|

|

To introduce the serpentine drive system with the drive belt auto-tensioner, the following

operations will be required.

|

|

1.

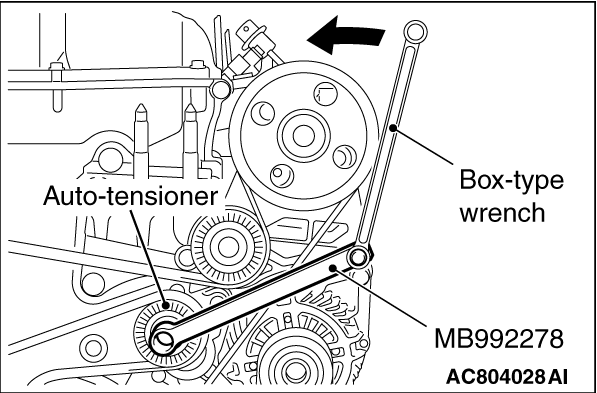

| caution |

To reuse the drive belt, draw an arrow indicating the rotating

direction on the back of the belt using chalk to install the same direction.

|

| warning |

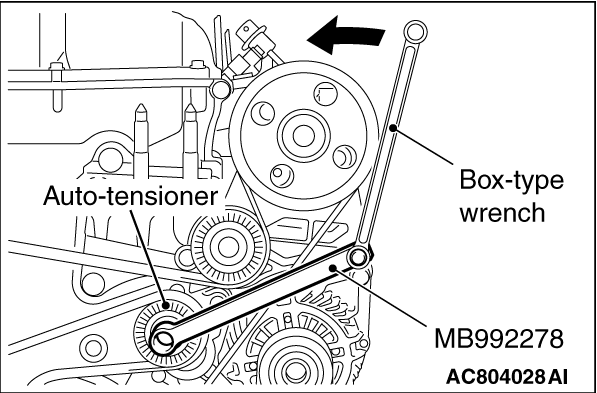

Always work from above when releasing the tension of the

auto-tensioner. When you try to gain access from underneath the vehicle, you will experience difficulty,

thus causing the tool to be dropped off.

|

| caution |

To work at the optimum angle, you must choose a most suitable

box-type wrench is applied to the special tool.

|

| warning |

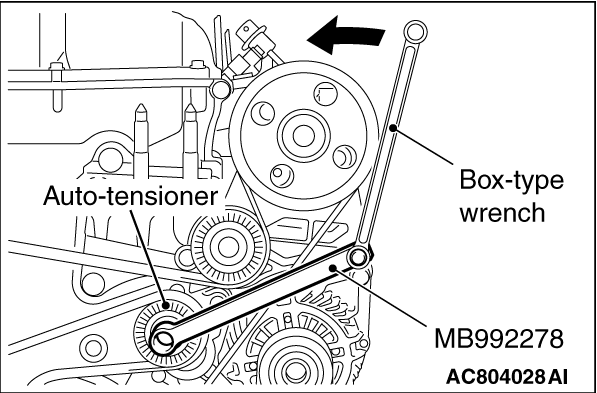

Be sure to set the box-type wrench and the special tool MB992278

to the hexagonal parts securely to prevent the tool from falling off because the tension of

the auto-tensioner is high.

|

Install special tool MB992278 and a box-type wrench at the optimum angle.

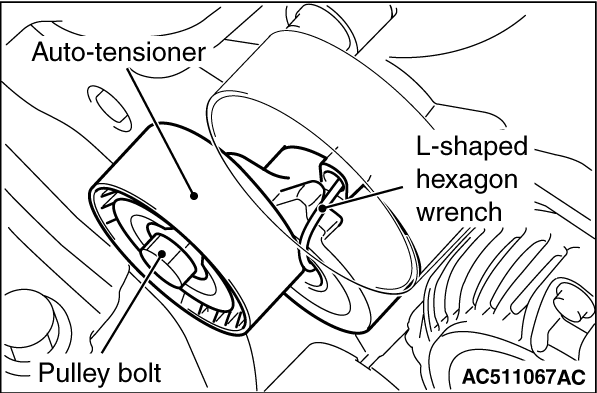

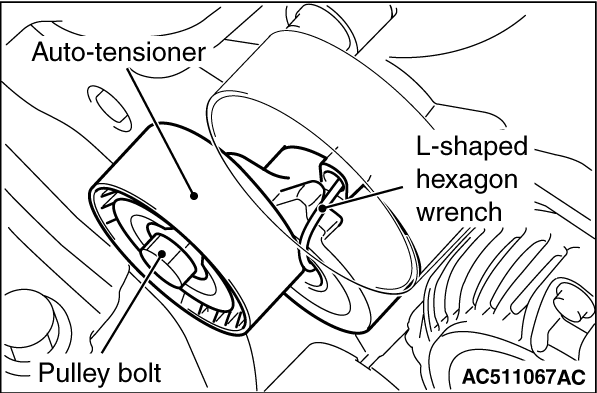

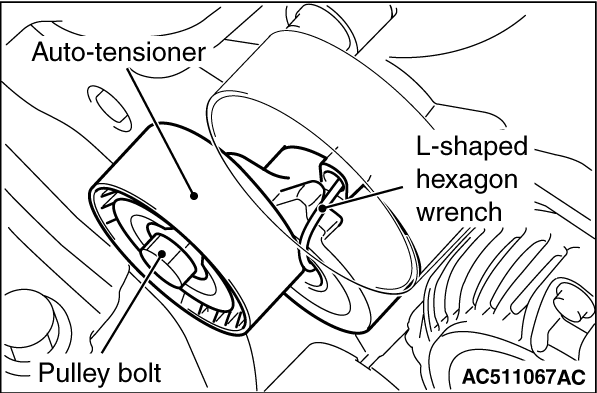

2.Rotate the pulley bolt of the auto-tensioner counterclockwise.

3.Insert the L-shaped hexagon wrench into the auto-tensioner hole to fix the auto-tensioner.

4.Remove the drive belt.

|

|

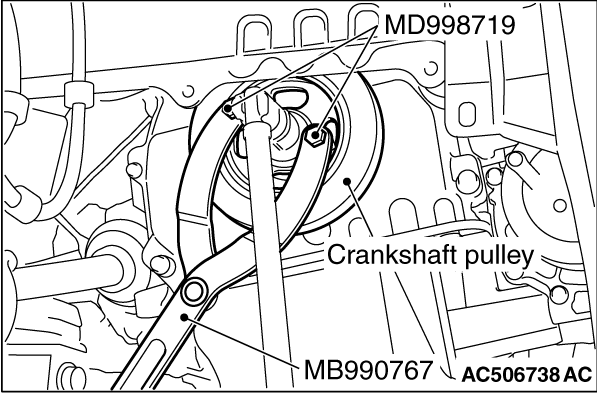

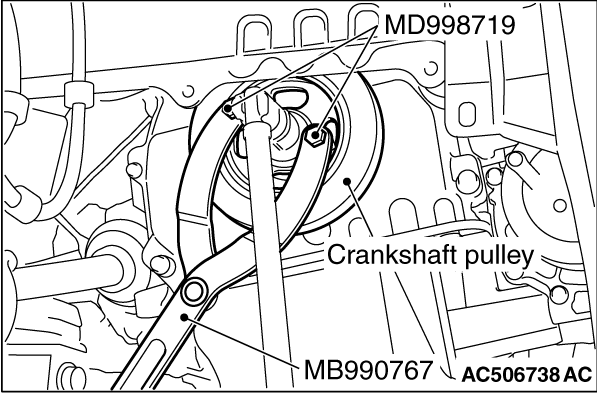

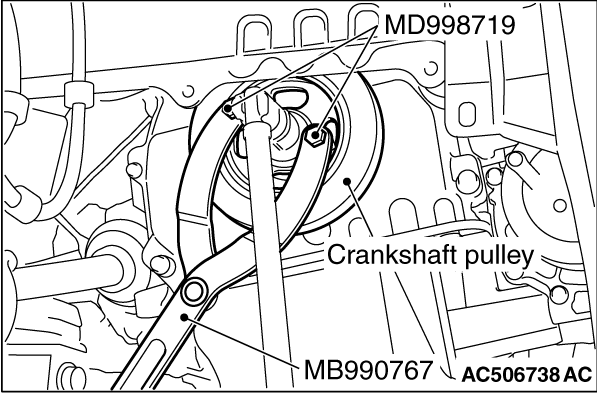

1.Hold the crankshaft drive sprocket with special tools MB990767 and MD998719.

2.Loosen the crankshaft pulley center bolt and remove the crankshaft pulley center bolt

and crankshaft pulley washer.

|

|

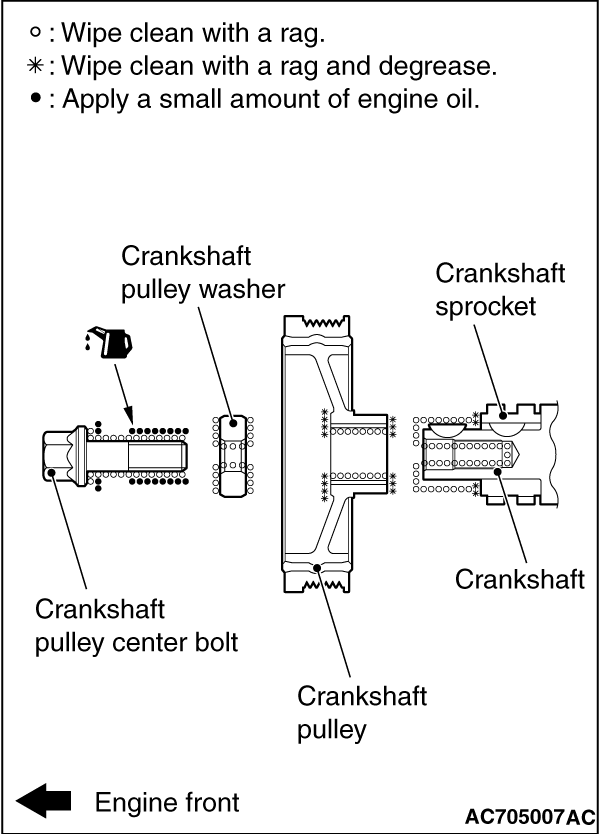

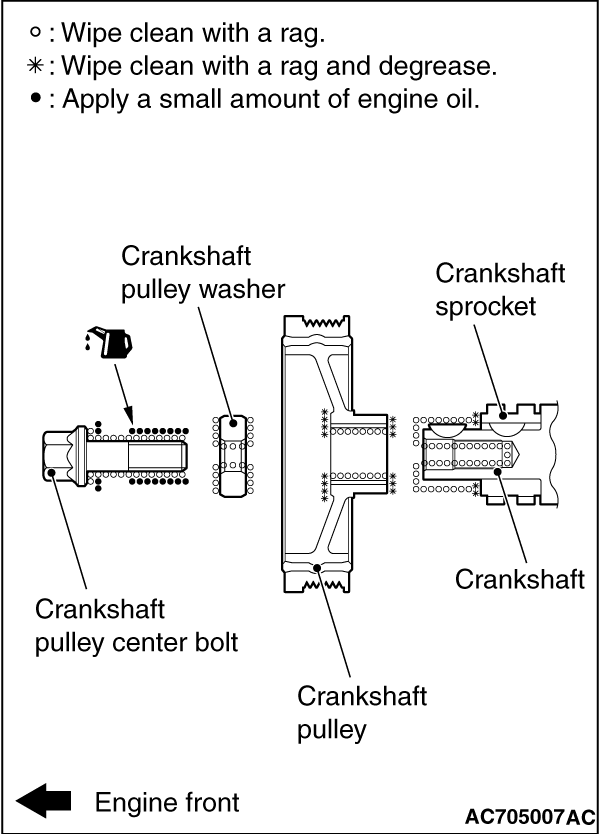

1.Wipe off the dirt on the crankshaft and the crankshaft pulley as shown in the figure using

a rag.

2.Wipe off the dirt on the crankshaft sprocket, the crankshaft and the crankshaft pulley

as shown in the figure using a rag, and then degrease them.

| note |

Degrease them to prevent drop in the friction coefficient of the pressed area, which is

caused by oil adhesion.

|

3.Install the crankshaft pulley.

4.Wipe off the dirt on the crankshaft pulley washer and the crankshaft pulley center

bolt as shown in the figure using a rag.

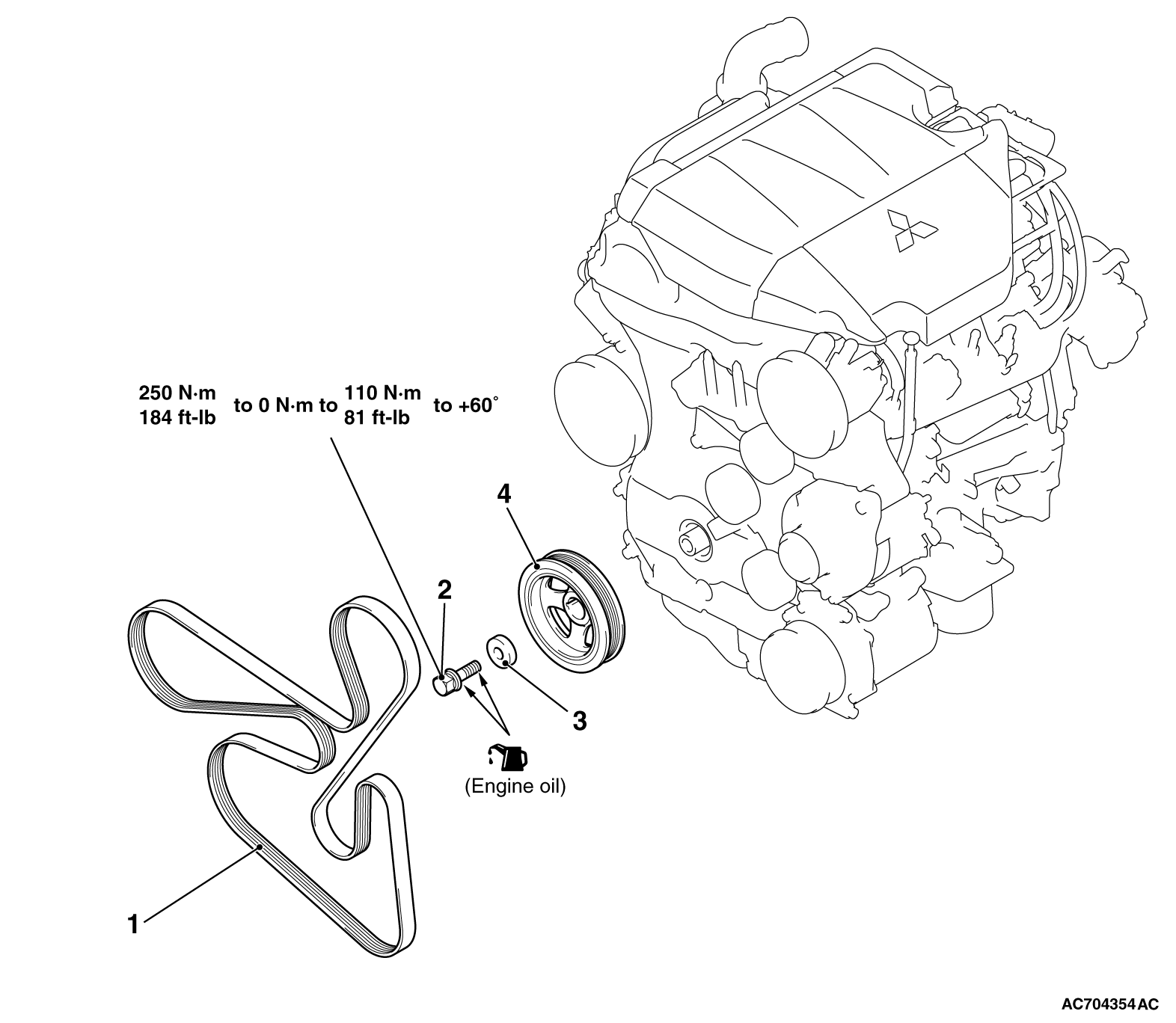

5.Apply an adequate and minimum amount of engine oil to the threads

of the crankshaft pulley center bolt and the lower area of the flange.

|

|

6.Hold the crankshaft pulley with special tools MB990767 and MD998719 in the same manner

as removal.

|

|

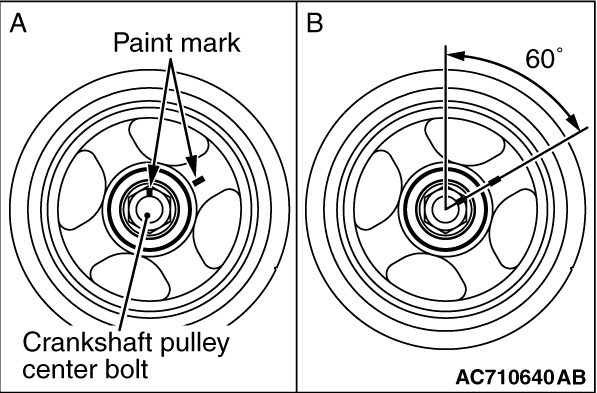

7.Tighten the crankshaft pulley center bolt according to the following procedure.

(1)

Tighten the crankshaft pulley center bolt to the specified torque 250 N·m

(184 ft-lb).

(2)

Loosen the crankshaft pulley center bolt fully.

(3)

Tighten the crankshaft pulley center bolt to the specified torque 110 N·m

(81 ft-lb).

(4)

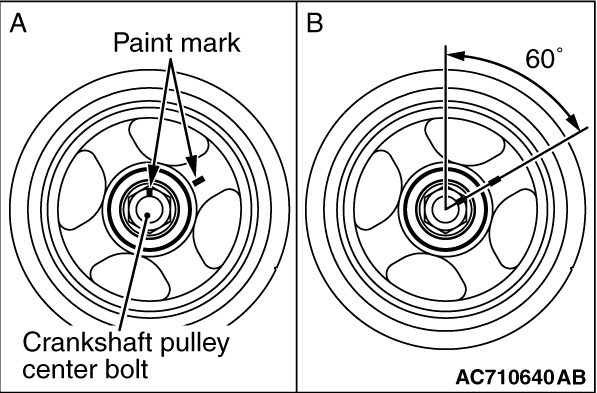

As shown in the illustration "A," apply the paint mark to the crankshaft pulley on the

extended line of the corner adjacent to the one of the crankshaft pulley center bolt corners.

(5)

|

|

| caution |

- When the tightening angle is smaller than

the specified tightening angle, the appropriate tightening capacity cannot be secured.

- When the tightening angle is larger than the specified tightening angle, remove

the bolt to start from the beginning again according to the procedure.

|

|

Tighten the crankshaft pulley center bolt by 60 degrees angle once more. Make sure the

paint mark of crankshaft pulley center bolt is aligned with the paint mark of crankshaft pulley

as shown in the illustration "B."

|

|

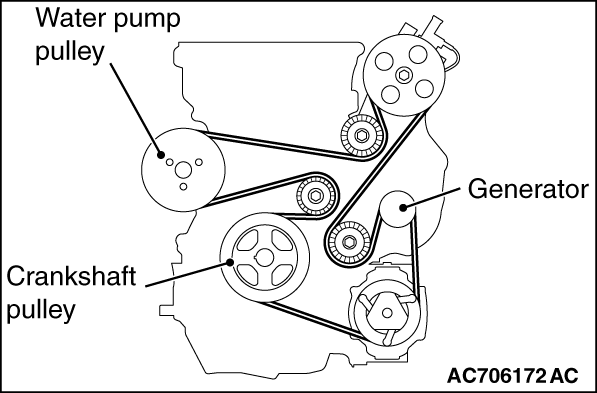

1.

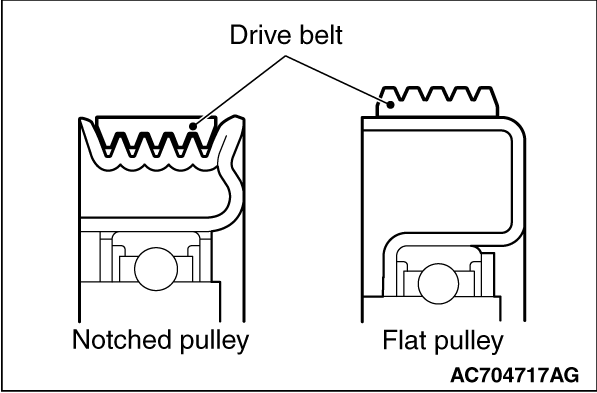

| caution |

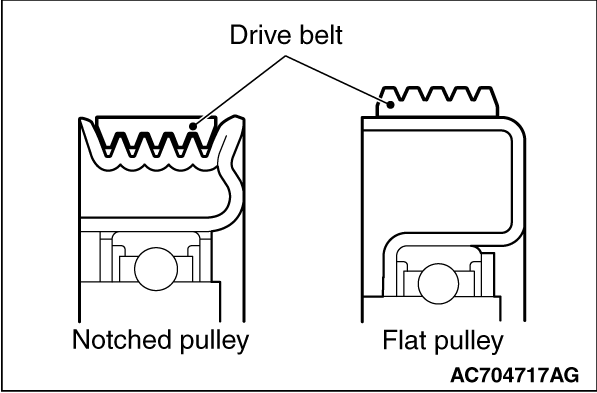

- To reuse the drive belt, install it by aligning

the arrow mark on the backside of belt marked at the removal with the rotating direction.

- Check that the notches of the notched pulley and the notches of the drive belt are fit

correctly.

- Check that the drive belt is installed in the center of the flat surface of the

flat pulley.

|

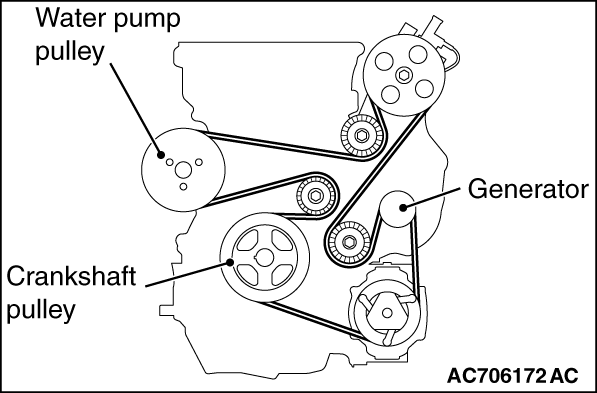

Install the drive belt to each pulley as shown in the figure.

|

|

2.

| warning |

Always work from above when releasing the tension of

the auto-tensioner. When you try to gain access from underneath the vehicle, you will experience difficulty,

thus causing the tool to be dropped off.

|

| caution |

To work at the optimum angle, you must choose a most suitable

box-type wrench is applied to the special tool.

|

| warning |

Be sure to set the box-type wrench and the special tool MB992278

to the hexagonal parts securely to prevent the tool from falling off because the tension of

the auto-tensioner is high.

|

Install special tool MB992278 and a box-type wrench at the optimum angle.

3.Rotate the auto-tensioner counterclockwise and remove the L-shaped hexagon wrench

fixing the auto-tensioner.

4.Apply tension to the drive belt while slowly turning the auto-tensioner clockwise.

|

).

). ).

). ).

). ).

). ).

).![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)