![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)

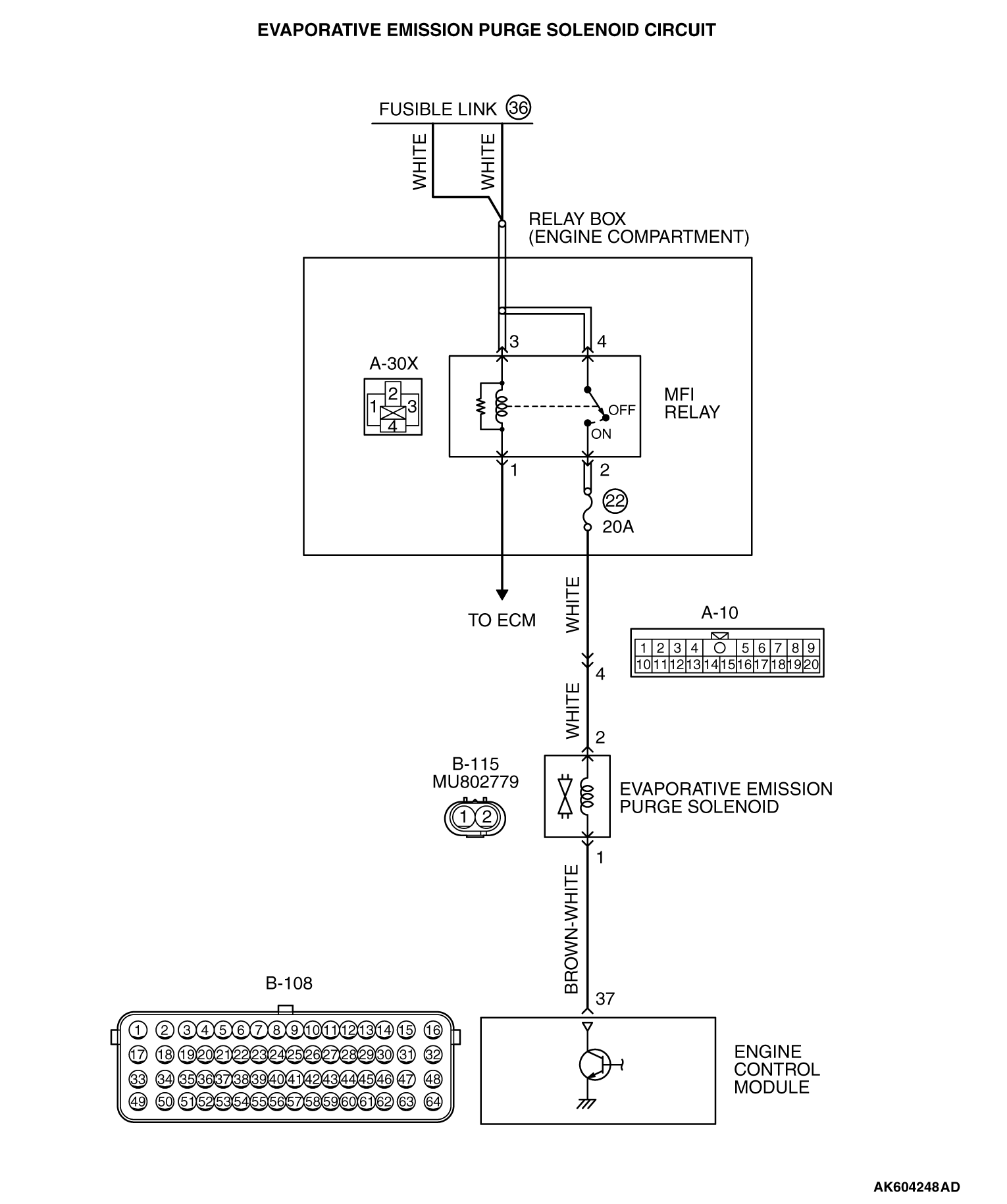

DTC P0443: Evaporative

Emission Control System Purge Control Valve Circuit

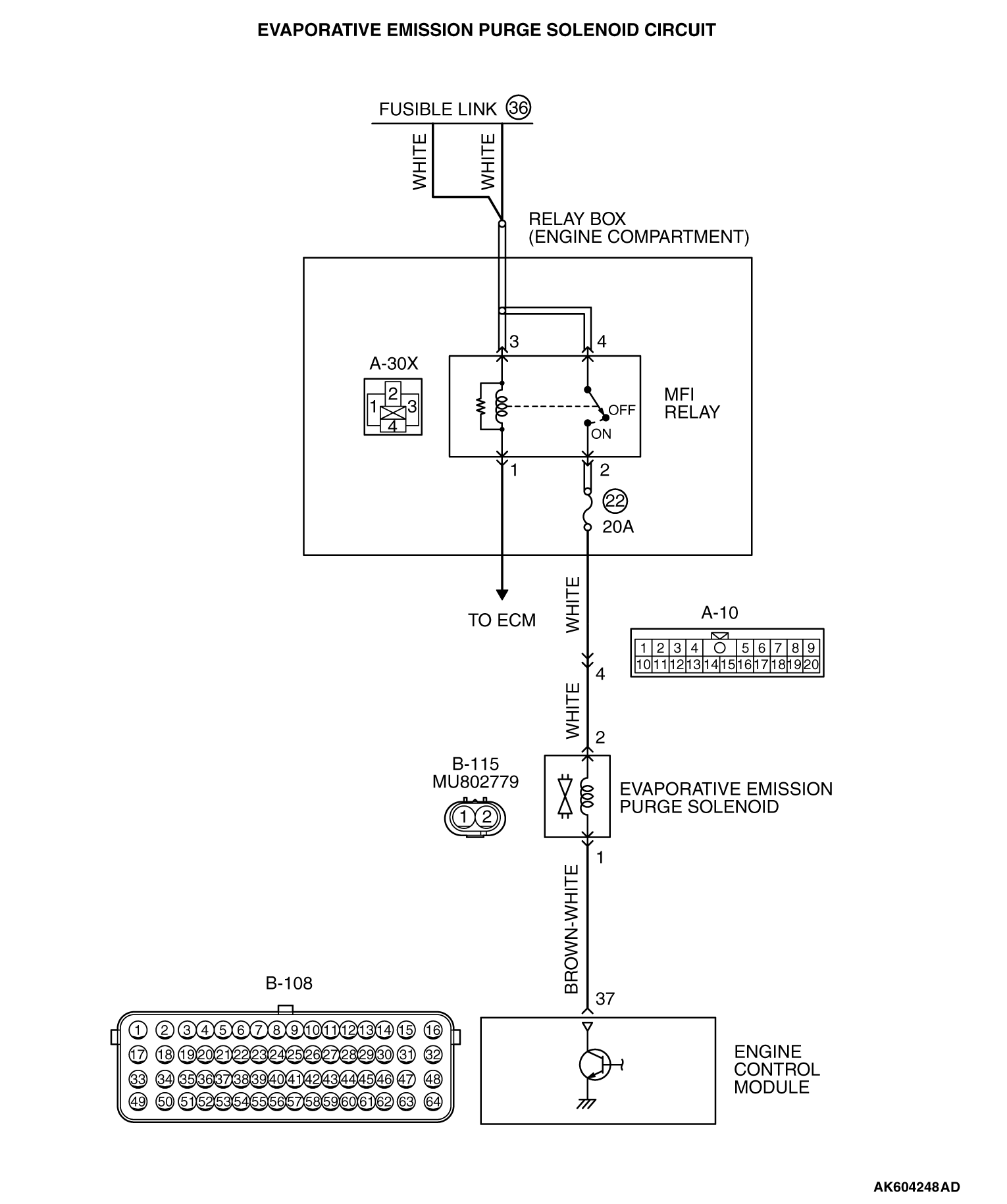

CIRCUIT OPERATION

- The evaporative emission purge solenoid power is supplied

from the MFI relay (terminal No. 2).

- The ECM controls ground evaporative emission purge solenoid by turning the power

transistor in the ECM "ON" and "OFF".

TECHNICAL DESCRIPTION

- To judge if there is open circuit in the evaporative

emission purge solenoid drive circuit, the ECM measures the surge voltage of the evaporative

emission purge solenoid coil.

DESCRIPTIONS OF MONITOR METHODS

Off-surge does not occur after solenoid is operated

from on to off.

MONITOR EXECUTION

MONITOR EXECUTION CONDITIONS (Other monitor and Sensor)

Other Monitor (There is no temporary DTC stored in memory

for the item monitored below)

Sensor (The sensor below is determined to be normal)

DTC SET CONDITIONS

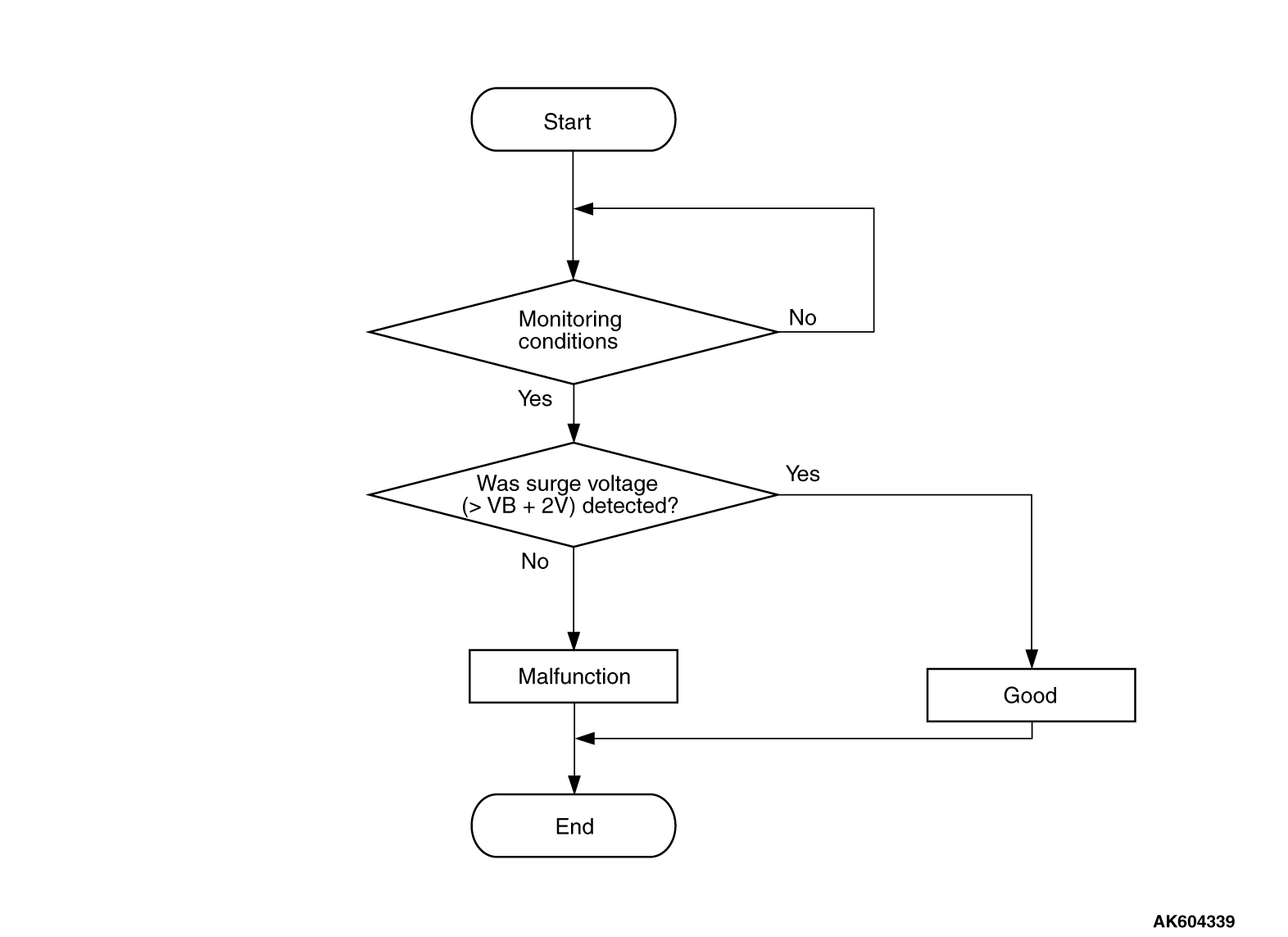

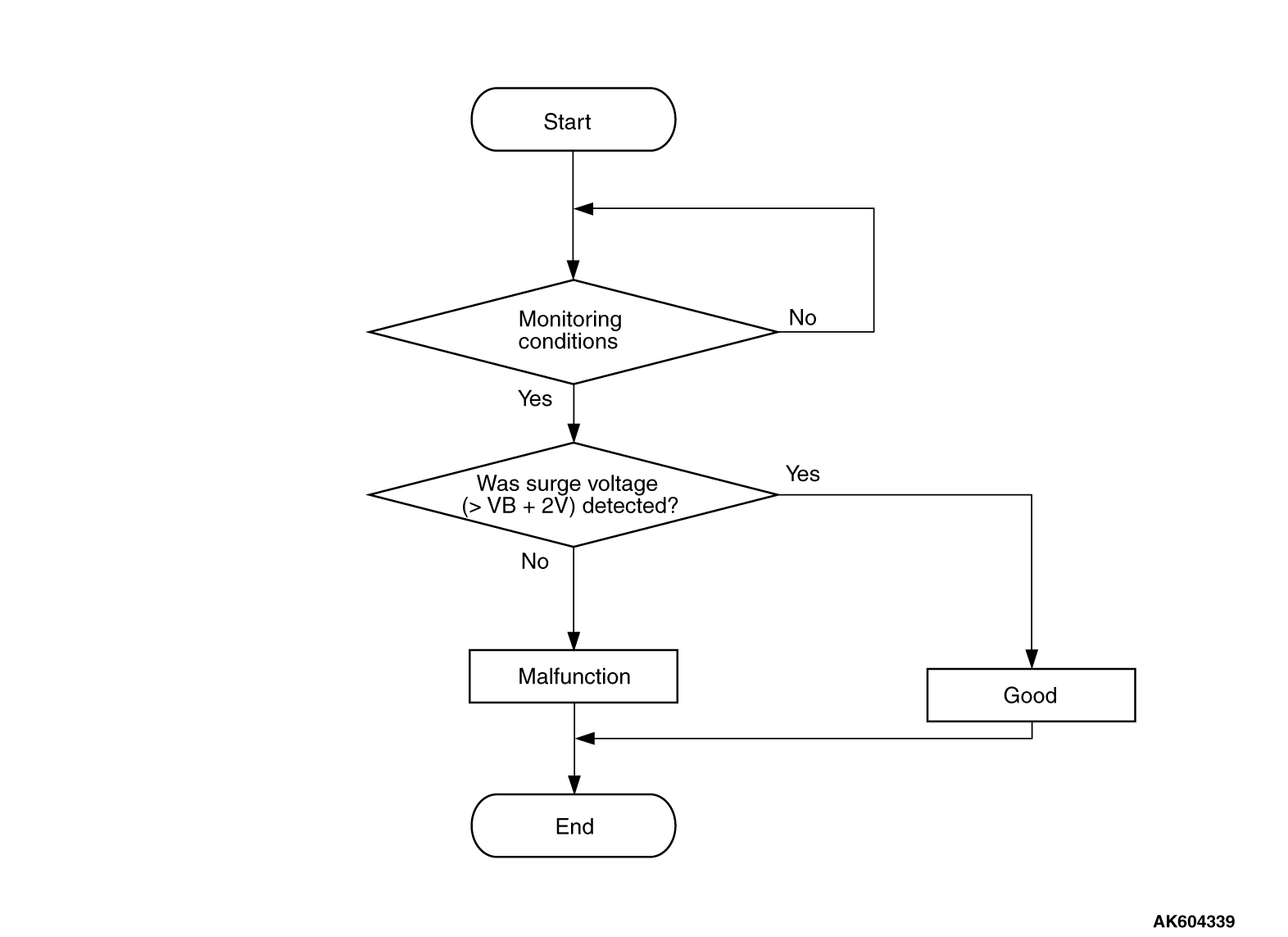

Logic Flow Chart

Check Conditions

- Engine is being cranked.

- Battery positive voltage is between 10 and 16.5 volts.

Judgement Criteria

- The evaporative emission purge solenoid coil surge voltage (battery positive voltage + 2

volts) is not detected for 0.2 second.

- The ECM monitors for this condition once during the drive cycle.

Check Conditions

- Battery positive voltage is between 10 and 16.5 volts.

- ON duty cycle of the evaporative emission purge solenoid is between 10 and 90 percent.

- Evaporative emission ventilation solenoid is off.

- More than 1 second has elapsed after the above mentioned conditions have been met.

Judgement Criterion

- The evaporative emission purge solenoid coil surge voltage (battery positive voltage + 2

volts) is not detected for 1 second after the evaporative emission purge solenoid is turned

off.

OBD-II DRIVE CYCLE PATTERN

Refer to Diagnostic Function - OBD-II Drive

Cycle - Pattern 23  .

.

TROUBLESHOOTING HINTS (The most likely causes for this code to be set are:)

- Evaporative emission purge solenoid failed.

- Open or shorted evaporative emission purge solenoid circuit, harness damage, or

connector damage.

- ECM failed.

|

|

Required Special Tools:

- MB991958: Scan tool (M.U.T.-III Sub Assembly)

- MB991824: V.C.I.

- MB991827: USB Cable

- MB991910: Main Harness A

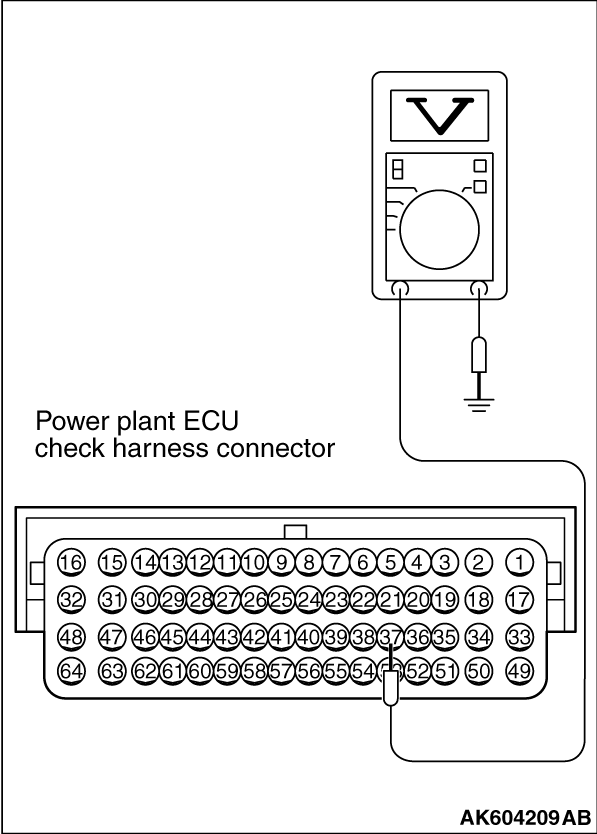

- MB992110: Power Plant ECU Check Harness

|

|

|

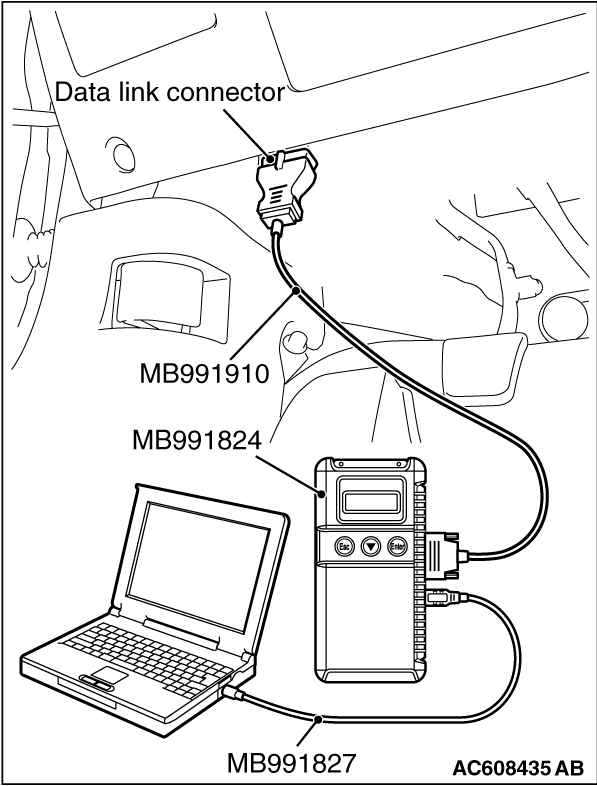

STEP 1. Using scan tool MB991958, check actuator test

item 10: Evaporative Emission Purge Solenoid.

|

|

| caution |

To prevent damage to scan tool MB991958, always turn the ignition switch to the "LOCK"

(OFF) position before connecting or disconnecting scan tool MB991958.

|

(1)Connect scan tool MB991958 to the data link connector.

(2)Turn the ignition switch to the "ON" position.

(3)Set scan tool MB991958 to the actuator test mode for item 10, Evaporative emission

purge solenoid.

- An operation sound should be heard and vibration should

be felt when the evaporative emission purge solenoid is operated.

(4)Turn the ignition switch to the "LOCK" (OFF) position.

Q.

Is the solenoid operating properly?

It can be assumed that this malfunction is intermittent. Refer to GROUP 00, How

to Use Troubleshooting/Inspection Service Points - How Cope with Intermittent

Malfunctions It can be assumed that this malfunction is intermittent. Refer to GROUP 00, How

to Use Troubleshooting/Inspection Service Points - How Cope with Intermittent

Malfunctions  . .

Go to Step 2. Go to Step 2.

|

|

|

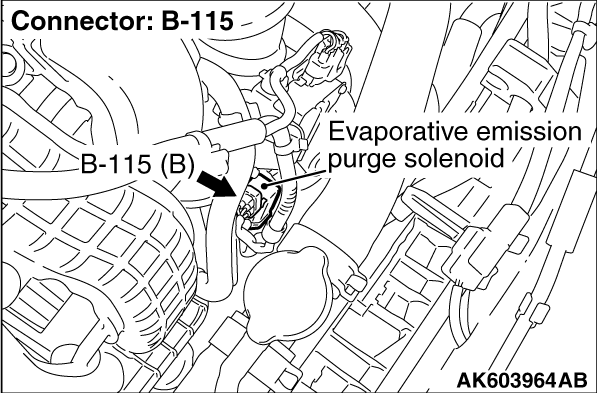

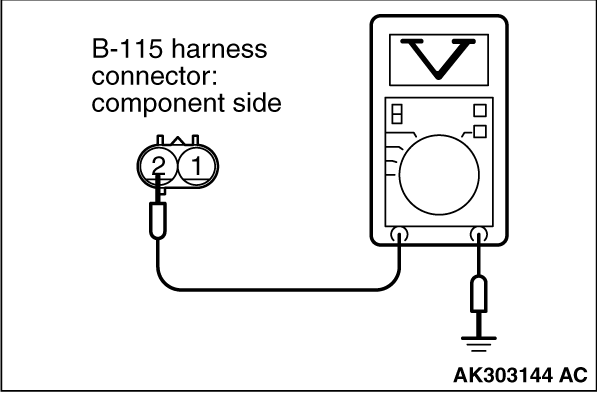

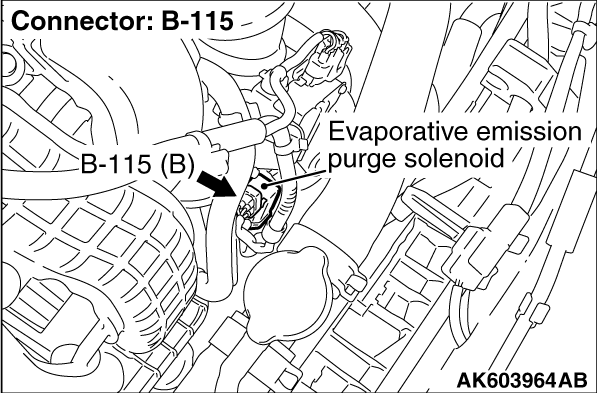

STEP 2. Check harness connector B-115 at the evaporative emission

purge solenoid for damage.

|

|

|

Q.

Is the harness connector in good condition?

|

|

|

Go to Step 3. Go to Step 3.

|

|

|

|

|

|

Repair or replace it. Refer to GROUP 00E, Harness Connector Inspection Repair or replace it. Refer to GROUP 00E, Harness Connector Inspection  .

Then go to Step 10. .

Then go to Step 10.

|

|

|

|

|

|

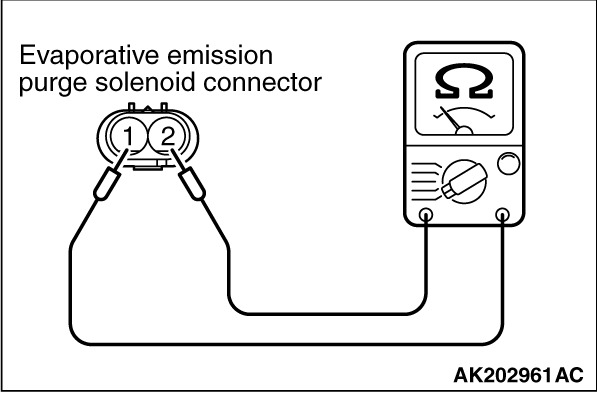

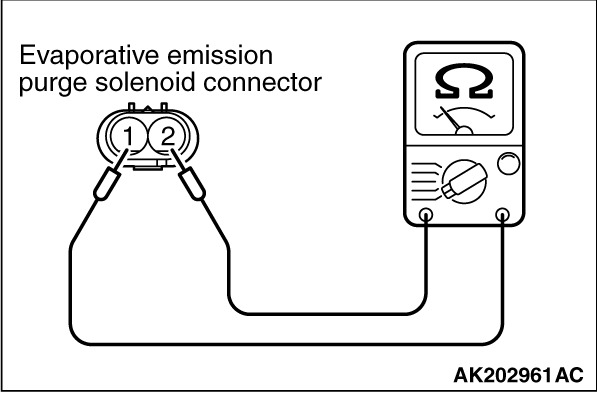

STEP 3. Check the evaporative emission purge solenoid.

|

|

|

(1)Disconnect the evaporative emission purge solenoid connector B-115.

|

|

(2)Measure the resistance between evaporative emission purge solenoid side connector terminal

No. 1 and No. 2.

Standard value: 22 - 26 Ω [at 20°C (68°F)]

Q.

Is the measured resistance between 22 and 26 Ω [at 20°C

(68°F)]?

Go to Step 4. Go to Step 4.

Replace the evaporative emission purge solenoid. Then go to Step 10. Replace the evaporative emission purge solenoid. Then go to Step 10.

|

|

|

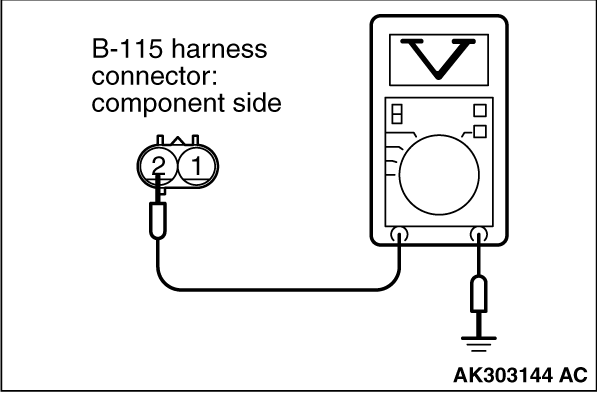

STEP 4. Measure the power supply voltage at evaporative emission purge

solenoid harness side connector B-115.

|

|

|

(1)Disconnect the connector B-115 and measure at the harness side.

|

|

|

(2)Turn the ignition switch to the "ON" position.

|

|

(3)Measure the voltage between terminal No. 2 and ground.

- Voltage should be battery positive voltage.

(4)Turn the ignition switch to the "LOCK" (OFF) position.

Q.

Is battery positive voltage (approximately 12 volts) present?

Go to Step 6. Go to Step 6.

Go to Step 5. Go to Step 5.

|

|

|

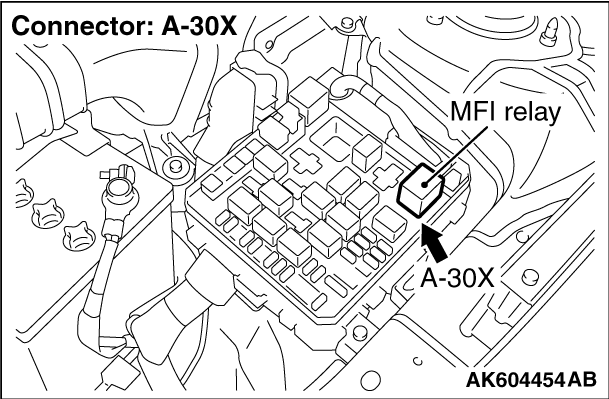

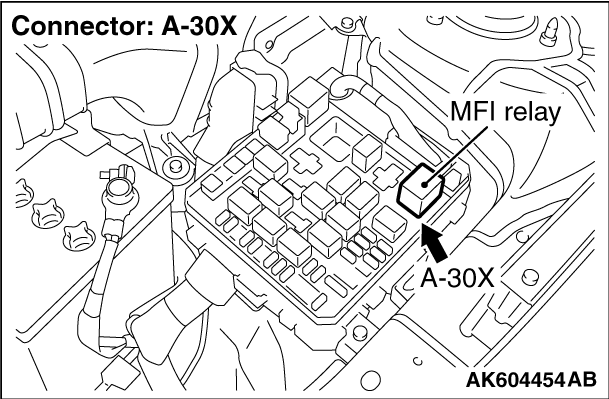

STEP 5. Check harness connector A-30X at MFI relay for damage.

|

|

|

Q.

Is the harness connector in good condition?

|

|

|

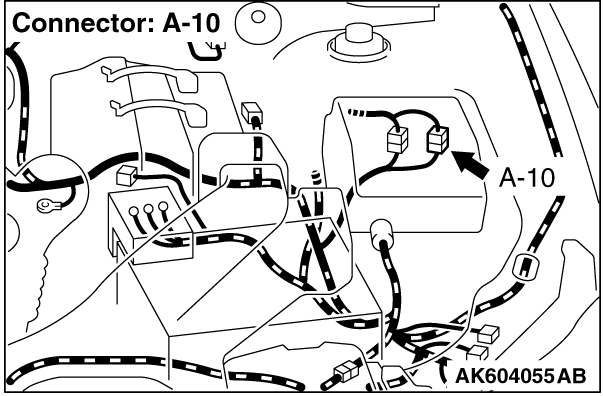

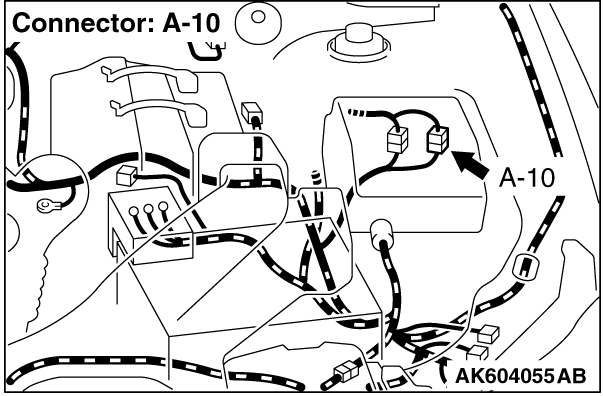

Check harness connector A-10 at intermediate connector for damage, and repair

or replace as required. Refer to GROUP 00E, Harness Connector Inspection Check harness connector A-10 at intermediate connector for damage, and repair

or replace as required. Refer to GROUP 00E, Harness Connector Inspection  .

If intermediate connector is in good condition, repair harness wire between MFI relay connector

A-30X (terminal No. 2) and evaporative emission purge solenoid connector B-115 (terminal No.

2) because of open circuit or short circuit to ground. Then go to Step 10. .

If intermediate connector is in good condition, repair harness wire between MFI relay connector

A-30X (terminal No. 2) and evaporative emission purge solenoid connector B-115 (terminal No.

2) because of open circuit or short circuit to ground. Then go to Step 10.

|

|

|

|

|

|

Repair or replace it. Refer to GROUP 00E, Harness Connector Inspection Repair or replace it. Refer to GROUP 00E, Harness Connector Inspection  .

Then go to Step 10. .

Then go to Step 10.

|

|

|

|

|

|

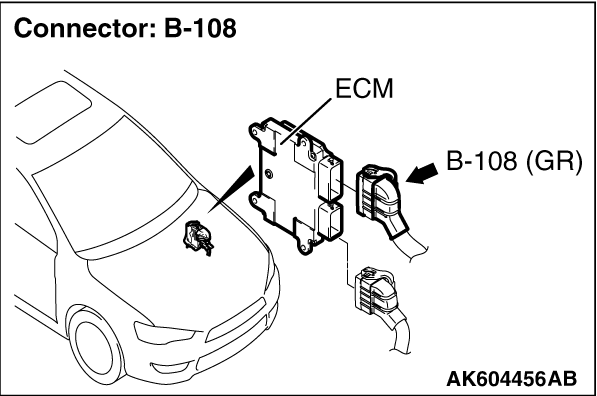

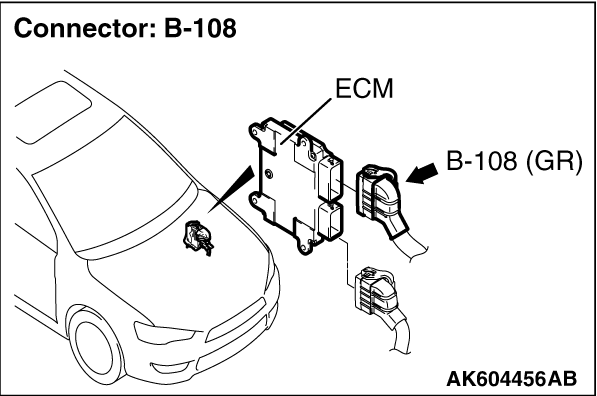

STEP 6. Check harness connector B-108 at the ECM for damage.

|

|

|

Q.

Is the harness connector in good condition?

|

|

|

Go to Step 7. Go to Step 7.

|

|

|

|

|

|

Repair or replace it. Refer to GROUP 00E, Harness Connector Inspection Repair or replace it. Refer to GROUP 00E, Harness Connector Inspection  .

Then go to Step 10. .

Then go to Step 10.

|

|

|

|

|

|

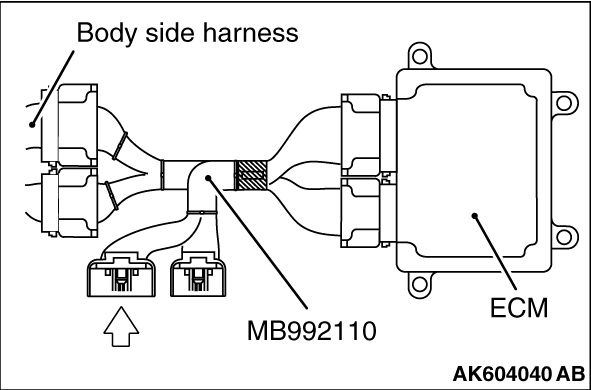

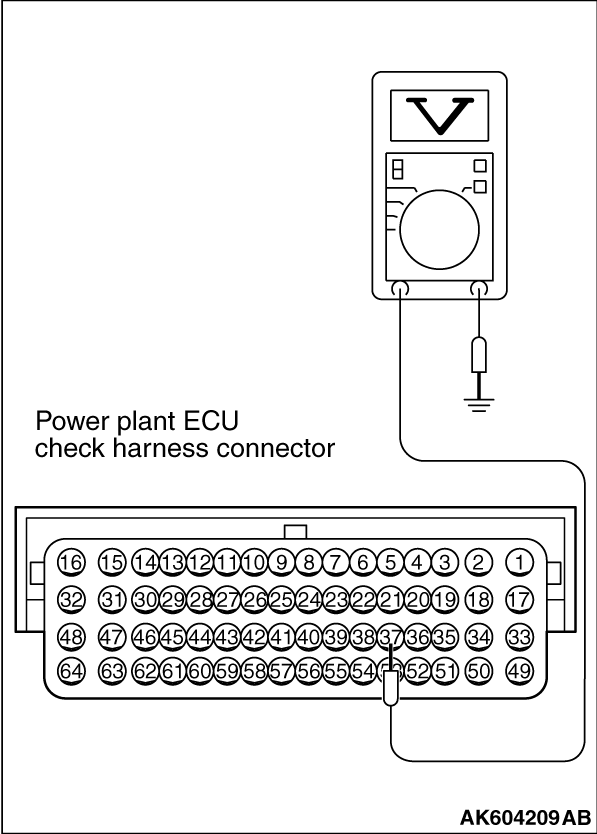

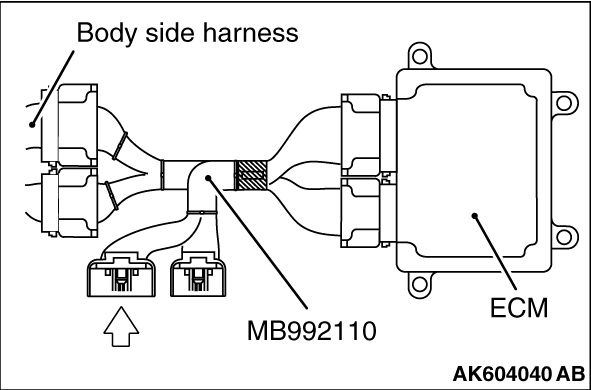

STEP 7. Measure the power supply voltage at ECM connector B-108 by

using power plant ECU check harness special tool MB992110.

|

|

(1)Disconnect all ECM connectors. Connect the power plant ECU check harness special

tool MB992110 between the separated connectors.

(2)Turn the ignition switch to the "ON" position.

|

|

(3)Measure the voltage between terminal No. 37 and ground.

- Voltage should be battery positive voltage.

(4)Turn the ignition switch to the "LOCK" (OFF) position.

Q.

Is battery positive voltage (approximately 12 volts) present?

Go to Step 8. Go to Step 8.

Repair harness wire between evaporative emission purge solenoid connector B-115

(terminal No. 1) and ECM connector B-108 (terminal No. 37) because of open circuit or short

circuit to ground. Then go to Step 10. Repair harness wire between evaporative emission purge solenoid connector B-115

(terminal No. 1) and ECM connector B-108 (terminal No. 37) because of open circuit or short

circuit to ground. Then go to Step 10.

|

|

|

STEP 8. Check for harness damage between MFI relay connector A-30X

(terminal No. 2) and evaporative emission purge solenoid connector B-115 (terminal No. 2).

|

|

|

| note |

Check harness connector after checking intermediate connector A-10. If intermediate connector

is damaged, repair or replace it. Refer to GROUP 00E, Harness Connector Inspection  .

Then go to Step 10. .

Then go to Step 10.

|

|

|

|

Q.

Is the harness wire in good condition?

|

|

|

Go to Step 9. Go to Step 9.

|

|

|

|

|

|

Repair it. Then go to Step 10. Repair it. Then go to Step 10.

|

|

|

|

|

|

STEP 9. Check for harness damage between evaporative emission purge

solenoid connector B-115 (terminal No. 1) and ECM connector B-108 (terminal No. 37).

|

|

|

Q.

Is the harness wire in good condition?

|

|

|

Replace the ECM. When the ECM is replaced, register the ID code. Refer to GROUP

42B, Diagnosis - ID Code Registration Judgment Table <Vehicles with KOS> Replace the ECM. When the ECM is replaced, register the ID code. Refer to GROUP

42B, Diagnosis - ID Code Registration Judgment Table <Vehicles with KOS>  or

GROUP 42C, Diagnosis - ID Codes Registration Judgment Table <Vehicles with WCM> or

GROUP 42C, Diagnosis - ID Codes Registration Judgment Table <Vehicles with WCM>  .

Then go to Step 10. .

Then go to Step 10.

|

|

|

|

|

|

Repair it. Then go to Step 10. Repair it. Then go to Step 10.

|

|

|

|

|

|

STEP 10. Test the OBD-II drive cycle.

|

|

|

(1)Carry out a test drive with the drive cycle pattern. Refer to Diagnostic Function - OBD-II

Drive Cycle - Pattern 23  . .

|

|

|

(2)Check the diagnostic trouble code (DTC).

|

|

|

Retry the troubleshooting. Retry the troubleshooting.

|

|

|

|

|

|

The inspection is complete. The inspection is complete.

|

|

|

|

.

.![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)

.

. Go to Step 3.

Go to Step 3. Repair or replace it. Refer to GROUP 00E, Harness Connector Inspection

Repair or replace it. Refer to GROUP 00E, Harness Connector Inspection  .

Then go to Step 10.

.

Then go to Step 10.

Go to Step 4.

Go to Step 4. Replace the evaporative emission purge solenoid. Then go to Step 10.

Replace the evaporative emission purge solenoid. Then go to Step 10.

Go to Step 6.

Go to Step 6. Go to Step 5.

Go to Step 5. Check harness connector A-10 at intermediate connector for damage, and repair

or replace as required. Refer to GROUP 00E, Harness Connector Inspection

Check harness connector A-10 at intermediate connector for damage, and repair

or replace as required. Refer to GROUP 00E, Harness Connector Inspection  .

If intermediate connector is in good condition, repair harness wire between MFI relay connector

A-30X (terminal No. 2) and evaporative emission purge solenoid connector B-115 (terminal No.

2) because of open circuit or short circuit to ground. Then go to Step 10.

.

If intermediate connector is in good condition, repair harness wire between MFI relay connector

A-30X (terminal No. 2) and evaporative emission purge solenoid connector B-115 (terminal No.

2) because of open circuit or short circuit to ground. Then go to Step 10. Repair or replace it. Refer to GROUP 00E, Harness Connector Inspection

Repair or replace it. Refer to GROUP 00E, Harness Connector Inspection  .

Then go to Step 10.

.

Then go to Step 10. Go to Step 7.

Go to Step 7. Repair or replace it. Refer to GROUP 00E, Harness Connector Inspection

Repair or replace it. Refer to GROUP 00E, Harness Connector Inspection  .

Then go to Step 10.

.

Then go to Step 10.

Go to Step 8.

Go to Step 8. Repair harness wire between evaporative emission purge solenoid connector B-115

(terminal No. 1) and ECM connector B-108 (terminal No. 37) because of open circuit or short

circuit to ground. Then go to Step 10.

Repair harness wire between evaporative emission purge solenoid connector B-115

(terminal No. 1) and ECM connector B-108 (terminal No. 37) because of open circuit or short

circuit to ground. Then go to Step 10. Go to Step 9.

Go to Step 9. Repair it. Then go to Step 10.

Repair it. Then go to Step 10. Replace the ECM. When the ECM is replaced, register the ID code. Refer to GROUP

42B, Diagnosis - ID Code Registration Judgment Table <Vehicles with KOS>

Replace the ECM. When the ECM is replaced, register the ID code. Refer to GROUP

42B, Diagnosis - ID Code Registration Judgment Table <Vehicles with KOS>  or

GROUP 42C, Diagnosis - ID Codes Registration Judgment Table <Vehicles with WCM>

or

GROUP 42C, Diagnosis - ID Codes Registration Judgment Table <Vehicles with WCM>  .

Then go to Step 10.

.

Then go to Step 10. Repair it. Then go to Step 10.

Repair it. Then go to Step 10. .

. Retry the troubleshooting.

Retry the troubleshooting. The inspection is complete.

The inspection is complete.