|

|

After removing the strut tower bar, temporarily install the strut assembly.

|

|

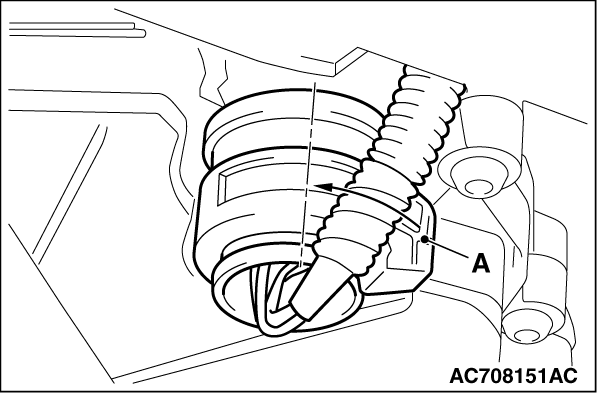

Rotate the section A of the connector 90° to the direction of the arrow to disconnect

the connector.

|

|

|

Remove the starter with its connector connected. Keep the starter fixed to the engine

side.

|

|

|

Only loosen the bolts from the engine and transaxle assembly (do not remove).

|

|

|

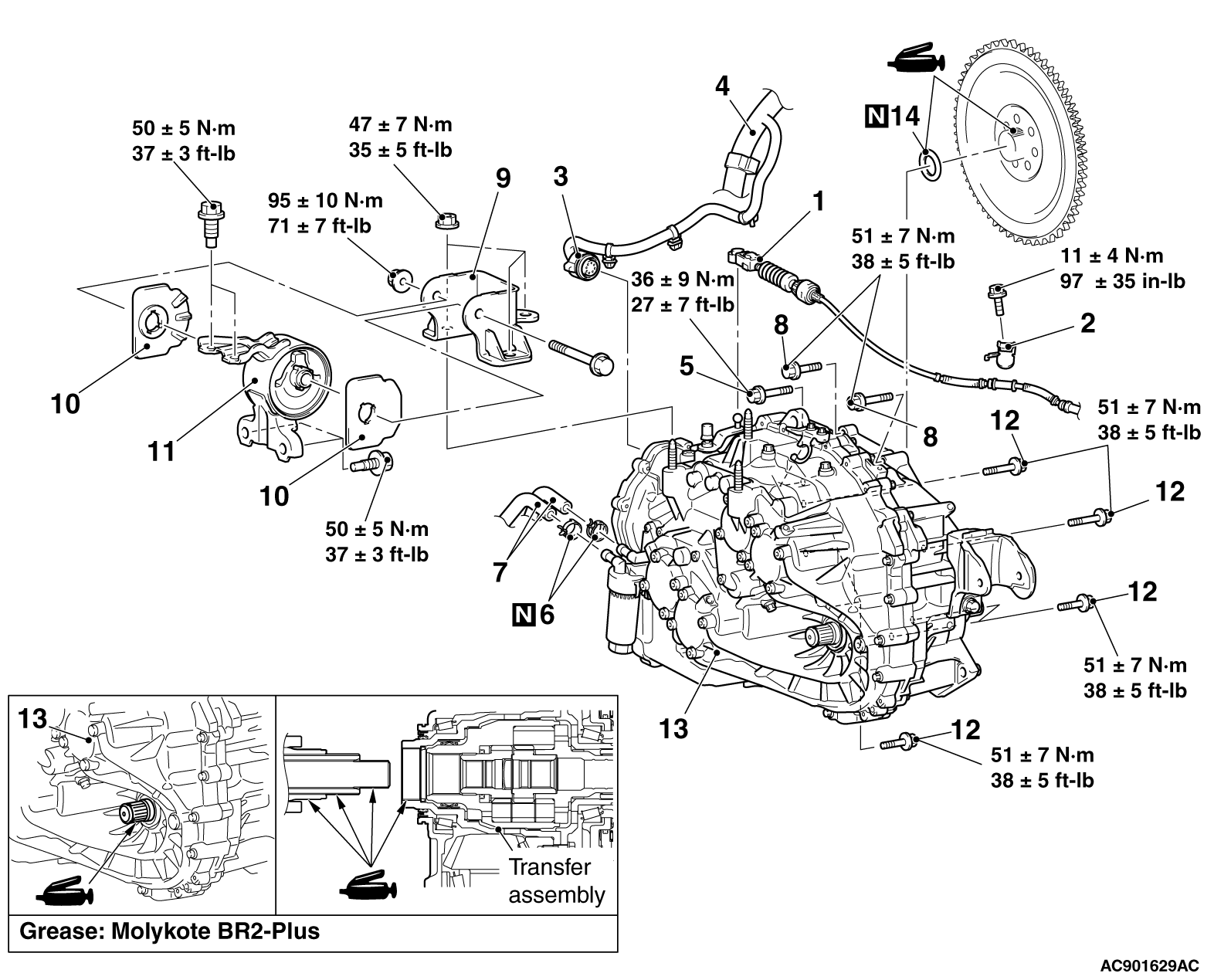

1.Place a garage jack against the transaxle case with a piece of wood in between to

support the engine and transaxle assembly.

|

|

|

2.Operate the garage jack so that the engine and transaxle assembly weight is not applied

to the transaxle mounting insulator, and remove the transaxle mounting bracket.

|

|

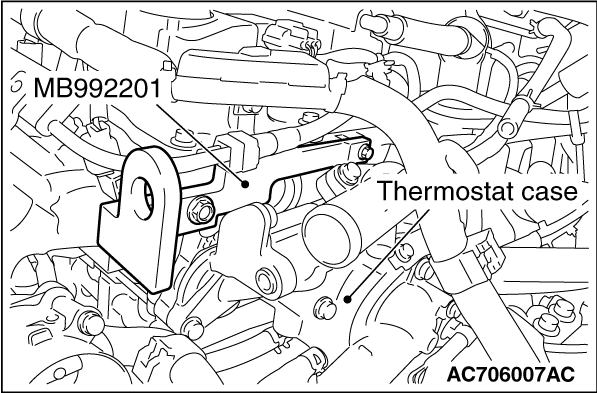

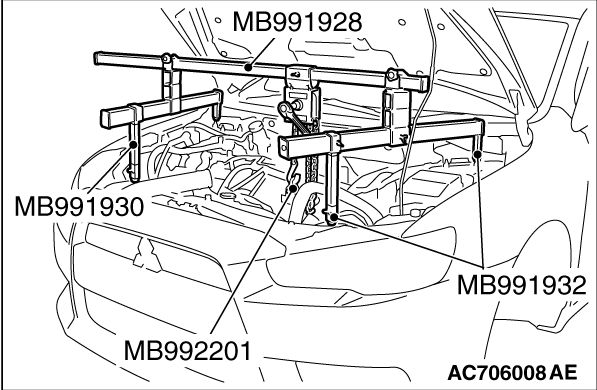

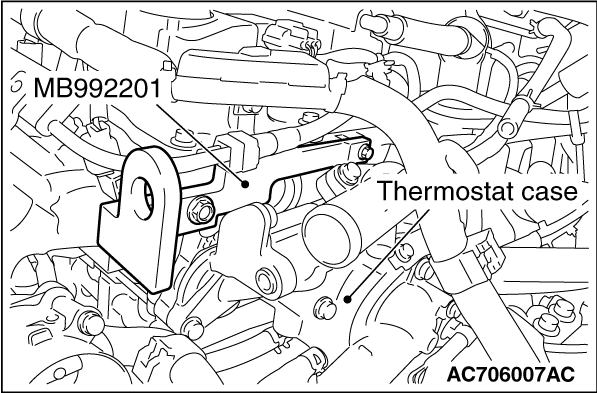

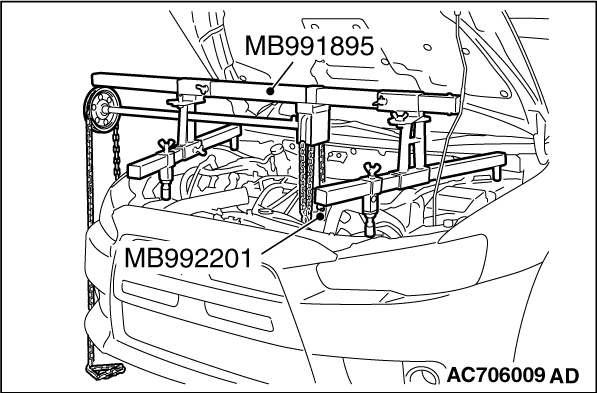

1.Remove the vacuum pipe assembly (refer to GROUP 14 - Water Hose and Water Pipe  ),

and install the engine hanger plate (Special tool: MB992201), then tighten the bolts to the

specified torque. ),

and install the engine hanger plate (Special tool: MB992201), then tighten the bolts to the

specified torque.

Tightening torque: 11± 1 N·m (97 ± 9 in-lb)

|

|

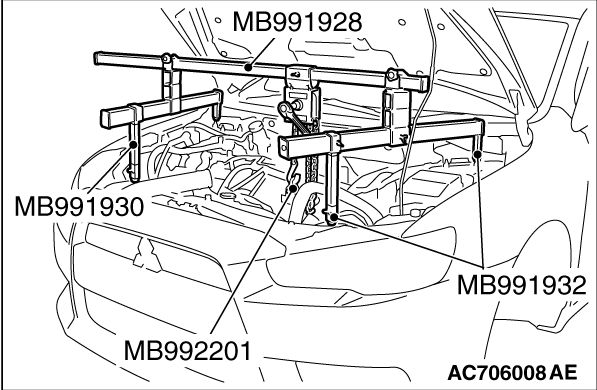

2.<When engine hanger (special tool MB991928) is used>

(1)

Assemble the engine hanger (special tool MB991928). (Set following

parts to the base hanger.)

- Slide bracket (HI)

- Foot x 4 (standard) (MB991932)

- Joint x 2 (90) (MB991930)

(2)

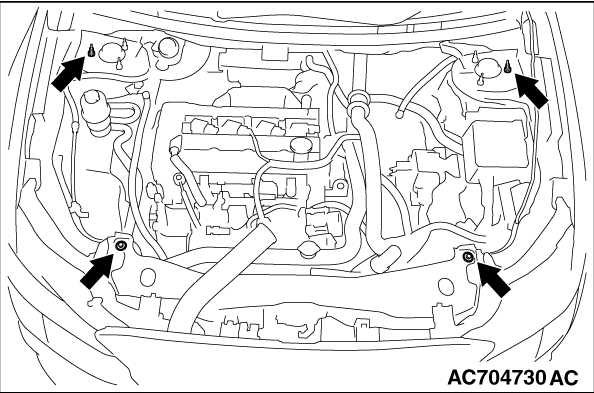

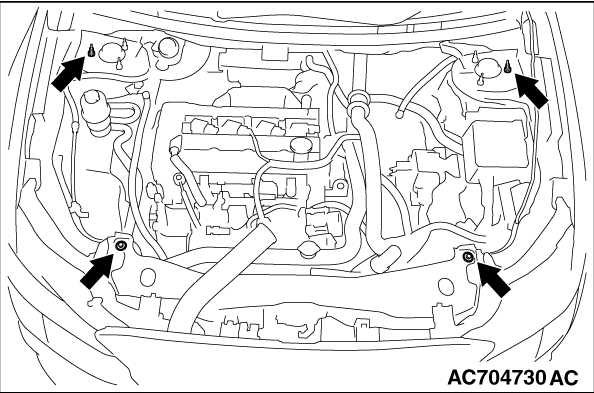

Set the feet of the special tool as shown in the figure.

|

|

| note |

Adjust the engine hanger balance by sliding the slide bracket (HI).

|

|

(3)

Set the chain to the engine hanger plate (Special tool: MB992201) to support the engine

and transaxle assembly. Remove the garage jack, and then remove the transaxle assembly upper

part coupling bolts that have been loosened previously.

|

|

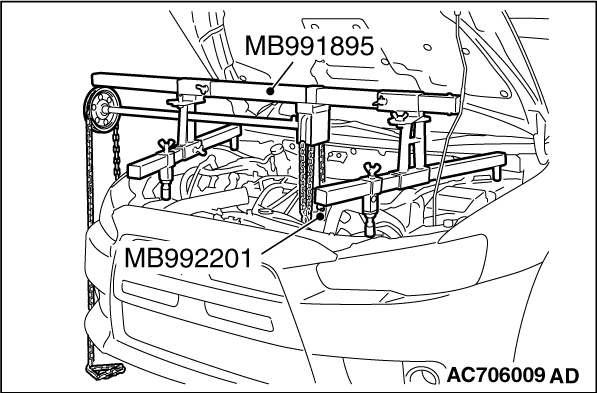

3.<Engine mechanical hanger (special tool MB991895) is used>

(1)

Set the feet of the engine mechanical hanger (special tool MB991895) as shown in the figure.

|

|

| note |

Slide the front foot of the engine mechanical hanger (Special tool: MB991895) to balance

the engine hanger.

|

|

(2)

Set the chain to the engine hanger plate (Special tool: MB992201) to support the engine

and transaxle assembly. Remove the garage jack, and then remove the transaxle assembly upper

part coupling bolts that have been loosened previously.

|

|

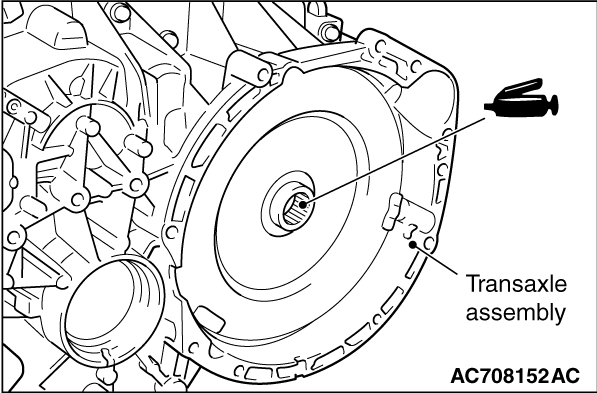

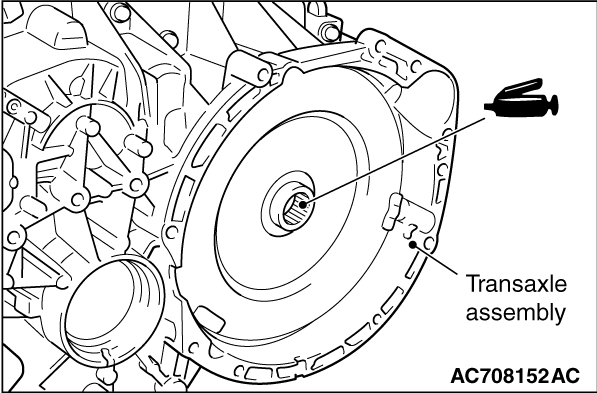

Apply the specified grease to the flywheel spline section, O-ring, and spline section

of transaxle assembly input shaft.

Grease

Brand name: Molykote BR2-Plus

|

|

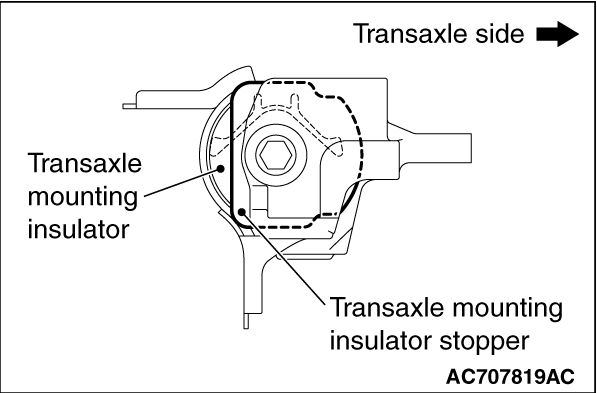

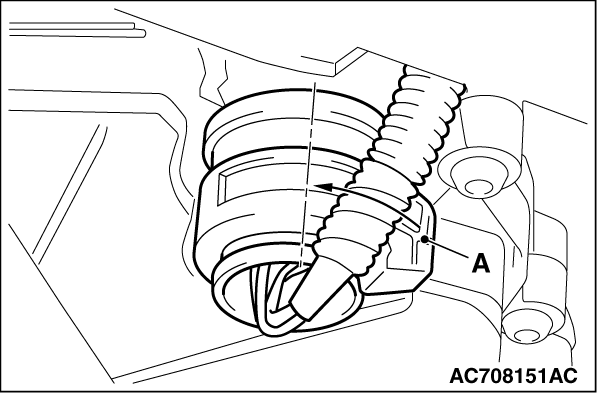

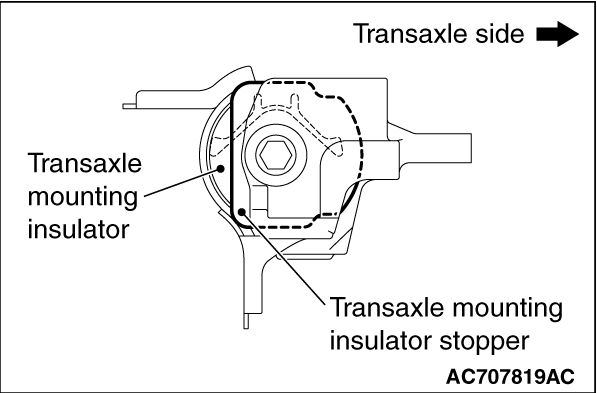

Install the transaxle mounting insulator stopper as shown in the figure.

|

|

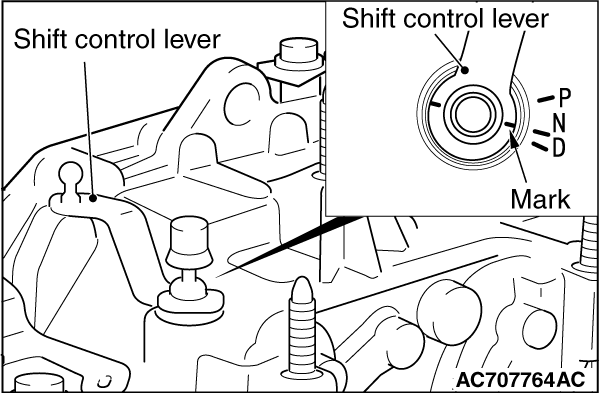

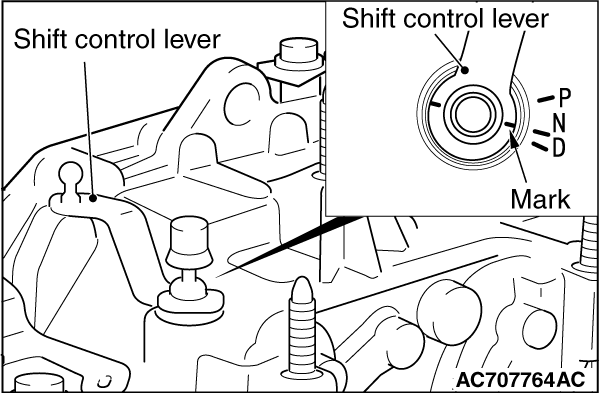

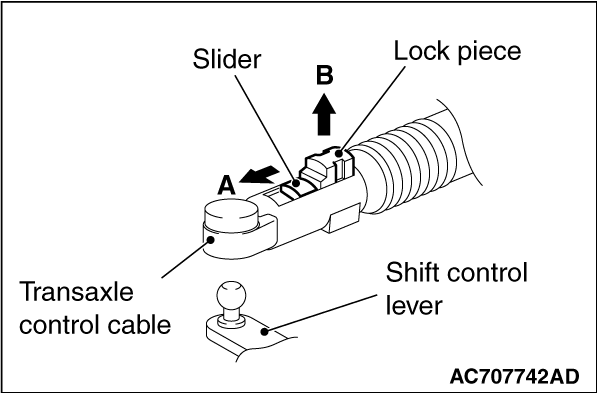

1.Operate the lever so that the shift control lever positioning mark is set to the N position.

|

|

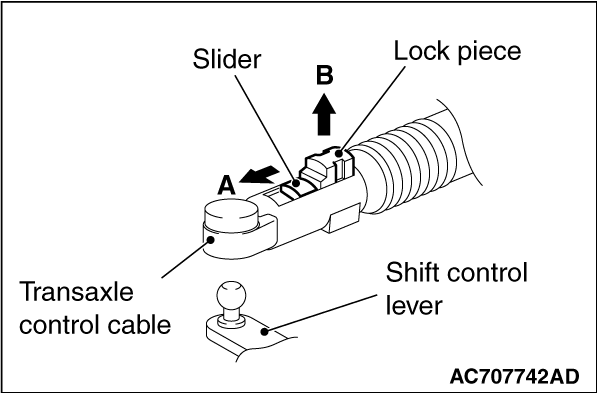

2.Move the slider of the transaxle control cable (transaxle side) tip to the direction A

to pull up the lock piece to the direction B.

3.Install the transaxle control cable (transaxle side) in the transaxle control cable

bracket at the top of transaxle.

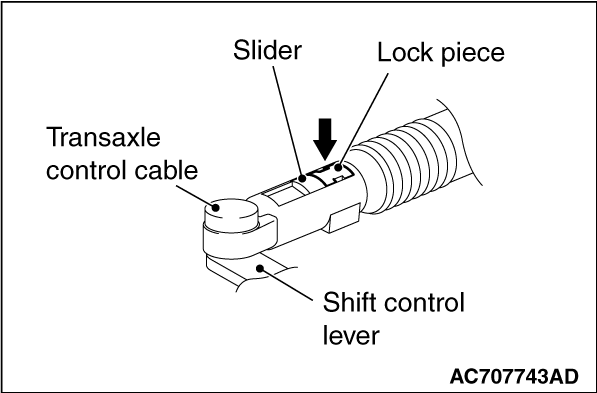

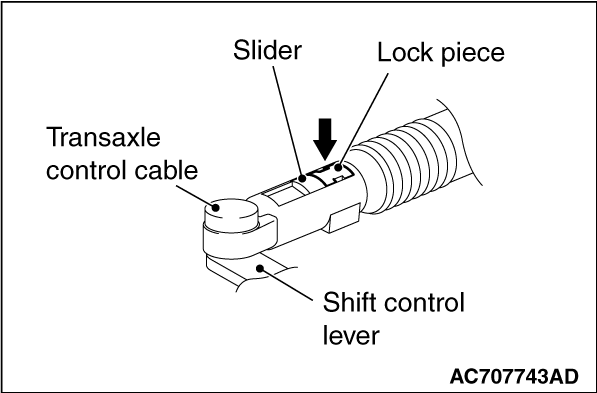

4.Move the shift lever to the N<=>D position three times or more, and shift to

the N position.

|

|

5.Connect the transaxle control cable to the shift control lever, and firmly push down the

lock piece of transaxle control cable to lock it.

| note |

- The slider automatically returns to the fixed position by the spring.

- The lock position of transaxle control cable is automatically adjusted by a spring.

|

|

.)

.) .)

.) .)

.) .)

.) .)

.) .)

.) .)

.) .)

.) .)

.) .)

.) .)

.) .)

.) .)

.) .)

.)![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)