connector Inspection Repair or replace it. Refer to GROUP 00E, Harness Connector Inspection  .

Then go to Step 4. .

Then go to Step 4.

|

|

|

|

|

|

STEP 4. Test the OBD-II drive cycle.

|

|

|

(1)Carry out a test drive with the drive cycle pattern. Refer to Diagnostic Function - OBD-II

Drive Cycle - Pattern 1  . .

|

|

|

(2)Check the diagnostic trouble code (DTC).

|

|

|

Retry the troubleshooting. Retry the troubleshooting.

|

|

|

|

|

|

The inspection is complete. The inspection is complete.

|

|

|

|

.

.![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)

.

.

Go to Step 3.

Go to Step 3. Replace the heated oxygen sensor (front). Then go to Step 4.

Replace the heated oxygen sensor (front). Then go to Step 4. Replace the ECM. When the ECM is replaced, register the ID code. Refer to GROUP

42B, ID Code Registration Necessity Judgment Table <Vehicles with KOS>

Replace the ECM. When the ECM is replaced, register the ID code. Refer to GROUP

42B, ID Code Registration Necessity Judgment Table <Vehicles with KOS>  or

GROUP 42C, ID Codes Registration Judgment Table <Vehicles with WCM>

or

GROUP 42C, ID Codes Registration Judgment Table <Vehicles with WCM>  .

Then go to Step 4.

.

Then go to Step 4. Repair or replace it. Refer to GROUP 00E, Harness Connector Inspection

Repair or replace it. Refer to GROUP 00E, Harness Connector Inspection  .

Then go to Step 4.

.

Then go to Step 4. .

. Retry the troubleshooting.

Retry the troubleshooting. The inspection is complete.

The inspection is complete.