![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)

DTC C1210 Abnormality

in G and yaw rate sensor (Abnormality in longitudinal G sensor output voltage) <AWD>

|

|

| caution |

- If there is

any problem in the CAN bus lines, an incorrect DTC may be set. Prior to this diagnosis, diagnose

the CAN bus lines (Refer to GROUP 54C - Diagnostic trouble code diagnosis

). ).

- Whenever ECU is replaced, ensure that the CAN bus lines are normal.

- Do not drop or shock the G and yaw rate sensor.

- When the G and yaw rate sensor is replaced, always carry out calibration to make

ASC-ECU learn the neutral point (Refer to

). ).

- When the hydraulic unit (integrated with ASC-ECU) is replaced, always carry out

the calibration of the steering wheel sensor, the G and yaw rate sensor and brake fluid pressure

sensor (Refer to

, ,  and and  ). ).

|

|

|

|

- ABS-ECU monitors if the output of G and yaw rate sensor is normal or not.

|

|

|

This DTC is set if any malfunction below is found:

|

|

|

- When the output value of the longitudinal G-sensor is abnormal

- When abnormality is detected by the self-diagnosis of the longitudinal G-sensor

|

|

|

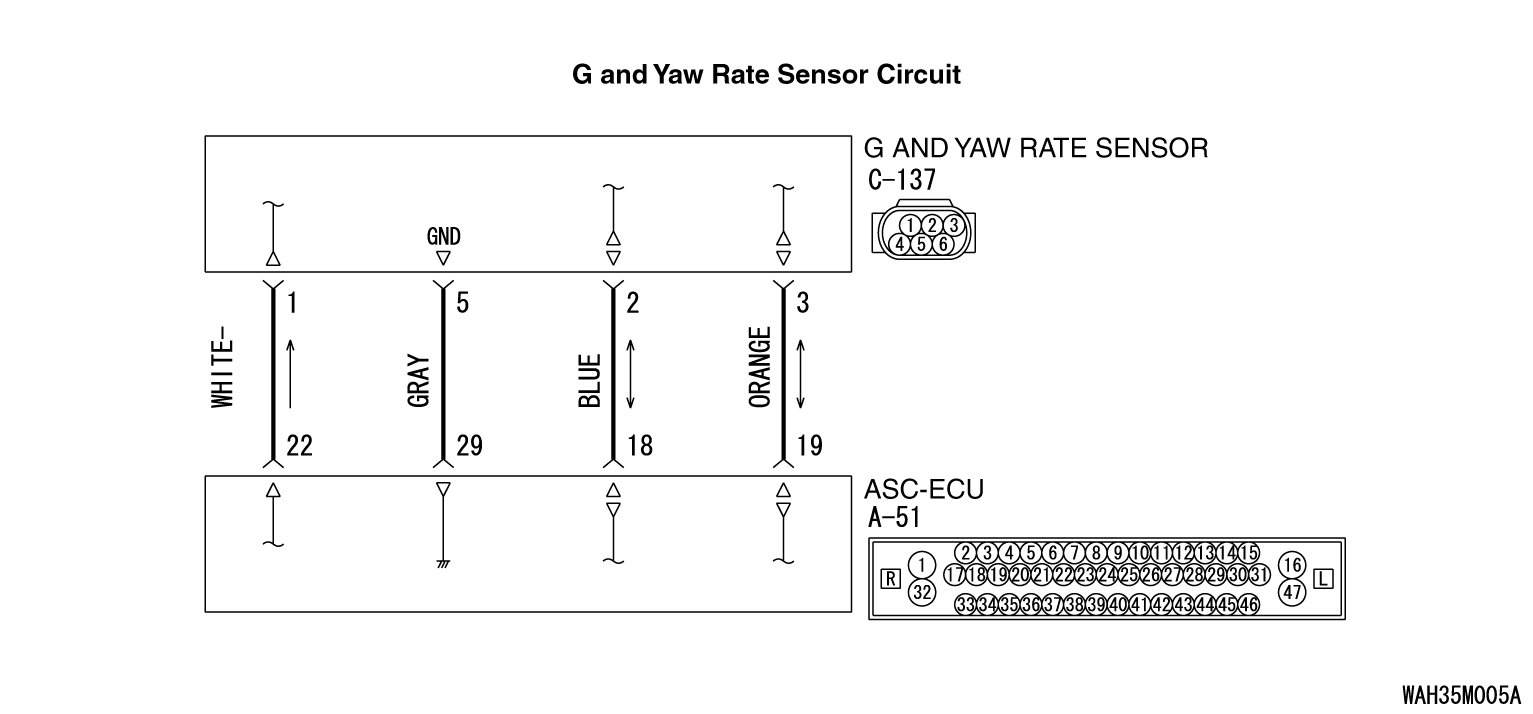

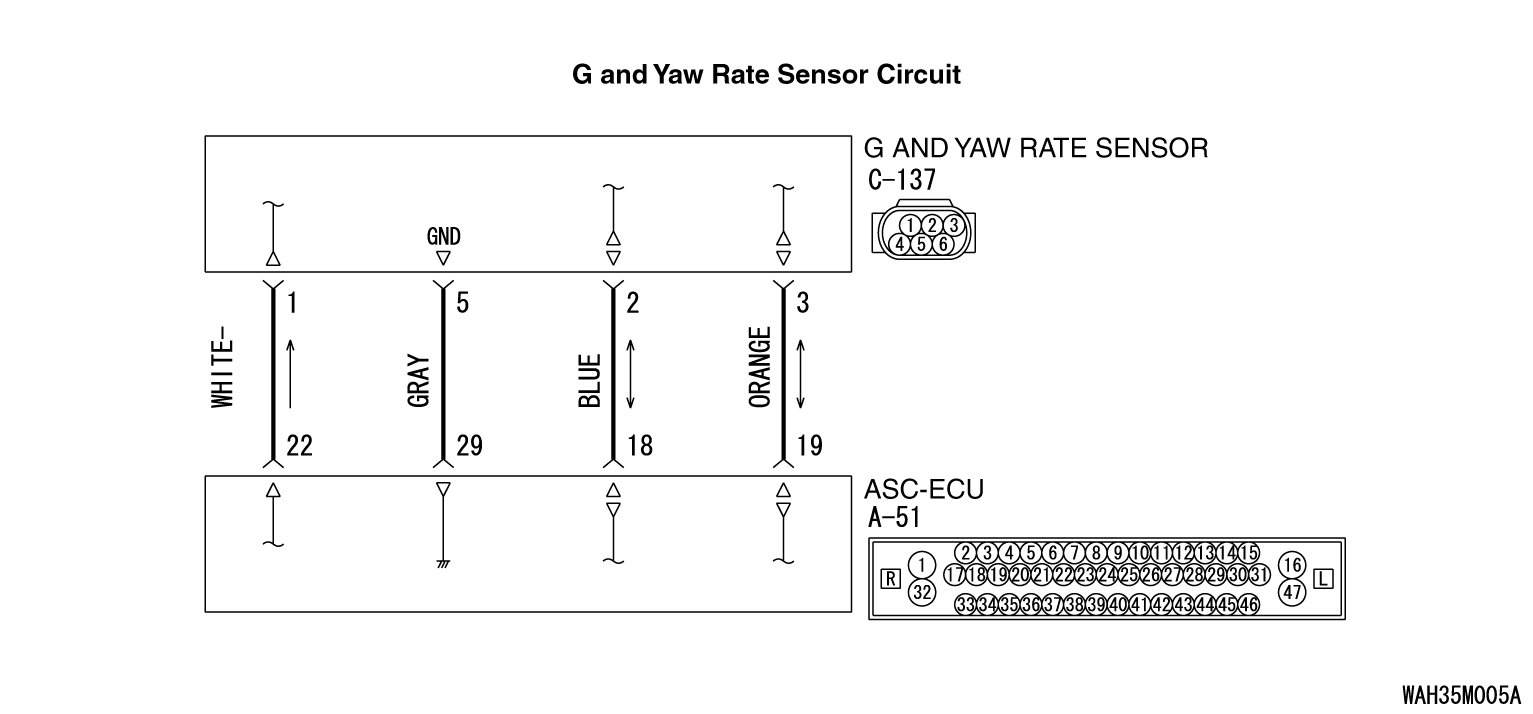

- Wiring harness or connector failure for the special CAN bus lines between

ASC-ECU and the G and yaw rate sensor

- G and yaw rate sensor malfunction

- ASC-ECU malfunction

- External noise interference

|

|

|

Required Special Tools:

- MB991958: Scan Tool (M.U.T.-III Sub Assembly)

- MB991824: Vehicle Communication Interface (V.C.I.)

- MB991827: M.U.T.-III USB Cable

- MB991910: M.U.T.-III Main Harness A

|

|

|

STEP 1. Using scan tool MB991958, diagnose the CAN bus lines.

|

|

|

Use scan tool to diagnose the CAN bus lines.

|

|

|

Q.

Is the check result normal?

|

|

|

Go to Step 3. Go to Step 3.

|

|

|

|

|

|

Repair the CAN bus lines (Refer to GROUP 54C - CAN Bus Diagnostic table Repair the CAN bus lines (Refer to GROUP 54C - CAN Bus Diagnostic table  ).

On completion, go to Step 2. ).

On completion, go to Step 2.

|

|

|

|

|

|

STEP 2. DTC recheck after resetting CAN bus lines

|

|

|

Go to Step 3. Go to Step 3.

|

|

|

|

|

|

The procedure is complete. The procedure is complete.

|

|

|

|

|

|

STEP 3. Using scan tool MB991958, check the data list

|

|

|

Check the following service data (Refer to  ). ).

|

|

|

Q.

Is the check result normal?

|

|

|

Go to Step 6. Go to Step 6.

|

|

|

|

|

|

Go to Step 4. Go to Step 4.

|

|

|

|

|

|

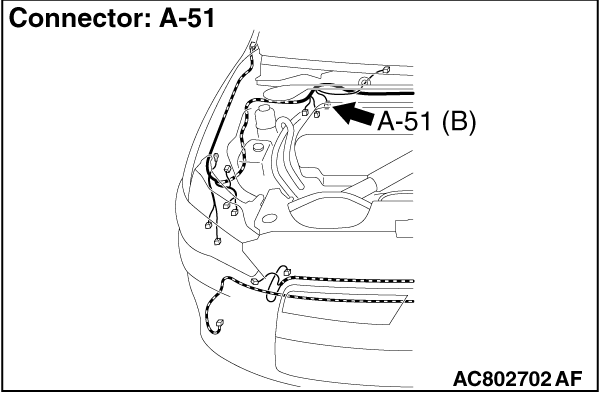

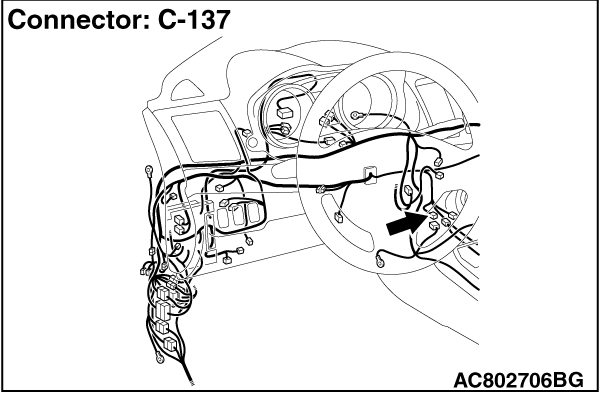

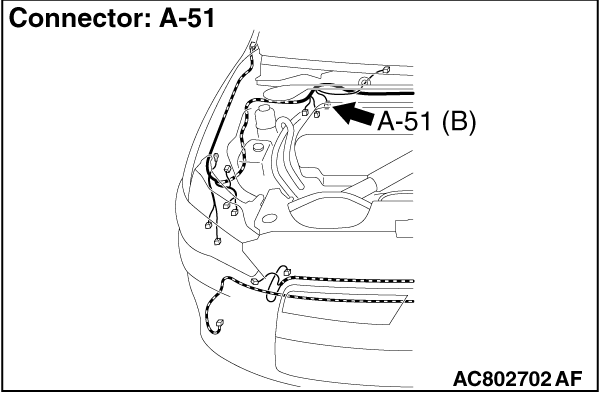

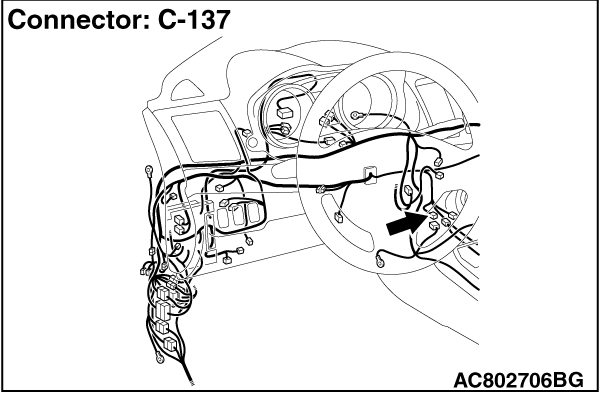

STEP 4. Connector check: A-51 ASC-ECU connector, C-137 G and yaw rate

sensor connector

|

|

|

Q.

Is the check result normal?

|

|

|

Go to Step 5. Go to Step 5.

|

|

|

|

|

|

Repair the connector, and then go to Step 8. Repair the connector, and then go to Step 8.

|

|

|

|

|

|

STEP 5. Wiring harness check between A-51 ASC-ECU connector terminal

No. 18 and C-137 G and yaw rate sensor connector terminal No. 2 as well as between A-51 ASC-ECU

connector terminal No. 19 and C-137 G and yaw rate sensor connector terminal No. 3

|

|

|

- Check the communication circuit for open and short circuit.

|

|

|

Q.

Is the check result normal?

|

|

|

Replace the G and yaw rate sensor (Refer to Replace the G and yaw rate sensor (Refer to  ) and

then go to Step 7. ) and

then go to Step 7.

|

|

|

|

|

|

Repair the wiring harness, and then go to Step 8. Repair the wiring harness, and then go to Step 8.

|

|

|

|

|

|

STEP 6. Check whether the DTC is reset.

|

|

|

(2)Drive the vehicle at 12mph (20 km/h) or higher.

|

|

|

Replace the G and yaw rate sensor (Refer to Replace the G and yaw rate sensor (Refer to  ), and then

go to Step 8. ), and then

go to Step 8.

|

|

|

|

|

|

Intermittent malfunction (Refer to GROUP 00 - How to Cope with Intermittent

Malfunction Intermittent malfunction (Refer to GROUP 00 - How to Cope with Intermittent

Malfunction  ). ).

|

|

|

|

|

|

STEP 7. Check whether the DTC is reset.

|

|

|

(2)Drive the vehicle at 12mph (20 km/h) or higher.

|

|

|

Replace the hydraulic unit (integrated with ASC-ECU) (Refer to Replace the hydraulic unit (integrated with ASC-ECU) (Refer to  ),

and then go to Step 8. ),

and then go to Step 8.

|

|

|

|

|

|

The procedure is complete. The procedure is complete.

|

|

|

|

|

|

STEP 8. Check whether the DTC is reset.

|

|

|

(2)Drive the vehicle at 12mph (20 km/h) or higher.

|

|

|

Return to Step 1. Return to Step 1.

|

|

|

|

|

|

The procedure is complete. The procedure is complete.

|

|

|

|

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)

Go to Step 3.

Go to Step 3. Repair the CAN bus lines (Refer to GROUP 54C - CAN Bus Diagnostic table

Repair the CAN bus lines (Refer to GROUP 54C - CAN Bus Diagnostic table  ).

On completion, go to Step 2.

).

On completion, go to Step 2. Go to Step 3.

Go to Step 3. The procedure is complete.

The procedure is complete. ).

). Go to Step 6.

Go to Step 6. Go to Step 4.

Go to Step 4. Go to Step 5.

Go to Step 5. Repair the connector, and then go to Step 8.

Repair the connector, and then go to Step 8. Replace the G and yaw rate sensor (Refer to

Replace the G and yaw rate sensor (Refer to  ) and

then go to Step 7.

) and

then go to Step 7. Repair the wiring harness, and then go to Step 8.

Repair the wiring harness, and then go to Step 8. Replace the G and yaw rate sensor (Refer to

Replace the G and yaw rate sensor (Refer to  ), and then

go to Step 8.

), and then

go to Step 8. Intermittent malfunction (Refer to GROUP 00 - How to Cope with Intermittent

Malfunction

Intermittent malfunction (Refer to GROUP 00 - How to Cope with Intermittent

Malfunction  ).

). Replace the hydraulic unit (integrated with ASC-ECU) (Refer to

Replace the hydraulic unit (integrated with ASC-ECU) (Refer to  ),

and then go to Step 8.

),

and then go to Step 8. The procedure is complete.

The procedure is complete. Return to Step 1.

Return to Step 1. The procedure is complete.

The procedure is complete.