|

|

|

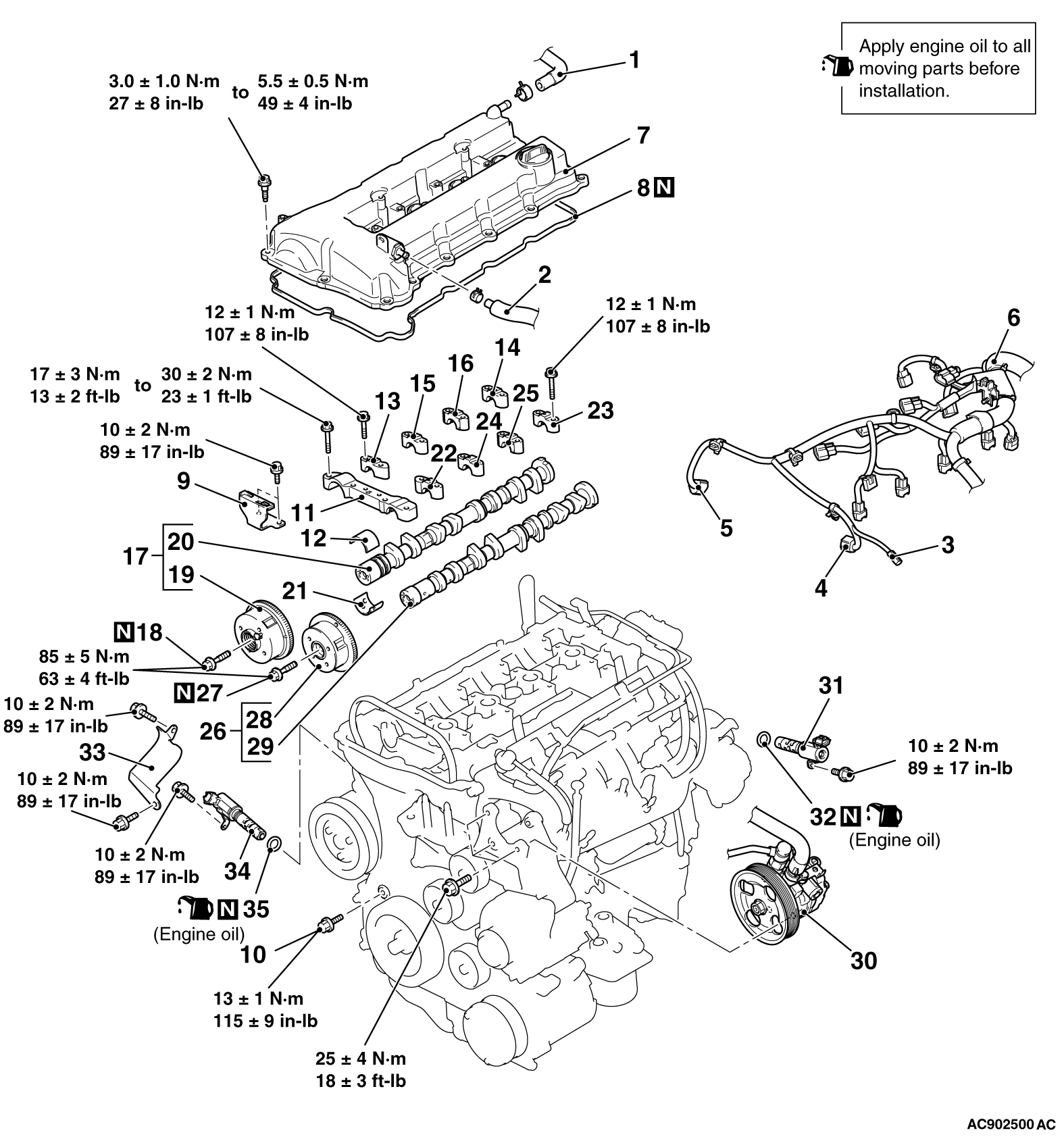

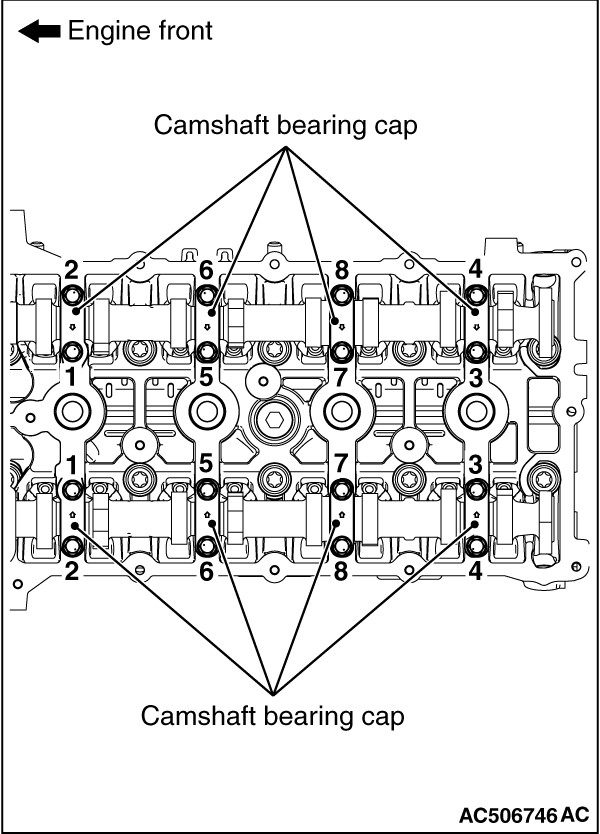

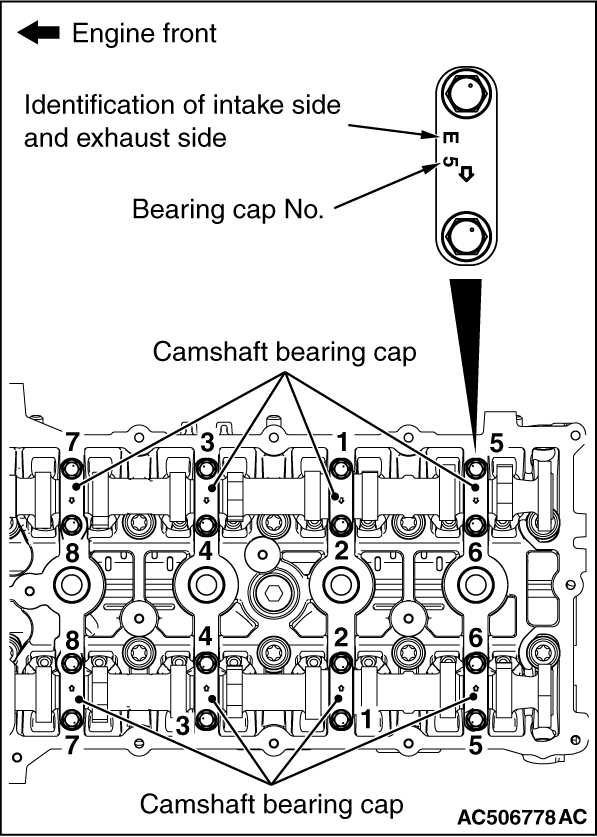

Camshaft removal steps

|

|

|

1.

|

Breather hose connection

|

|

|

2.

|

PCV hose connection

|

|

|

3.

|

Power steering fluid pressure switch connector connection

|

|

|

4.

|

Intake oil feeder control valve connector connection

|

|

|

5.

|

Exhaust oil feeder control valve connector connection

|

|

|

6.

|

Control harness connection

|

<<A>>

|

>>G<<

|

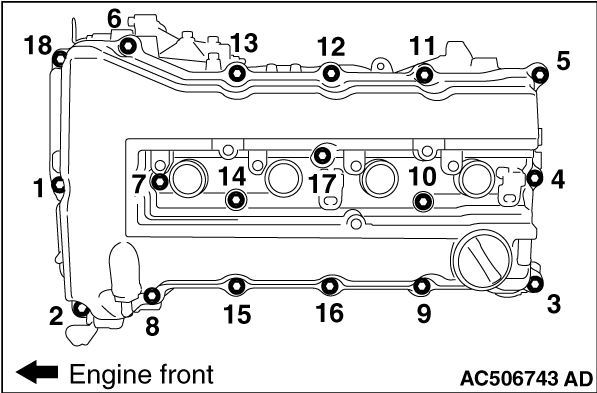

7.

|

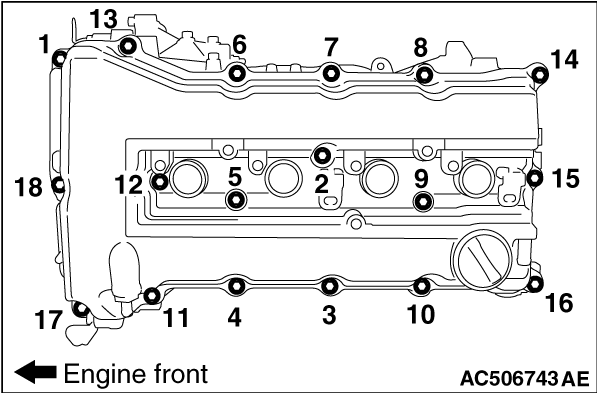

Rocker cover assembly

|

|

|

8.

|

Rocker cover gasket

|

<<B>>

|

|

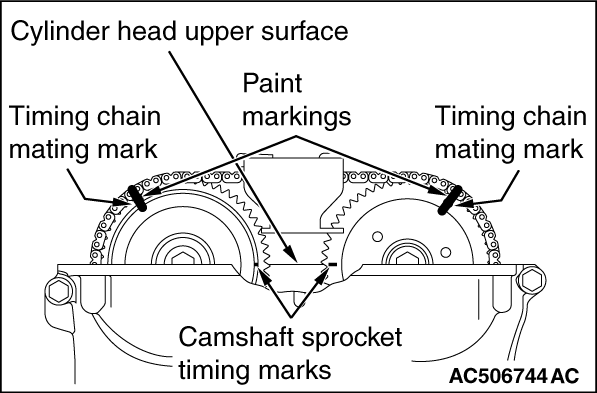

·

|

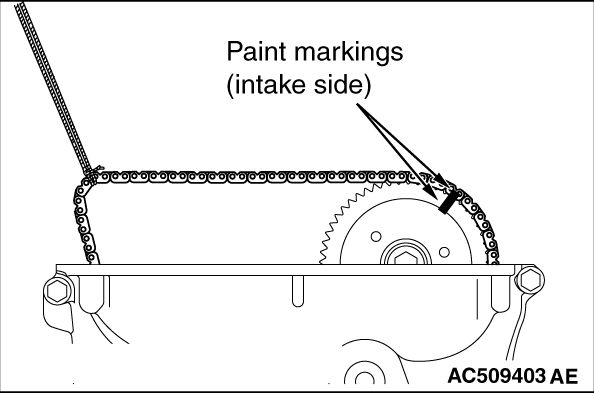

Cylinder No. 1 compression top dead center setting (only at removal)

|

|

|

·

|

Valve clearance adjustment (Refer to  ). (only at installation) ). (only at installation)

|

|

|

9.

|

Timing chain upper guide

|

|

|

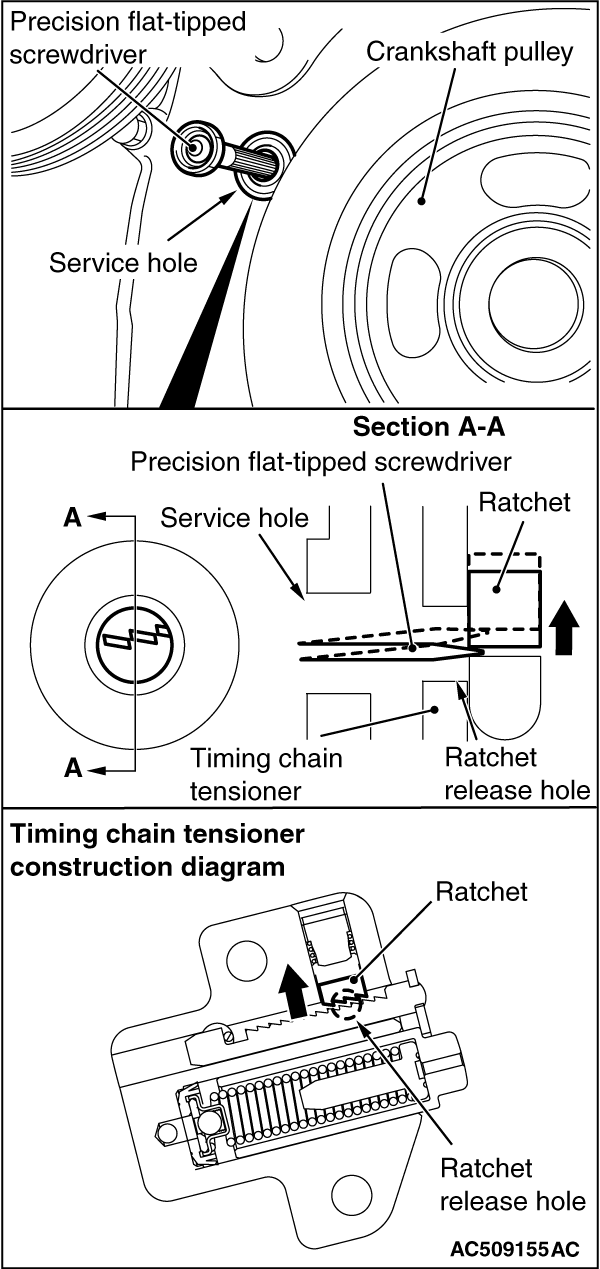

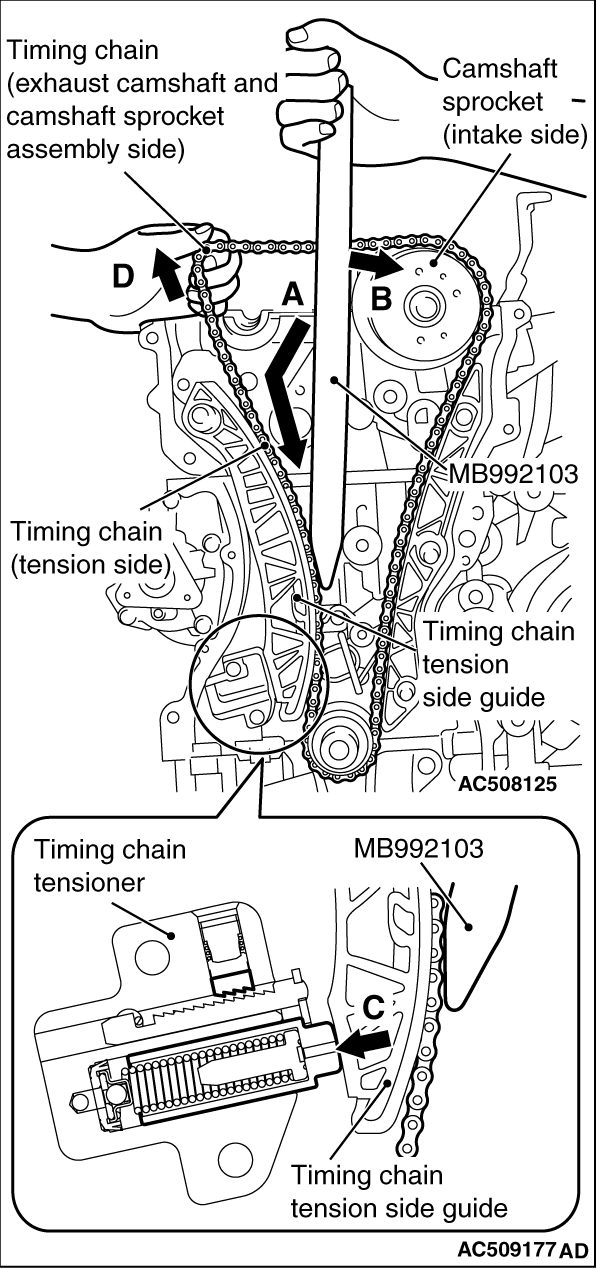

10.

|

Service hole bolt

|

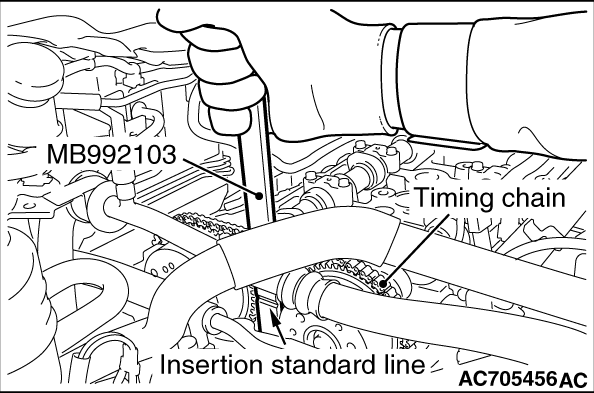

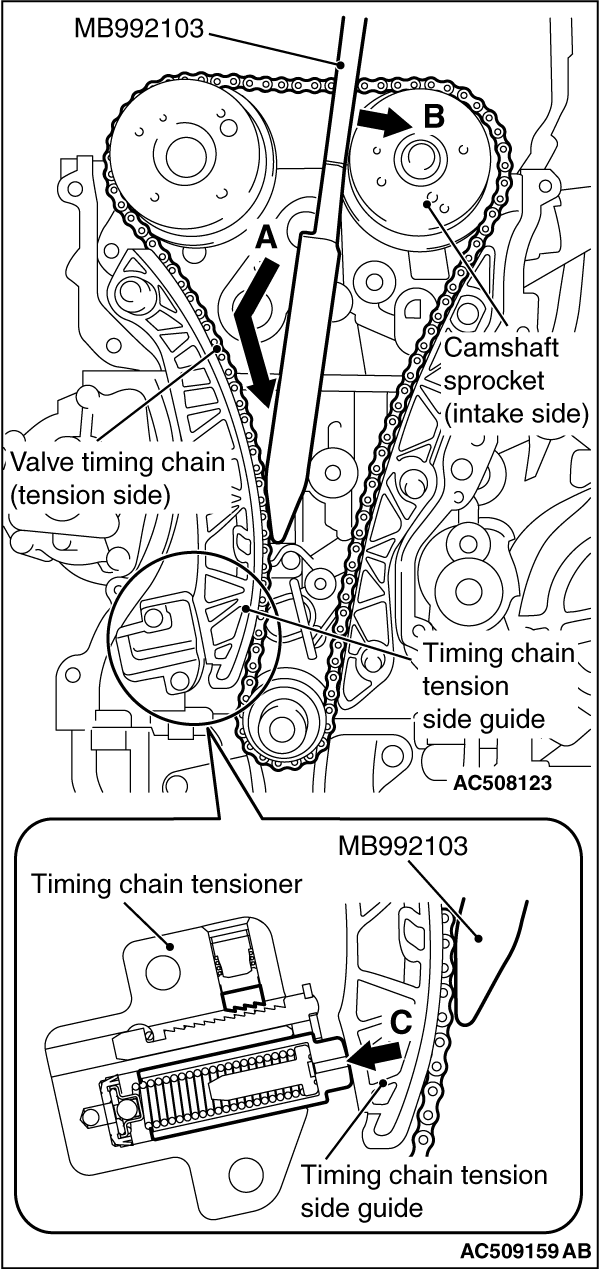

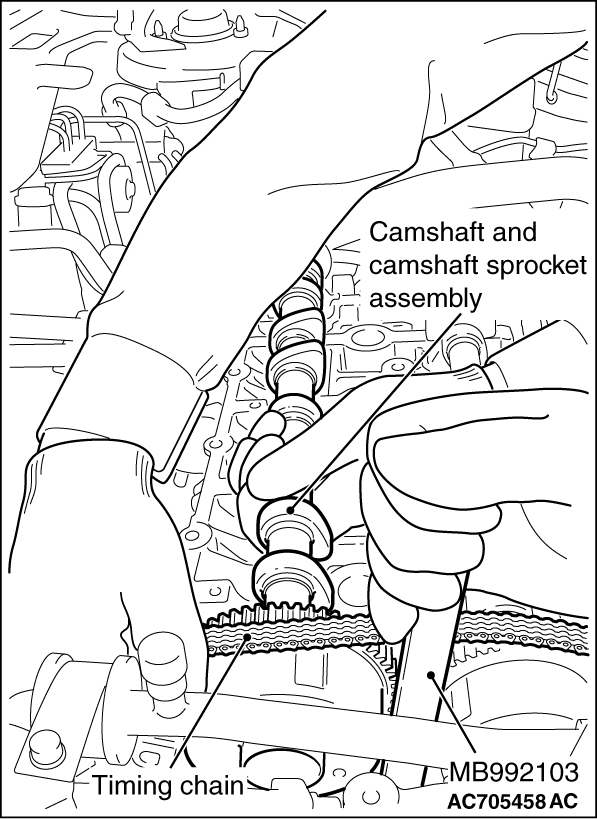

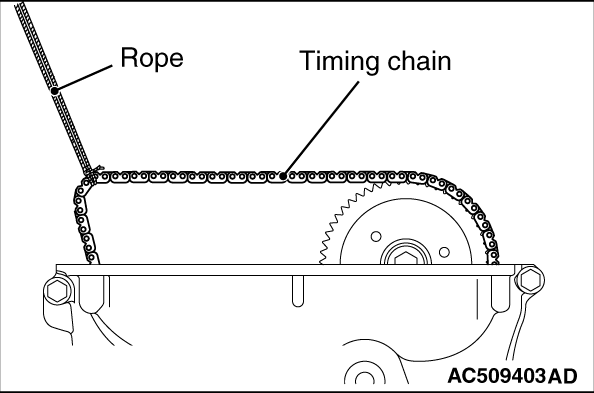

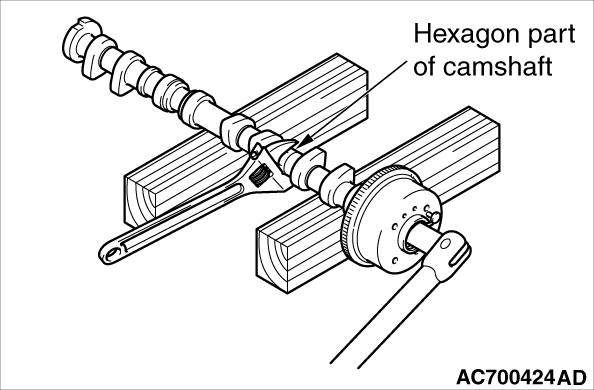

<<C>>

|

|

·

|

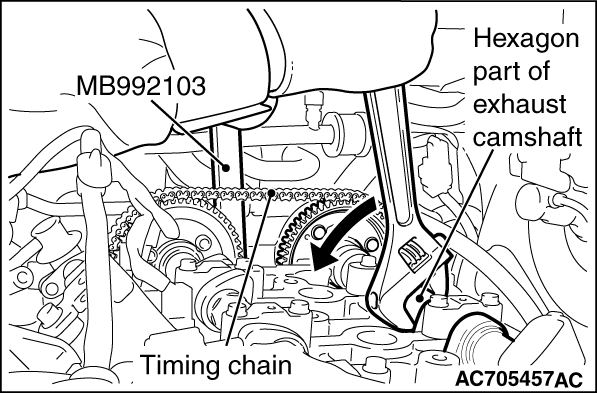

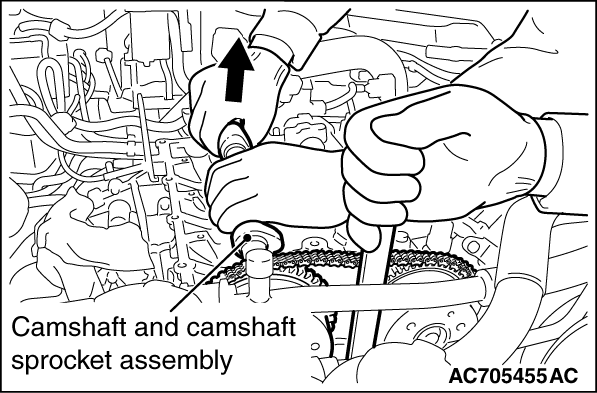

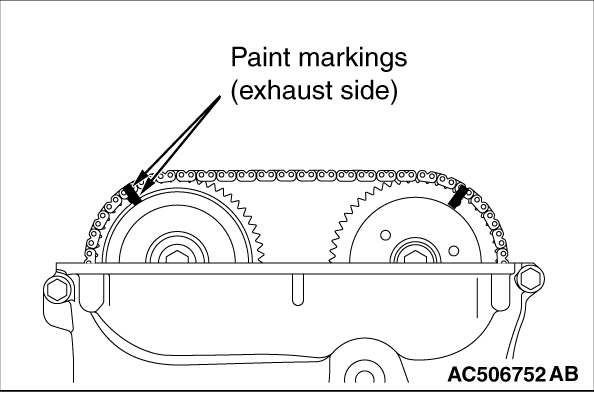

Camshaft and camshaft sprocket assembly (exhaust side) removal preparatory operation (only at removal)

|

<<D>>

|

>>F<<

|

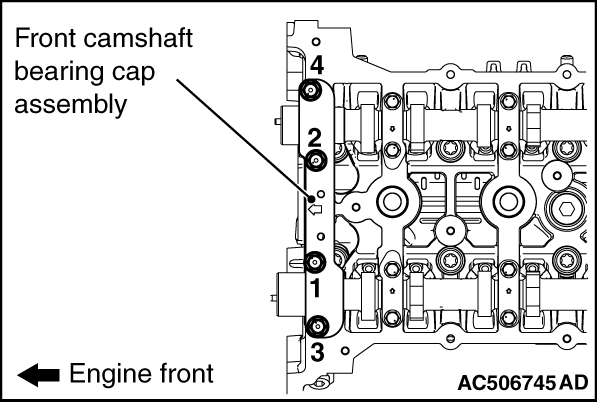

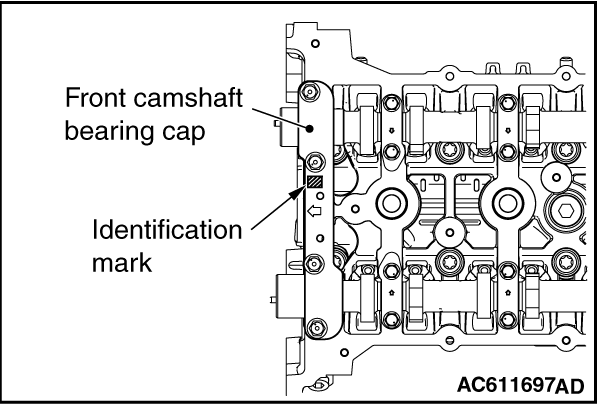

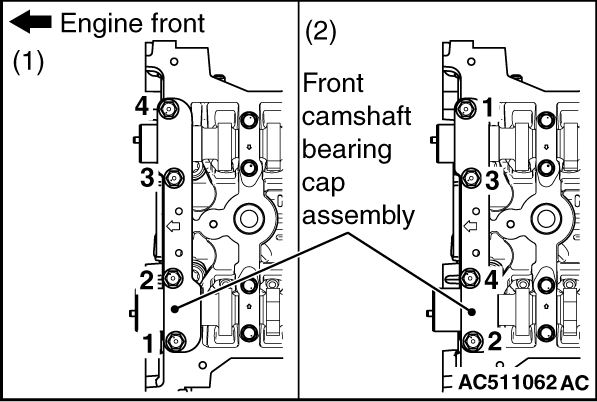

11.

|

Front camshaft bearing cap assembly

|

|

>>E<<

|

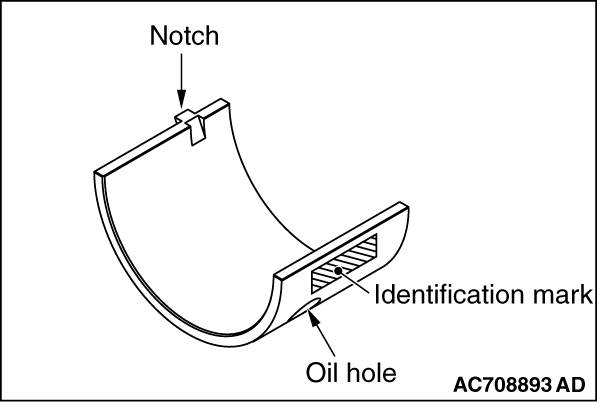

12.

|

Camshaft bearing

|

<<E>>

|

>>D<<

|

13.

|

Oil feeding camshaft bearing cap (exhaust side)

|

<<E>>

|

>>D<<

|

14.

|

Camshaft bearing cap (exhaust side)

|

<<E>>

|

>>D<<

|

15.

|

Camshaft bearing cap (exhaust side)

|

<<E>>

|

>>D<<

|

16.

|

Thrust camshaft bearing cap (exhaust side)

|

<<F>>

|

>>E<<

|

17.

|

Camshaft and camshaft sprocket assembly (exhaust side)

|

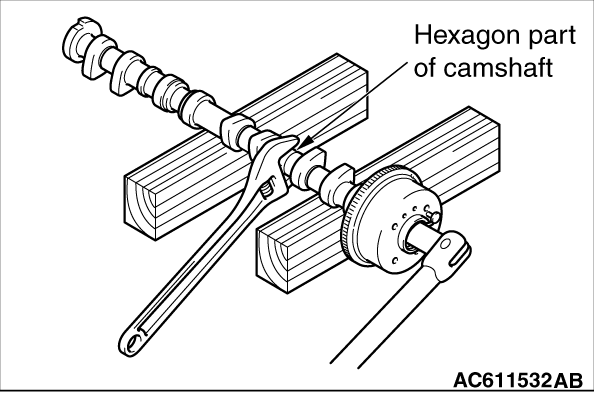

<<G>>

|

>>B<<

|

18.

|

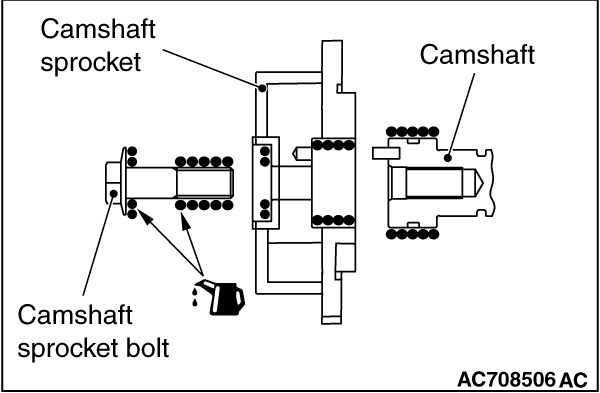

Camshaft sprocket bolt

|

|

>>B<<

|

19.

|

Camshaft sprocket (exhaust side)

|

|

>>B<<

|

20.

|

Camshaft (exhaust side)

|

|

>>E<<

|

21.

|

Camshaft bearing

|

<<E>>

|

>>D<<

|

22.

|

Oil feeding camshaft bearing cap (intake side)

|

<<E>>

|

>>D<<

|

23.

|

Camshaft bearing cap (intake side)

|

<<E>>

|

>>D<<

|

24.

|

Camshaft bearing cap (intake side)

|

<<E>>

|

>>D<<

|

25.

|

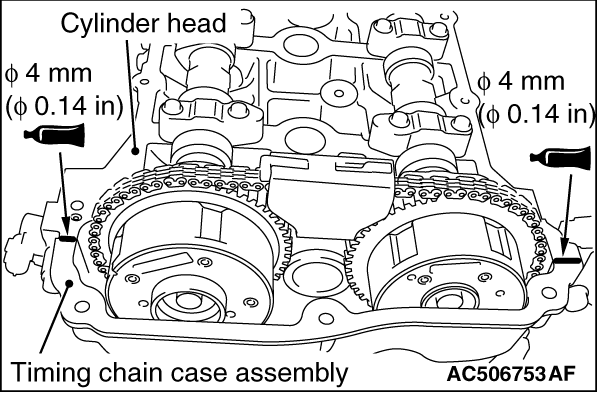

Thrust camshaft bearing cap (intake side)

|

|

>>C<<

|

26.

|

Camshaft and camshaft sprocket assembly (intake side)

|

<<G>>

|

>>B<<

|

27.

|

Camshaft sprocket bolt

|

|

>>B<<

|

28.

|

Camshaft sprocket (intake side)

|

|

>>B<<

|

29.

|

Camshaft (intake side)

|

|

|

|

Intake oil feeder control valve removal steps

|

|

|

4.

|

Intake oil feeder control valve connector connection

|

|

|

·

|

Drive belt (Refer to  ) )

|

<<H>>

|

|

30.

|

Power steering oil pump assembly

|

<<I>>

|

>>A<<

|

31.

|

Intake oil feeder control valve

|

|

>>A<<

|

32.

|

O-ring

|

|

|

|

Exhaust oil feeder control valve removal steps

|

|

|

5.

|

Exhaust oil feeder control valve connector connection

|

|

|

33.

|

Exhaust oil feeder control valve heat protector

|

<<I>>

|

>>A<<

|

34.

|

Exhaust oil feeder control valve

|

|

>>A<<

|

35.

|

O-ring

|

).

). ).

). ).

). ).

). ).

). ).

). ).

). ).

). ).

). ).

).![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)