![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)

DIAGNOSTIC ITEM

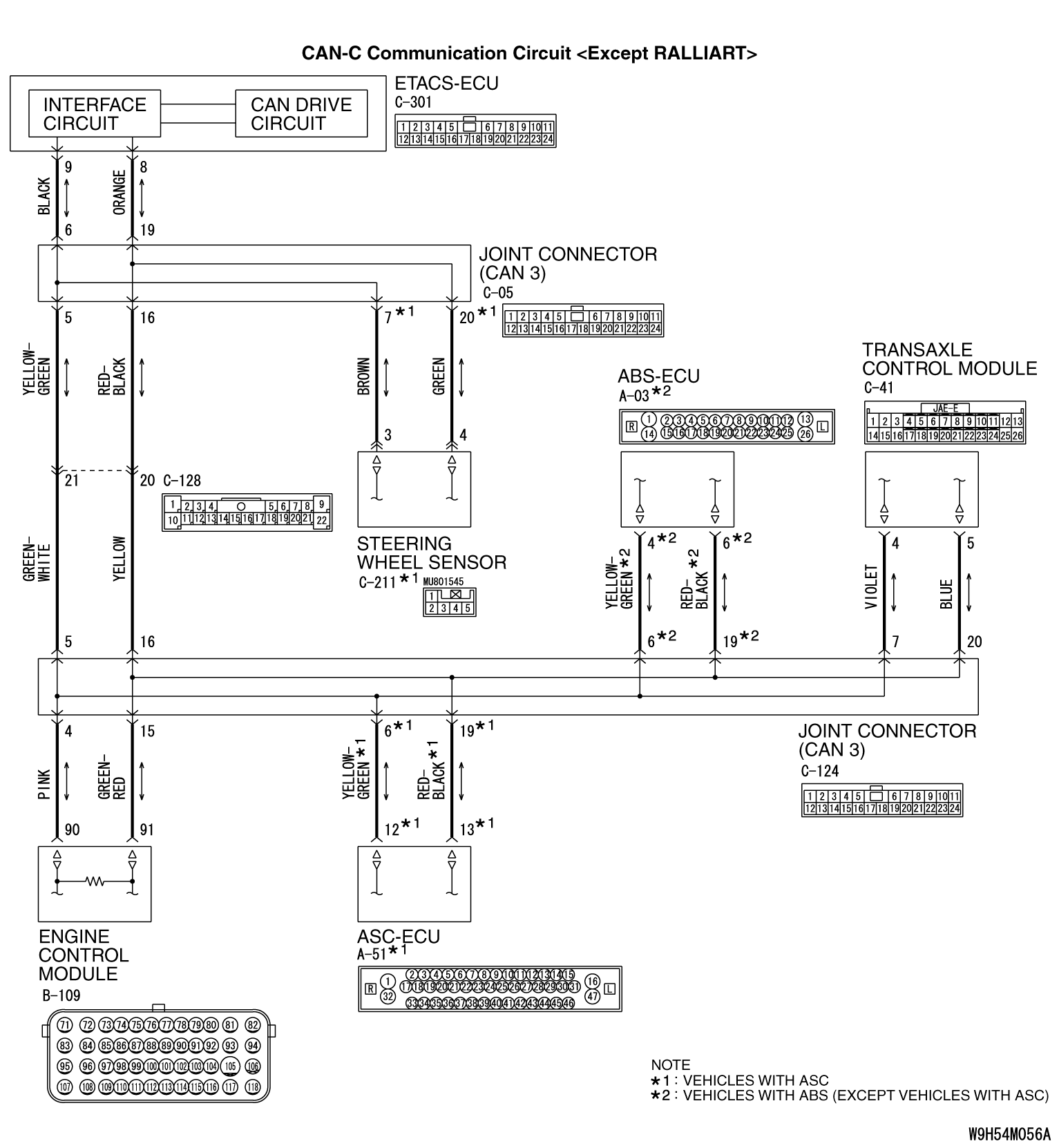

3: Abnormal short between the CAN-C bus lines.

| caution |

When servicing a CAN bus line, ground yourself by

touching a metal object such as an unpainted water pipe. If you fail to do so, a component connected

to the CAN bus line may be damaged.

|

FUNCTION

If a line-to-line short is present in the CAN-C lines, this diagnosis result will be set.

TROUBLE JUDGEMENT CONDITIONS

If only diagnostic trouble code U0001 is set, the ETACS-ECU determines that there is a

failure.

TROUBLESHOOTING HINTS

- Malfunction of the connector (joint connectors or ECU connectors improperly

connected)

- Malfunction of the wiring harness (line-to-line short in the CAN-C main or sub bus

lines)

- Malfunction of the ECU (ECU on CAN-C lines failed)

|

|

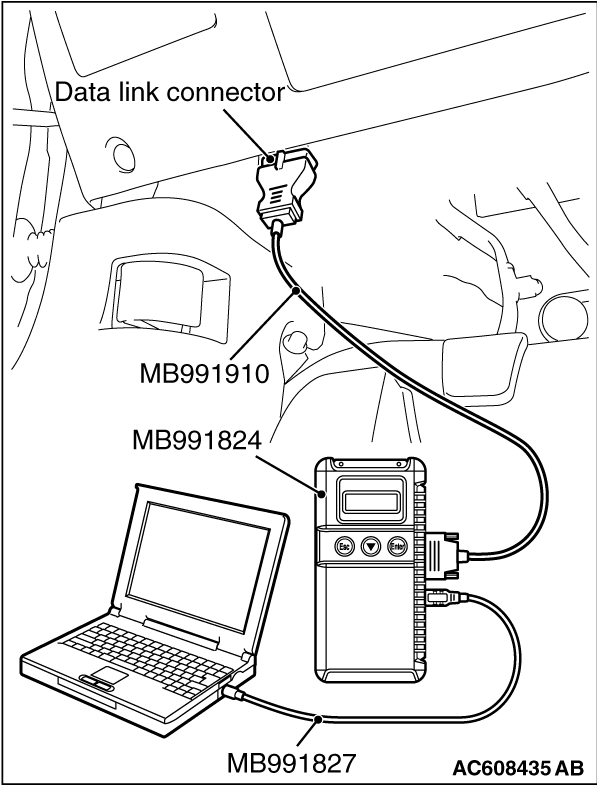

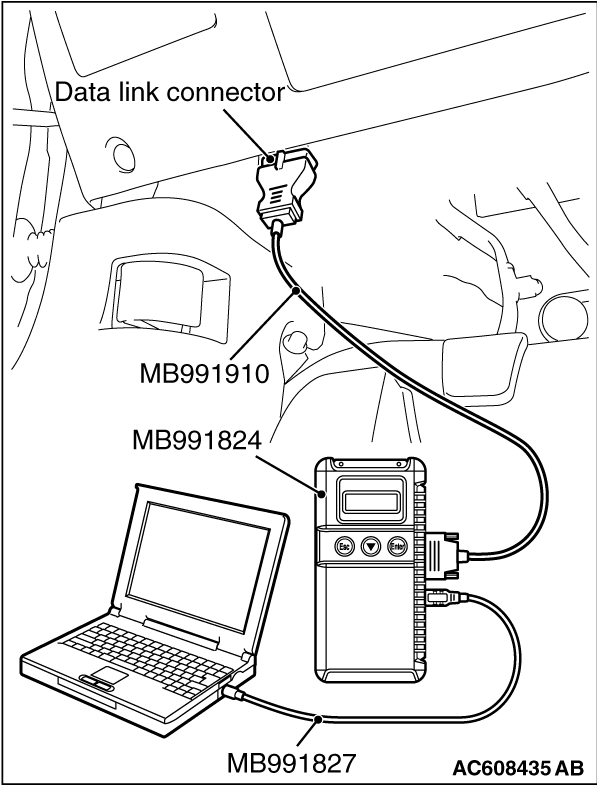

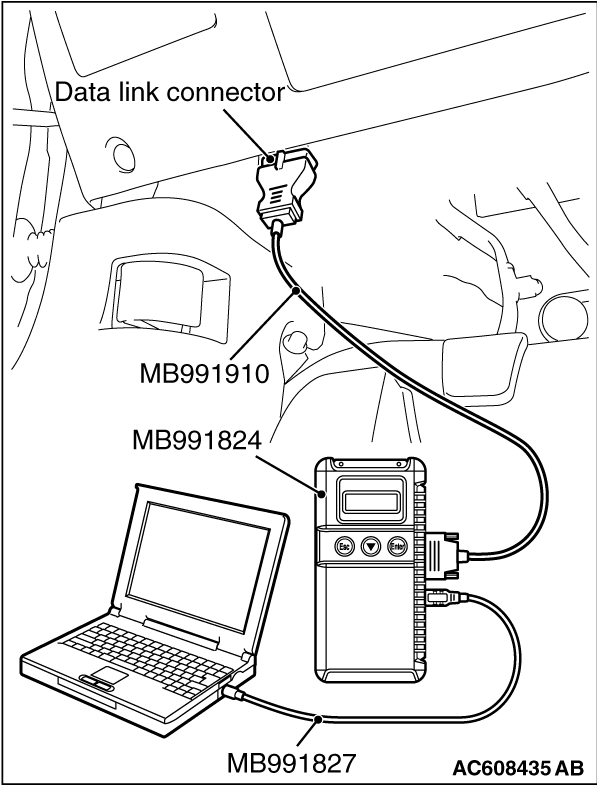

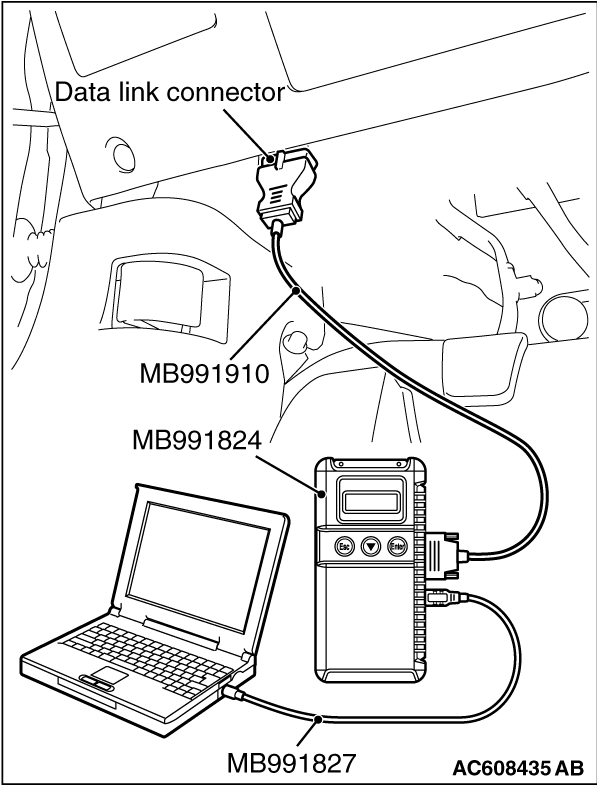

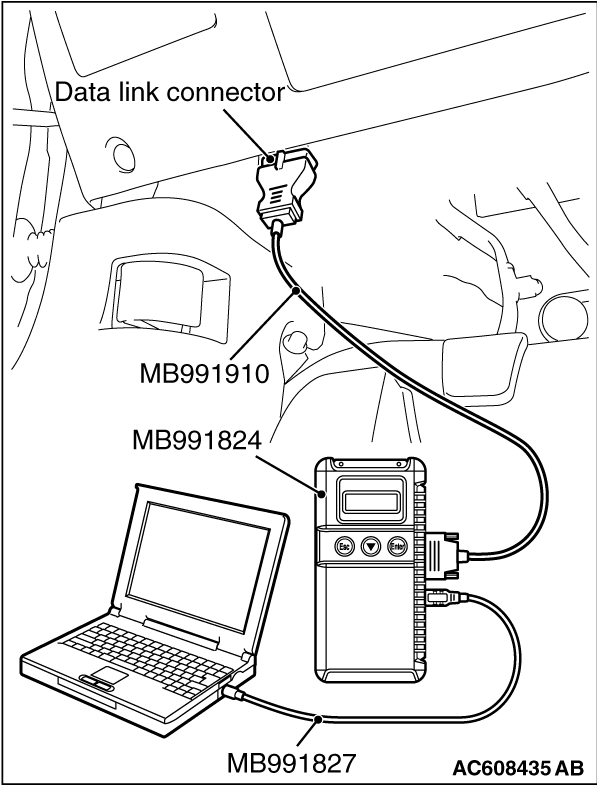

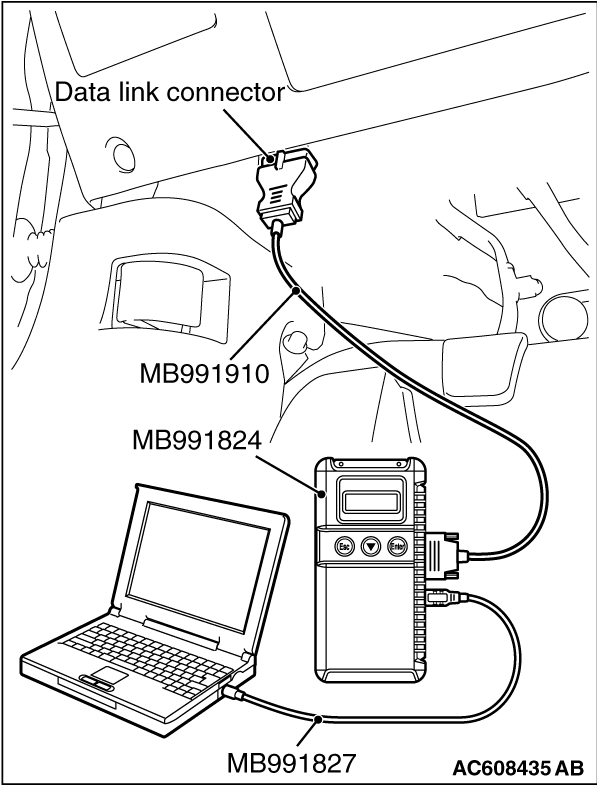

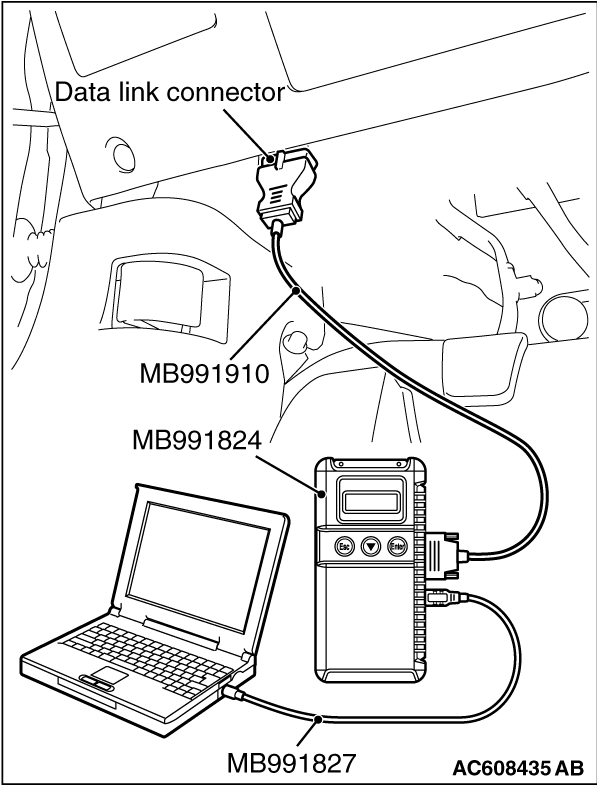

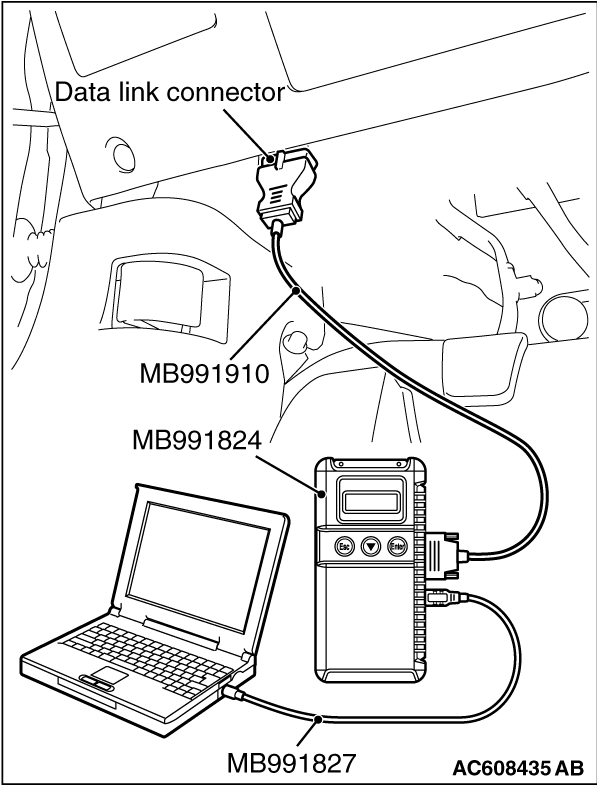

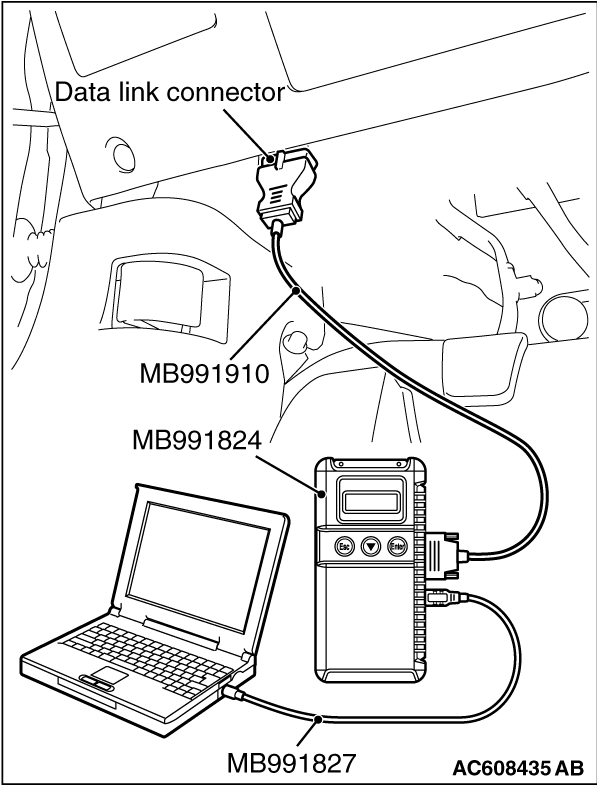

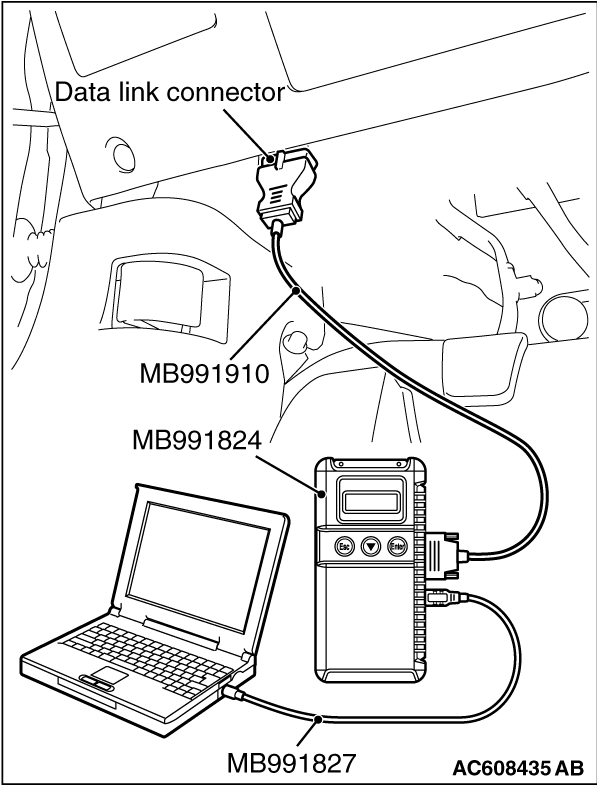

Required Special Tools:

- MB991223: Harness Set

- MB992006: Extra Fine Probe

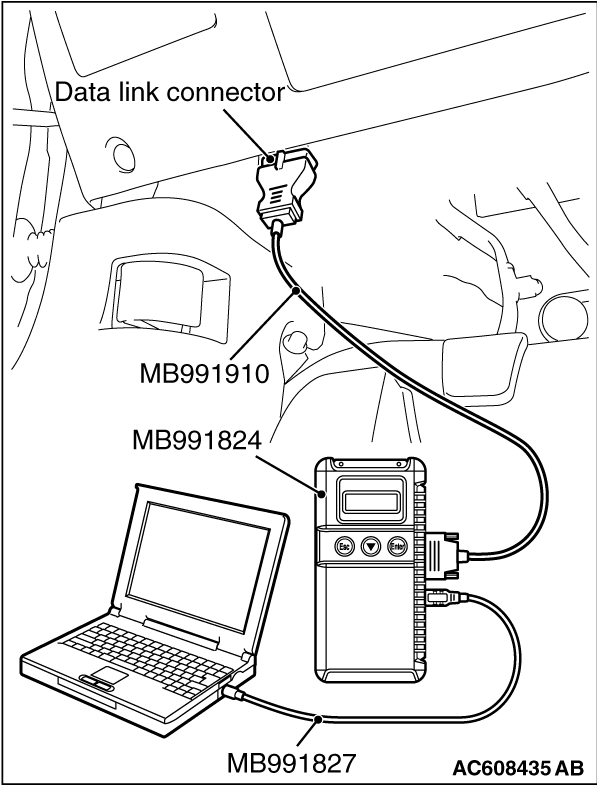

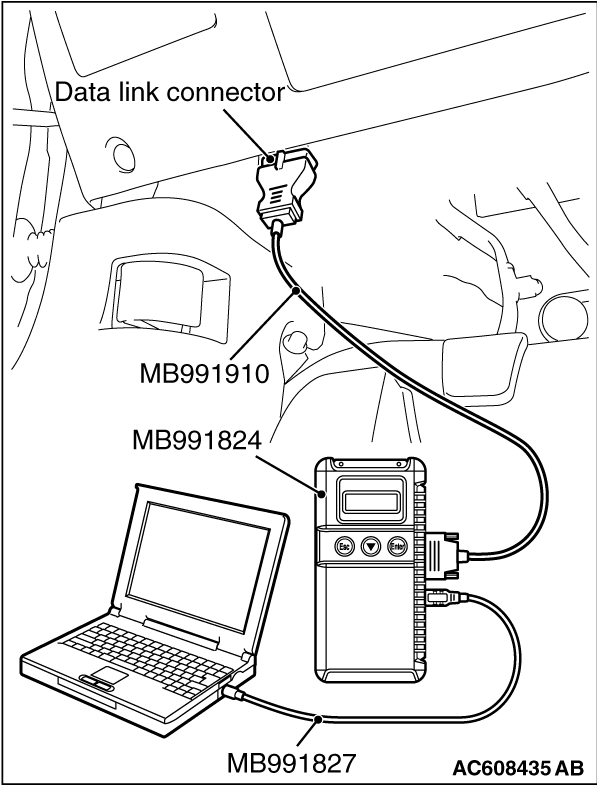

- MB991958: Scan Tool (M.U.T.-III Sub Assembly)

- MB991824: Vehicle Communication Interface (V.C.I.)

- MB991827: M.U.T.-III USB Cable

- MB991910: M.U.T.-III Main Harness A

- MB991970: ABS Check Harness

|

|

|

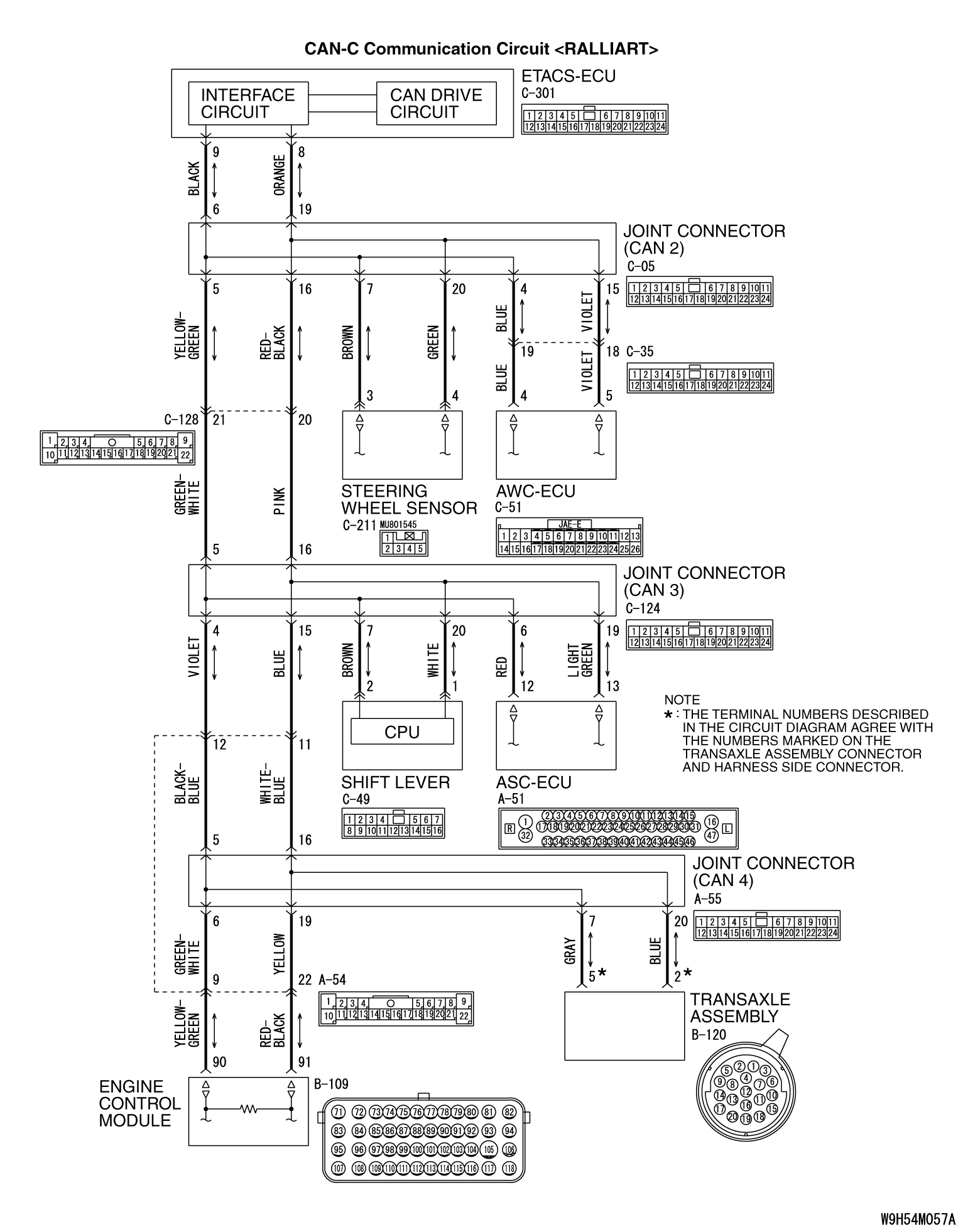

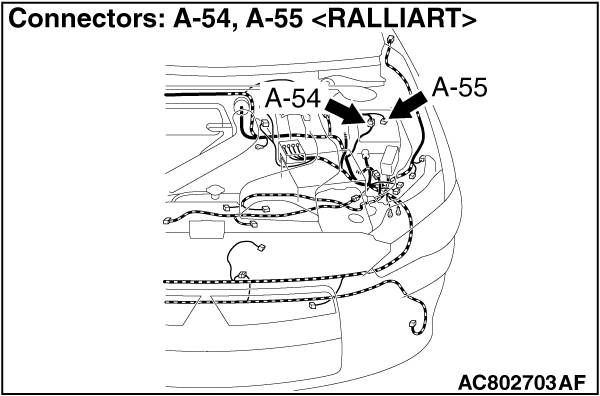

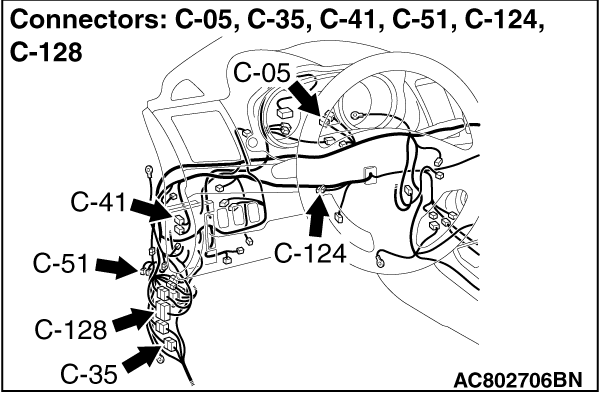

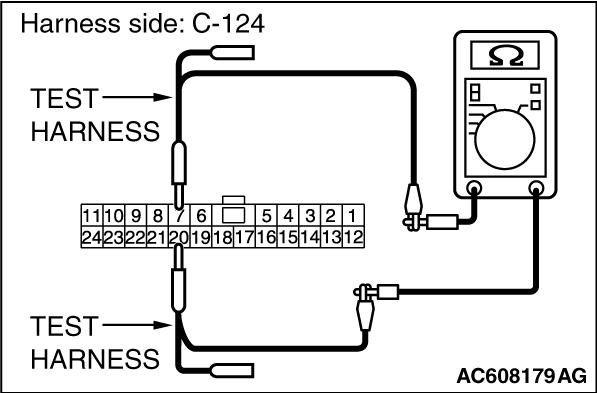

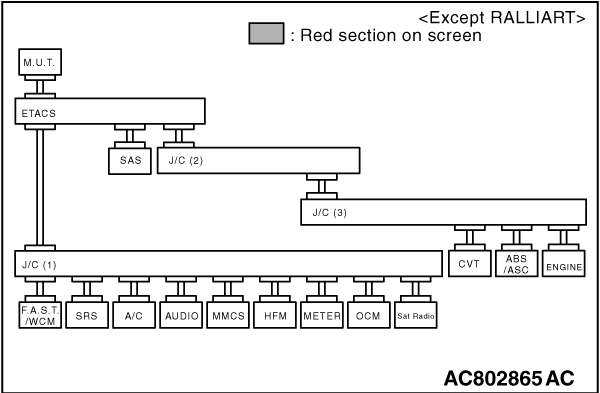

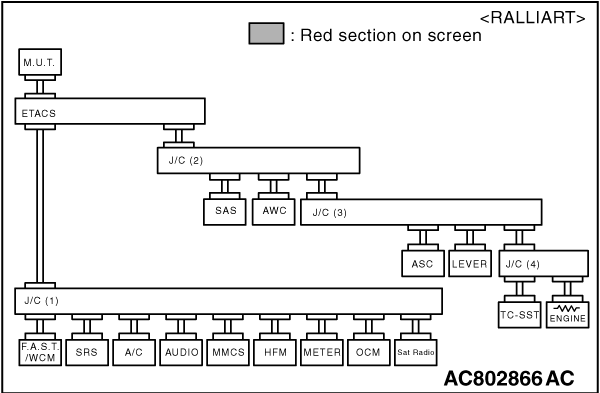

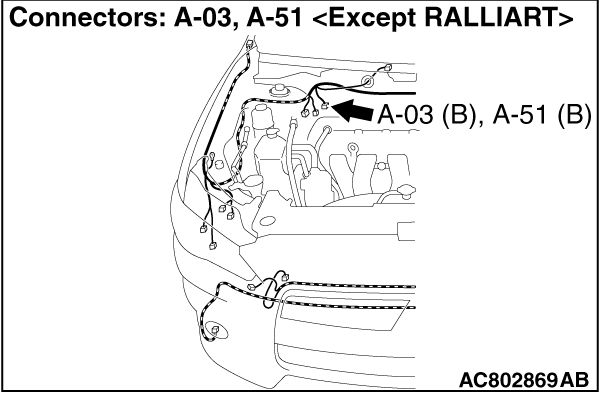

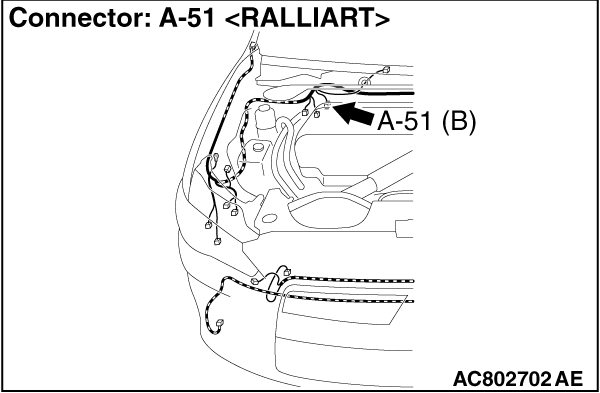

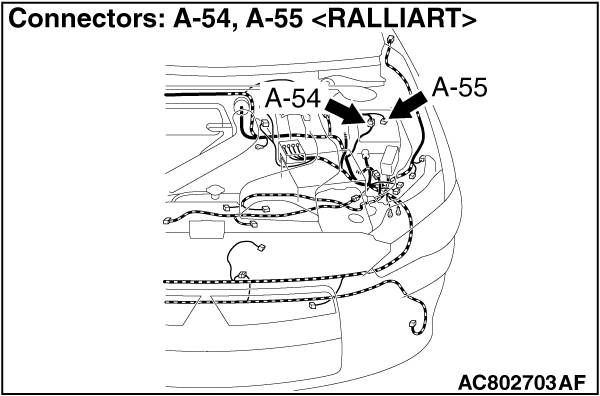

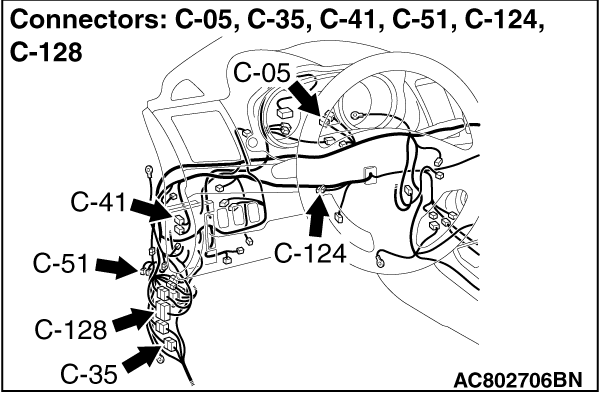

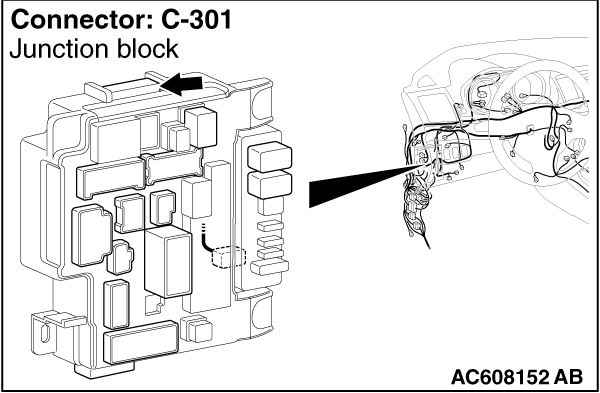

STEP 1. Check joint connector (CAN2) C-05, joint connector

(CAN3) C-124 and joint connector (CAN4) A-55 <RALLIART> for loose, corroded or damaged terminals,

or terminals pushed back in the connector.

|

|

|

| caution |

The strand end of the twisted wire should be within 10 cm (4

inches) from the connector. For details refer to  . .

|

|

|

|

Q.

Are joint connector (CAN2) C-05, joint connector (CAN3) C-124 and joint connector

(CAN4) A-55 <RALLIART> in good condition?

|

|

|

YES <vehicles with ASC> : Go to Step 2. : Go to Step 2.

|

|

|

|

|

|

YES <vehicles with ABS (Except vehicles with ASC)> : Go to Step 4. : Go to Step 4.

|

|

|

|

|

|

NO : Repair the damaged parts.

|

|

|

|

|

|

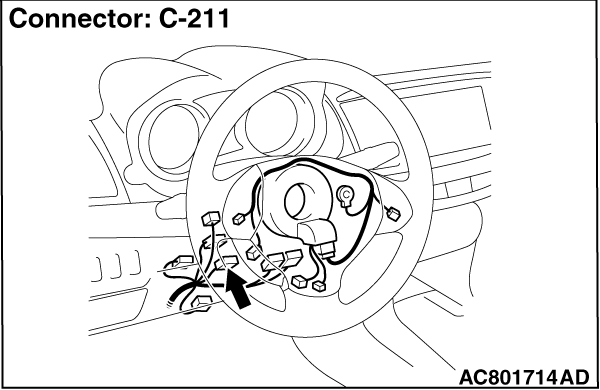

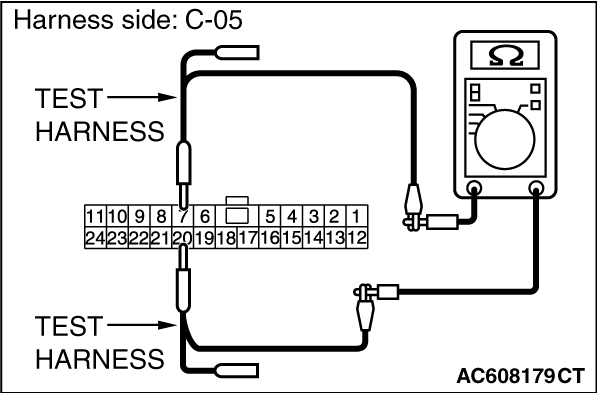

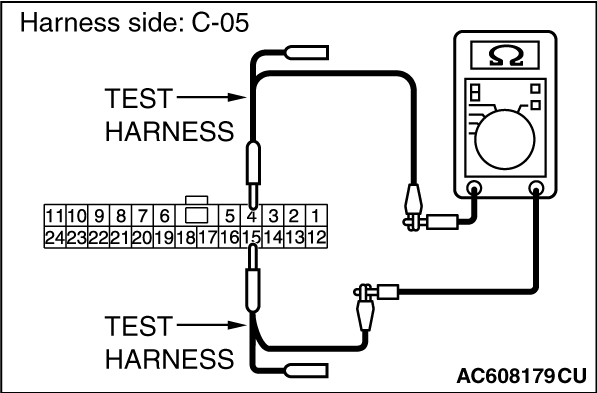

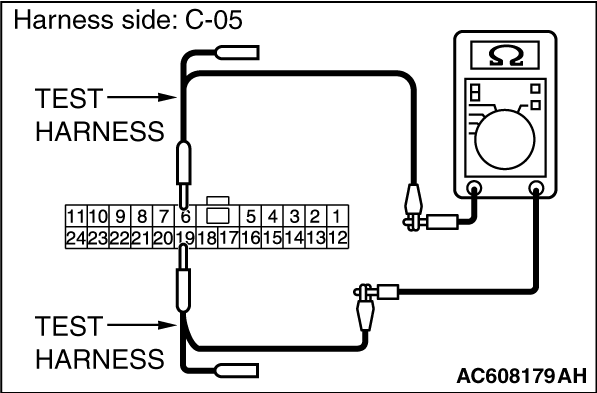

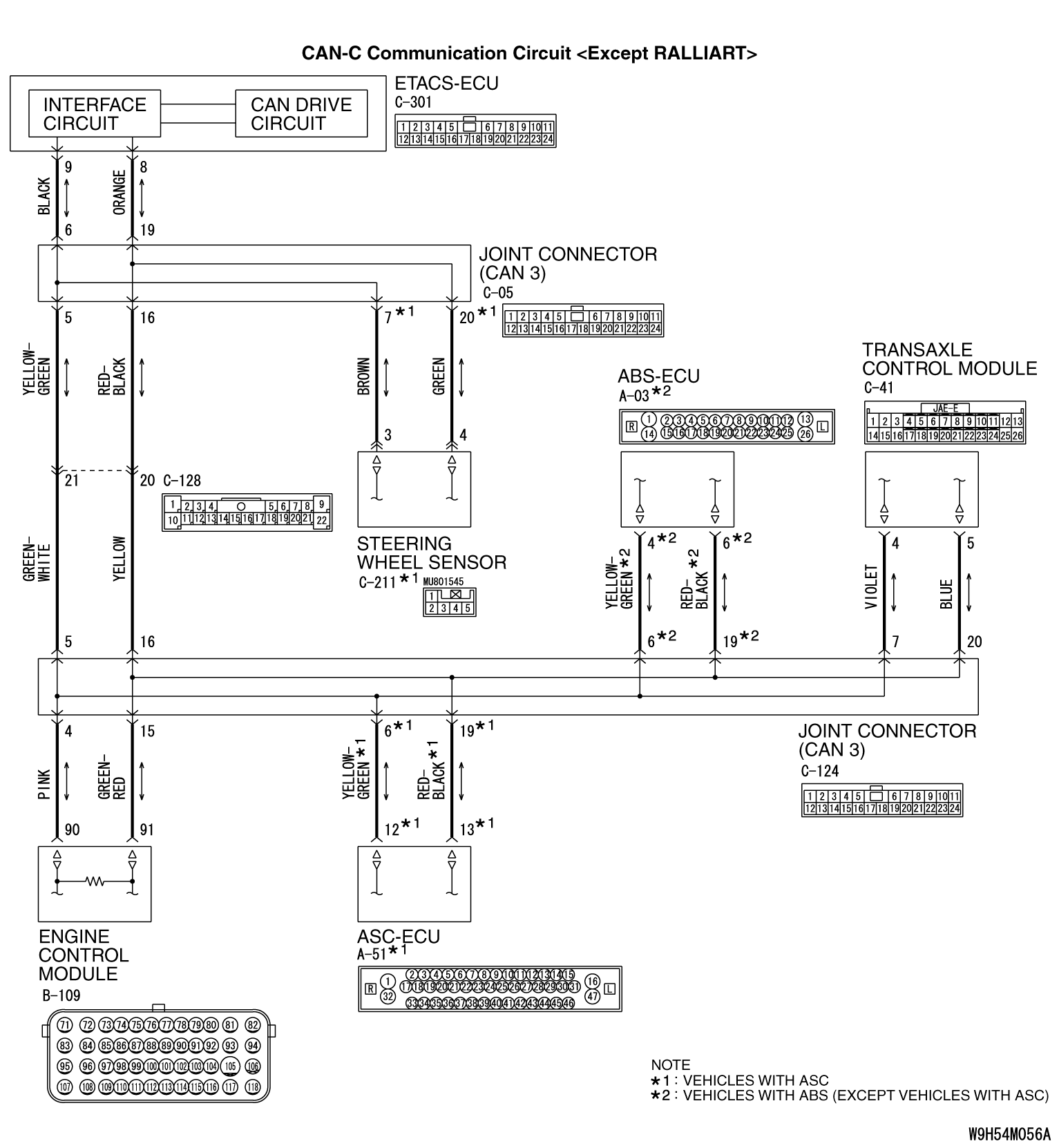

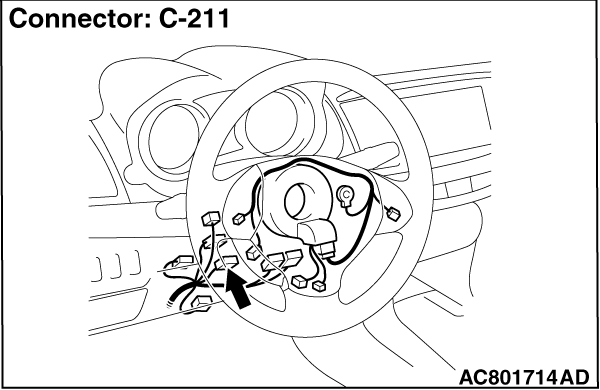

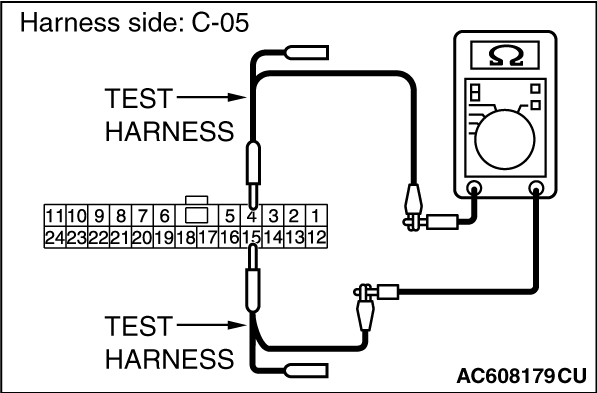

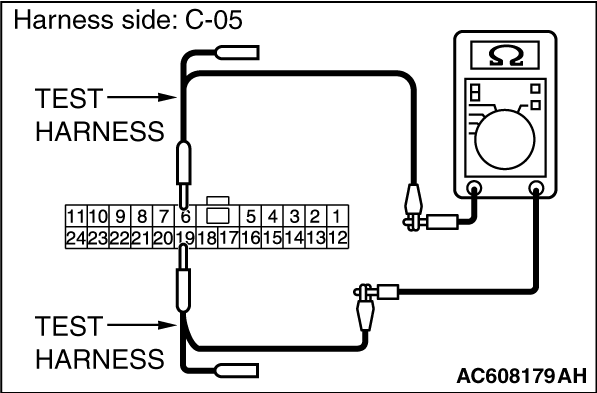

STEP 2. Check the wiring harness between joint connector (CAN2) C-05

and steering wheel sensor connector C-211 for line-to-line short. Measure the resistance at

joint connector (CAN2) C-05.

|

|

|

| caution |

Disconnect the negative battery terminal. For details refer to  . .

|

|

|

|

| caution |

A digital multimeter should be used. For details refer to  . .

|

|

|

|

| caution |

The test wiring harness should be used. For details refer to  . .

|

|

|

|

(1)Disconnect joint connector (CAN2), and check that there is continuity at the harness

side of joint connector (CAN2).

|

|

(2)Check that there is continuity between joint connector (CAN2) terminals 7 and 20.

OK: No continuity

Q.

Is the check result normal?

YES <except RALLIART> : Go to Step 4. : Go to Step 4.

YES <RALLIART> : Go to Step 3. : Go to Step 3.

NO  : Go to Step 12. : Go to Step 12.

|

|

|

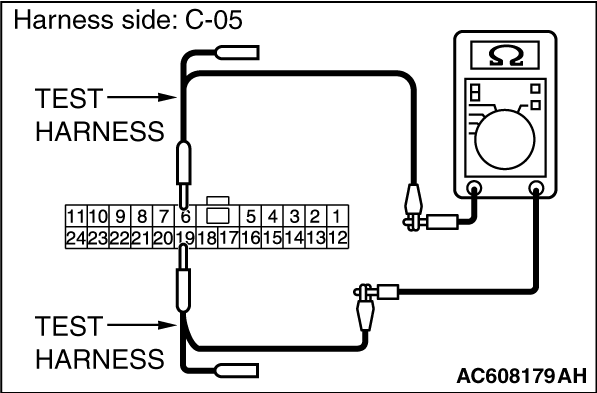

STEP 3. Check the wiring harness between joint connector (CAN2) C-05

and AWC-ECU connector C-51 for line-to-line short. Measure the resistance at joint connector

(CAN2) C-05.

|

|

|

| caution |

Disconnect the negative battery terminal. For details refer to  . .

|

|

|

|

| caution |

A digital multimeter should be used. For details refer to  . .

|

|

|

|

| caution |

The test wiring harness should be used. For details refer to  . .

|

|

|

|

(1)Disconnect joint connector (CAN2), and check that there is continuity at the harness

side of joint connector (CAN2).

|

|

(2)Check that there is continuity between joint connector (CAN2) terminals 4 and 15.

OK: No continuity

Q.

Is the check result normal?

Go to Step 4. Go to Step 4.

Go to Step 13. Go to Step 13.

|

|

|

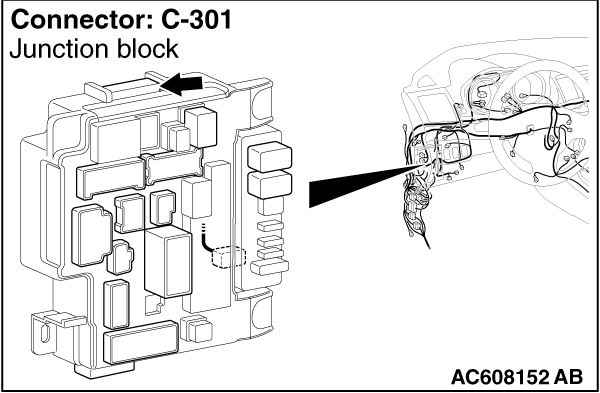

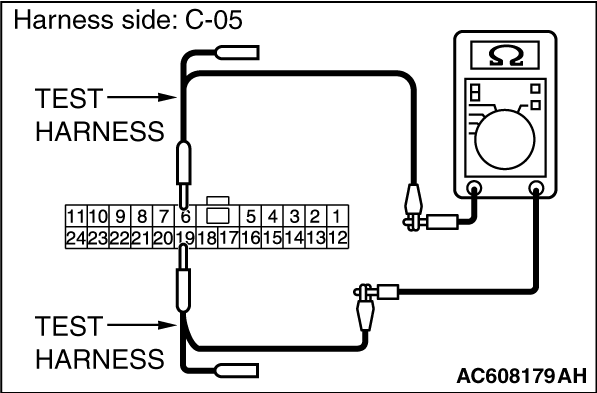

STEP 4. Check the wiring harness between joint connector (CAN2) C-05

and ETACS-ECU connector C-301 for line-to-line short. Measure the resistance at joint connector (CAN3)

C-05.

|

|

|

| caution |

Disconnect the negative battery terminal. For details refer to  . .

|

|

|

|

| caution |

A digital multimeter should be used. For details refer to  . .

|

|

|

|

| caution |

The test wiring harness should be used. For details refer to  . .

|

|

|

|

(1)Disconnect joint connector (CAN2), and check that there is continuity at the harness

side of joint connector (CAN2).

|

|

(2)Check that there is continuity between joint connector (CAN2) terminals 6 and 19.

OK: No continuity

Q.

Is the check result normal?

Go to Step 5. Go to Step 5.

Go to Step 14. Go to Step 14.

|

|

|

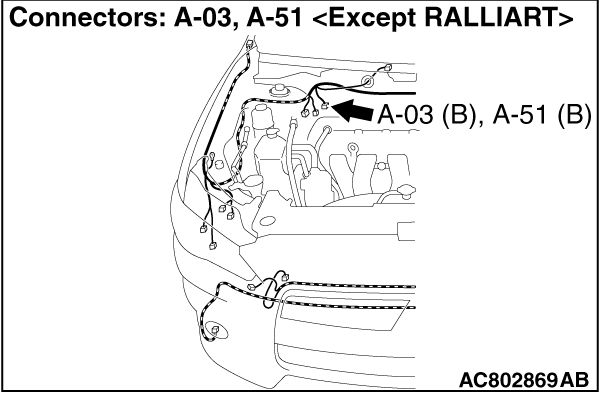

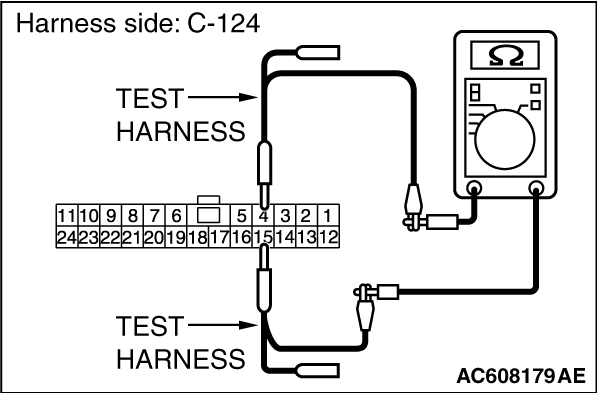

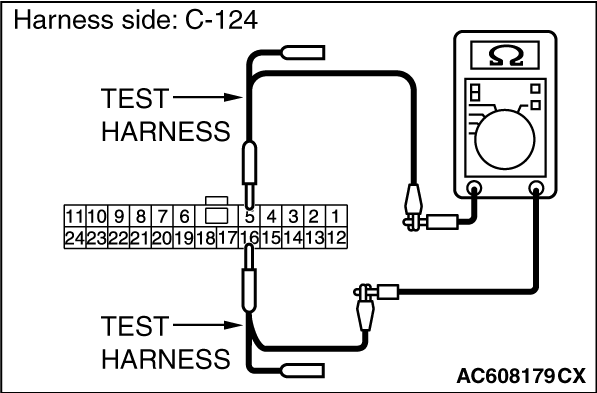

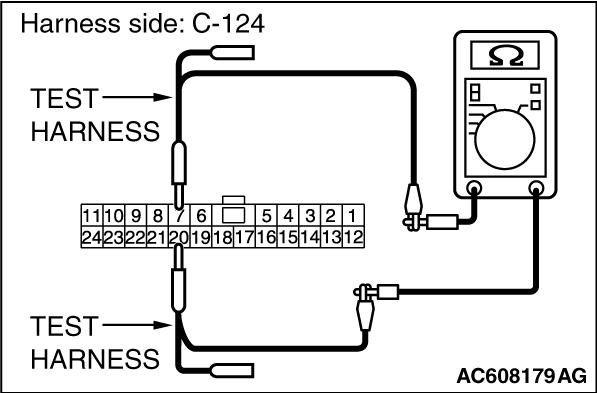

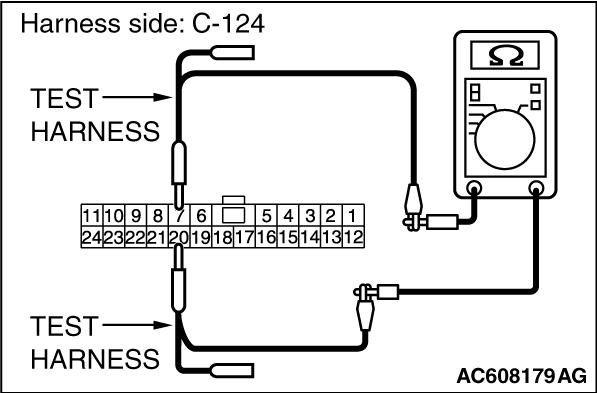

STEP 5. Check the wiring harness between joint connector (CAN3) C-124

and ASC-ECU connector A-51 <vehicles with ASC> or ABS-ECU connector A-03 <vehicles with

ABS (Except vehicles with ASC)> for line-to-line short. Measure the resistance at joint connector

(CAN3) C-124.

|

|

|

| caution |

Disconnect the negative battery terminal. For details refer to  . .

|

|

|

|

| caution |

A digital multimeter should be used. For details refer to  . .

|

|

|

|

| caution |

The test wiring harness should be used. For details refer to  . .

|

|

|

|

(1)Disconnect joint connector (CAN2), and check that there is continuity at the harness

side of joint connector (CAN2).

|

|

(2)Check that there is continuity between joint connector (CAN2) terminals 6 and 19.

OK: No continuity

Q.

Is the check result normal?

YES <except RALLIART> : Go to Step 6. : Go to Step 6.

YES <RALLIART> : Go to Step 8. : Go to Step 8.

NO  : Go to Step 15. : Go to Step 15.

|

|

|

STEP 6. Check the wiring harness between joint connector (CAN3) C-124

and TCM connector C-41 for line-to-line short. Measure the resistance at joint connector (CAN3)

C-124.

|

|

|

| caution |

Disconnect the negative battery terminal. For details refer to  . .

|

|

|

|

| caution |

A digital multimeter should be used. For details refer to  . .

|

|

|

|

| caution |

The test wiring harness should be used. For details refer to  . .

|

|

|

|

(1)Disconnect joint connector (CAN3), and check that there is continuity at the harness

side of joint connector (CAN3).

|

|

(2)Check that there is continuity between joint connector (CAN3) terminals 7 and 20.

OK: No continuity

Q.

Is the check result normal?

Go to Step 7. Go to Step 7.

Go to Step 16. Go to Step 16.

|

|

|

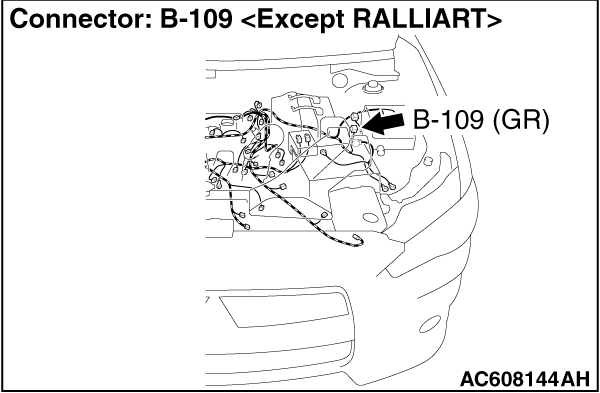

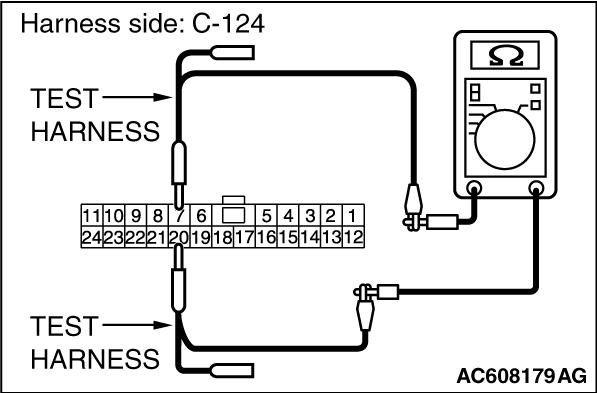

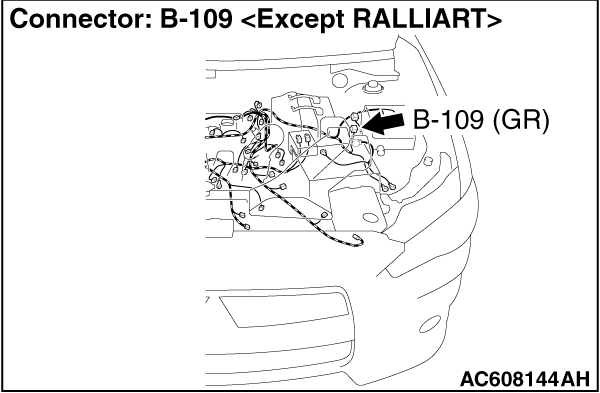

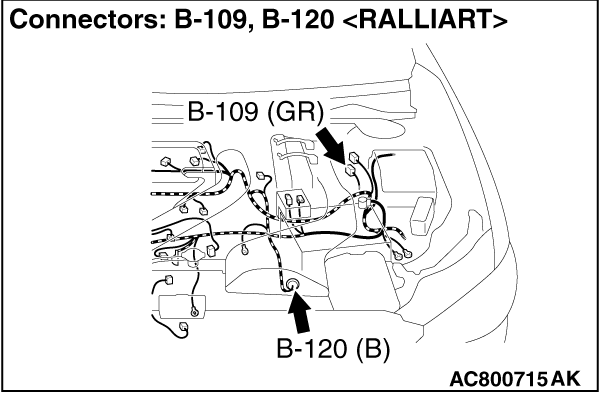

STEP 7. Check the wiring harness between joint connector (CAN3) C-124

and ECM connector B-109 <except RALLIART> for line-to-line short. Measure the resistance at

joint connector (CAN3) C-124.

|

|

|

| caution |

Disconnect the negative battery terminal. For details refer to  . .

|

|

|

|

| caution |

A digital multimeter should be used. For details refer to  . .

|

|

|

|

| caution |

The test wiring harness should be used. For details refer to  . .

|

|

|

|

(1)Disconnect joint connector (CAN3), and check that there is continuity at the harness

side of joint connector (CAN3).

|

|

(2)Check that there is continuity between joint connector (CAN3) terminals 4 and 15.

OK: No continuity

Q.

Is the check result normal?

Check intermediate connector C-128, and repair if necessary. If the intermediate

connector is in good condition, repair the wiring harness between joint connector (CAN2) C-05

and joint connector (CAN3) C-124. Check intermediate connector C-128, and repair if necessary. If the intermediate

connector is in good condition, repair the wiring harness between joint connector (CAN2) C-05

and joint connector (CAN3) C-124.

Go to Step 17. Go to Step 17.

|

|

|

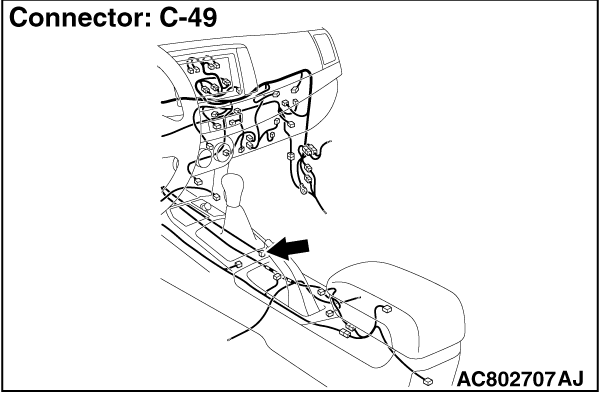

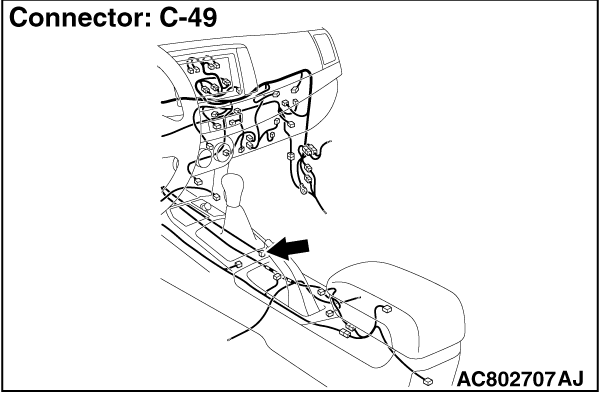

STEP 8. Check the wiring harness between joint connector (CAN3) C-124

and shift lever connector C-49 for line-to-line short. Measure the resistance at joint connector

(CAN3) C-124.

|

|

|

| caution |

Disconnect the negative battery terminal. For details refer to  . .

|

|

|

|

| caution |

A digital multimeter should be used. For details refer to  . .

|

|

|

|

| caution |

The test wiring harness should be used. For details refer to  . .

|

|

|

|

(1)Disconnect joint connector (CAN3), and check that there is continuity at the harness

side of joint connector (CAN3).

|

|

(2)Check that there is continuity between joint connector (CAN3) terminals 7 and 20.

OK: No continuity

Q.

Is the check result normal?

Go to Step 9. Go to Step 9.

Go to Step 18. Go to Step 18.

|

|

|

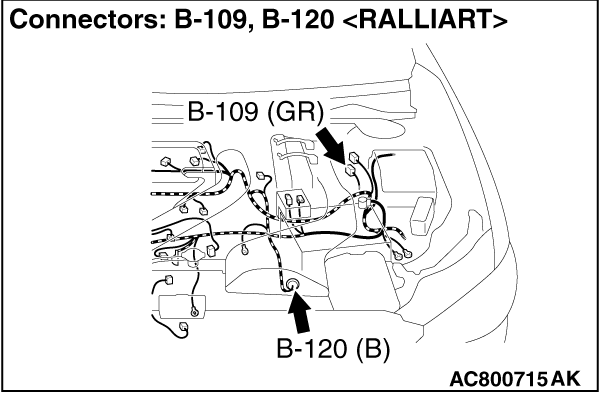

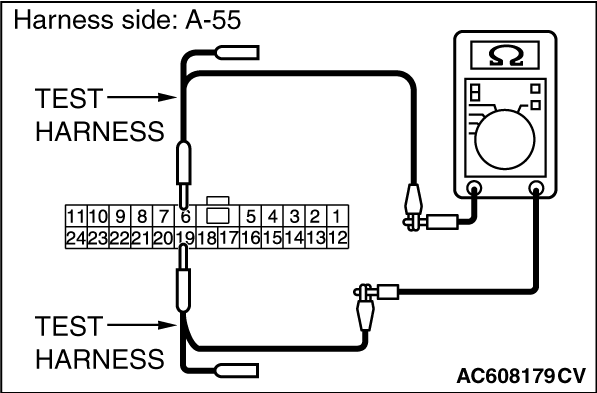

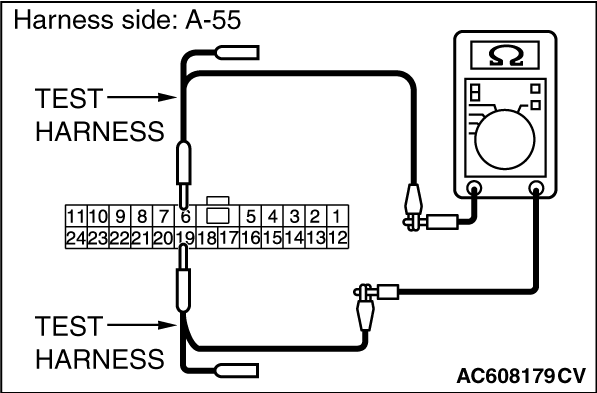

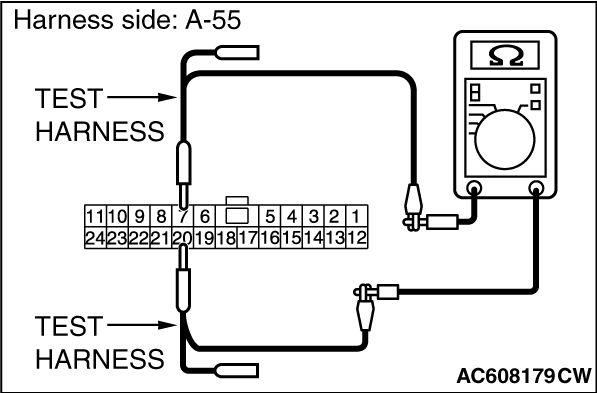

STEP 9. Check the wiring harness between joint connector (CAN4) A-55

and ECM connector B-109 <RALLIART> for line-to-line short. Measure the resistance at joint connector

(CAN4) A-55.

|

|

|

| caution |

Disconnect the negative battery terminal. For details refer to  . .

|

|

|

|

| caution |

A digital multimeter should be used. For details refer to  . .

|

|

|

|

| caution |

The test wiring harness should be used. For details refer to  . .

|

|

|

|

(1)Disconnect joint connector (CAN4), and check that there is continuity at the harness

side of joint connector (CAN4).

|

|

(2)Check that there is continuity between joint connector (CAN4) terminals 6 and 19.

OK: No continuity

Q.

Is the check result normal?

Go to Step 10. Go to Step 10.

Go to Step 17. Go to Step 17.

|

|

|

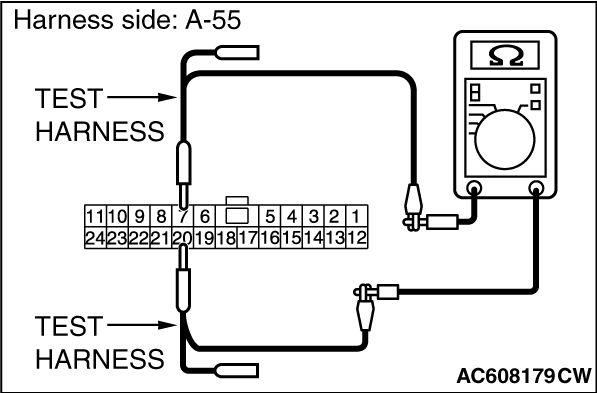

STEP 10. Check the wiring harness between joint connector (CAN4) A-55

and transaxle assembly (TC-SST-ECU) connector B-120 for line-to-line short. Measure the resistance

at joint connector (CAN4) A-55.

|

|

|

| caution |

Disconnect the negative battery terminal. For details refer to  . .

|

|

|

|

| caution |

A digital multimeter should be used. For details refer to  . .

|

|

|

|

| caution |

The test wiring harness should be used. For details refer to  . .

|

|

|

|

(1)Disconnect joint connector (CAN4), and check that there is continuity at the harness

side of joint connector (CAN4).

|

|

(2)Check that there is continuity between joint connector (CAN4) terminals 7 and 20.

OK: No continuity

Q.

Is the check result normal?

Go to Step 11. Go to Step 11.

Go to Step 19. Go to Step 19.

|

|

|

STEP 11. Check the wiring harness between joint connector (CAN3) C-124

and joint connector (CAN2) C-05 for line-to-line short. Measure the resistance at joint connector

(CAN3) C-124.

|

|

|

| caution |

Disconnect the negative battery terminal. For details refer to  . .

|

|

|

|

| caution |

A digital multimeter should be used. For details refer to  . .

|

|

|

|

| caution |

The test wiring harness should be used. For details refer to  . .

|

|

|

|

(1)Disconnect joint connector (CAN3) and Disconnect joint connector (CAN2), and check

that there is continuity at the harness side of joint connector (CAN3).

|

|

(2)Check that there is continuity between joint connector (CAN3) terminals 5 and 16.

OK: No continuity

Q.

Is the check result normal?

Check intermediate connector A-54, and repair if necessary. If the intermediate

connector is in good condition, repair the wiring harness between joint connector (CAN3) C-124

and joint connector (CAN4) A-55. Check intermediate connector A-54, and repair if necessary. If the intermediate

connector is in good condition, repair the wiring harness between joint connector (CAN3) C-124

and joint connector (CAN4) A-55.

Check intermediate connector C-128, and repair if necessary. If the intermediate

connector is in good condition, repair the wiring harness between joint connector (CAN2) C-05

and joint connector (CAN3) C-124. Check intermediate connector C-128, and repair if necessary. If the intermediate

connector is in good condition, repair the wiring harness between joint connector (CAN2) C-05

and joint connector (CAN3) C-124.

|

|

|

STEP 12. Using scan tool MB991958, diagnose the CAN bus line. (checking

the steering wheel sensor for internal short)

|

|

|

| caution |

Strictly observe the specified wiring harness repair procedure.

For details refer to  . .

|

|

|

|

| caution |

To prevent damage to scan tool MB991958, always turn the ignition switch to

the "LOCK" (OFF) position before connecting or disconnecting scan tool MB991958.

|

|

|

|

(1)Disconnect steering wheel sensor connector C-209.

|

|

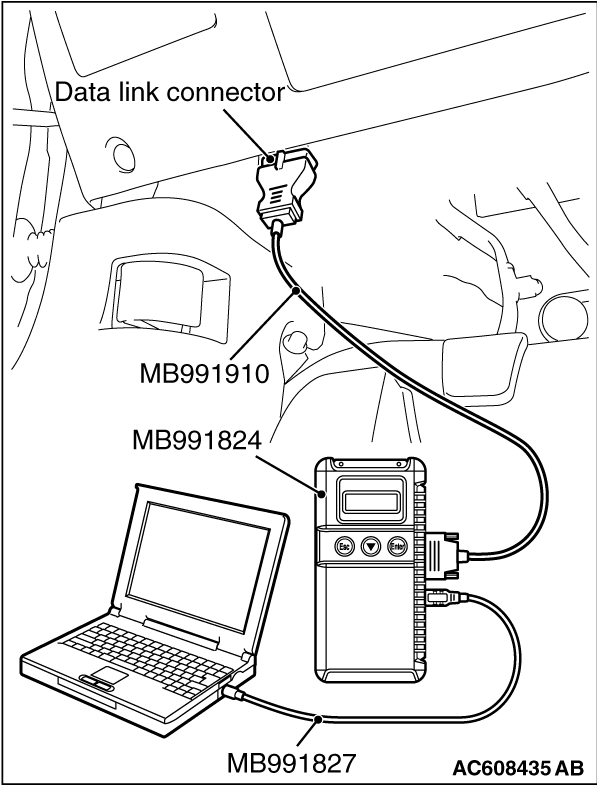

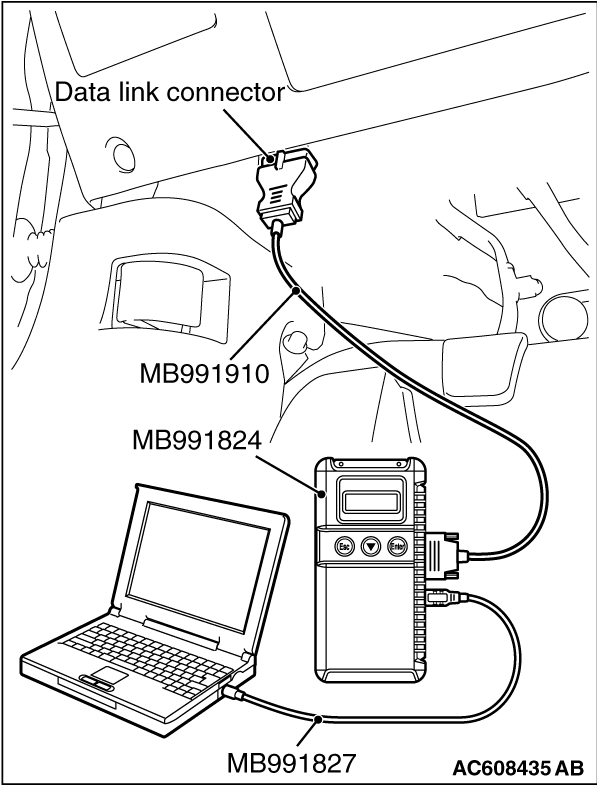

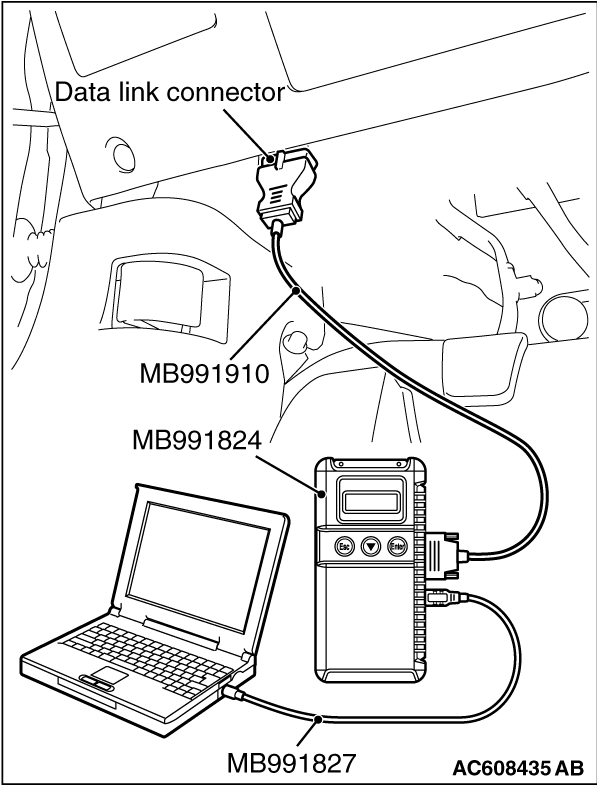

(2)Connect scan tool MB991958 to the data link connector.

(3)Turn the ignition switch to the "ON" position.

|

|

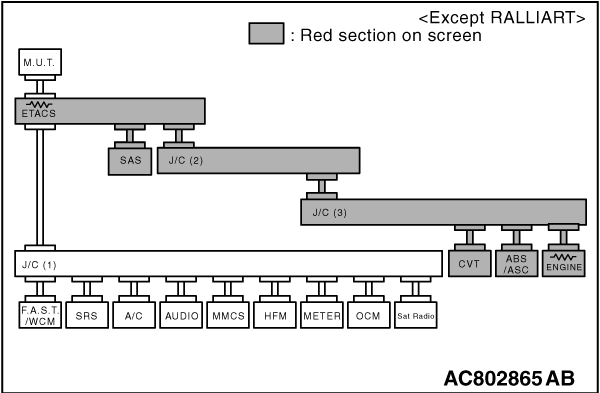

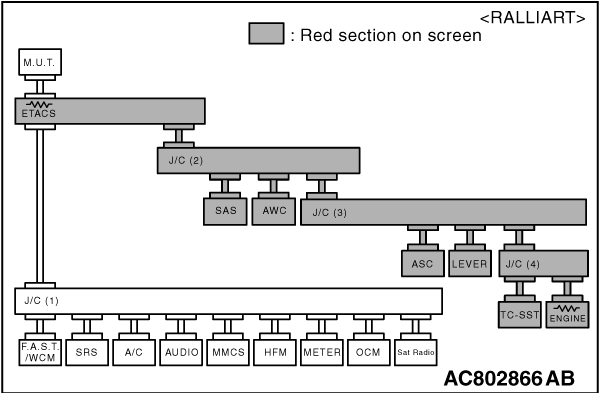

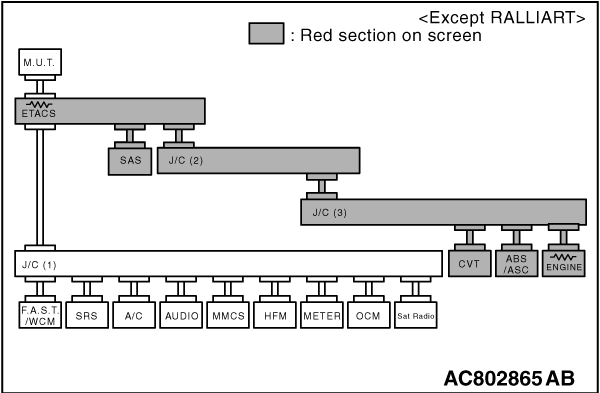

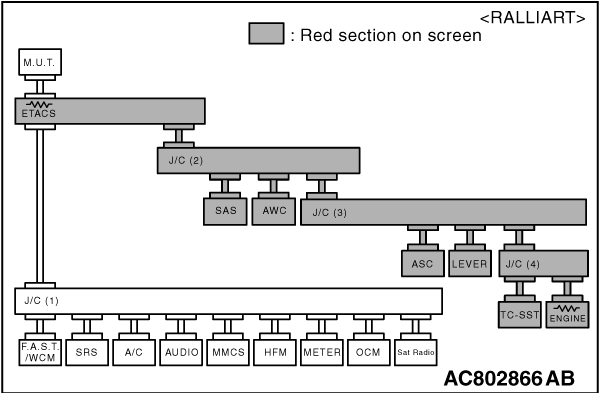

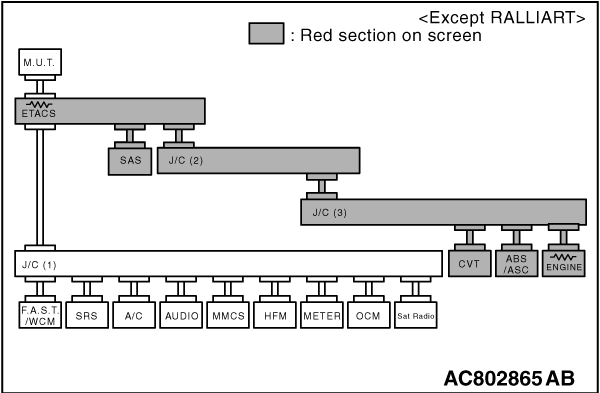

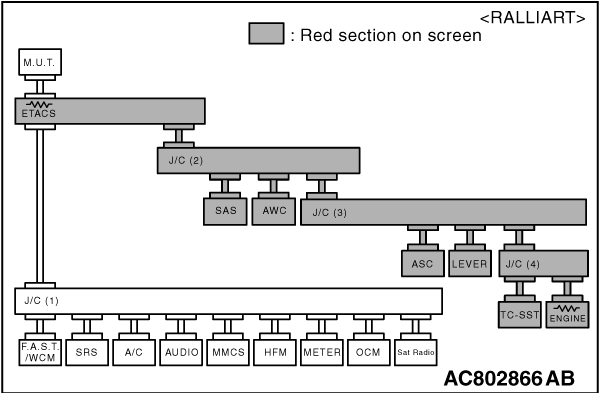

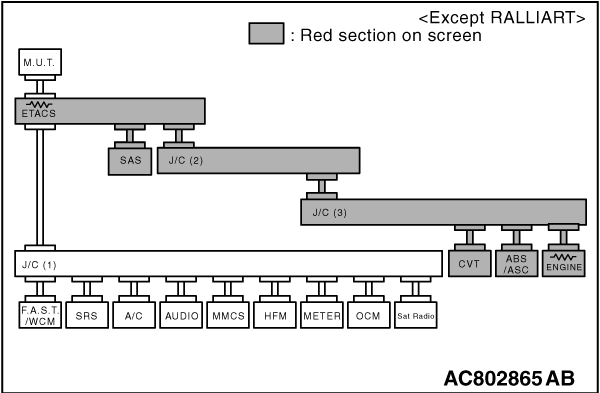

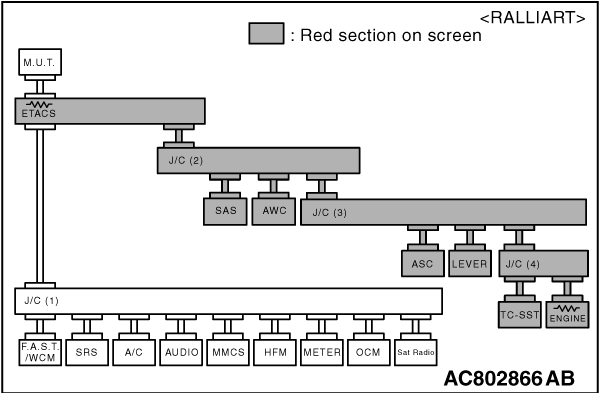

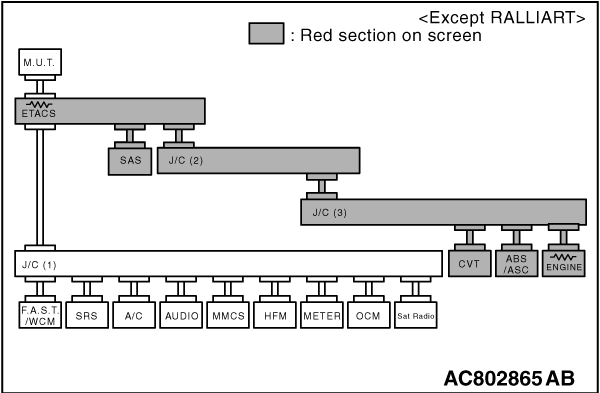

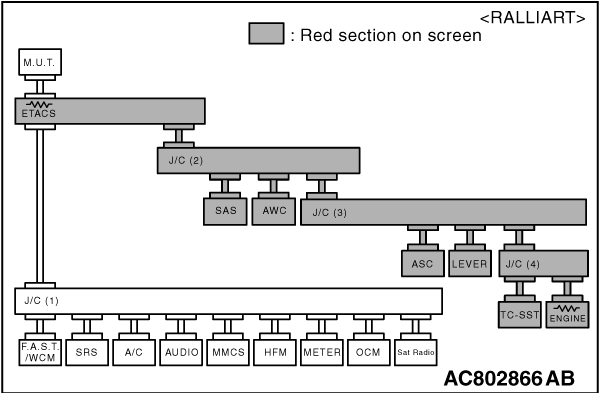

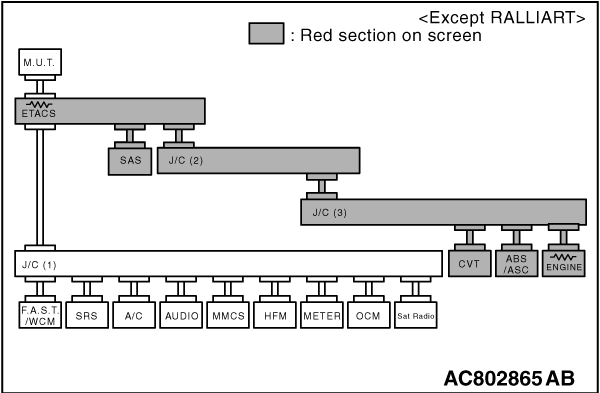

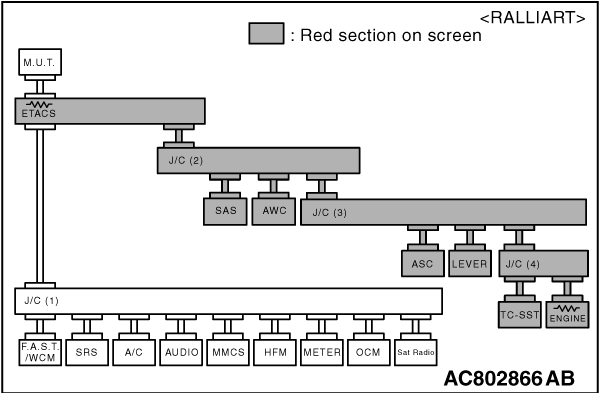

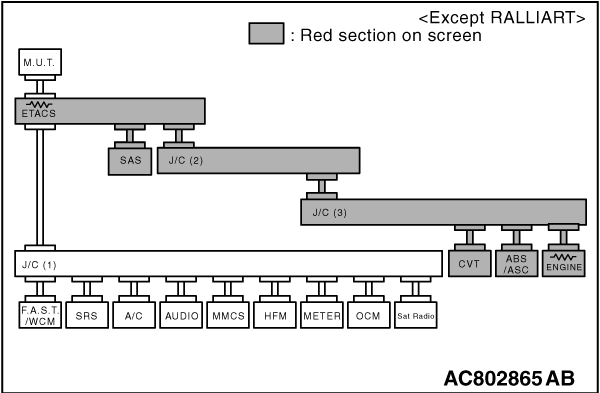

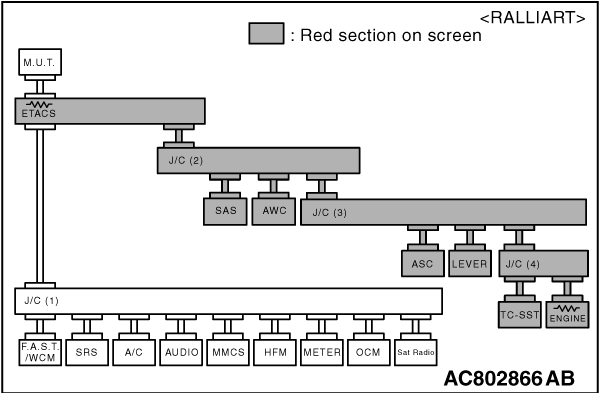

(4)Diagnose CAN bus lines, and check if the scan tool MB991958 screen is as shown in the

figure.

OK: The display of the scan tool MB991958 is as shown in the figure.

Q.

Does scan tool MB991958 screen correspond to the illustration?

Repair the wiring harness between steering wheel sensor connector C-211 and joint

connector (CAN2) C-05. Repair the wiring harness between steering wheel sensor connector C-211 and joint

connector (CAN2) C-05.

Check steering wheel sensor connector C-211, and repair if necessary. If the steering

wheel sensor connector is in good condition, replace the steering wheel sensor. Check steering wheel sensor connector C-211, and repair if necessary. If the steering

wheel sensor connector is in good condition, replace the steering wheel sensor.

|

|

|

STEP 13. Using scan tool MB991958, diagnose the CAN bus line. (checking

the AWC-ECU for internal short)

|

|

|

| caution |

Strictly observe the specified wiring harness repair procedure.

For details refer to  . .

|

|

|

|

| caution |

To prevent damage to scan tool MB991958, always turn the ignition switch to

the "LOCK" (OFF) position before connecting or disconnecting scan tool MB991958.

|

|

|

|

(1)Disconnect AWC-ECU connector C-51.

|

|

(2)Connect scan tool MB991958 to the data link connector.

(3)Turn the ignition switch to the "ON" position.

|

|

(4)Diagnose CAN bus lines, and check if the scan tool MB991958 screen is as shown in the

figure.

OK: The display of the scan tool MB991958 is as shown in the figure.

Q.

Does scan tool MB991958 screen correspond to the illustration?

Check C-35 intermediate connector, and repair if necessary. If the intermediate

connector is in good condition, repair the wiring harness between AWC-ECU connector C-51 and

joint connector (CAN2) C-05. Check C-35 intermediate connector, and repair if necessary. If the intermediate

connector is in good condition, repair the wiring harness between AWC-ECU connector C-51 and

joint connector (CAN2) C-05.

Check AWC-ECU connector C-51, and repair if necessary. If the AWC-ECU connector

is in good condition, replace the AWC-ECU. Check AWC-ECU connector C-51, and repair if necessary. If the AWC-ECU connector

is in good condition, replace the AWC-ECU.

|

|

|

STEP 14. Check the wiring harness between joint connector (CAN2) C-05

and ETACS-ECU connector C-301 for line-to-line short. Measure the resistance at joint connector

(CAN2) C-05.

|

|

|

(1)Disconnect joint connector (CAN2) and ETACS-ECU connector, and check that there

is continuity at the harness side of joint connector (CAN2).

|

|

(2)Check that there is continuity between joint connector (CAN2) terminals 6 and 19.

OK: No continuity

Q.

Is the check result normal?

Go to Step 20. Go to Step 20.

Repair the wiring harness between ETACS-ECU connector C-301 and joint connector

(CAN2) C-05. Repair the wiring harness between ETACS-ECU connector C-301 and joint connector

(CAN2) C-05.

|

|

|

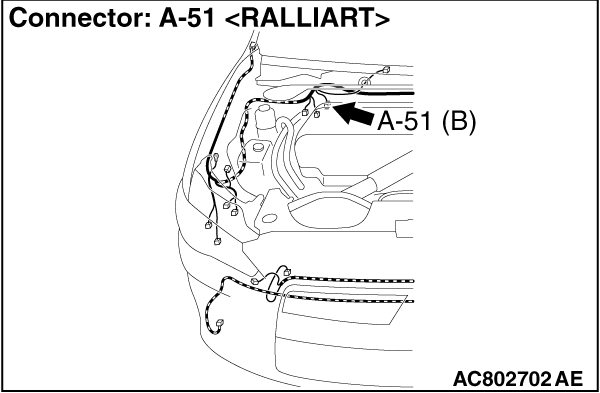

STEP 15. Using scan tool MB991958, diagnose the CAN bus line. (checking

the ASC-ECU <vehicles with ASC> or ABS-ECU <vehicles with ABS (Except vehicles with

ASC)> for internal short)

|

|

|

| caution |

Strictly observe the specified wiring harness repair procedure.

For details refer to  . .

|

|

|

|

| caution |

To prevent damage to scan tool MB991958, always turn the ignition switch to

the "LOCK" (OFF) position before connecting or disconnecting scan tool MB991958.

|

|

|

|

(1)Disconnect ASC-ECU connector A-51 <vehicles with ASC> or ABS-ECU connector

A-03 <vehicles with ABS (Except vehicles with ASC)>.

|

|

(2)Connect scan tool MB991958 to the data link connector.

(3)Turn the ignition switch to the "ON" position.

|

|

(4)Diagnose CAN bus lines, and check if the scan tool MB991958 screen is as shown in the

figure.

OK: The display of the scan tool MB991958 is as shown in the figure.

Q.

Does scan tool MB991958 screen correspond to the illustration?

Repair the wiring harness between ASC-ECU connector A-51 <vehicles with ASC>

or ABS-ECU connector A-03 <vehicles with ABS (Except vehicles with ASC)> and joint connector

(CAN3) C-124. Repair the wiring harness between ASC-ECU connector A-51 <vehicles with ASC>

or ABS-ECU connector A-03 <vehicles with ABS (Except vehicles with ASC)> and joint connector

(CAN3) C-124.

Check ASC-ECU connector A-51 <vehicles with ASC> or ABS-ECU connector A-03 <vehicles

with ABS (Except vehicles with ASC)>, and repair if necessary. If the ASC-ECU connector <vehicles

with ASC> or ABS-ECU connector <vehicles with ABS (Except vehicles with ASC)> is in good

condition, replace the ASC-ECU connector <vehicles with ASC> or ABS-ECU connector <vehicles

with ABS (Except vehicles with ASC)>. Check ASC-ECU connector A-51 <vehicles with ASC> or ABS-ECU connector A-03 <vehicles

with ABS (Except vehicles with ASC)>, and repair if necessary. If the ASC-ECU connector <vehicles

with ASC> or ABS-ECU connector <vehicles with ABS (Except vehicles with ASC)> is in good

condition, replace the ASC-ECU connector <vehicles with ASC> or ABS-ECU connector <vehicles

with ABS (Except vehicles with ASC)>.

|

|

|

STEP 16. Using scan tool MB991958, diagnose the CAN bus line. (checking

the TCM for internal short)

|

|

|

| caution |

Strictly observe the specified wiring harness repair procedure.

For details refer to  . .

|

|

|

|

| caution |

To prevent damage to scan tool MB991958, always turn the ignition switch to

the "LOCK" (OFF) position before connecting or disconnecting scan tool MB991958.

|

|

|

|

(1)Disconnect TCM connector C-41.

|

|

(2)Connect scan tool MB991958 to the data link connector.

(3)Turn the ignition switch to the "ON" position.

|

|

(4)Diagnose CAN bus lines, and check if the scan tool MB991958 screen is as shown in the

figure.

OK: The display of the scan tool MB991958 is as shown in the figure.

Q.

Does scan tool MB991958 screen correspond to the illustration?

Repair the wiring harness between TCM connector C-41 and joint connector (CAN3)

C-124. Repair the wiring harness between TCM connector C-41 and joint connector (CAN3)

C-124.

Check TCM connector C-41, and repair if necessary. If the TCM connector is in

good condition, replace the TCM connector. Check TCM connector C-41, and repair if necessary. If the TCM connector is in

good condition, replace the TCM connector.

|

|

|

STEP 17. Using scan tool MB991958, diagnose the CAN bus line. (checking

the ECM for internal short)

|

|

|

| caution |

Strictly observe the specified wiring harness repair procedure.

For details refer to  . .

|

|

|

|

| caution |

To prevent damage to scan tool MB991958, always turn the ignition switch to

the "LOCK" (OFF) position before connecting or disconnecting scan tool MB991958.

|

|

|

|

(1)Disconnect ECM connector B-109.

|

|

(2)Connect scan tool MB991958 to the data link connector.

(3)Turn the ignition switch to the "ON" position.

|

|

(4)Diagnose CAN bus lines, and check if the scan tool MB991958 screen is as shown in the

figure.

OK: The display of the scan tool MB991958 is as shown in the figure.

Q.

Does scan tool MB991958 screen correspond to the illustration?

Repair the wiring harness between ECM connector B-109 and joint connector (CAN3)

C-124 <except RALLIART>, or check intermediate connector is in good condition, repair the

wiring harness between ECM connector B-109 and joint connector (CAN4) A-55 <RALLIART>. Repair the wiring harness between ECM connector B-109 and joint connector (CAN3)

C-124 <except RALLIART>, or check intermediate connector is in good condition, repair the

wiring harness between ECM connector B-109 and joint connector (CAN4) A-55 <RALLIART>.

Check ECM connector B-109, and repair if necessary. If the ECM connector is in

good condition, replace the ECM connector. Check ECM connector B-109, and repair if necessary. If the ECM connector is in

good condition, replace the ECM connector.

|

|

|

STEP 18. Using scan tool MB991958, diagnose the CAN bus line. (checking

the shift lever for internal short)

|

|

|

| caution |

Strictly observe the specified wiring harness repair procedure.

For details refer to  . .

|

|

|

|

| caution |

To prevent damage to scan tool MB991958, always turn the ignition switch to

the "LOCK" (OFF) position before connecting or disconnecting scan tool MB991958.

|

|

|

|

(1)Disconnect shift lever connector C-49.

|

|

(2)Connect scan tool MB991958 to the data link connector.

(3)Turn the ignition switch to the "ON" position.

|

|

(4)Diagnose CAN bus lines, and check if the scan tool MB991958 screen is as shown in the

figure.

OK: The display of the scan tool MB991958 is as shown in the figure.

Q.

Does scan tool MB991958 screen correspond to the illustration?

Repair the wiring harness between shift lever connector C-49 and joint connector

(CAN3) C-124. Repair the wiring harness between shift lever connector C-49 and joint connector

(CAN3) C-124.

Check shift lever connector C-49, and repair if necessary. If the shift lever

is in good condition, replace the shift lever. Check shift lever connector C-49, and repair if necessary. If the shift lever

is in good condition, replace the shift lever.

|

|

|

STEP 19. Using scan tool MB991958, diagnose the CAN bus line. (checking

the transaxle assembly (TC-SST-ECU) for internal short)

|

|

|

| caution |

Strictly observe the specified wiring harness repair procedure.

For details refer to  . .

|

|

|

|

| caution |

To prevent damage to scan tool MB991958, always turn the ignition switch to

the "LOCK" (OFF) position before connecting or disconnecting scan tool MB991958.

|

|

|

|

(1)Disconnect transaxle assembly (TC-SST-ECU) connector B-120.

|

|

(2)Connect scan tool MB991958 to the data link connector.

(3)Turn the ignition switch to the "ON" position.

|

|

(4)Diagnose CAN bus lines, and check if the scan tool MB991958 screen is as shown in the

figure.

OK: The display of the scan tool MB991958 is as shown in the figure.

Q.

Does scan tool MB991958 screen correspond to the illustration?

Repair the wiring harness between transaxle assembly (TC-SST-ECU) connector B-120

and joint connector (CAN4) A-55. Repair the wiring harness between transaxle assembly (TC-SST-ECU) connector B-120

and joint connector (CAN4) A-55.

Check transaxle assembly (TC-SST-ECU) connector B-120, and repair if necessary.

If the transaxle assembly (TC-SST-ECU) is in good condition, replace the transaxle assembly

(TC-SST-ECU). Check transaxle assembly (TC-SST-ECU) connector B-120, and repair if necessary.

If the transaxle assembly (TC-SST-ECU) is in good condition, replace the transaxle assembly

(TC-SST-ECU).

|

|

|

STEP 20. Using scan tool MB991958, diagnose the CAN bus line.

|

|

(1)

| caution |

To prevent damage to scan tool MB991958, always turn the ignition switch

to the "LOCK" (OFF) position before connecting or disconnecting scan tool MB991958.

|

Connect scan tool MB991958 to the data link connector.

(2)Turn the ignition switch to the "ON" position.

|

|

(3)Diagnose CAN bus lines, and check if the scan tool screen is as shown in the illustration.

Q.

Does the scan tool screen correspond to the illustration?

The trouble can be an intermittent malfunction (Refer to GROUP 00, How to use

Troubleshooting/inspection Service Points - How to Cope with Intermittent

Malfunction The trouble can be an intermittent malfunction (Refer to GROUP 00, How to use

Troubleshooting/inspection Service Points - How to Cope with Intermittent

Malfunction  ). ).

Replace the ETACS-ECU. Replace the ETACS-ECU.

|

.

.![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)

: Go to Step 2.

: Go to Step 2. : Go to Step 4.

: Go to Step 4.

Go to Step 4.

Go to Step 4. Go to Step 13.

Go to Step 13.

Go to Step 5.

Go to Step 5. Go to Step 14.

Go to Step 14.

Go to Step 7.

Go to Step 7. Go to Step 16.

Go to Step 16.

Go to Step 9.

Go to Step 9. Go to Step 18.

Go to Step 18.

Go to Step 10.

Go to Step 10. Go to Step 17.

Go to Step 17.

Go to Step 11.

Go to Step 11. Go to Step 19.

Go to Step 19.

The trouble can be an intermittent malfunction (Refer to GROUP 00, How to use

Troubleshooting/inspection Service Points - How to Cope with Intermittent

Malfunction

The trouble can be an intermittent malfunction (Refer to GROUP 00, How to use

Troubleshooting/inspection Service Points - How to Cope with Intermittent

Malfunction  ).

). Replace the ETACS-ECU.

Replace the ETACS-ECU.