![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)

DTC C1047: FR

wheel speed sensor control phase time exceeded

|

|

| caution |

- If there is

any problem in the CAN bus lines, an incorrect DTC may be set. Prior to this diagnosis, diagnose

the CAN bus lines (Refer to GROUP 54C -

CAN Bus Line Diagnostic Flow

). ).

- Whenever ECU is replaced, ensure that the CAN bus lines are normal.

|

|

|

|

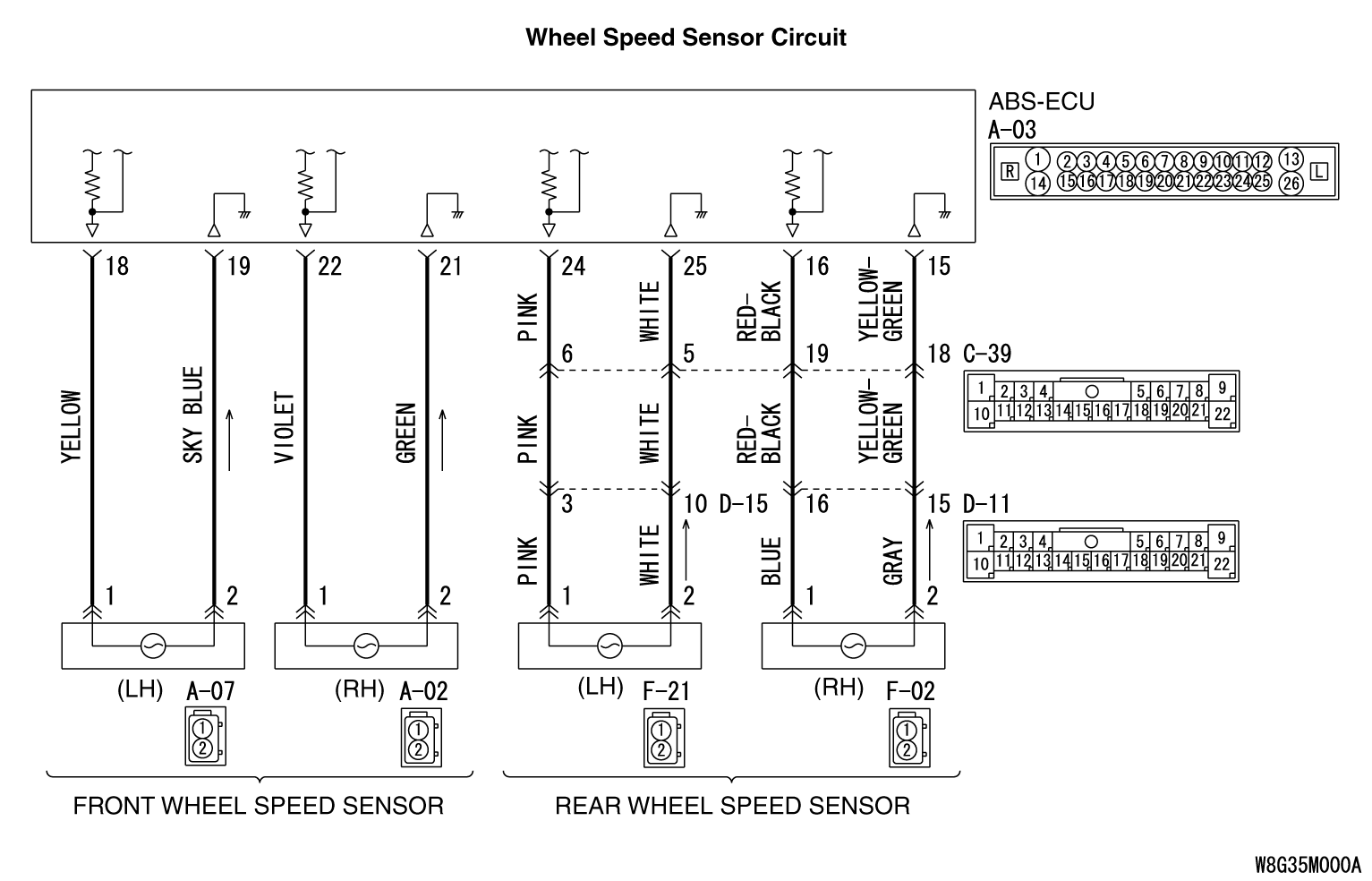

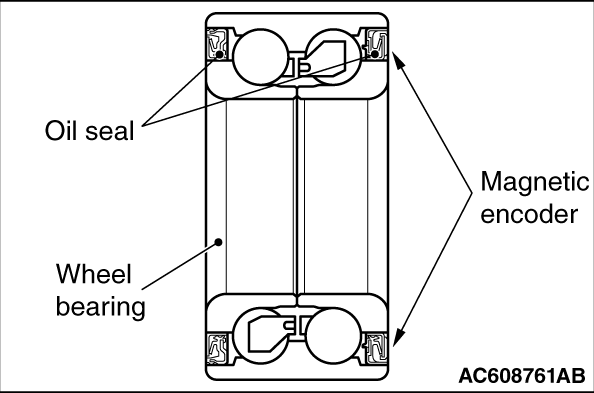

- The wheel speed sensor is a kind of a pulse generator. It consists of encoders

(a plate on which north and south pole sides of the magnets are arranged alternately) for detecting the

wheel speed which rotates at the same speed of the wheels and wheel speed sensors. This sensor

outputs frequency pulse signals in proportion to the wheel speed.

- The pulse signals, which the wheel speed sensor creates, are sent to ABS-ECU. ABS-ECU

uses the frequency of the pulse signals to determine the wheel speed.

|

|

|

This DTC is set if any malfunction below is found:

|

|

|

- When the brake fluid pressure is decreased for a long time.

- When the brake fluid pressure is held for a long time.

|

|

|

- Damaged wiring harness and connectors

- External noise interference

- Malfunction of wheel speed sensor

- ABS-ECU malfunction

- Excessive gap between the wheel speed sensor and the magnetic encoder for wheel

speed detection

- Adhesion of foreign materials on the wheel speed sensor

- Adhesion of foreign materials on the magnetic encoder for wheel speed detection

- Wheel bearing malfunction

- Improper installation of the wheel speed sensor

- Deformation of the magnetic encoder for wheel speed detection

- Disturbance of magnetization pattern for magnetic encoder for wheel speed detection

- Missing teeth of the magnetic encoder for wheel speed detection

|

|

|

Required Special Tools:

- MB991958: Scan Tool (M.U.T.-III Sub Assembly)

- MB991824: Vehicle Communication Interface (V.C.I.)

- MB991827: M.U.T.-III USB Cable

- MB991910: M.U.T.-III Main Harness A

|

|

|

STEP 1. Using scan tool MB991958, diagnose the CAN bus lines.

|

|

|

Use scan tool to diagnose the CAN bus lines.

|

|

|

Q.

Is the check result normal?

|

|

|

Go to Step 3. Go to Step 3.

|

|

|

|

|

|

Repair the CAN bus lines (Refer to GROUP 54C -

CAN Bus Diagnostics Table Repair the CAN bus lines (Refer to GROUP 54C -

CAN Bus Diagnostics Table  ).

On completion, go to Step 2. ).

On completion, go to Step 2.

|

|

|

|

|

|

STEP 2. DTC recheck after resetting CAN bus lines

|

|

|

Go to Step 3. Go to Step 3.

|

|

|

|

|

|

The procedure is complete. The procedure is complete.

|

|

|

|

|

|

STEP 3. Using scan tool MB991958, check the DTC

|

|

|

Check that the DTCs C1015, C101C, C101F, or C1042 are also set.

|

|

|

Q.

Are DTC C1015, C101C, C101F, or C1042 also set?

|

|

|

Carry out the diagnosis for the relevant DTCs. Carry out the diagnosis for the relevant DTCs.

|

|

|

|

|

|

Go to Step 4. Go to Step 4.

|

|

|

|

|

|

STEP 4. Using scan tool MB991958, check the data list

|

|

|

Check the following data list (Refer to  ). ).

|

|

|

- Item No.02: FR wheel speed sensor

|

|

|

Q.

Is the check result normal?

|

|

|

Go to Step 11. Go to Step 11.

|

|

|

|

|

|

Go to Step 5. Go to Step 5.

|

|

|

|

|

|

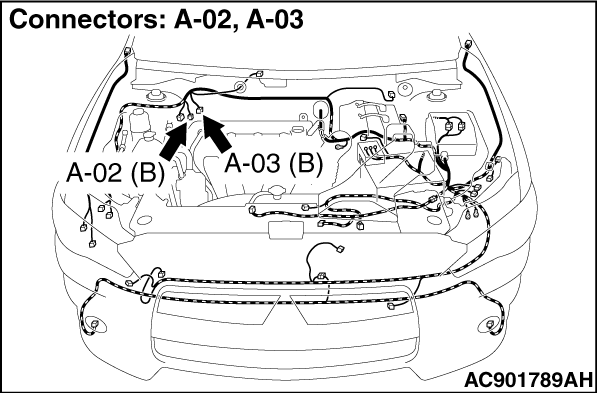

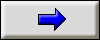

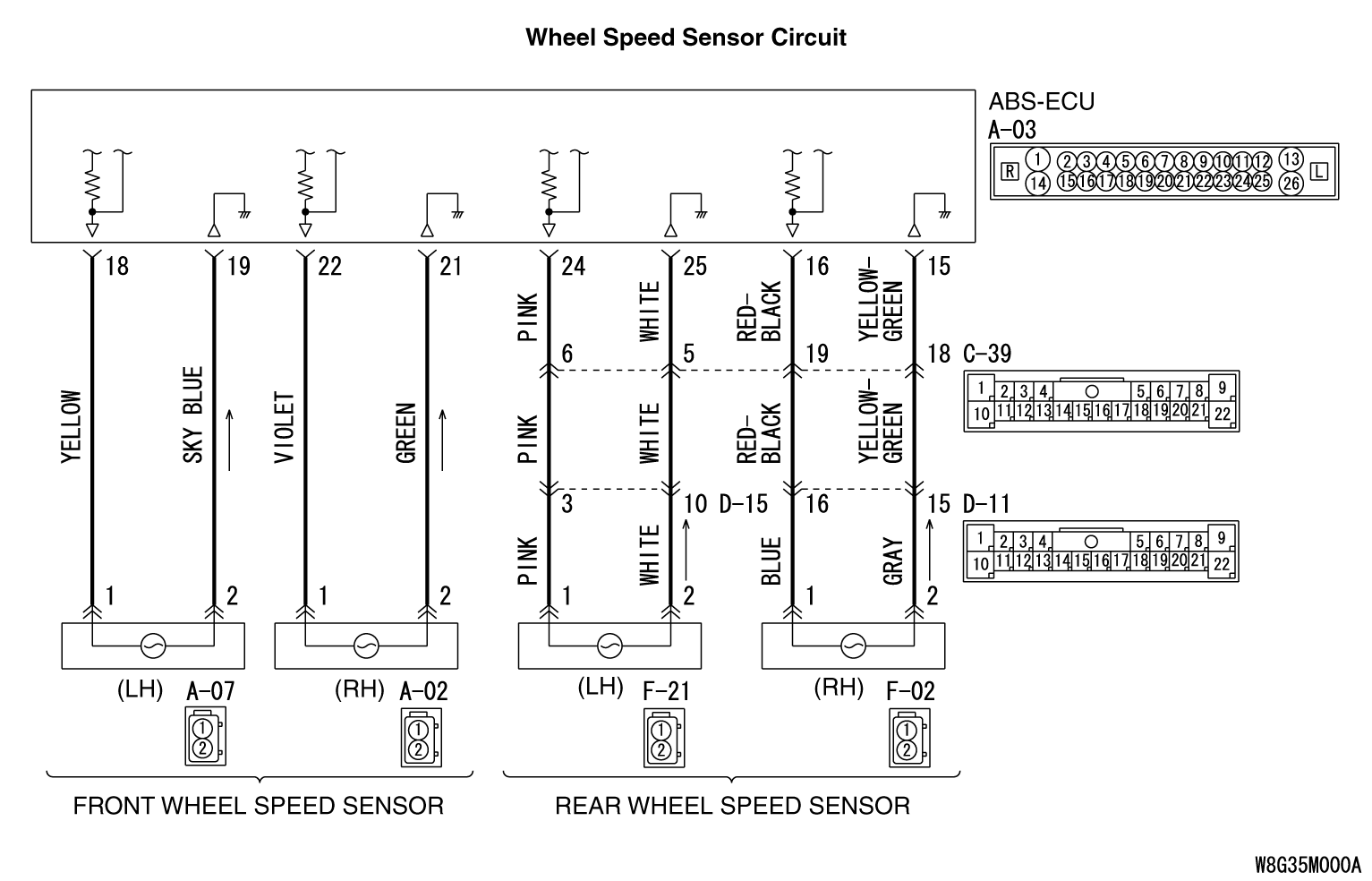

STEP 5. Connector check: A-03 ABS-ECU connector, A-02 front wheel

speed sensor (RH) connector

|

|

|

Q.

Is the check result normal?

|

|

|

Go to Step 6. Go to Step 6.

|

|

|

|

|

|

Repair the defective connector. Then go to Step 13. Repair the defective connector. Then go to Step 13.

|

|

|

|

|

|

STEP 6. Wiring harness check between A-03 ABS-ECU connector terminal

No.22 and A-02 front wheel speed sensor (RH) connector terminal No.1, and between A-03 ABS-ECU

connector terminal No.21 and A-02 front wheel speed sensor (RH) connector terminal No.2.

|

|

|

Q.

Is the check result normal?

|

|

|

Go to Step 7. Go to Step 7.

|

|

|

|

|

|

Repair the wiring harness. Then go to Step 13. Repair the wiring harness. Then go to Step 13.

|

|

|

|

|

|

STEP 7. Check wheel speed sensor <FR>

installation

|

|

|

Check how the wheel speed sensor <FR>

is installed (Disconnection of

wheel speed sensor <FR>, loose mounting bolt, etc.).

|

|

|

Q.

Is the check result normal?

|

|

|

Go to Step 8. Go to Step 8.

|

|

|

|

|

|

Reinstall the wheel speed sensor <FR>

(Refer to Reinstall the wheel speed sensor <FR>

(Refer to  ).

Then go to Step 8. ).

Then go to Step 8.

|

|

|

|

|

|

STEP 8. Check for wheel speed sensor <FR>

output

current

|

|

|

Refer to  . .

|

|

|

Q.

Is the check result normal?

|

|

|

Go to Step 9. Go to Step 9.

|

|

|

|

|

|

Replace the wheel speed sensor <FR>

(Refer to Replace the wheel speed sensor <FR>

(Refer to  ). Then

go to Step 12. ). Then

go to Step 12.

|

|

|

|

|

|

STEP 9. Check for wheel bearing looseness

|

|

|

| note |

- Loose wheel bearing may increase the gap between the wheel speed sensor <FR>

and

the wheel speed detection magnet encoder.

- Check the wheel bearing <FR>

for looseness (Refer to GROUP 26 -

Wheel

Bearing Play Check

). ).

|

|

|

|

Q.

Is the check result normal?

|

|

|

Go to Step 10. Go to Step 10.

|

|

|

|

|

|

Replace the wheel bearing <FR>

(Refer to GROUP 26 -

Front

Axle Hub Assembly Replace the wheel bearing <FR>

(Refer to GROUP 26 -

Front

Axle Hub Assembly  ). Then go to Step 13. ). Then go to Step 13.

|

|

|

|

|

|

STEP 10. Check wheel speed detection encoder

|

|

Check the encoder for adhesion of foreign materials or deformation.

Q.

Is the check result normal?

Go to Step 11. Go to Step 11.

NO (Adhesion of foreign materials) : Remove the foreign materials and clean the encoder so as not to disturb the magnetization

pattern on it while taking care of the magnet, magnetic substance, and magnetic attraction.

Then go to Step 13. : Remove the foreign materials and clean the encoder so as not to disturb the magnetization

pattern on it while taking care of the magnet, magnetic substance, and magnetic attraction.

Then go to Step 13.

NO (Deformation) : Replace the wheel bearing <FR>

(Refer to GROUP 26 -

Front

Axle Hub Assembly : Replace the wheel bearing <FR>

(Refer to GROUP 26 -

Front

Axle Hub Assembly  ). Then go to Step 13. ). Then go to Step 13.

|

|

|

STEP 11. Check whether the DTC is reset.

|

|

|

(2)Drive the vehicle at 12mph (20 km/h) or higher.

| note |

The ABS warning light does not turn OFF in some cases unless the vehicle runs at 12mph

(20 km/h) or higher.

|

|

|

|

Replace the wheel speed sensor <FR>

(Refer to Replace the wheel speed sensor <FR>

(Refer to  ). Then

go to Step 12. ). Then

go to Step 12.

|

|

|

|

|

|

Intermittent malfunction (Refer to GROUP 00 -

How to Use Troubleshooting/How

to Cope with Intermittent Malfunctions Intermittent malfunction (Refer to GROUP 00 -

How to Use Troubleshooting/How

to Cope with Intermittent Malfunctions  ). ).

|

|

|

|

|

|

STEP 12. Check whether the DTC is reset.

|

|

|

(2)Drive the vehicle at 12mph (20 km/h) or higher.

| note |

The ABS warning light does not turn OFF in some cases unless the vehicle runs at 12mph

(20 km/h) or higher.

|

|

|

|

Replace the hydraulic unit (integrated with ABS-ECU) (Refer to Replace the hydraulic unit (integrated with ABS-ECU) (Refer to  ). Then

go to Step 13. ). Then

go to Step 13.

|

|

|

|

|

|

The procedure is complete. The procedure is complete.

|

|

|

|

|

|

STEP 13. Check whether the DTC is reset.

|

|

|

(2)Drive the vehicle at 12mph (20 km/h) or higher.

| note |

The ABS warning light does not turn OFF in some cases unless the vehicle runs at 12mph

(20 km/h) or higher.

|

|

|

|

Return to Step 1. Return to Step 1.

|

|

|

|

|

|

The procedure is complete. The procedure is complete.

|

|

|

|

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)

Go to Step 3.

Go to Step 3. Repair the CAN bus lines (Refer to GROUP 54C -

CAN Bus Diagnostics Table

Repair the CAN bus lines (Refer to GROUP 54C -

CAN Bus Diagnostics Table  ).

On completion, go to Step 2.

).

On completion, go to Step 2. Go to Step 3.

Go to Step 3. The procedure is complete.

The procedure is complete. Carry out the diagnosis for the relevant DTCs.

Carry out the diagnosis for the relevant DTCs. Go to Step 4.

Go to Step 4. ).

). Go to Step 11.

Go to Step 11. Go to Step 5.

Go to Step 5. Go to Step 6.

Go to Step 6. Repair the defective connector. Then go to Step 13.

Repair the defective connector. Then go to Step 13. Go to Step 7.

Go to Step 7. Repair the wiring harness. Then go to Step 13.

Repair the wiring harness. Then go to Step 13. Go to Step 8.

Go to Step 8. Reinstall the wheel speed sensor <FR>

(Refer to

Reinstall the wheel speed sensor <FR>

(Refer to  ).

Then go to Step 8.

).

Then go to Step 8. .

. Go to Step 9.

Go to Step 9. Replace the wheel speed sensor <FR>

(Refer to

Replace the wheel speed sensor <FR>

(Refer to  ). Then

go to Step 12.

). Then

go to Step 12. Go to Step 10.

Go to Step 10. Replace the wheel bearing <FR>

(Refer to GROUP 26 -

Front

Axle Hub Assembly

Replace the wheel bearing <FR>

(Refer to GROUP 26 -

Front

Axle Hub Assembly  ). Then go to Step 13.

). Then go to Step 13. Replace the wheel speed sensor <FR>

(Refer to

Replace the wheel speed sensor <FR>

(Refer to  ). Then

go to Step 12.

). Then

go to Step 12. Intermittent malfunction (Refer to GROUP 00 -

How to Use Troubleshooting/How

to Cope with Intermittent Malfunctions

Intermittent malfunction (Refer to GROUP 00 -

How to Use Troubleshooting/How

to Cope with Intermittent Malfunctions  ).

). Replace the hydraulic unit (integrated with ABS-ECU) (Refer to

Replace the hydraulic unit (integrated with ABS-ECU) (Refer to  ). Then

go to Step 13.

). Then

go to Step 13. The procedure is complete.

The procedure is complete. Return to Step 1.

Return to Step 1. The procedure is complete.

The procedure is complete.