![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)

DTC P1836: Shift

Fork 1 Malfunction

| caution |

- If there is any problem in the

CAN bus lines, an incorrect diagnostic trouble code may be set. Prior to this diagnosis, diagnose

the CAN bus lines.

- Whenever the ECU is replaced, ensure that the CAN bus lines are normal.

|

DIAGNOSTIC FUNCTION

TC-SST-ECU checks that the movement of the shift fork 1 is normal.

DESCRIPTIONS OF MONITOR METHODS

The movement of the shift fork 1 is determined to be abnormal.

MONITOR EXECUTION

MONITOR EXECUTION CONDITIONS (OTHER MONITOR AND SENSOR)

Other Monitor (There is no temporary DTC stored in memory

for the item monitored below)

- P183D: Shift fork 2 malfunction

- P1844: Shift fork 3 malfunction

Sensor (The sensor below is determined to be normal)

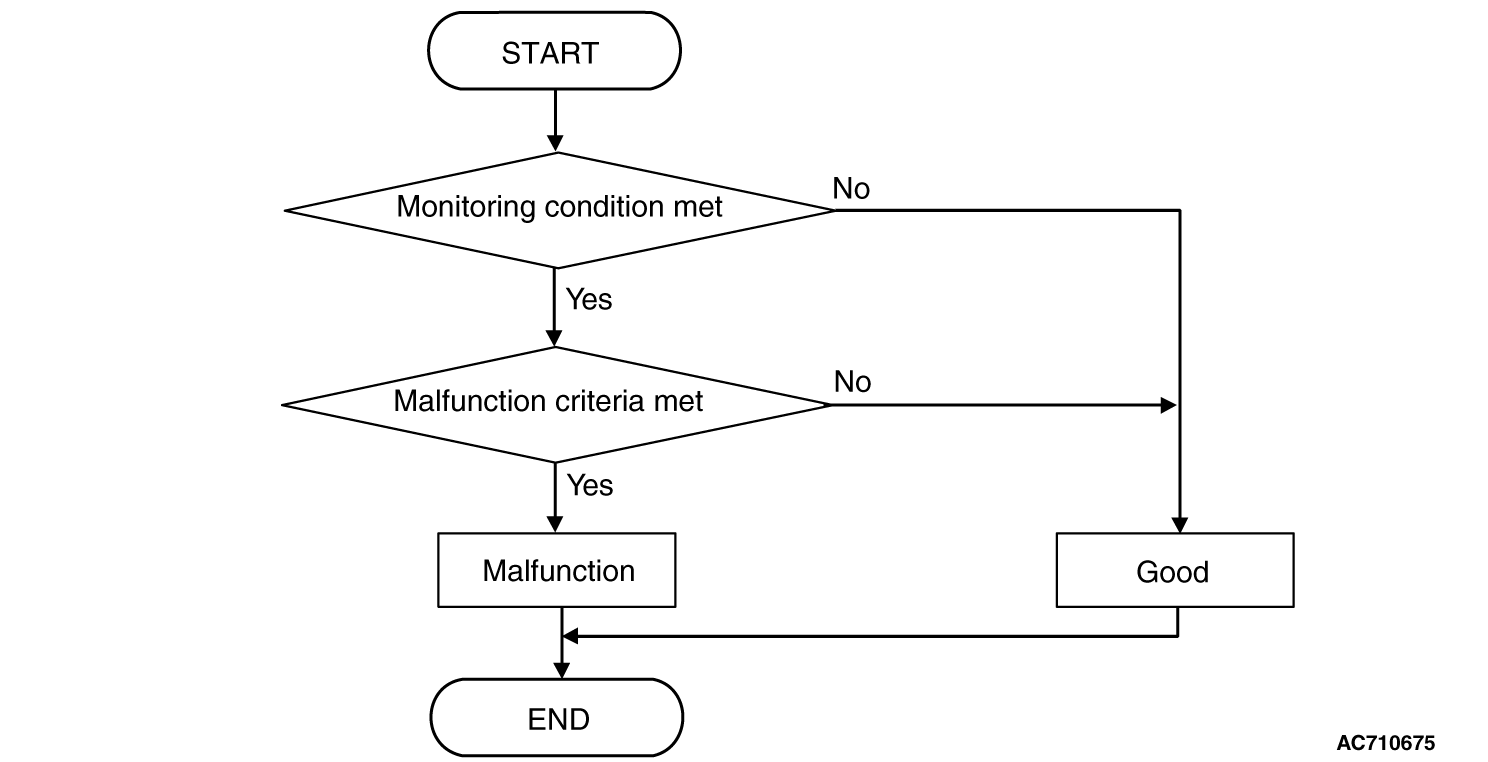

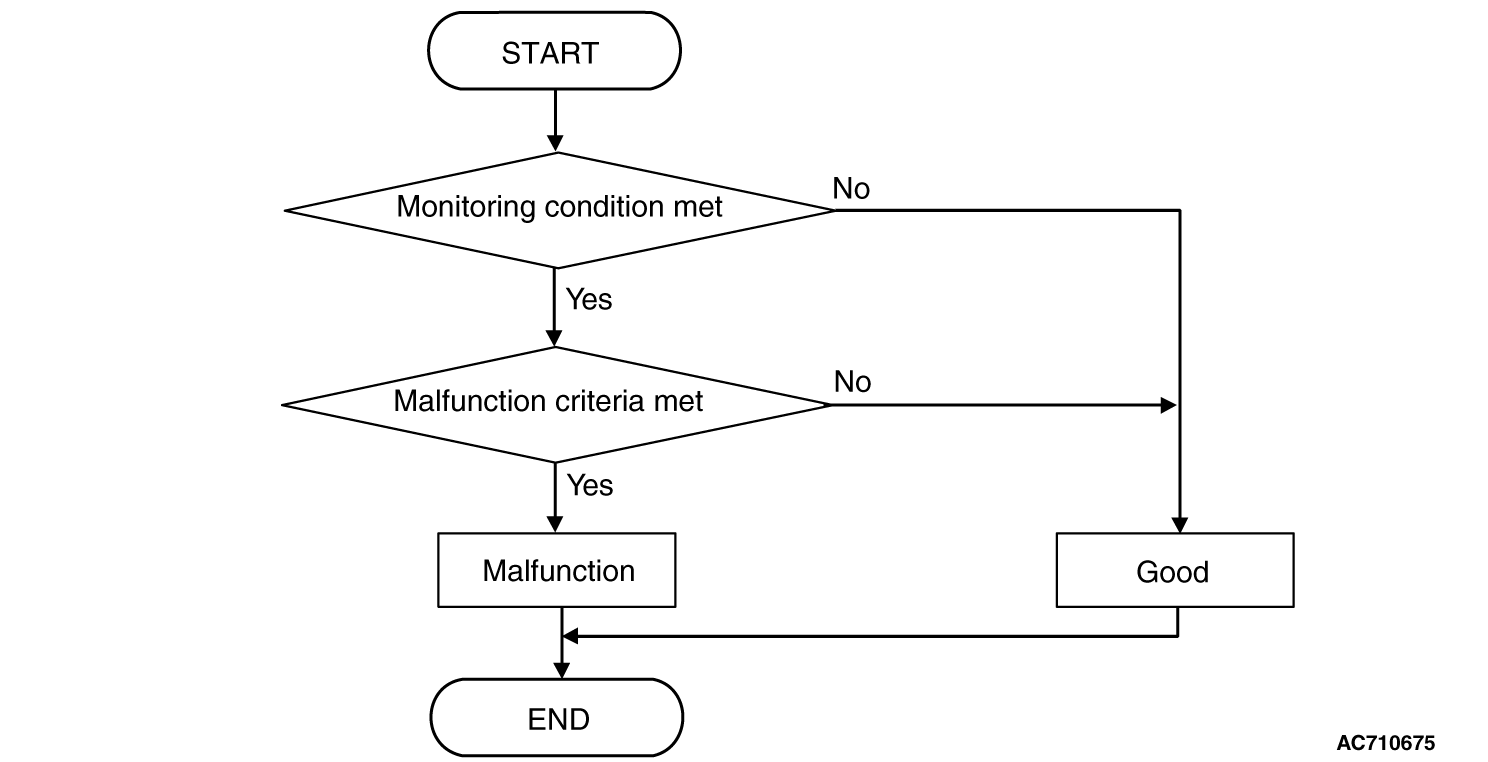

LOGIC FLOW CHARTS (Monitor Sequence) <Functional check - blocked>

DTC SET CONDITIONS <FUNCTIONAL CHECK - BLOCKED>

Check Conditions

- Voltage of battery: 8 V or more.

- Voltage of battery: 16.5 V or less.

- Engine speed: 650 r/min or more.

- Time since above engine condition: 1.5 second or more.

- Common high side 1 voltage: 2.5 V or more.

- Common high side 3 voltage: 2.5 V or more.

JUDGMENT CRITERIA

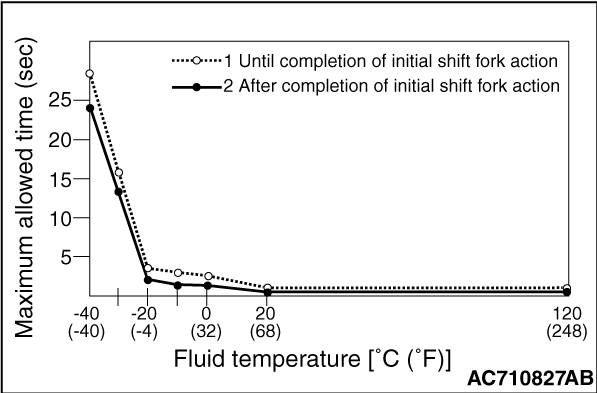

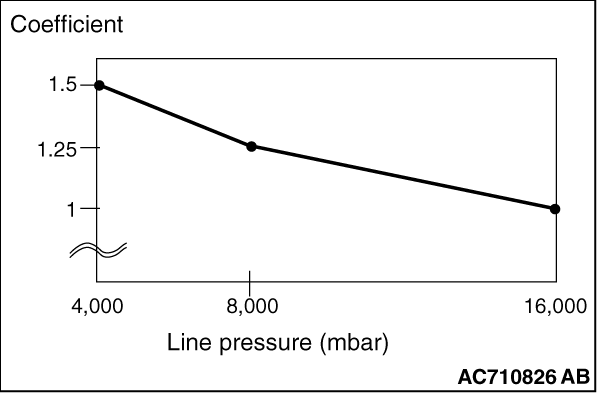

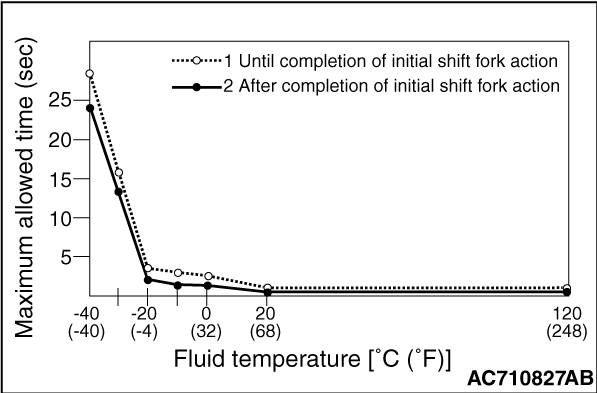

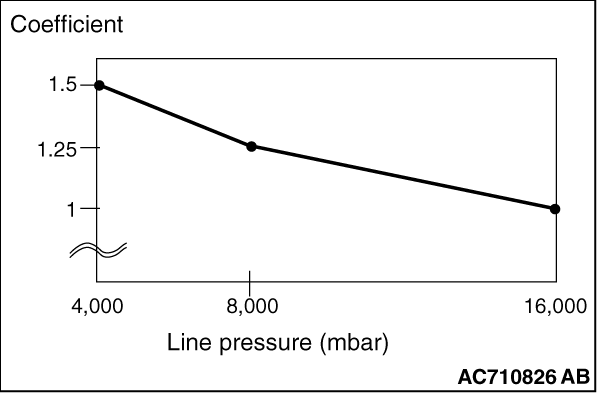

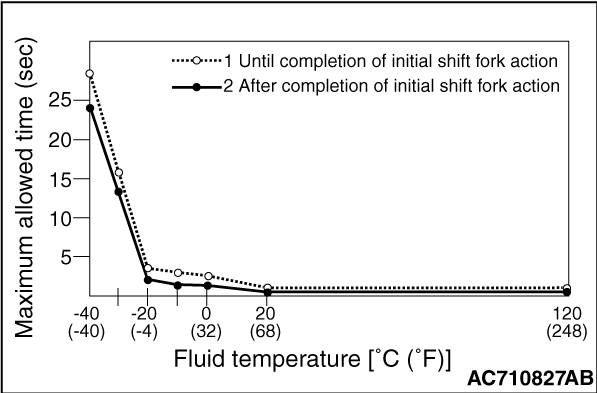

- Shift fork operation time: Shift fork operation time (threshold value) or more.

(immediately)

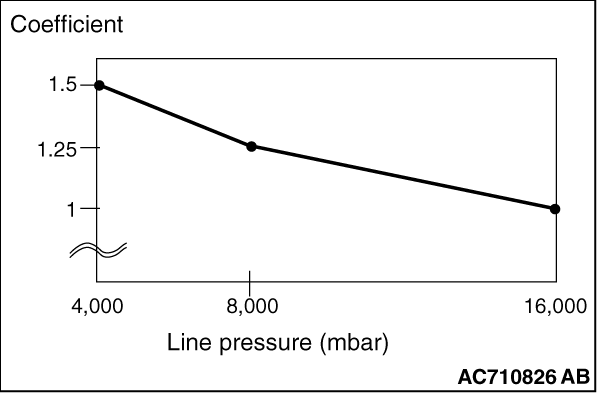

- Shift fork operation time (threshold value): Equal the maximum allowed time x Coefficient. (immediately)

OBD-II DRIVE CYCLE PATTERN <FUNCTIONAL CHECK - BLOCKED>

The shift fork operation time is threshold value or less.

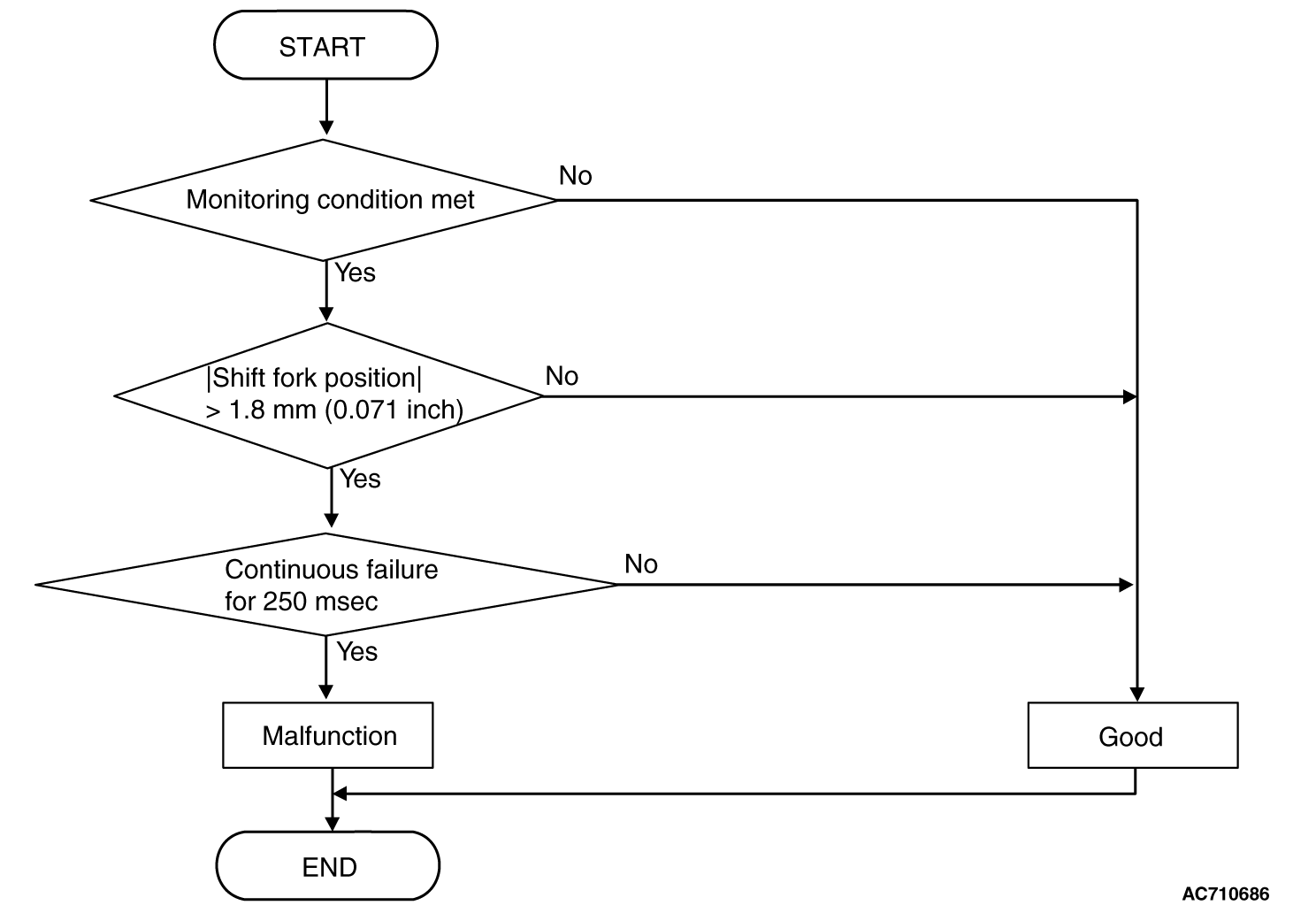

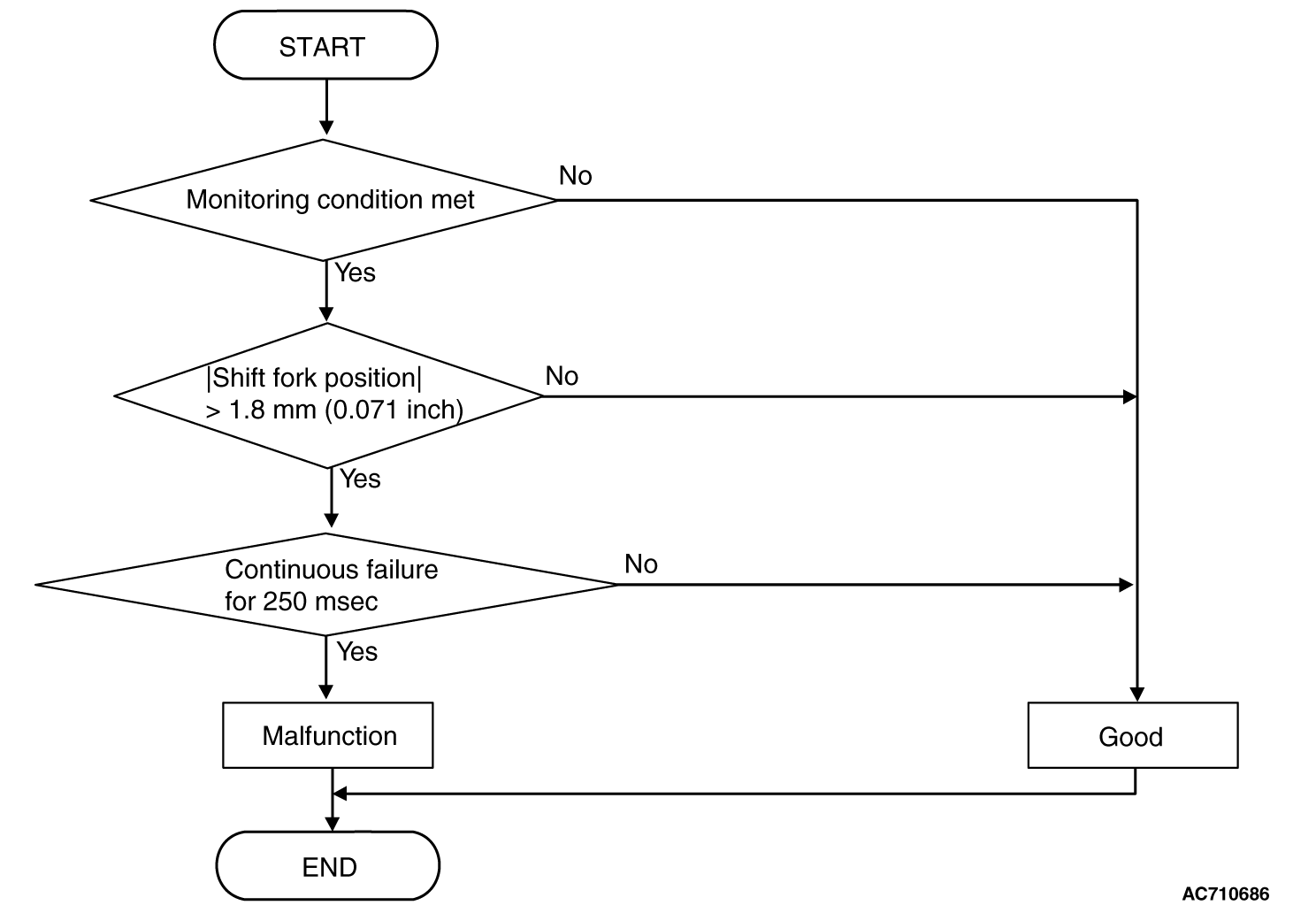

LOGIC FLOW CHARTS (Monitor Sequence) <Functional check - Neutral>

DTC SET CONDITIONS <FUNCTIONAL CHECK - NEUTRAL>

Check Conditions

- Voltage of battery: 8 V or more.

- Voltage of battery: 16.5 V or less.

- Engine speed: 650 r/min or more.

- Time since above engine condition: 1.5 second or more.

- Shift fork 1 current gear: Neutral.

JUDGMENT CRITERIA

- Shift fork position: 1.8 mm (0.071 inch) or more. (250 millisecond)

OBD-II DRIVE CYCLE PATTERN <FUNCTIONAL CHECK - NEUTRAL>

The shift fork position remains 1.8 mm (0.071 inch) or less for 250 milliseconds.

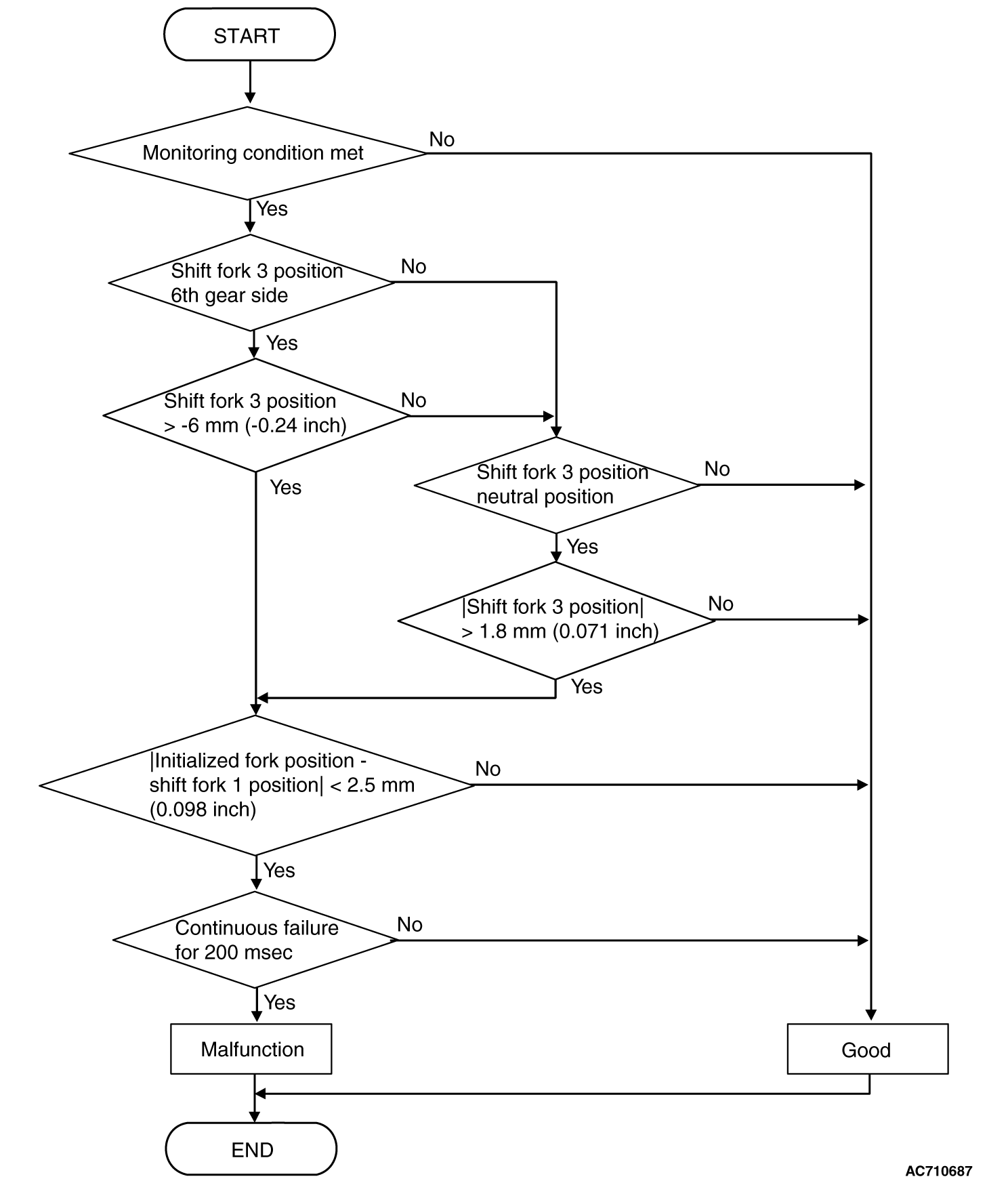

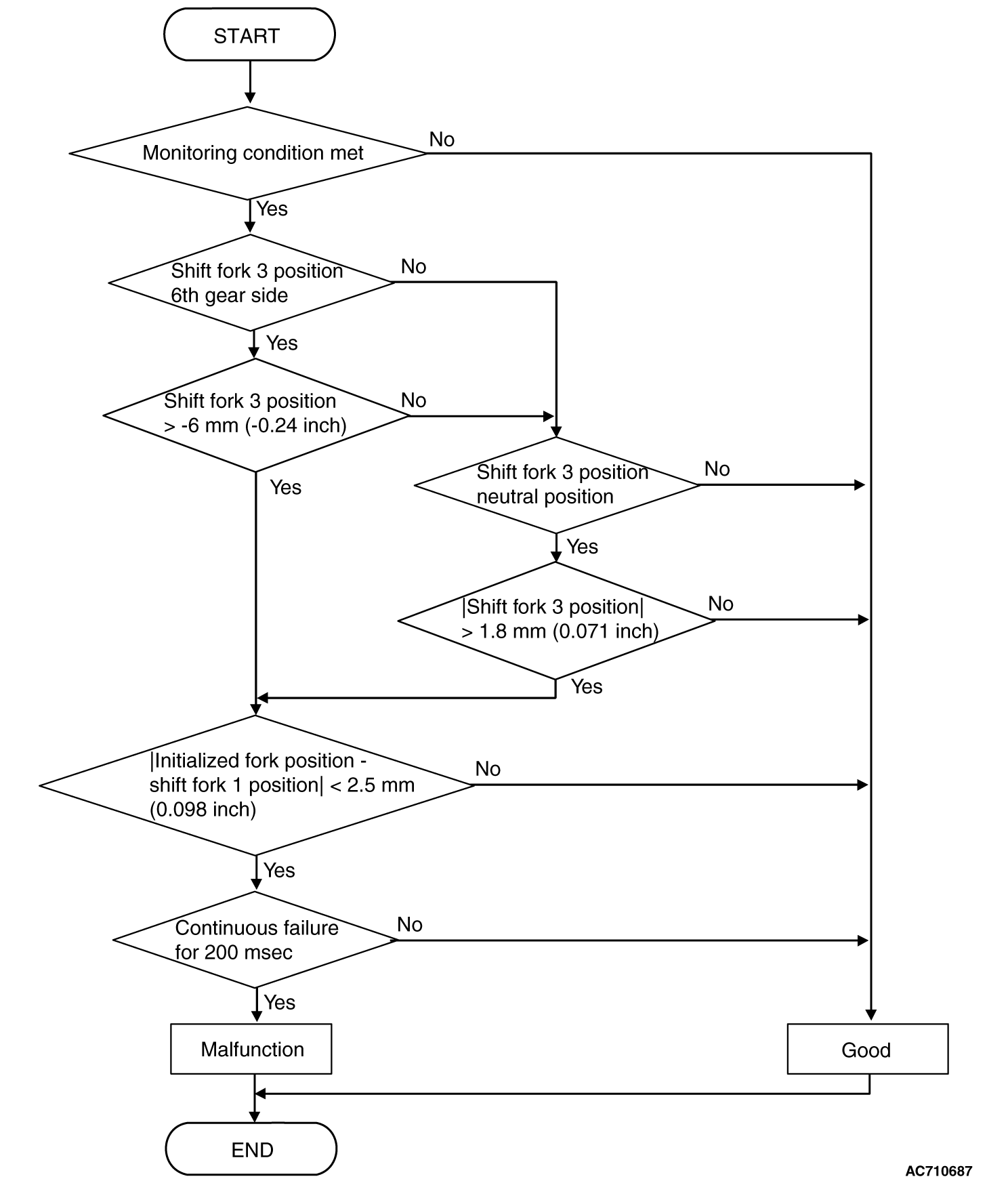

LOGIC FLOW CHARTS (Monitor Sequence) <Functional check - Shift

fork 1 requested but shift fork 3 movement>

DTC SET CONDITIONS <FUNCTIONAL CHECK - SHIFT FORK 1 REQUESTED BUT SHIFT FORK

3 MOVEMENT>

Check Conditions

- Voltage of battery: 8 V or more.

- Voltage of battery: 16.5 V or less.

- Engine speed: 650 r/min or more.

- Time since above engine condition: 1.5 second or more.

- Requested shift fork: Shift fork 1.

JUDGMENT CRITERIA

- Shift fork 3 position: -6 mm (-0.24 inch) [6th gear side] or

more, or 1.8 mm (0.071 inch) [neutral position] or more, and initialized fork

position - shift fork 1 position: 2.5 mm (0.098 inch) or less. (200 millisecond)

OBD-II DRIVE CYCLE PATTERN <FUNCTIONAL CHECK - SHIFT FORK 1 REQUESTED BUT SHIFT

FORK 3 MOVEMENT>

The status with the shift fork position -6 mm (-0.24 inch) [6th

gear side] or less, or with 1.8 mm (0.071 inch) [neutral position] or

less and with the initialized fork position - shift fork 1 position 2.5 mm (0.098 inch)

or more continues for 200 milliseconds.

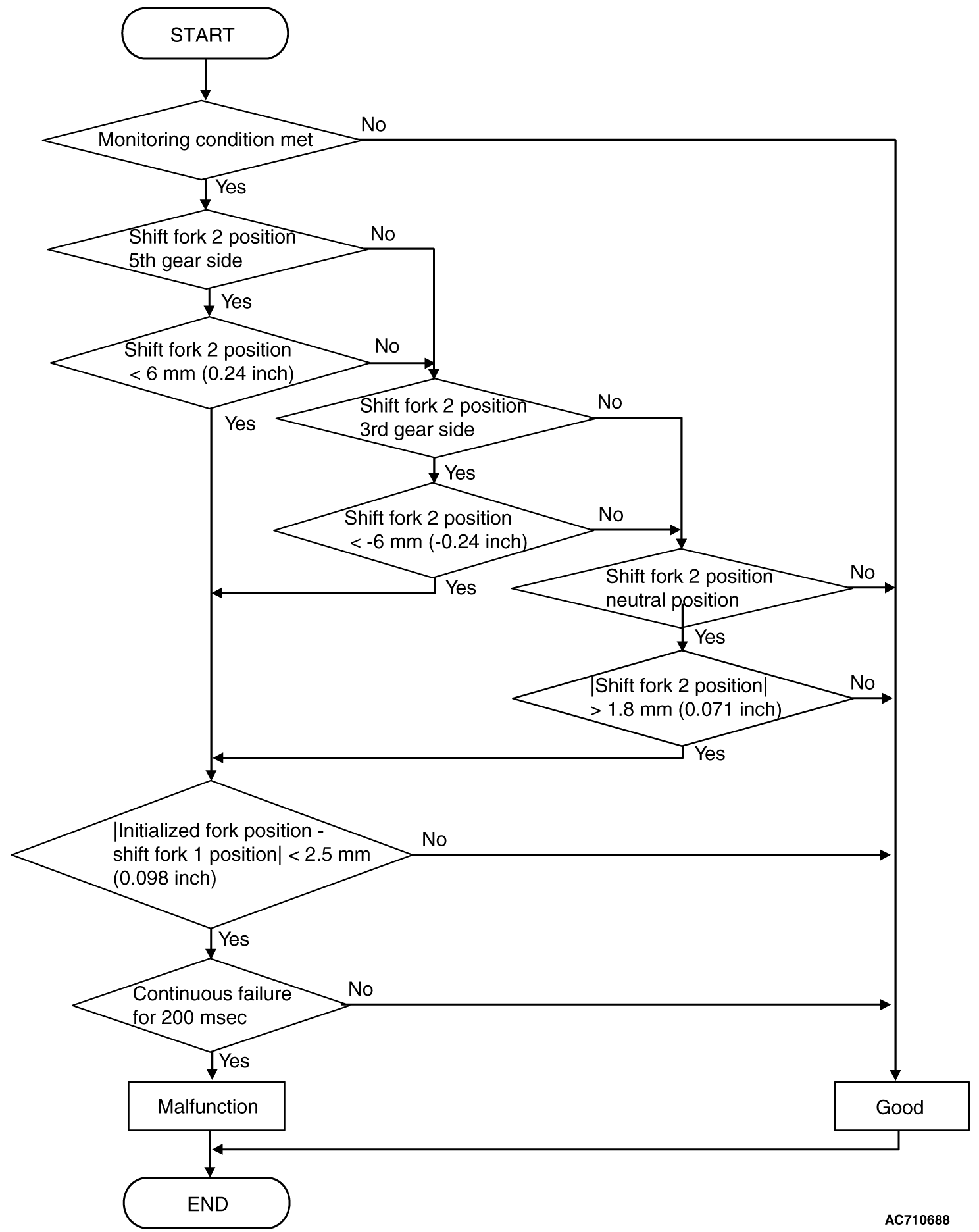

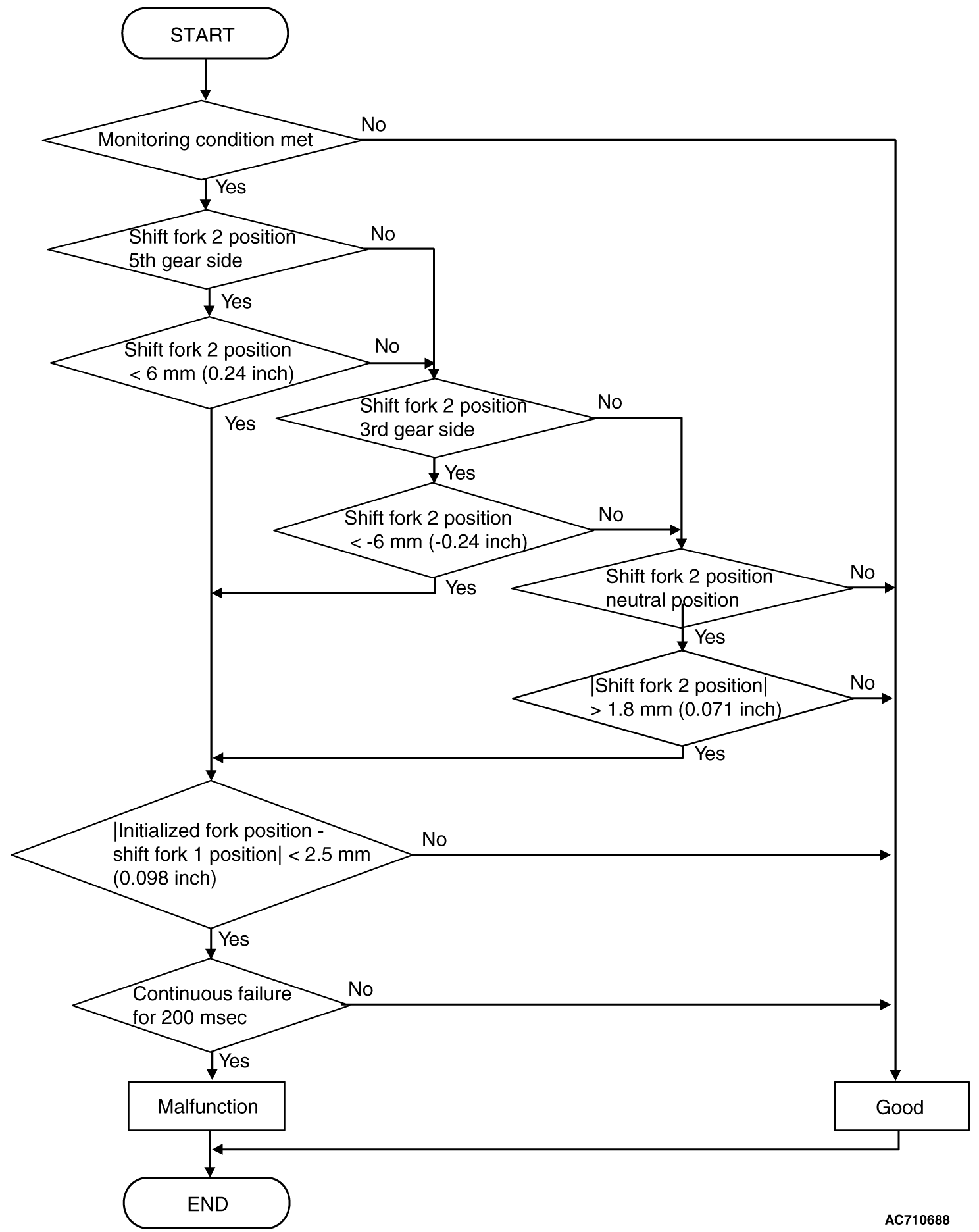

LOGIC FLOW CHARTS (Monitor Sequence) <Functional check - Shift

fork 1 requested but shift fork 2 movement>

DTC SET CONDITIONS <FUNCTIONAL CHECK - SHIFT FORK 1 REQUESTED BUT SHIFT FORK

2 MOVEMENT>

Check Conditions

- Voltage of battery: 8 V or more.

- Voltage of battery: 16.5 V or less.

- Engine speed: 650 r/min or more.

- Time since above engine condition: 1.5 second or more.

- Requested shift fork: Shift fork 1.

JUDGMENT CRITERIA

- Shift fork position: 6 mm (0.24 inch) [5th gear side] or less,

or -6 mm (-0.24 inch) [3rd gear side] or more, or 1.8 mm

(0.071 inch) [neutral position] or more, and initialized fork position - shift

fork 1 position: 2.5 mm (0.098 inch) or less. (200 millisecond)

OBD-II DRIVE CYCLE PATTERN <FUNCTIONAL CHECK - SHIFT FORK 1 REQUESTED BUT SHIFT

FORK 2 MOVEMENT>

The status with the shift fork position 6 mm (0.24 inch) [5th gear side] or

more, or with -6 mm (-0.24 inch) [3rd gear side] or less,

or with 1.8 mm (0.071 inch) [neutral position] or less and with the initialized

fork position - shift fork 1 position 2.5 mm (0.098 inch) or more continues for 200

milliseconds.

PROBABLE CAUSES

- Malfunction of TC-SST-ECU

- Malfunction of TC-SST shift fork

|

|

Required Special Tools:

- MB991958 Scan Tool (M.U.T.-III Sub Assembly)

- MB991824: Vehicle Communication Interface (V.C.I.)

- MB991827 M.U.T.-III USB Cable

- MB991910 M.U.T.-III Main Harness A

|

|

|

STEP 1. Scan tool CAN bus diagnostics

|

|

|

Using scan tool MB991958, diagnose the CAN bus lines.

|

|

|

Q.

Is the check result normal?

|

|

|

Go to Step 2. Go to Step 2.

|

|

|

|

|

|

Repair the CAN bus lines. (Refer to GROUP 54C - Troubleshooting Repair the CAN bus lines. (Refer to GROUP 54C - Troubleshooting  .)

After repairing the CAN bus line, go to Step 2. .)

After repairing the CAN bus line, go to Step 2.

|

|

|

|

|

|

STEP 2. Monitoring unit No. check

|

|

|

(1)Check the freeze frame data (item No. 30 to No. 37).

|

|

|

(2)Check which monitoring unit (No. 160, No. 172, No. 182, or No. 183) is set.

|

|

|

Q.

Which monitoring unit is set, No. 160, No. 172, No. 182, or No. 183?

|

|

|

No. 160 : Go to Step 4 : Go to Step 4

|

|

|

|

|

|

Other than No. 160 : Go to Step 3 : Go to Step 3

|

|

|

|

|

|

STEP 3. Check whether the DTC is reset.

|

|

|

(2)Drive with shifting to each gear range.

|

|

|

(3)Check that the DTC is reset.

|

|

|

Replace the transaxle assembly. (Refer to Replace the transaxle assembly. (Refer to  .) .)

|

|

|

|

|

|

Intermittent malfunction. (Refer to GROUP 00 - How to Cope with Intermittent

Malfunction Intermittent malfunction. (Refer to GROUP 00 - How to Cope with Intermittent

Malfunction  .) .)

|

|

|

|

|

|

STEP 4. Check whether the DTC is reset.

|

|

|

(2)With the engine idle status, operate the shift lever in the following sequence:

P → R → D → R → P. (Hold each range for 5 seconds or more.)

|

|

|

(3)Check that the DTC is reset.

|

|

|

Replace the transaxle assembly. (Refer to Replace the transaxle assembly. (Refer to  .) .)

|

|

|

|

|

|

Intermittent malfunction. (Refer to GROUP 00 - How to Cope with Intermittent

Malfunction Intermittent malfunction. (Refer to GROUP 00 - How to Cope with Intermittent

Malfunction  .) .)

|

|

|

|

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)

Go to Step 2.

Go to Step 2. Repair the CAN bus lines. (Refer to GROUP 54C - Troubleshooting

Repair the CAN bus lines. (Refer to GROUP 54C - Troubleshooting  .)

After repairing the CAN bus line, go to Step 2.

.)

After repairing the CAN bus line, go to Step 2. : Go to Step 4

: Go to Step 4 : Go to Step 3

: Go to Step 3 Replace the transaxle assembly. (Refer to

Replace the transaxle assembly. (Refer to  .)

.) Intermittent malfunction. (Refer to GROUP 00 - How to Cope with Intermittent

Malfunction

Intermittent malfunction. (Refer to GROUP 00 - How to Cope with Intermittent

Malfunction  .)

.) Replace the transaxle assembly. (Refer to

Replace the transaxle assembly. (Refer to  .)

.) Intermittent malfunction. (Refer to GROUP 00 - How to Cope with Intermittent

Malfunction

Intermittent malfunction. (Refer to GROUP 00 - How to Cope with Intermittent

Malfunction  .)

.)