![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)

DTC B1000: Control

Panel Communication Error

|

|

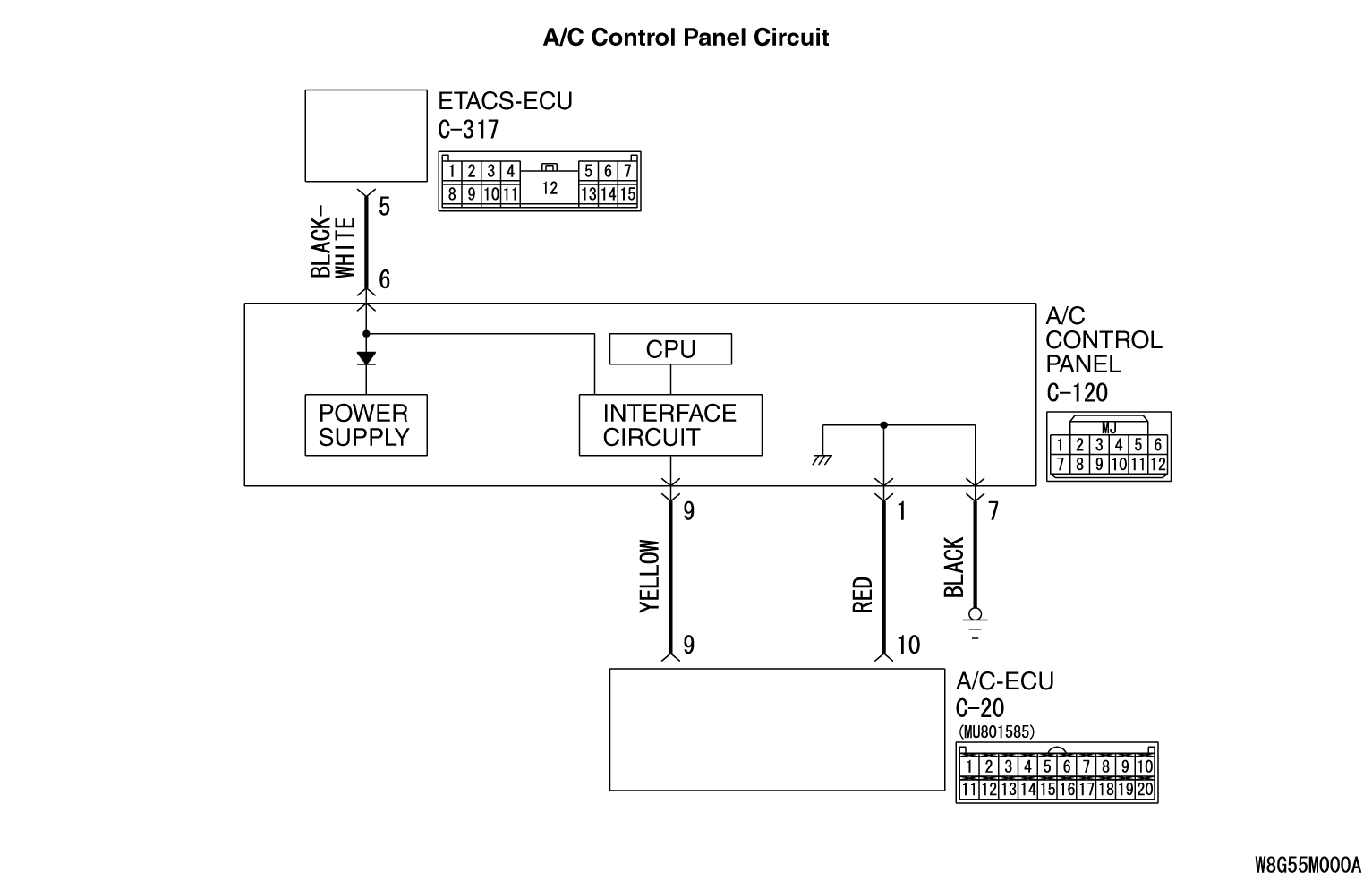

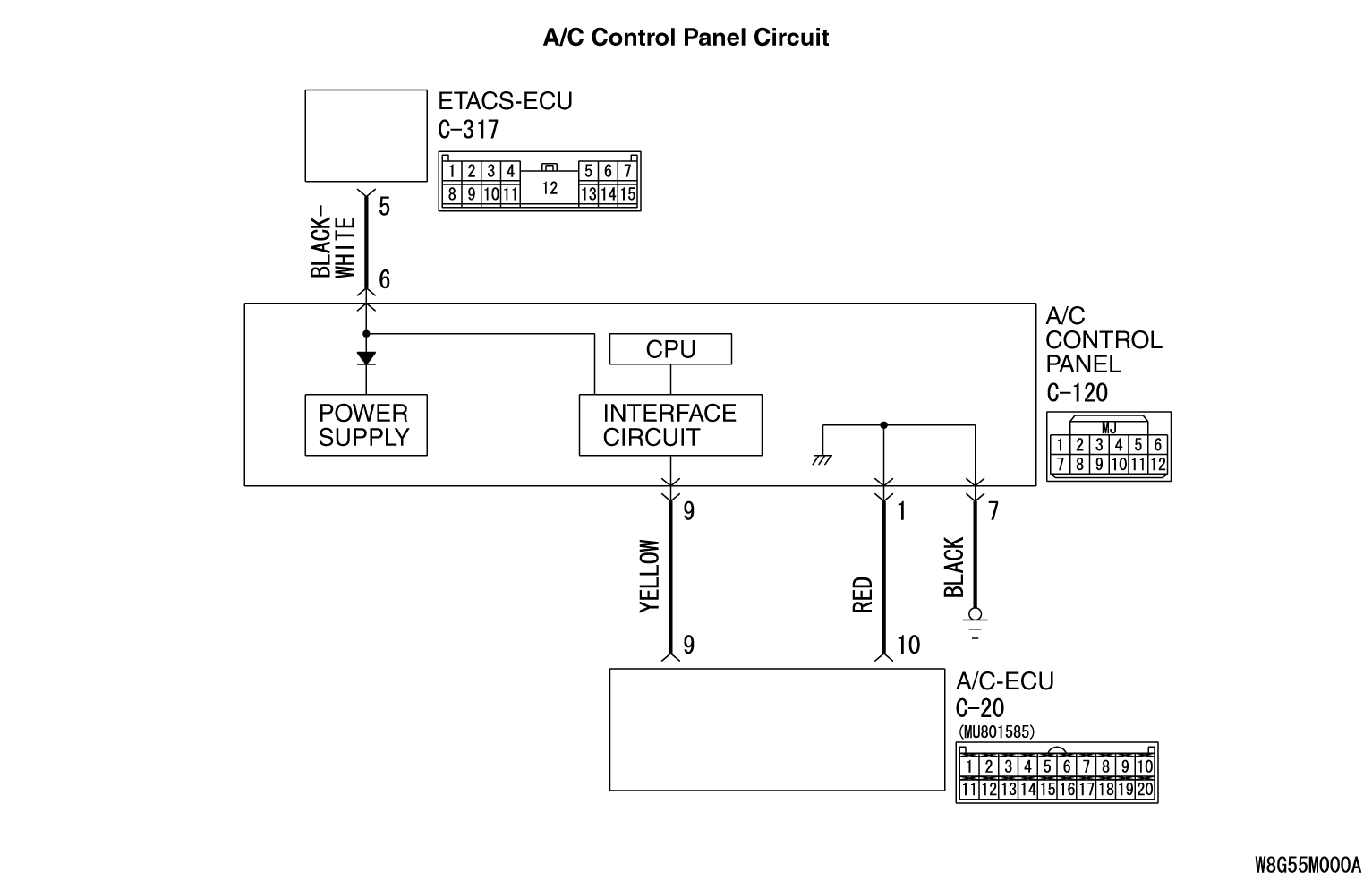

DTC B1000 will be set when the communication between A/C-ECU and A/C

control panel cannot be performed.

|

|

|

TECHNICAL DESCRIPTION (COMMENT)

|

|

|

Current trouble

- The A/C-ECU, the A/C control panel, or connector(s) or wiring

between the two may be defective.

|

|

|

Past trouble

- If DTC B1000 is stored as a past trouble, carry out diagnosis with particular emphasis

on wiring and connector(s) between the A/C-ECU and the A/C control panel.

If the connectors and wiring are normal, and obviously the ECU is the cause of the trouble,

replace the ECU. If in doubt, do not replace the ECU.

|

|

|

- Malfunction of connector.

- Malfunction of the harness.

- Malfunction of the A/C control panel.

- Malfunction of the A/C-ECU.

|

|

|

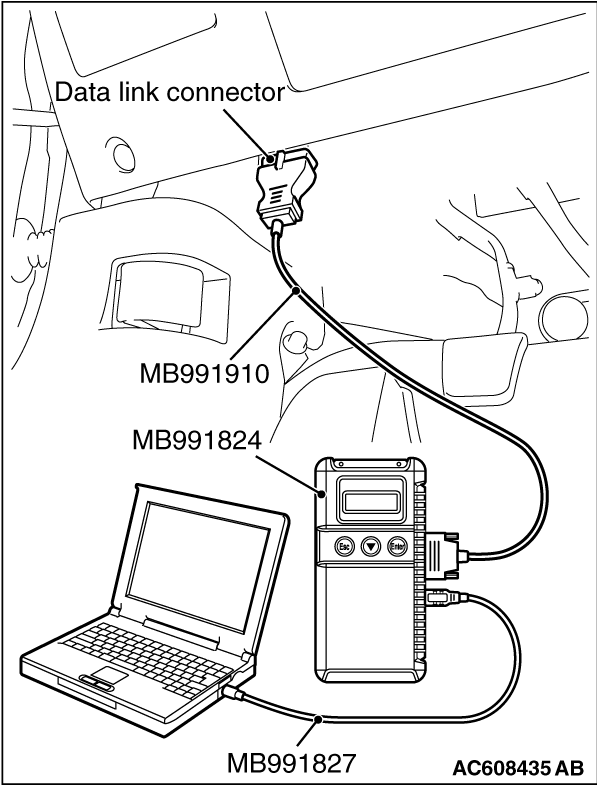

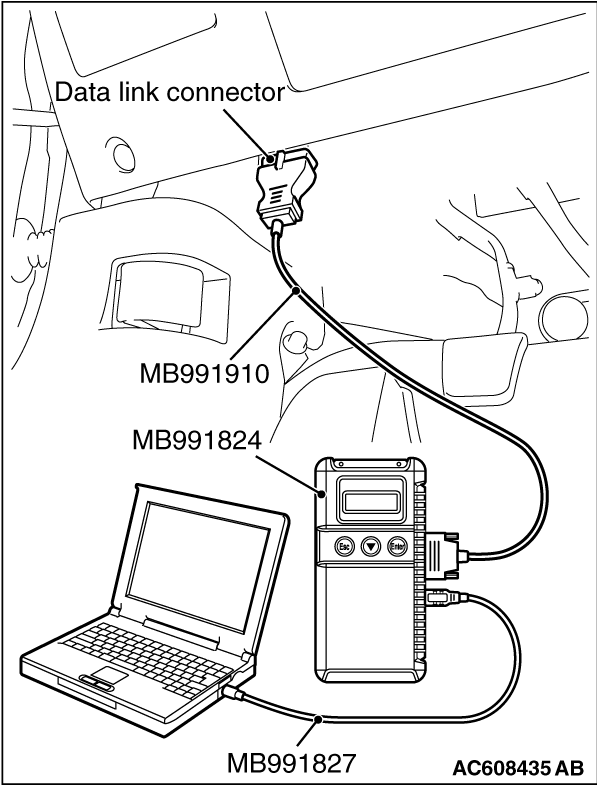

Required Special Tool:

- MB991958: Scan Tool (M.U.T.-III Sub Assembly)

- MB991824: Vehicle Communication Interface (V.C.I.)

- MB991827: M.U.T.-III USB Cable

- MB991910: M.U.T.-III Main Harness A

|

|

|

STEP 1. Using scan tool MB991958, diagnose the CAN bus line.

|

|

|

Use scan tool MB991958 to diagnose the CAN bus lines.

|

|

(1)Connect scan tool MB991958 to the data link connector.

(2)Turn the ignition switch to "ON" position.

(3)Diagnose the CAN bus line.

Q.

Is the check result satisfactory?

Go to Step 2. Go to Step 2.

Repair the CAN bus lines. Repair the CAN bus lines (Refer to GROUP 54C, Diagnosis-Can

Bus Diagnostic Chart Repair the CAN bus lines. Repair the CAN bus lines (Refer to GROUP 54C, Diagnosis-Can

Bus Diagnostic Chart  ). ).

|

|

|

STEP 2. Recheck for diagnostic trouble code.

|

|

|

Recheck if the DTC is set.

|

|

|

(2)Turn the ignition switch to "ON" position.

|

|

|

(3)Check if the DTC is set.

|

|

|

Go to Step 3. Go to Step 3.

|

|

|

|

|

|

It can be assumed that this malfunction is intermittent. Refer to GROUP 00, How

to Use Troubleshooting/Inspection Service Points -

How to Cope with Intermittent

Malfunctions It can be assumed that this malfunction is intermittent. Refer to GROUP 00, How

to Use Troubleshooting/Inspection Service Points -

How to Cope with Intermittent

Malfunctions  . .

|

|

|

|

|

|

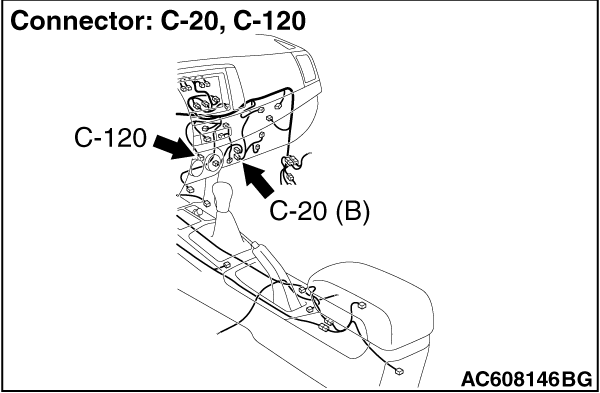

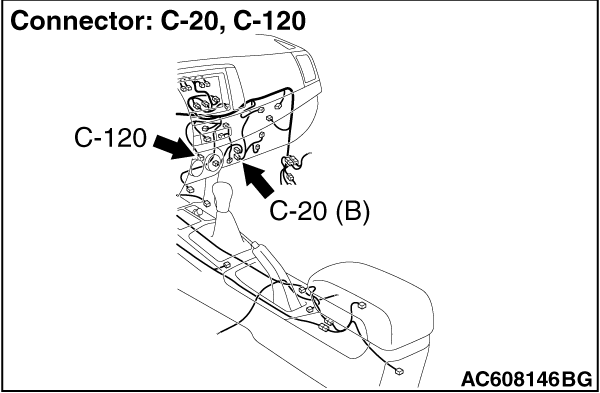

STEP 3. Check A/C control panel connector C-120 for loose,

corroded or damaged terminals, or terminals pushed back in the connector.

|

|

|

Q.

Is A/C control panel connector C-120 in good condition?

|

|

|

Go to Step 4. Go to Step 4.

|

|

|

|

|

|

Repair or replace the connector. Refer to GROUP 00E, Harness Connector Inspection Repair or replace the connector. Refer to GROUP 00E, Harness Connector Inspection  . .

|

|

|

|

|

|

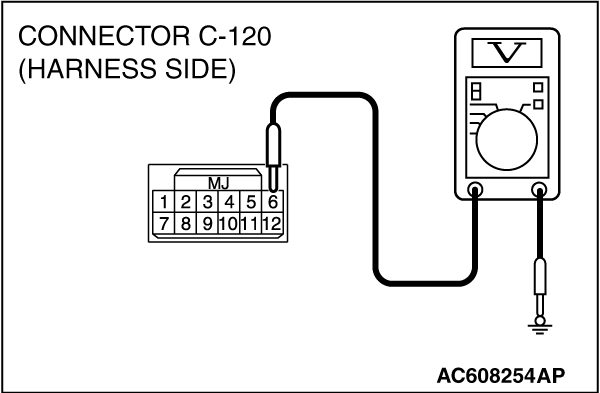

STEP 4. Measure the voltage at A/C control panel connector

C-120.

|

|

|

(1)Disconnect A/C control panel connector C-120, and measure the voltage

at the harness side.

|

|

|

(2)Turn the ignition switch to the "ON" position.

|

|

(3)Measure the voltage between terminal 6 and ground.

- The measured value should be approximately 12 volts (battery

positive voltage).

Q.

Is the measured voltage approximately 12 volts?

Go to Step 6. Go to Step 6.

Go to Step 5. Go to Step 5.

|

|

|

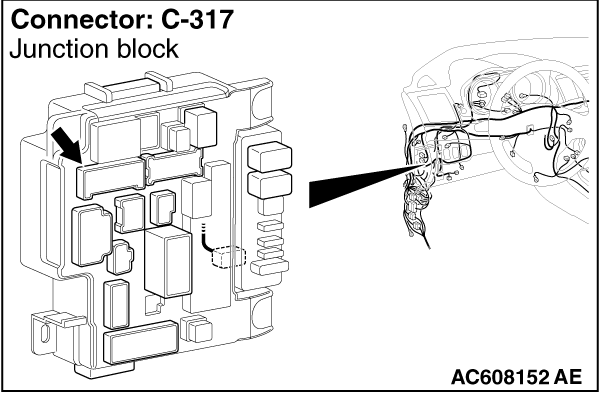

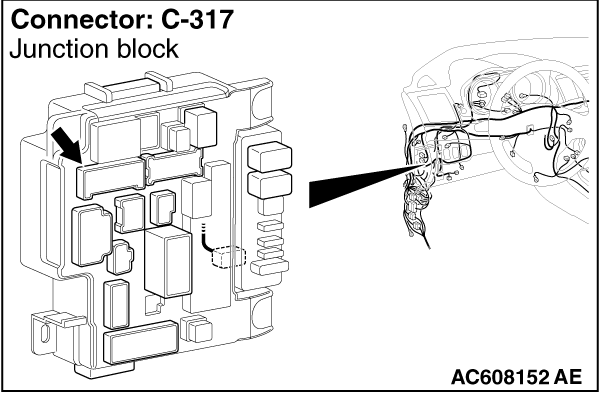

STEP 5. Check the wiring harness between A/C control panel

connector C-120 (terminal 6) and ETACS-ECU connector C-317 (terminal 5).

|

|

|

- Check the A/C control panel power supply line for open circuit.

|

|

|

Q.

Is the wiring harness between A/C control panel connector C-120 (terminal

6) and ETACS-ECU connector C-317 (terminal 5) in good condition?

|

|

|

It can be assumed that this malfunction is intermittent. Refer to GROUP 00, How

to Use Troubleshooting/Inspection Service Points -

How to Cope with Intermittent

Malfunctions It can be assumed that this malfunction is intermittent. Refer to GROUP 00, How

to Use Troubleshooting/Inspection Service Points -

How to Cope with Intermittent

Malfunctions  . .

|

|

|

|

|

|

Repair the wiring harness. Repair the wiring harness.

|

|

|

|

|

|

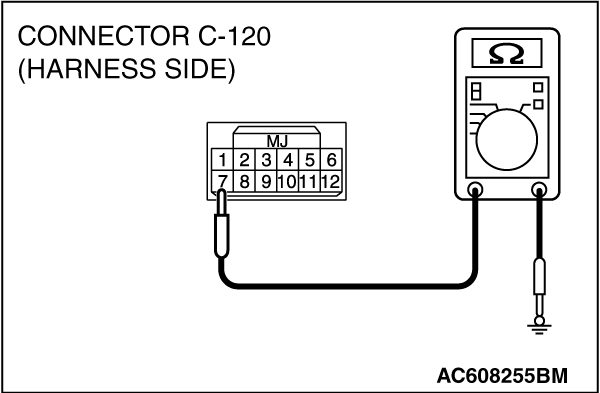

STEP 6. Measure the resistance at A/C control panel connector

C-120.

|

|

(1)Disconnect A/C control panel connector C-120, and measure the resistance at the

wiring harness side.

(2)Measure the resistance value between terminal 7 and ground.

- The measured value should be 2 ohms or less.

Q.

Does the measured resistance value correspond with this range?

Go to Step 8. Go to Step 8.

Go to Step 7. Go to Step 7.

|

|

|

STEP 7. Check the wiring harness between A/C control panel

connector C-120 (terminal 7) and ground.

|

|

|

- Check the A/C control panel ground line for open circuit.

|

|

|

Q.

Is the wiring harness between A/C control panel connector C-120 (terminal

7) and ground in good condition?

|

|

|

It can be assumed that this malfunction is intermittent. Refer to GROUP 00, How

to Use Troubleshooting/Inspection Service Points -

How to Cope with Intermittent

Malfunctions It can be assumed that this malfunction is intermittent. Refer to GROUP 00, How

to Use Troubleshooting/Inspection Service Points -

How to Cope with Intermittent

Malfunctions  . .

|

|

|

|

|

|

Repair the wiring harness. Repair the wiring harness.

|

|

|

|

|

|

STEP 8. Check A/C-ECU connector C-20 for loose, corroded

or damaged terminals, or terminals pushed back in the connector.

|

|

|

Q.

Is A/C-ECU connector C-20 in good condition?

|

|

|

Go to Step 9. Go to Step 9.

|

|

|

|

|

|

Repair or replace the connector. Refer to GROUP 00E, Harness Connector Inspection Repair or replace the connector. Refer to GROUP 00E, Harness Connector Inspection  . .

|

|

|

|

|

|

STEP 9. Check the wiring harness between A/C-ECU connector

C-20 (terminal 9 and 10) and A/C control panel connector C-120 (terminals 9 and 1).

|

|

|

- Check the AC control panel signal line and ground line for open or short

circuit.

|

|

|

Q.

Is the wiring harness between A/C-ECU connector C-20 (terminal 9 and 10)

and A/C control panel connector C-120 (terminals 9 and 1) in good condition?

|

|

|

Go to Step 10. Go to Step 10.

|

|

|

|

|

|

Repair the wiring harness. Repair the wiring harness.

|

|

|

|

|

|

STEP 10. Recheck for diagnostic trouble code.

|

|

|

Recheck if the DTC is set.

|

|

|

(2)Turn the ignition switch to "ON" position.

|

|

|

(3)Check if the DTC is set.

|

|

|

Replace the A/C control panel. Then go to Step 11. Replace the A/C control panel. Then go to Step 11.

|

|

|

|

|

|

It can be assumed that this malfunction is intermittent. Refer to GROUP 00, How

to Use Troubleshooting/Inspection Service Points -

How to Cope with Intermittent

Malfunctions It can be assumed that this malfunction is intermittent. Refer to GROUP 00, How

to Use Troubleshooting/Inspection Service Points -

How to Cope with Intermittent

Malfunctions  . .

|

|

|

|

|

|

STEP 11. Recheck for diagnostic trouble code.

|

|

|

Recheck if the DTC is set.

|

|

|

(2)Turn the ignition switch to "ON" position.

|

|

|

(3)Check if the DTC is set.

|

|

|

Replace the A/C-ECU. Replace the A/C-ECU.

|

|

|

|

|

|

It can be assumed that this malfunction is intermittent. Refer to GROUP 00, How

to Use Troubleshooting/Inspection Service Points -

How to Cope with Intermittent

Malfunctions It can be assumed that this malfunction is intermittent. Refer to GROUP 00, How

to Use Troubleshooting/Inspection Service Points -

How to Cope with Intermittent

Malfunctions  . .

|

|

|

|

Go to Step 2.

Go to Step 2. Repair the CAN bus lines. Repair the CAN bus lines (Refer to GROUP 54C, Diagnosis-Can

Bus Diagnostic Chart

Repair the CAN bus lines. Repair the CAN bus lines (Refer to GROUP 54C, Diagnosis-Can

Bus Diagnostic Chart  ).

).![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)

Go to Step 3.

Go to Step 3.  It can be assumed that this malfunction is intermittent. Refer to GROUP 00, How

to Use Troubleshooting/Inspection Service Points -

How to Cope with Intermittent

Malfunctions

It can be assumed that this malfunction is intermittent. Refer to GROUP 00, How

to Use Troubleshooting/Inspection Service Points -

How to Cope with Intermittent

Malfunctions  .

. Go to Step 4.

Go to Step 4. Repair or replace the connector. Refer to GROUP 00E, Harness Connector Inspection

Repair or replace the connector. Refer to GROUP 00E, Harness Connector Inspection  .

. It can be assumed that this malfunction is intermittent. Refer to GROUP 00, How

to Use Troubleshooting/Inspection Service Points -

How to Cope with Intermittent

Malfunctions

It can be assumed that this malfunction is intermittent. Refer to GROUP 00, How

to Use Troubleshooting/Inspection Service Points -

How to Cope with Intermittent

Malfunctions  .

. Repair the wiring harness.

Repair the wiring harness. It can be assumed that this malfunction is intermittent. Refer to GROUP 00, How

to Use Troubleshooting/Inspection Service Points -

How to Cope with Intermittent

Malfunctions

It can be assumed that this malfunction is intermittent. Refer to GROUP 00, How

to Use Troubleshooting/Inspection Service Points -

How to Cope with Intermittent

Malfunctions  .

. Repair the wiring harness.

Repair the wiring harness. Go to Step 9.

Go to Step 9. Repair or replace the connector. Refer to GROUP 00E, Harness Connector Inspection

Repair or replace the connector. Refer to GROUP 00E, Harness Connector Inspection  .

. Go to Step 10.

Go to Step 10. Repair the wiring harness.

Repair the wiring harness. Replace the A/C control panel. Then go to Step 11.

Replace the A/C control panel. Then go to Step 11. It can be assumed that this malfunction is intermittent. Refer to GROUP 00, How

to Use Troubleshooting/Inspection Service Points -

How to Cope with Intermittent

Malfunctions

It can be assumed that this malfunction is intermittent. Refer to GROUP 00, How

to Use Troubleshooting/Inspection Service Points -

How to Cope with Intermittent

Malfunctions  .

. Replace the A/C-ECU.

Replace the A/C-ECU. It can be assumed that this malfunction is intermittent. Refer to GROUP 00, How

to Use Troubleshooting/Inspection Service Points -

How to Cope with Intermittent

Malfunctions

It can be assumed that this malfunction is intermittent. Refer to GROUP 00, How

to Use Troubleshooting/Inspection Service Points -

How to Cope with Intermittent

Malfunctions  .

.