![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)

DTC B1B02: Driver’s

Air Bag Module (1st squib) System (Squib Circuit Open)

DTC B1B06: Driver’s

Air Bag Module (2nd squib) System (Squib Circuit Open)

| caution |

- If DTC B1B02 <1st

squib> or B1B06 <2nd squib> is set in the SRS-ECU, always diagnose

the CAN main bus line.

- When DTC B1B02 is set in the following diagnosis, check the 1st squib circuit. When DTC

B1B06 is set, check the 2nd squib circuit.

|

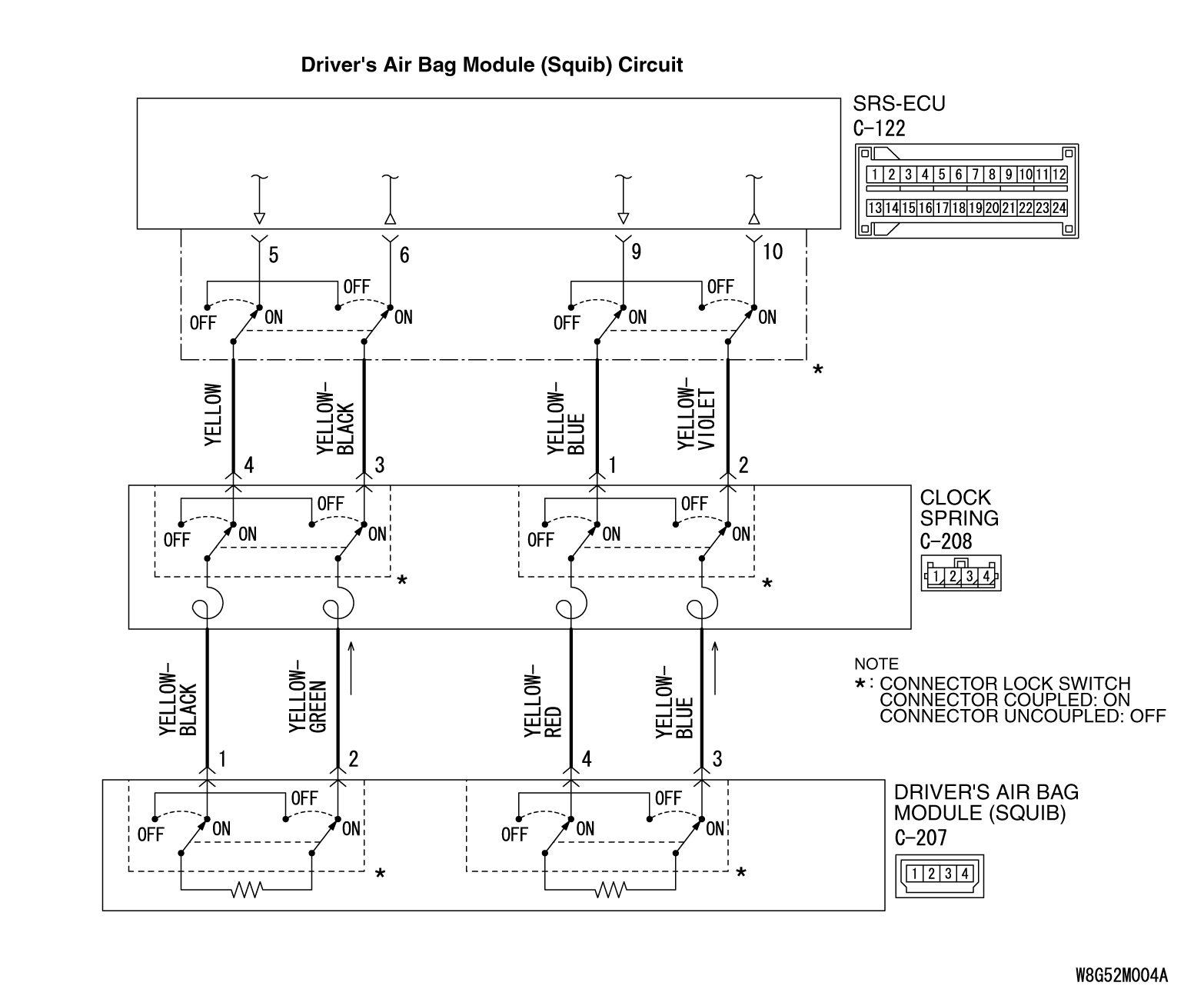

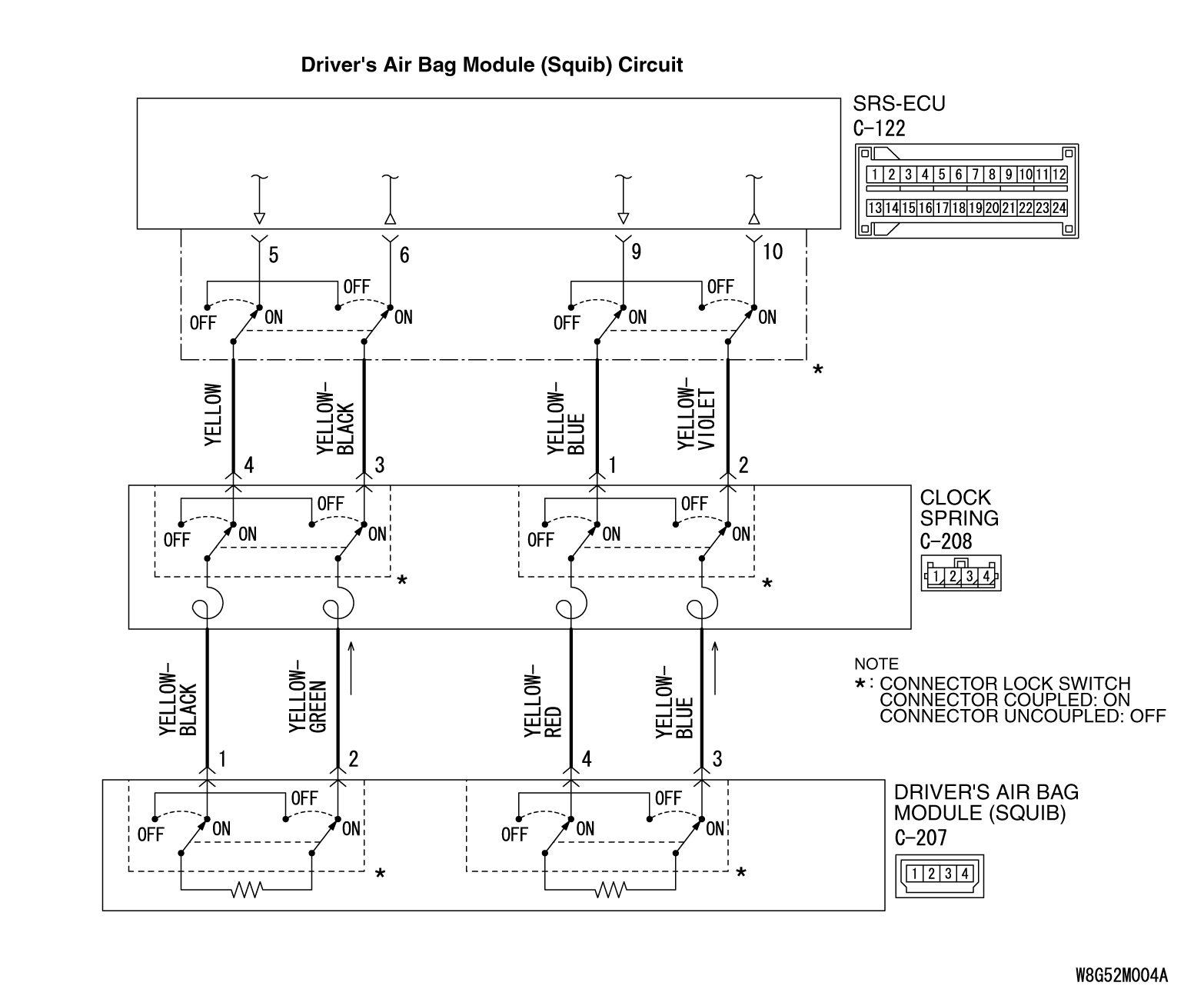

CIRCUIT OPERATION

- The SRS-ECU judges how severe a collision is by detecting signals from the

front impact sensors and the front air bag analog G-sensor. If the impact is over a predetermined

level, the SRS-ECU sends an ignition signal. At this time, if the front air bag safing G-sensor

is on, the SRS air bag will inflate.

- The ignition signal is input to the air bag module via the clock spring to inflate

the air bag.

DTC SET CONDITIONS

- This DTC is set if there is abnormal resistance between

the input terminals of the driver’s air bag module (squib). The most likely causes

for this code to be set are the followings:

- Open circuit in the driver’s air bag module (squib)

or harness

- Open circuit in the clock spring

- Malfunction of connector contact

TROUBLESHOOTING HINTS

- Open circuit in the clock spring

- Open circuit due to improper neutral position of the clock spring

- Open circuit in the driver’s air bag module (squib) circuit

- Disengaged driver’s air bag module (squib) connector

- Improper connector contact

- Malfunction of the SRS-ECU

|

|

Required Special Tools:

- MB991958: Scan Tool (M.U.T.-III Sub Assembly)

- MB991824: Vehicle Communication Interface (V.C.I.)

- MB991827: M.U.T.-III USB Cable

- MB991910: M.U.T.-III Main Harness A (Vehicles with CAN Communication System)

- MB991865: Dummy resistor

- MB991866: Resister harness

|

|

|

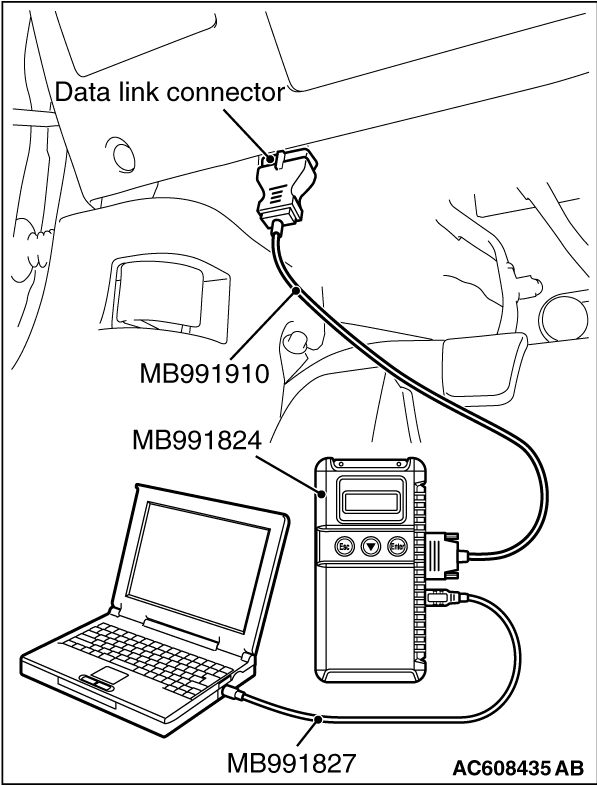

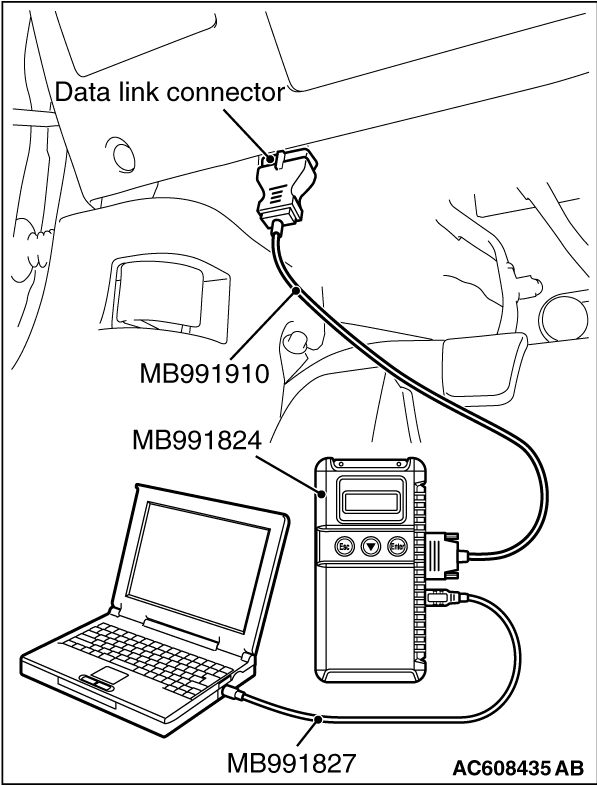

STEP 1. Using scan tool MB991958, diagnose the CAN bus line.

|

|

(1)

| caution |

To prevent damage to scan tool MB991958, always turn the ignition switch

to the "LOCK" (OFF) position before connecting or disconnecting scan tool MB991958.

|

Connect scan tool MB991958. Refer to "How to connect the scan tool  ." ."

(2)Turn the ignition switch to the "ON" position.

(3)Diagnose the CAN bus line.

(4)Turn the ignition switch to the "LOCK" (OFF) position.

Q.

Is the CAN bus line found to be normal?

Go to Step 2. Go to Step 2.

Repair the CAN bus line (Refer to GROUP 54C, Diagnosis Repair the CAN bus line (Refer to GROUP 54C, Diagnosis  ). ).

|

|

|

STEP 2. Recheck for diagnostic trouble code.

|

|

|

Check again if the DTC is set.

|

|

|

(2)Turn the ignition switch to the "ON" position.

|

|

|

(3)Check if the DTC is set.

|

|

|

(4)Turn the ignition switch to the "LOCK" (OFF) position.

|

|

|

Go to Step 3. Go to Step 3.

|

|

|

|

|

|

There is an intermittent malfunction such as poor engaged connector(s) or open

circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction There is an intermittent malfunction such as poor engaged connector(s) or open

circuit (Refer to GROUP 00, How to Cope with Intermittent Malfunction  ). ).

|

|

|

|

|

|

STEP 3. Check the driver’s air bag module.

|

|

|

(1)Disconnect the negative battery terminal.

|

|

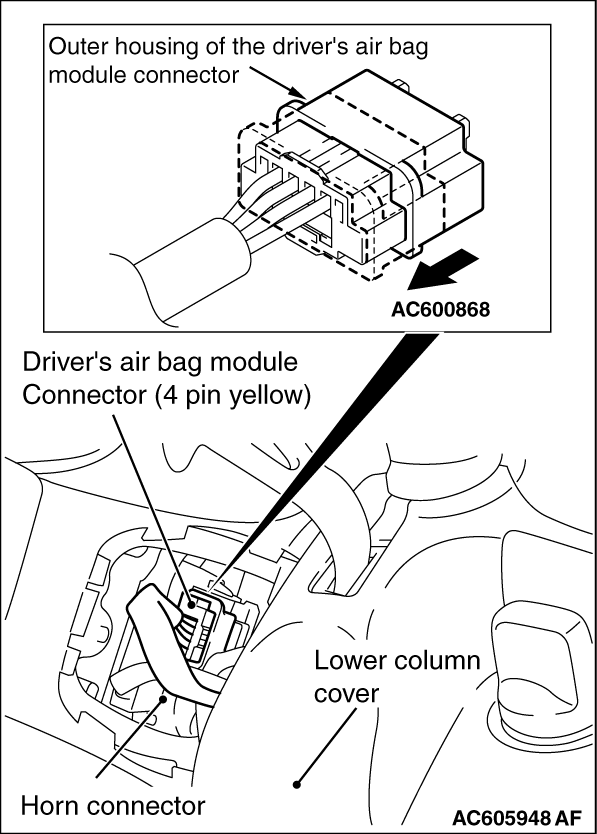

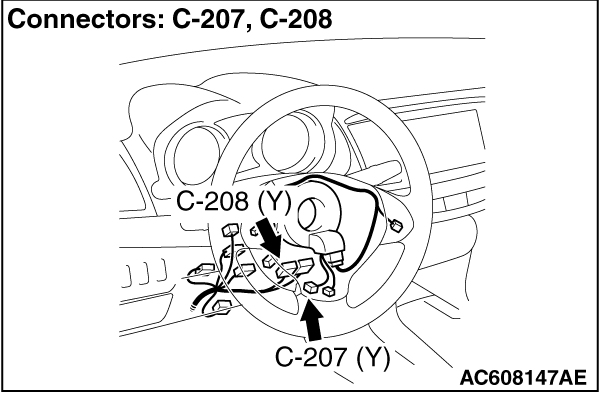

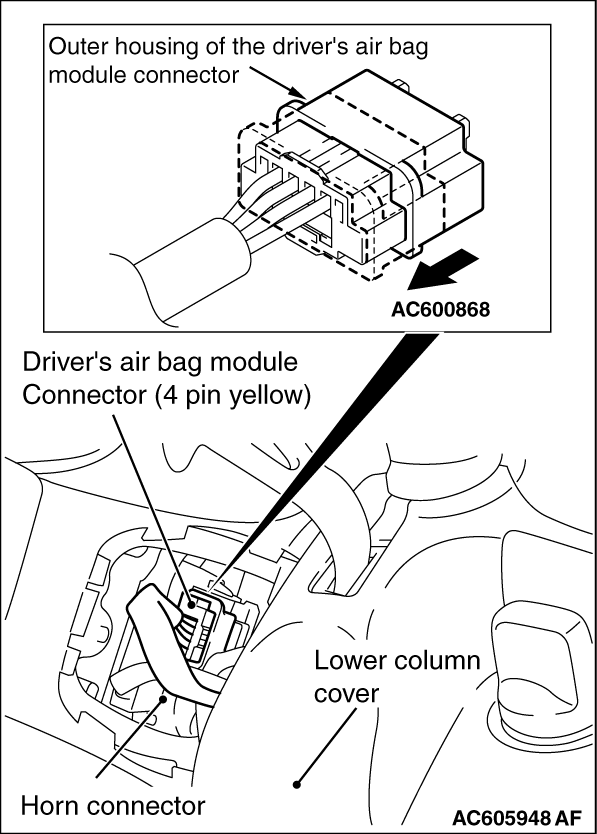

(2)Slide the outer housing of the driver’ s air bag module connector C-207 in the

arrow direction shown, and disconnect the connector.

|

|

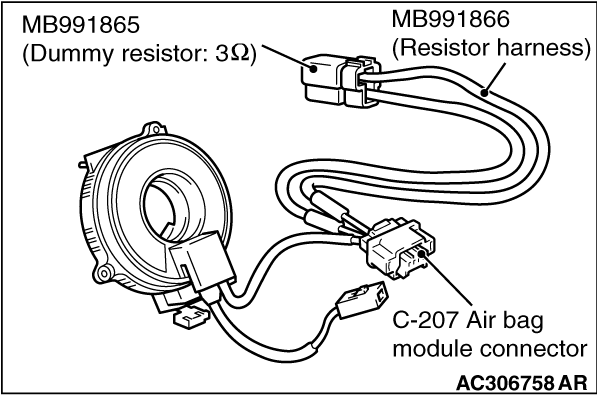

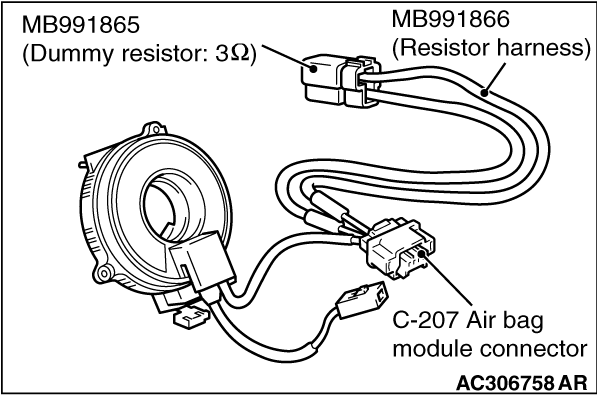

(3)Connect special tool MB991865 to special tool MB991866.

(4)

| caution |

Do not insert a test probe into the

terminal from its front side directly, as the connector contact pressure may be weakened.

|

Insert special tool MB991866 into clock spring side of driver’s air bag module

connector C-207 (terminal No.1 and 2 <1st squib> or terminal No.3 and 4 <2nd squib>)

by backprobing.

(5)Connect the negative battery terminal.

(6)

| caution |

Always DTC B1B06 is set when checking DTC B1B02. This is

because the second side terminal is isolated when checking it. DTC B1B06 is set but this is

not a fault. In addition, always DTC B1B02 is set when checking DTC B1B06 because the first

side terminal is isolated.

|

Erase the diagnostic trouble code memory, and check the diagnostic trouble code.

Q.

Is the checked DTC set?

Go to Step 4. Go to Step 4.

Replace the driver’s air bag module (Refer to Replace the driver’s air bag module (Refer to  ) <Except

RALLIART>, (Refer to ) <Except

RALLIART>, (Refer to  ) <RALLIART>. Then go to Step 6. ) <RALLIART>. Then go to Step 6.

|

|

|

STEP 4. Check the clock spring.

|

|

|

(1)Disconnect the negative battery terminal.

|

|

|

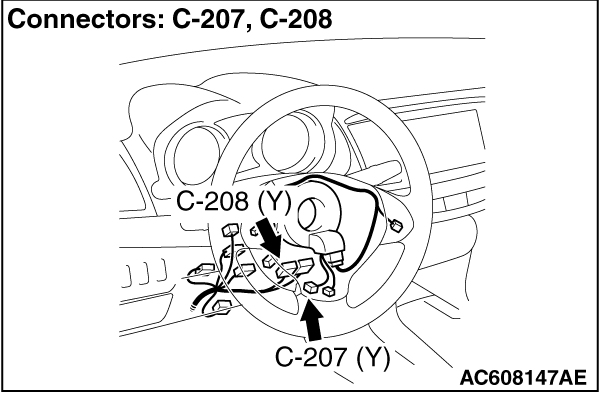

(2)Disconnect the clock spring connector C-208.

|

|

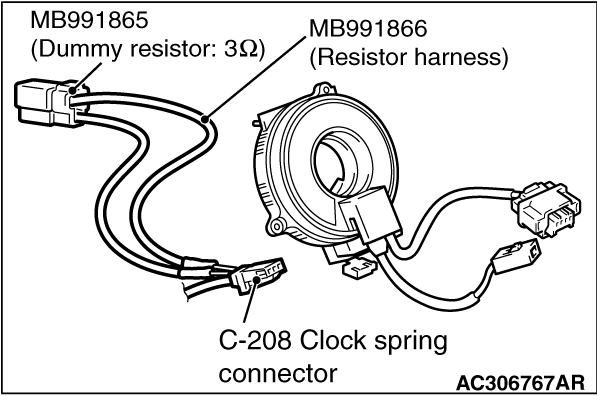

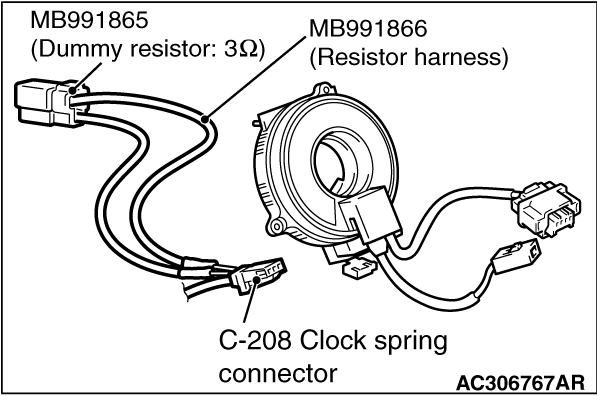

(3)Connect special tool MB991865 to special tool MB991866.

(4)

| caution |

Do not insert a probe into the terminal

from its front side directly, as the connector contact pressure may be weakened.

|

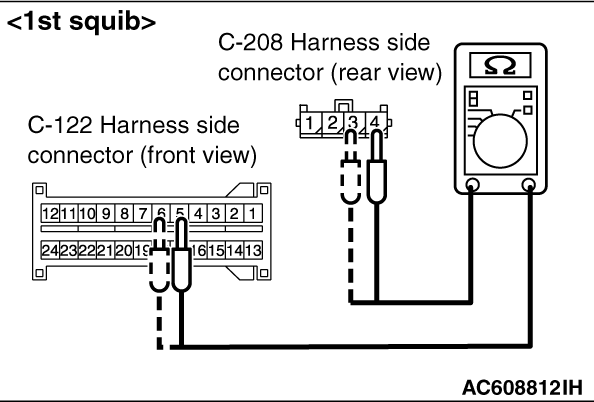

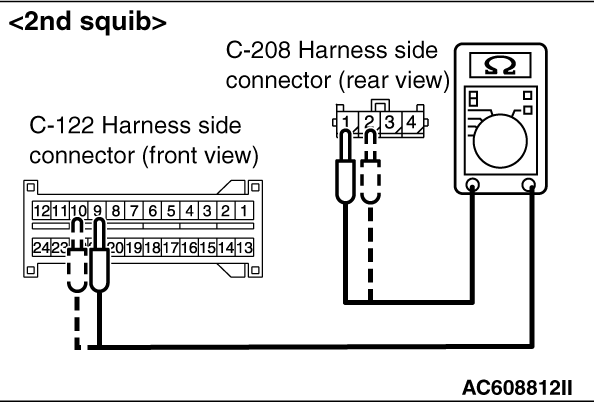

Insert special tool MB991866 into harness side of clock spring connector C-208 (terminal

No.3 and 4 <1st squib> or terminal No.1 and 2 <2nd squib>)

by backprobing.

(5)Connect the negative battery terminal.

(6)

| caution |

Always DTC B1B06 is set when checking DTC B1B02. This is

because the second side terminal is isolated when checking it. DTC B1B06 is set but this is

not a fault. In addition, always DTC B1B02 is set when checking DTC B1B06 because the first

side terminal is isolated.

|

Erase the diagnostic trouble code memory, and check the diagnostic trouble code.

Q.

Is the checked DTC set?

Go to Step 5. Go to Step 5.

Replace the clock spring (Refer to Replace the clock spring (Refer to  ) <Except RALLIART>,

(Refer to ) <Except RALLIART>,

(Refer to  ) <RALLIART>. Then go to Step 6. ) <RALLIART>. Then go to Step 6.

|

|

|

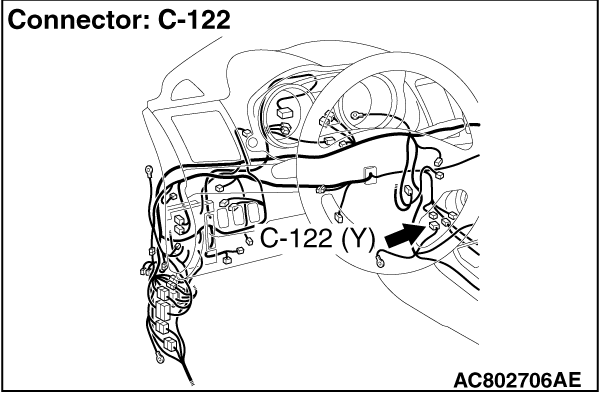

STEP 5. Check the harness for open circuit between the SRS-ECU connector

C-122 and the clock spring connector C-208.

|

|

|

(1)Disconnect the negative battery terminal.

|

|

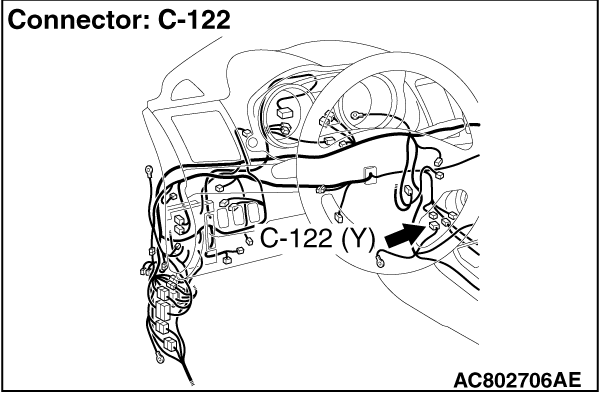

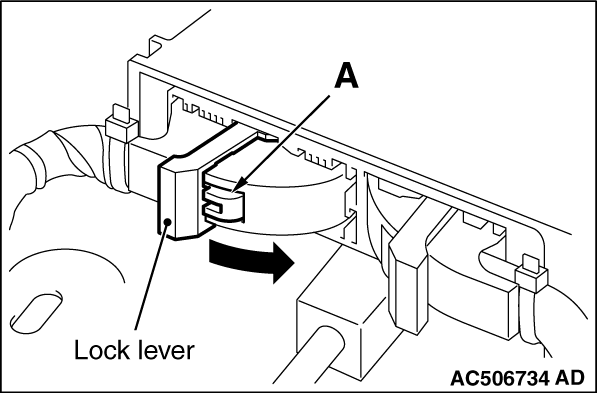

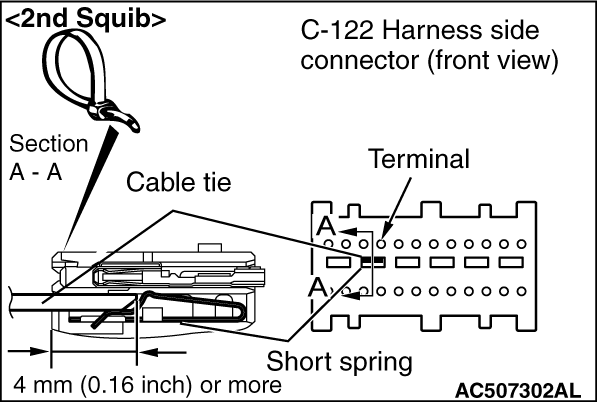

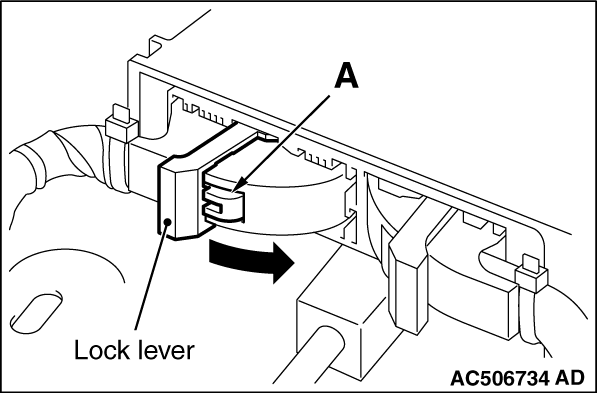

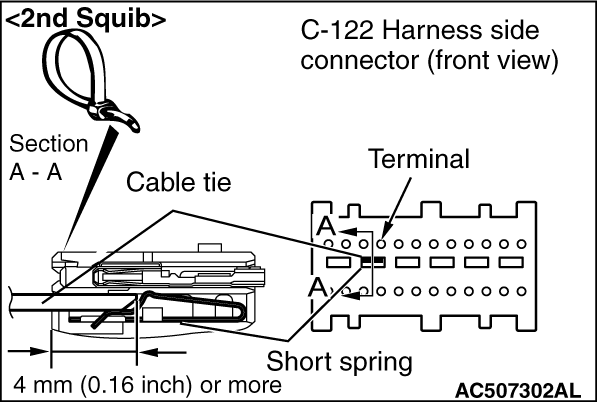

(2)While pushing the part "A" indicated in the figure of the harness side connector, turn

the lock lever to the direction of the arrow to release the lock lever, and disconnect the C-122

SRS-ECU connector.

(3)Disconnect the clock spring connector C-208.

|

|

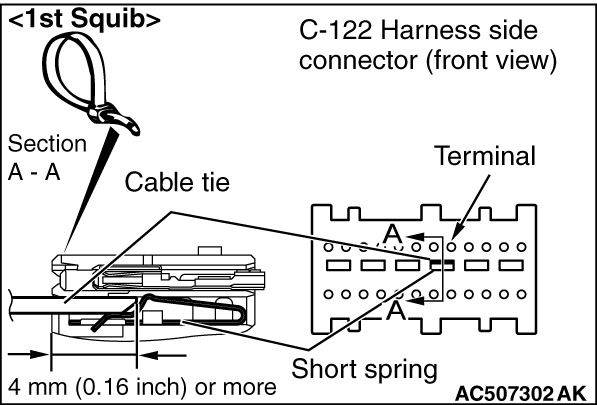

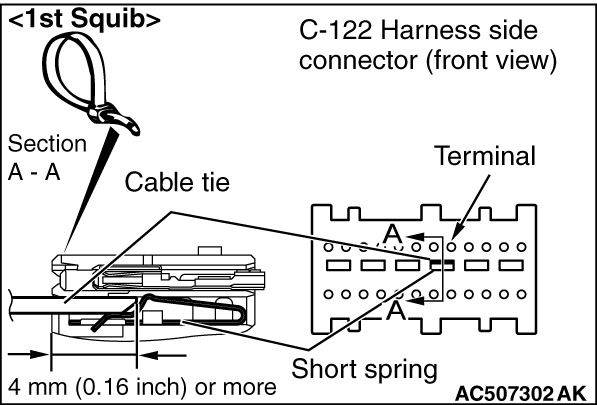

(4)

| caution |

Insert an insulator such as a cable tie to a depth of 4mm (0.16 inch) or more, otherwise

the short spring will not be released.

|

Insert a cable tie [3 mm (0.12 inch) wide, 0.5 mm (0.02 inch) thick] between

terminals 5, 6 <1st squib> or 9, 10 <2nd squib> and the

short spring to release the short spring.

|

|

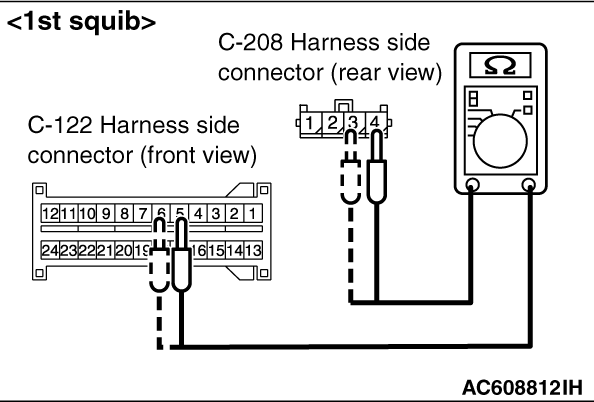

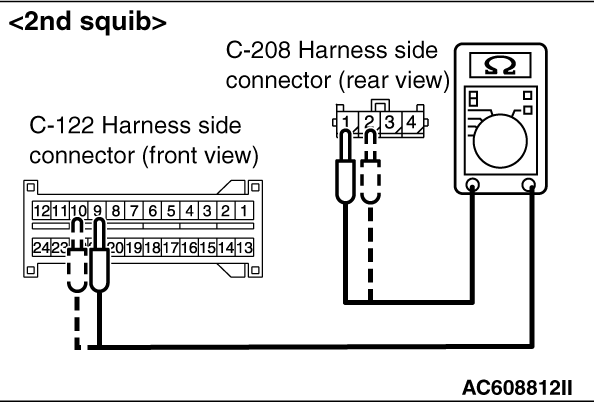

(5)

| caution |

Do not insert a probe into the terminal from C-208

harness side connector front side directly, as the connector contact pressure may be weakened.

|

Check for continuity between the following terminals. It should be less than 2 ohms.

- SRS-ECU connector C-122 (terminal No.5) and the clock spring connector C-208

(terminal No.4) <1st squib>

- SRS-ECU connector C-122 (terminal No.6) and the clock spring connector C-208 (terminal

No.3) <1st squib>

- SRS-ECU connector C-122 (terminal No.9) and the clock spring connector C-208

(terminal No.1) <2nd squib>

- SRS-ECU connector C-122 (terminal No.10) and the clock spring connector C-208 (terminal

No.2) <2nd squib>

Q.

Does continuity exist?

Erase the diagnostic trouble code memory, and check the diagnostic trouble code.

If DTCB1B02 <1st squib> or B1B06 <2nd squib> set, replace the

SRS-ECU (Refer to Erase the diagnostic trouble code memory, and check the diagnostic trouble code.

If DTCB1B02 <1st squib> or B1B06 <2nd squib> set, replace the

SRS-ECU (Refer to  ). Then go to Step 6. ). Then go to Step 6.

Repair the harness wires between SRS-ECU connector C-122 and clock spring connector

C-208. Then go to Step 6. Repair the harness wires between SRS-ECU connector C-122 and clock spring connector

C-208. Then go to Step 6.

|

|

|

STEP 6. Recheck for diagnostic trouble code.

|

|

|

Check again if the DTC is set.

|

|

|

(2)Turn the ignition switch to the "ON" position.

|

|

|

(3)Check if the DTC is set.

|

|

|

(4)Turn the ignition switch to the "LOCK" (OFF) position.

|

|

|

Q.

Is DTCB1B02 <1st squib> or B1B06 <2nd squib> set?

|

|

|

Return to Step 1. Return to Step 1.

|

|

|

|

|

|

The procedure is complete. The procedure is complete.

|

|

|

|

."

." Go to Step 2.

Go to Step 2. Repair the CAN bus line (Refer to GROUP 54C, Diagnosis

Repair the CAN bus line (Refer to GROUP 54C, Diagnosis  ).

).![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)