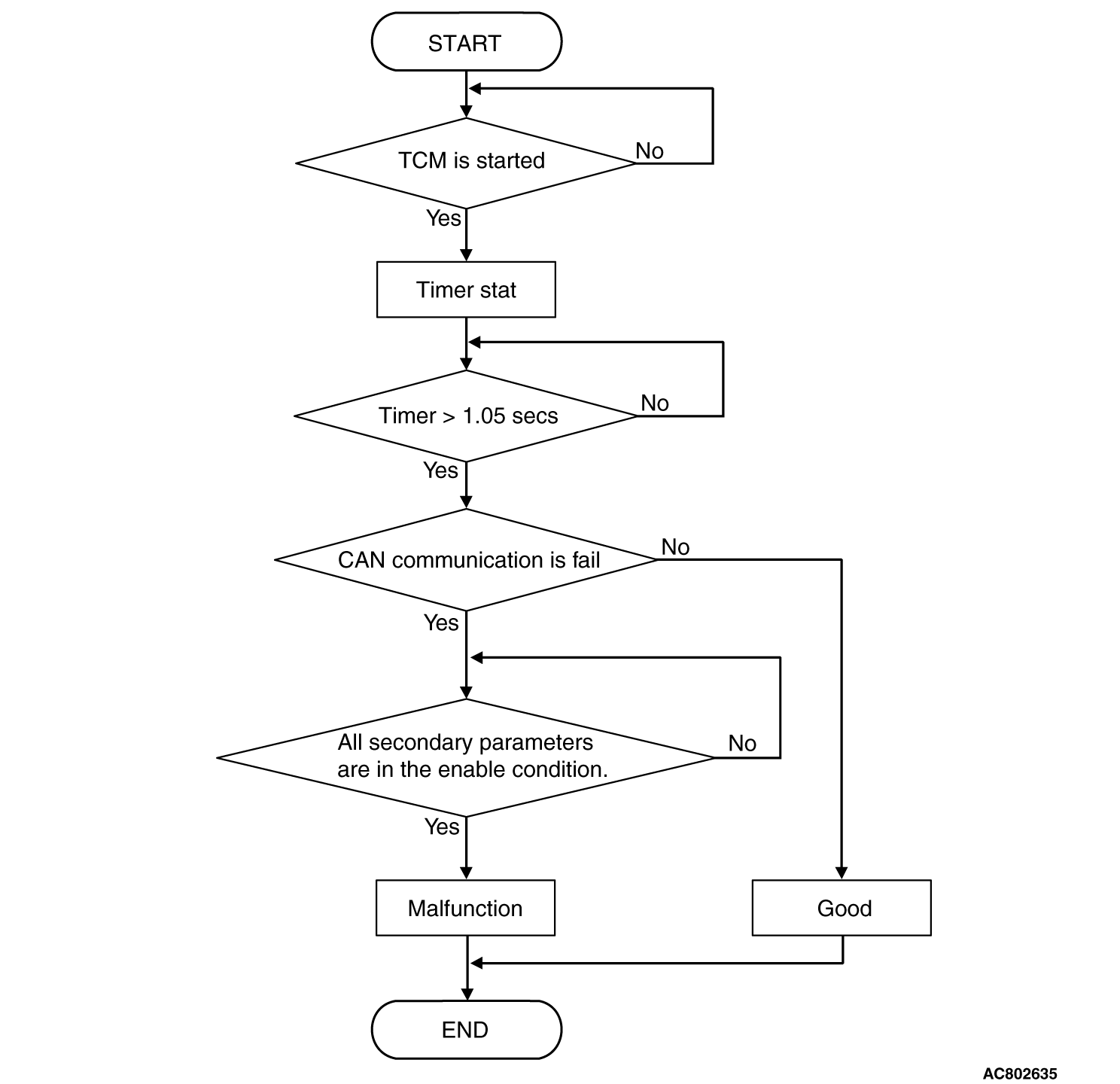

Intermittent malfunction

Intermittent malfunction![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)

DIAGNOSTIC PROCEDURE |

STEP 1. M.U.T.-III CAN bus diagnostics |

| Use M.U.T.-III to perform the CAN bus diagnosis. |

Q.

Is the check result normal?

|

Intermittent malfunction Intermittent malfunction |

|

Repair the CAN bus lines (Refer to GROUP 54C - Troubleshooting, Diagnosis Code Chart Repair the CAN bus lines (Refer to GROUP 54C - Troubleshooting, Diagnosis Code Chart  ). ). |

|