![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)

DTC C1009 Low

brake fluid level

|

|

| caution |

- If there is

any problem in the CAN bus lines, an incorrect DTC may be set. Prior to this diagnosis, diagnose

the CAN bus lines (Refer to GROUP 54C - Diagnostic trouble code diagnosis

). ).

- Whenever ECU is replaced, ensure that the CAN bus lines are normal.

- When the hydraulic unit (integrated with ASC-ECU) is replaced, always carry out

the calibration of the steering wheel sensor, the G and yaw rate sensor and brake fluid pressure

sensor (Refer to

, ,  and and  ). ).

|

|

|

|

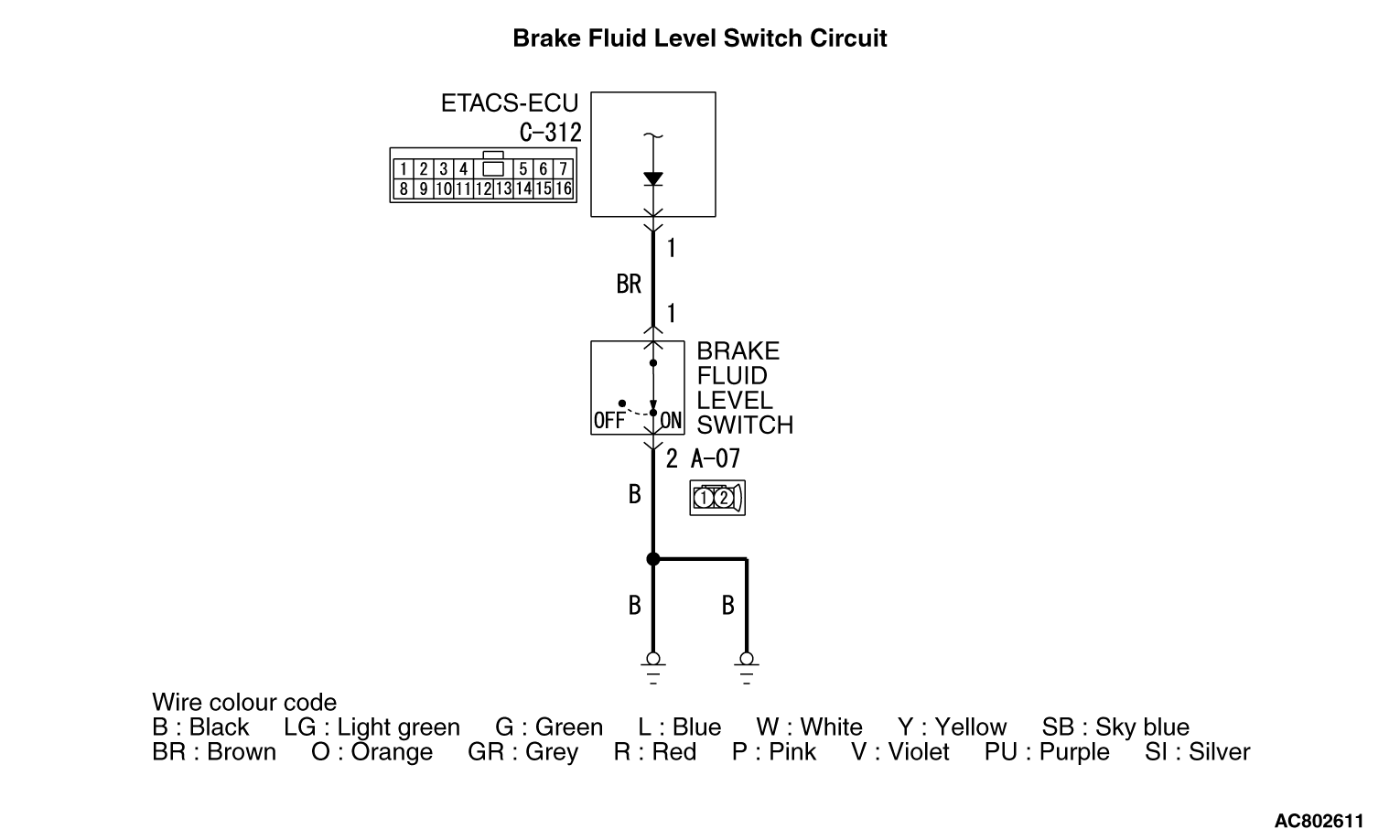

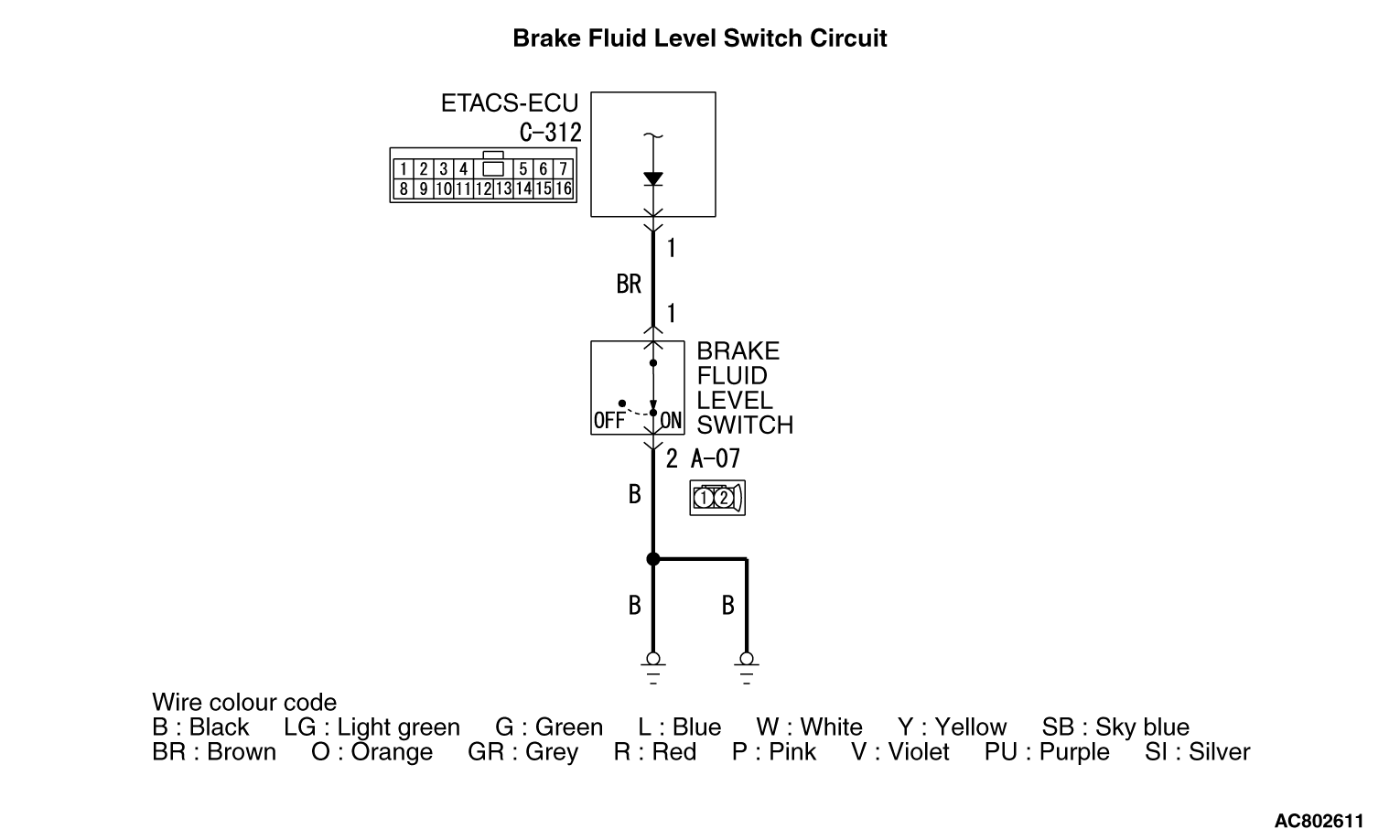

ASC-ECU receives the OFF signal of the brake fluid level switch in ETACS-ECU via the CAN

bus lines. This indicates that the brake fluid level is lower than the specified.

|

|

|

This DTC is set when the brake fluid level is lower than the specified.

|

|

|

- Low brake fluid level

- Brake fluid level switch malfunction

- Brake pad wear

- Damaged wiring harness and connectors

- Malfunction of ETACS-ECU

- ASC-ECU malfunction

|

|

|

Required Special Tools:

- MB991958: Scan Tool (M.U.T.-III Sub Assembly)

- MB991824: Vehicle Communication Interface (V.C.I.)

- MB991827: M.U.T.-III USB Cable

- MB991910: M.U.T.-III Main Harness A

|

|

|

STEP 1. M.U.T.-III CAN bus diagnostics

|

|

|

Use scan tool to diagnose the CAN bus lines.

|

|

|

Q.

Is the check result normal?

|

|

|

Go to Step 3. Go to Step 3.

|

|

|

|

|

|

Repair the CAN bus lines (Refer to GROUP 54C - CAN Bus Diagnostic table Repair the CAN bus lines (Refer to GROUP 54C - CAN Bus Diagnostic table  ).

On completion, go to Step 2. ).

On completion, go to Step 2.

|

|

|

|

|

|

STEP 2. DTC recheck after resetting CAN bus lines

|

|

|

Go to Step 3. Go to Step 3.

|

|

|

|

|

|

The procedure is complete. The procedure is complete.

|

|

|

|

|

|

STEP 3. Brake fluid level check

|

|

|

Check that the brake fluid level is higher than the lower limit.

|

|

|

Q.

Is the check result normal?

|

|

|

Go to Step 6. Go to Step 6.

|

|

|

|

|

|

Go to Step 4. Go to Step 4.

|

|

|

|

|

|

Check that the brake pad is thicker than the limit (Refer to GROUP 35A - On-vehicle

Service, Brake Pad Check  ). ).

|

|

|

Q.

Is the check result normal?

|

|

|

Go to Step 5. Go to Step 5.

|

|

|

|

|

|

Replace the brake pad <Refer to GROUP 35A - On-vehicle Service, Brake

Pad Replacement Replace the brake pad <Refer to GROUP 35A - On-vehicle Service, Brake

Pad Replacement  (Except RALLIART), (Except RALLIART),  (RALLIART)>,

and then add brake fluid as necessary. Then go to Step 13. (RALLIART)>,

and then add brake fluid as necessary. Then go to Step 13.

|

|

|

|

|

|

STEP 5. Brake fluid leak check

|

|

|

Check that the brake fluid is not leaking from the hydraulic unit (incorporated in ASC-ECU),

brake caliper, brake hose, brake tube, or master cylinder assembly.

|

|

|

Q.

Is the check result normal?

|

|

|

Fill the brake fluid up to the "MAX" level. Then go to Step 13. Fill the brake fluid up to the "MAX" level. Then go to Step 13.

|

|

|

|

|

|

Repair the brake fluid leak area. Then go to Step 13. Repair the brake fluid leak area. Then go to Step 13.

|

|

|

|

|

|

STEP 6. Brake fluid level switch check

|

|

|

Refer to GROUP 35A - On-vehicle service  . .

|

|

|

Q.

Is the check result normal?

|

|

|

Go to Step 7. Go to Step 7.

|

|

|

|

|

|

Replace the reservoir assembly <Refer to GROUP 35A - Master Cylinder

Assembly and Brake Booster Replace the reservoir assembly <Refer to GROUP 35A - Master Cylinder

Assembly and Brake Booster  (Except RALLIART), (Except RALLIART),  (RALLIART)>.

Then go to Step 13. (RALLIART)>.

Then go to Step 13.

|

|

|

|

|

|

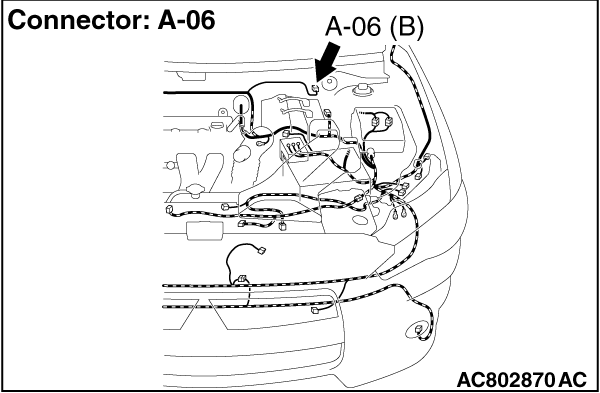

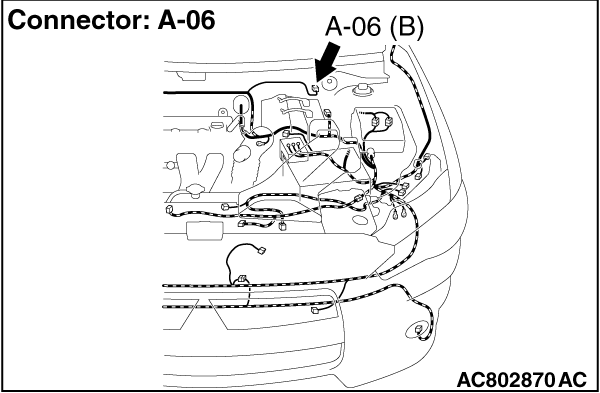

STEP 7. Connector check: A-06 brake fluid level switch connector,

C-312 ETACS-ECU connector

|

|

|

Q.

Is the check result normal?

|

|

|

Go to Step 8. Go to Step 8.

|

|

|

|

|

|

Repair the damaged connector. Repair the damaged connector.

|

|

|

|

|

|

STEP 8. Voltage measurement at A-06 brake fluid level switch connector

|

|

|

(1)Disconnect the connector, and measure at the wiring harness side.

|

|

|

(2)Turn the ignition switch to the ON position.

|

|

|

(3)Measure the voltage between the terminal No.1 and the body ground.

OK: Approximately 5 V

|

|

|

Q.

Is the check result normal?

|

|

|

Go to Step 10. Go to Step 10.

|

|

|

|

|

|

Go to Step 9. Go to Step 9.

|

|

|

|

|

|

STEP 9. Voltage measurement at C-312 ETACS-ECU connector

|

|

|

| caution |

With the C-312 ETACS-ECU connector kept connected, disconnect

the A-07 brake fluid level switch connector.

|

|

|

|

(1)Turn the ignition switch to the ON position.

|

|

|

(2)Measure the voltage between the terminal No.1 and the body ground to the back probing.

OK: Approximately 5 V

|

|

|

Q.

Is the check result normal?

|

|

|

Repair the wiring harness between the C-312 ETACS-ECU connector terminal No.1

and the A-06 brake fluid level switch connector terminal No.1. Repair the wiring harness between the C-312 ETACS-ECU connector terminal No.1

and the A-06 brake fluid level switch connector terminal No.1.

|

|

|

|

|

|

Replace the ETACS-ECU (Refer to GROUP 54A - ETACS-ECU Replace the ETACS-ECU (Refer to GROUP 54A - ETACS-ECU  ), and

then go to Step 13. ), and

then go to Step 13.

|

|

|

|

|

|

STEP 10. Harness check: Between A-06 brake fluid level switch connector

and the body ground

|

|

|

Check the wiring harness for open circuit between the A-06 brake fluid level switch connector

terminal No.2 and the body ground.

|

|

|

Q.

Is the check result normal?

|

|

|

Go to Step 11. Go to Step 11.

|

|

|

|

|

|

Repair the wiring harness. Repair the wiring harness.

|

|

|

|

|

|

STEP 11. M.U.T.-III data list

|

|

|

Check the following service data (Refer to  ). ).

|

|

|

- Item 26: Brake fluid level switch

|

|

|

Q.

Is the check result normal?

|

|

|

Go to Step 12. Go to Step 12.

|

|

|

|

|

|

Replace the ETACS-ECU (Refer to GROUP 54A - ETACS-ECU Replace the ETACS-ECU (Refer to GROUP 54A - ETACS-ECU  ), and

then go to Step 13. ), and

then go to Step 13.

|

|

|

|

|

|

STEP 12. Check whether the DTC is reset.

|

|

|

(2)Ignition switch "LOCK" (OFF)

|

|

|

Replace the hydraulic unit (ASC-ECU) (Refer to Replace the hydraulic unit (ASC-ECU) (Refer to  ). Then

go to Step 13. ). Then

go to Step 13.

|

|

|

|

|

|

The trouble can be an intermittent malfunction (Refer to GROUP 00 - How

to Cope with Intermittent Malfunction The trouble can be an intermittent malfunction (Refer to GROUP 00 - How

to Cope with Intermittent Malfunction  ). ).

|

|

|

|

|

|

STEP 13. Check whether the DTC is reset.

|

|

|

(2)Ignition switch "LOCK" (OFF)

|

|

|

Return to Step 1. Return to Step 1.

|

|

|

|

|

|

The procedure is complete. The procedure is complete.

|

|

|

|

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)

Go to Step 3.

Go to Step 3. Repair the CAN bus lines (Refer to GROUP 54C - CAN Bus Diagnostic table

Repair the CAN bus lines (Refer to GROUP 54C - CAN Bus Diagnostic table  ).

On completion, go to Step 2.

).

On completion, go to Step 2. Go to Step 3.

Go to Step 3. The procedure is complete.

The procedure is complete. Go to Step 6.

Go to Step 6. Go to Step 4.

Go to Step 4. ).

). Go to Step 5.

Go to Step 5. Replace the brake pad <Refer to GROUP 35A - On-vehicle Service, Brake

Pad Replacement

Replace the brake pad <Refer to GROUP 35A - On-vehicle Service, Brake

Pad Replacement  (Except RALLIART),

(Except RALLIART),  (RALLIART)>,

and then add brake fluid as necessary. Then go to Step 13.

(RALLIART)>,

and then add brake fluid as necessary. Then go to Step 13. Fill the brake fluid up to the "MAX" level. Then go to Step 13.

Fill the brake fluid up to the "MAX" level. Then go to Step 13. Repair the brake fluid leak area. Then go to Step 13.

Repair the brake fluid leak area. Then go to Step 13. .

. Go to Step 7.

Go to Step 7. Replace the reservoir assembly <Refer to GROUP 35A - Master Cylinder

Assembly and Brake Booster

Replace the reservoir assembly <Refer to GROUP 35A - Master Cylinder

Assembly and Brake Booster  (Except RALLIART),

(Except RALLIART),  (RALLIART)>.

Then go to Step 13.

(RALLIART)>.

Then go to Step 13. Go to Step 8.

Go to Step 8. Repair the damaged connector.

Repair the damaged connector. Go to Step 10.

Go to Step 10. Go to Step 9.

Go to Step 9. Repair the wiring harness between the C-312 ETACS-ECU connector terminal No.1

and the A-06 brake fluid level switch connector terminal No.1.

Repair the wiring harness between the C-312 ETACS-ECU connector terminal No.1

and the A-06 brake fluid level switch connector terminal No.1. Replace the ETACS-ECU (Refer to GROUP 54A - ETACS-ECU

Replace the ETACS-ECU (Refer to GROUP 54A - ETACS-ECU  ), and

then go to Step 13.

), and

then go to Step 13. Go to Step 11.

Go to Step 11. Repair the wiring harness.

Repair the wiring harness. ).

). Go to Step 12.

Go to Step 12. Replace the ETACS-ECU (Refer to GROUP 54A - ETACS-ECU

Replace the ETACS-ECU (Refer to GROUP 54A - ETACS-ECU  ), and

then go to Step 13.

), and

then go to Step 13. Replace the hydraulic unit (ASC-ECU) (Refer to

Replace the hydraulic unit (ASC-ECU) (Refer to  ). Then

go to Step 13.

). Then

go to Step 13. The trouble can be an intermittent malfunction (Refer to GROUP 00 - How

to Cope with Intermittent Malfunction

The trouble can be an intermittent malfunction (Refer to GROUP 00 - How

to Cope with Intermittent Malfunction  ).

). Return to Step 1.

Return to Step 1. The procedure is complete.

The procedure is complete.