|

|

Required Special Tools:

- MB991958: Scan Tool (M.U.T.-III Sub Assembly)

- MB991824: V.C.I.

- MB991827: USB Cable

- MB991910: Main Harness A

|

|

|

Q.

Is the harness connector in good condition?

|

|

|

Repair or replace it. Refer to GROUP 00E, Harness Connector Inspection Repair or replace it. Refer to GROUP 00E, Harness Connector Inspection  .

Then go to Step 5. .

Then go to Step 5.

|

|

|

|

|

|

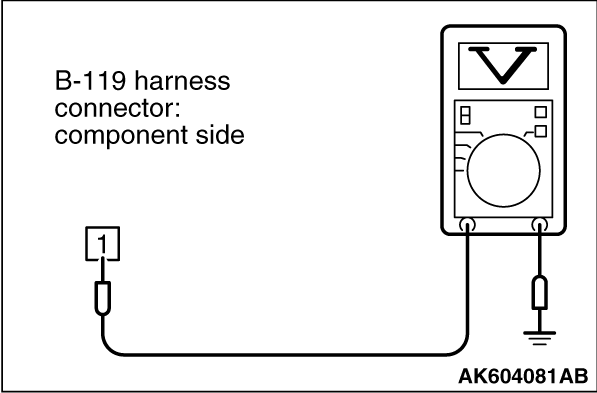

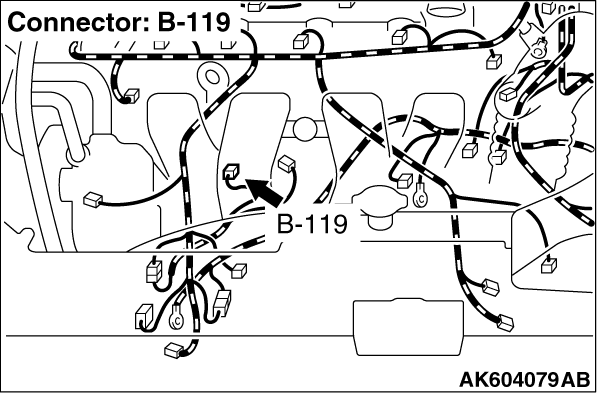

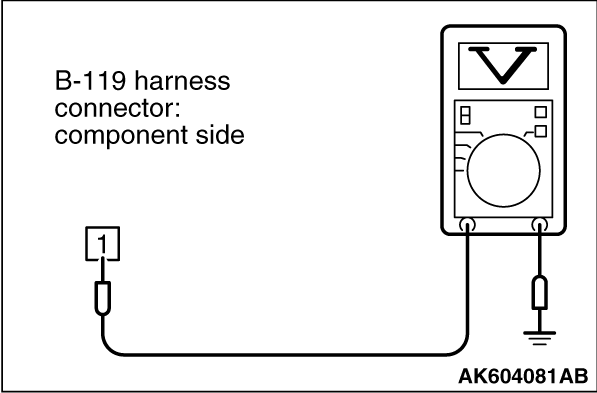

(1)Disconnect the connector B-119 measure at the harness side.

|

|

|

(2)Turn the ignition switch to the "ON" position.

|

|

(3)Measure the voltage between terminal No. 1 and ground.

- The voltage should equal battery positive voltage.

(4)Turn the ignition switch to the "LOCK" (OFF) position.

Q.

Is battery positive voltage (approximately 12 volts) present?

Go to Step 5. Go to Step 5.

Go to Step 3. Go to Step 3.

|

|

|

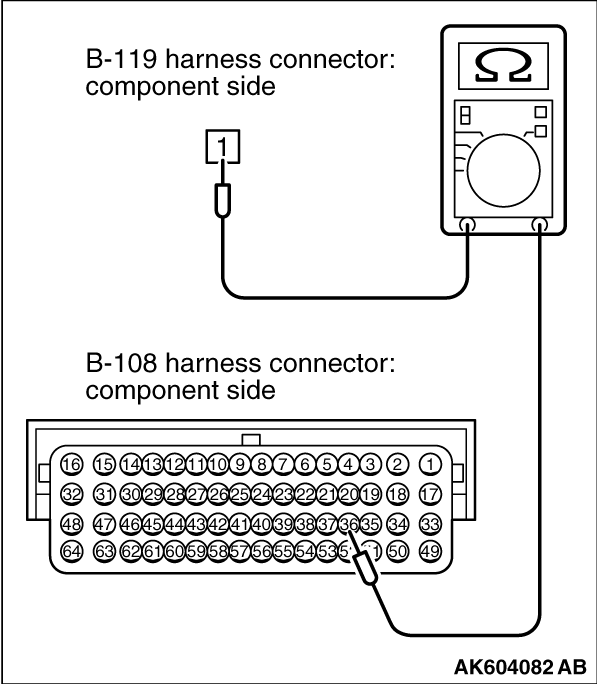

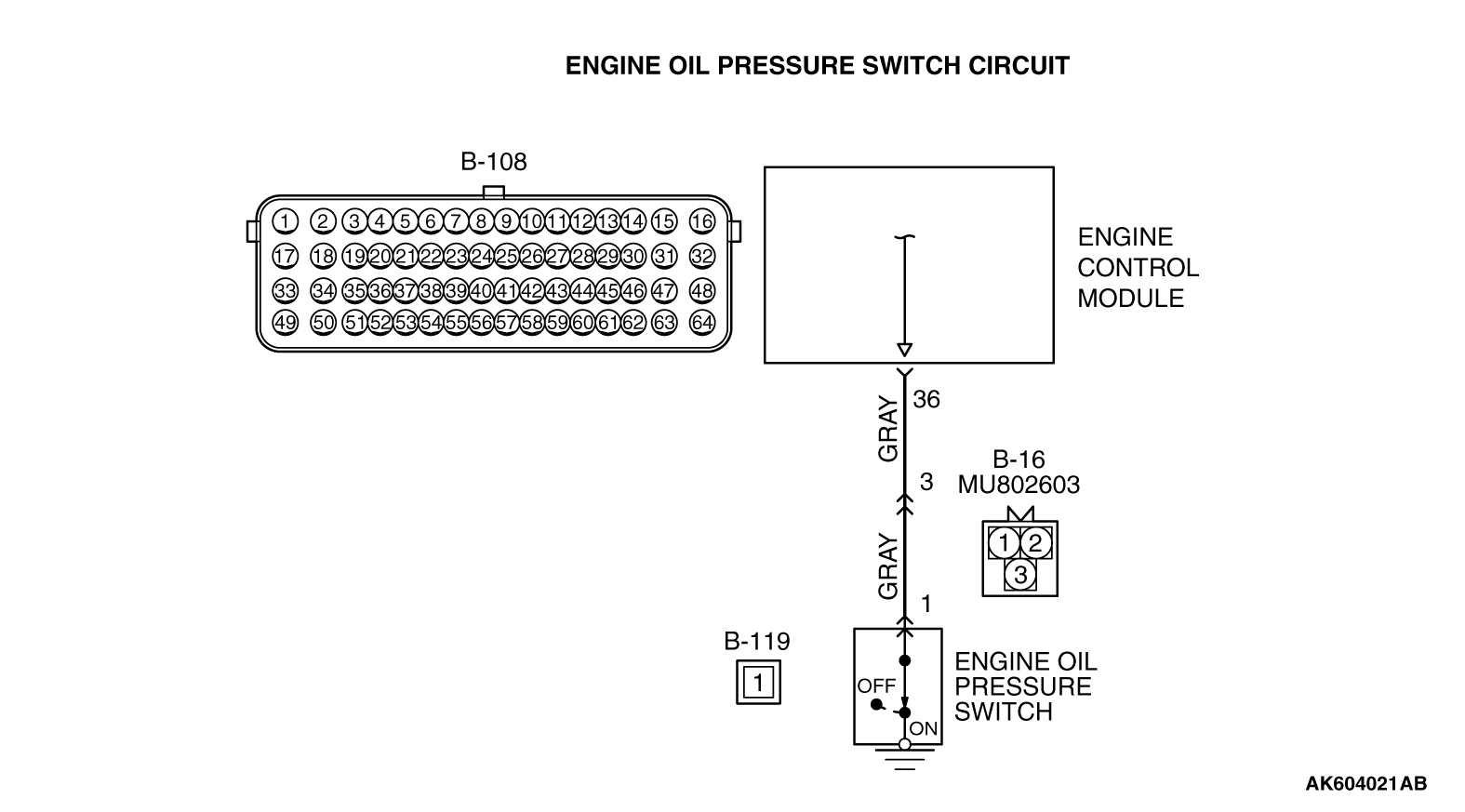

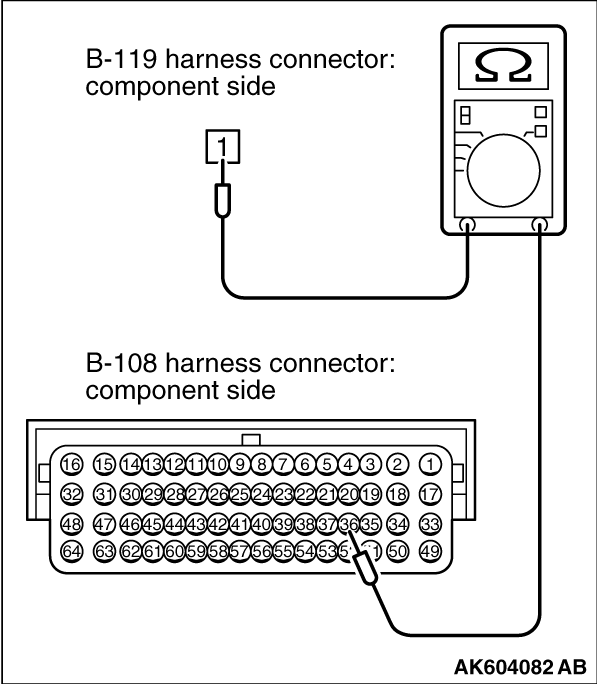

(1)Disconnect the connector B-119 and B-108 measure at the harness side.

|

|

(2)Measure the resistance between connector B-119 (terminal No. 1) and connector B-108 (terminal

No. 36).

|

|

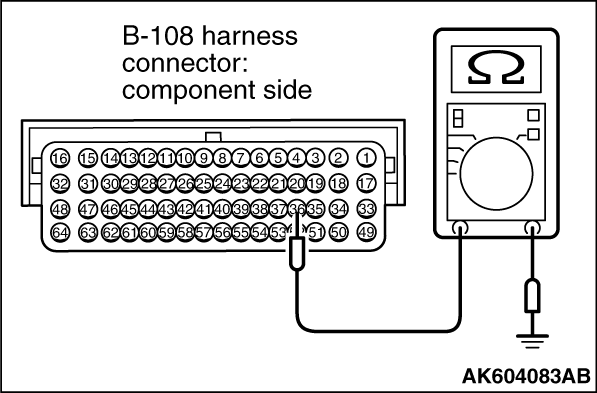

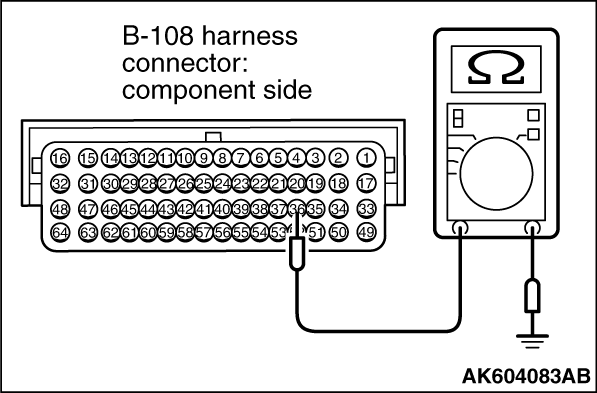

(3)Check for the continuity between connector B-108 (terminal No. 36) and ground.

Q.

Is the harness wire in good condition?

Then go to Step 4. Then go to Step 4.

Repair it. Then confirm that the malfunction symptom is eliminated. Repair it. Then confirm that the malfunction symptom is eliminated.

|

|

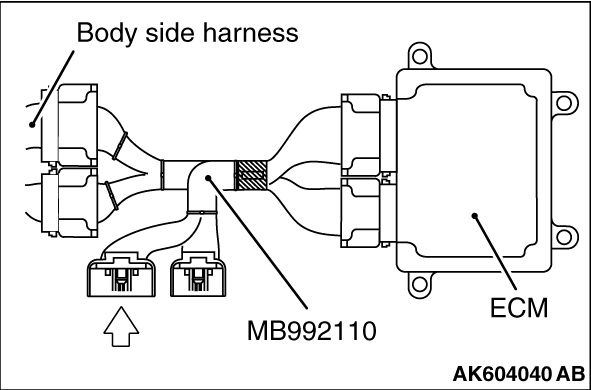

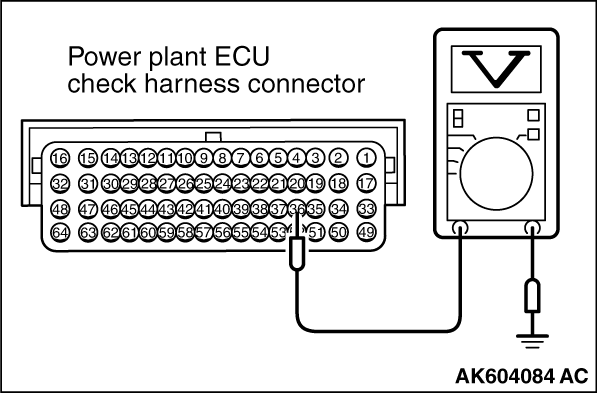

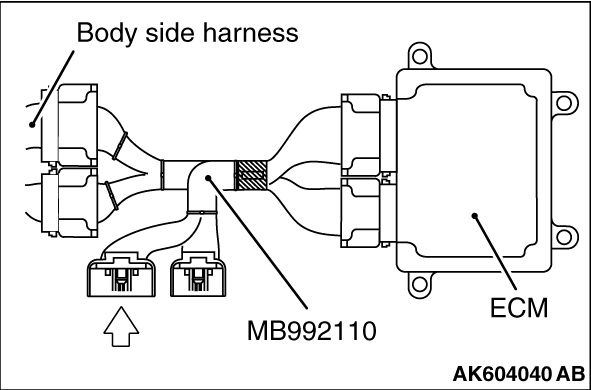

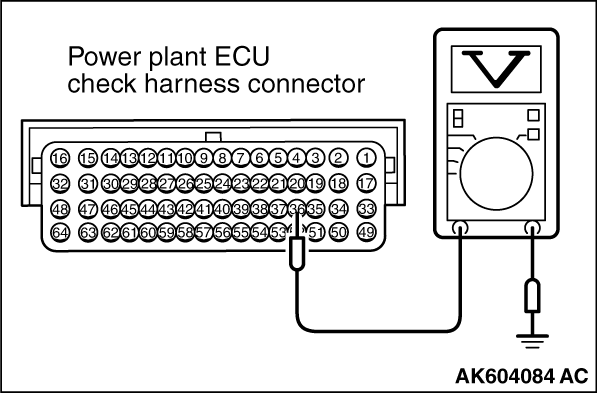

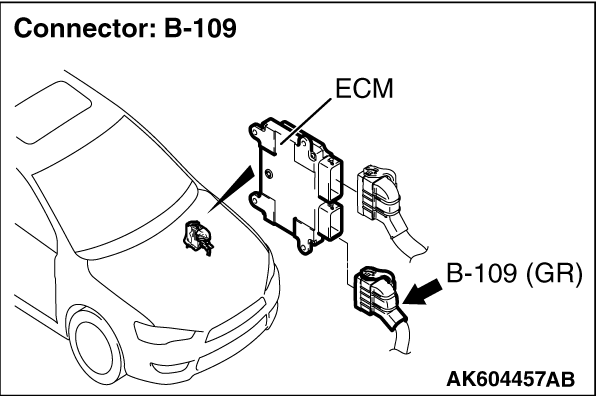

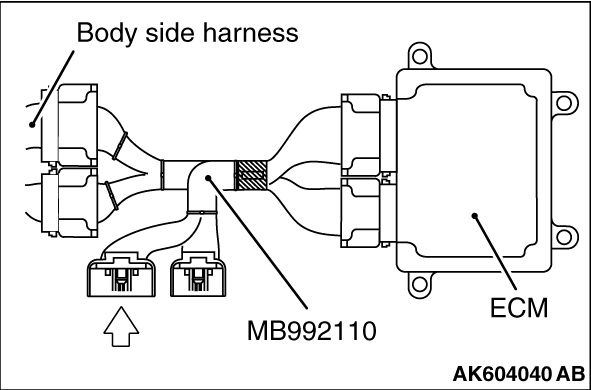

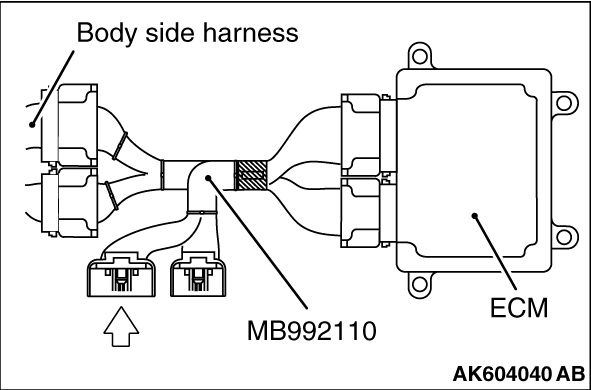

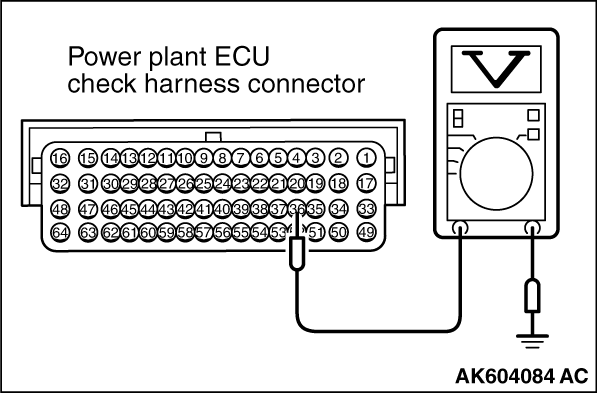

(1)Disconnect all ECM connectors. Connect the power plant ECU check harness special

tool MB992110 between the separated connectors.

|

|

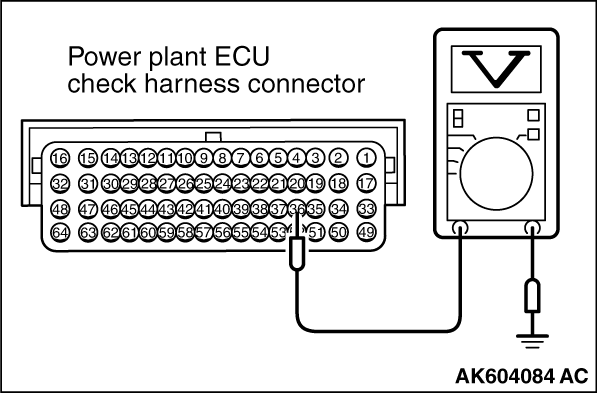

(2)Measure the voltage between terminal No. 36 and ground.

OK:

1 V or less (ignition switch: ON)

System voltage (during idling)

Q.

Is the measured voltage normal?

It can be assumed that this malfunction is intermittent.Refer to GROUP 00, How

to Use Troubleshooting/Inspection Service Points -

How to Cope with Intermittent Malfunctions It can be assumed that this malfunction is intermittent.Refer to GROUP 00, How

to Use Troubleshooting/Inspection Service Points -

How to Cope with Intermittent Malfunctions  . .

Replace the ECM. When the ECM is replaced, register the ID code. Refer to GROUP

42B, Diagnosis - ID Code Registration Judgment Table <Vehicles with KOS> Replace the ECM. When the ECM is replaced, register the ID code. Refer to GROUP

42B, Diagnosis - ID Code Registration Judgment Table <Vehicles with KOS>  or

GROUP 42C, Diagnosis - ID Codes Registration Judgment Table <Vehicles with WCM> or

GROUP 42C, Diagnosis - ID Codes Registration Judgment Table <Vehicles with WCM>  . .

|

|

(1)Disconnect all ECM connectors. Connect the power plant ECU check harness special

tool MB992110 between the separated connectors.

|

|

(2)Measure the voltage between terminal No. 36 and ground.

OK:

1 V or less (ignition switch: ON)

10 V or more (during idling)

Q.

Is the measured voltage normal?

It can be assumed that this malfunction is intermittent.Refer to GROUP 00, How

to Use Troubleshooting/Inspection Service Points -

How to Cope with Intermittent Malfunctions It can be assumed that this malfunction is intermittent.Refer to GROUP 00, How

to Use Troubleshooting/Inspection Service Points -

How to Cope with Intermittent Malfunctions  . .

Replace the engine oil pressure switch. Then confirm that the malfunction symptom

is eliminated. Replace the engine oil pressure switch. Then confirm that the malfunction symptom

is eliminated.

|

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)

Go to Step 2.

Go to Step 2. Repair or replace it. Refer to GROUP 00E, Harness Connector Inspection

Repair or replace it. Refer to GROUP 00E, Harness Connector Inspection  .

Then go to Step 5.

.

Then go to Step 5.

Go to Step 5.

Go to Step 5. Go to Step 3.

Go to Step 3.

Then go to Step 4.

Then go to Step 4. Repair it. Then confirm that the malfunction symptom is eliminated.

Repair it. Then confirm that the malfunction symptom is eliminated.

It can be assumed that this malfunction is intermittent.Refer to GROUP 00, How

to Use Troubleshooting/Inspection Service Points -

How to Cope with Intermittent Malfunctions

It can be assumed that this malfunction is intermittent.Refer to GROUP 00, How

to Use Troubleshooting/Inspection Service Points -

How to Cope with Intermittent Malfunctions  .

. Replace the ECM. When the ECM is replaced, register the ID code. Refer to GROUP

42B, Diagnosis - ID Code Registration Judgment Table <Vehicles with KOS>

Replace the ECM. When the ECM is replaced, register the ID code. Refer to GROUP

42B, Diagnosis - ID Code Registration Judgment Table <Vehicles with KOS>  or

GROUP 42C, Diagnosis - ID Codes Registration Judgment Table <Vehicles with WCM>

or

GROUP 42C, Diagnosis - ID Codes Registration Judgment Table <Vehicles with WCM>  .

.

It can be assumed that this malfunction is intermittent.Refer to GROUP 00, How

to Use Troubleshooting/Inspection Service Points -

How to Cope with Intermittent Malfunctions

It can be assumed that this malfunction is intermittent.Refer to GROUP 00, How

to Use Troubleshooting/Inspection Service Points -

How to Cope with Intermittent Malfunctions  .

. Replace the engine oil pressure switch. Then confirm that the malfunction symptom

is eliminated.

Replace the engine oil pressure switch. Then confirm that the malfunction symptom

is eliminated.