![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)

DTC P0171: System

too Lean

Fuel Trim Circuit

- Refer to DTC P0201 - Injector Circuit-Cylinder 1

,

DTC P0202 - Injector Circuit-Cylinder 2

,

DTC P0202 - Injector Circuit-Cylinder 2  , DTC P0203 - Injector

Circuit-Cylinder 3

, DTC P0203 - Injector

Circuit-Cylinder 3  , DTC P0204 - Injector Circuit-Cylinder

4

, DTC P0204 - Injector Circuit-Cylinder

4  .

.

CIRCUIT OPERATION

- Refer to DTC P0201 - Injector Circuit-Cylinder 1

,

DTC P0202 - Injector Circuit-Cylinder 2

,

DTC P0202 - Injector Circuit-Cylinder 2  , DTC P0203 - Injector

Circuit-Cylinder 3

, DTC P0203 - Injector

Circuit-Cylinder 3  , DTC P0204 - Injector Circuit-Cylinder

4

, DTC P0204 - Injector Circuit-Cylinder

4  .

.

TECHNICAL DESCRIPTION

- If a malfunction occurs in the fuel system, the fuel

trim value becomes too large.

- The ECM checks whether the fuel trim value is within a specified range.

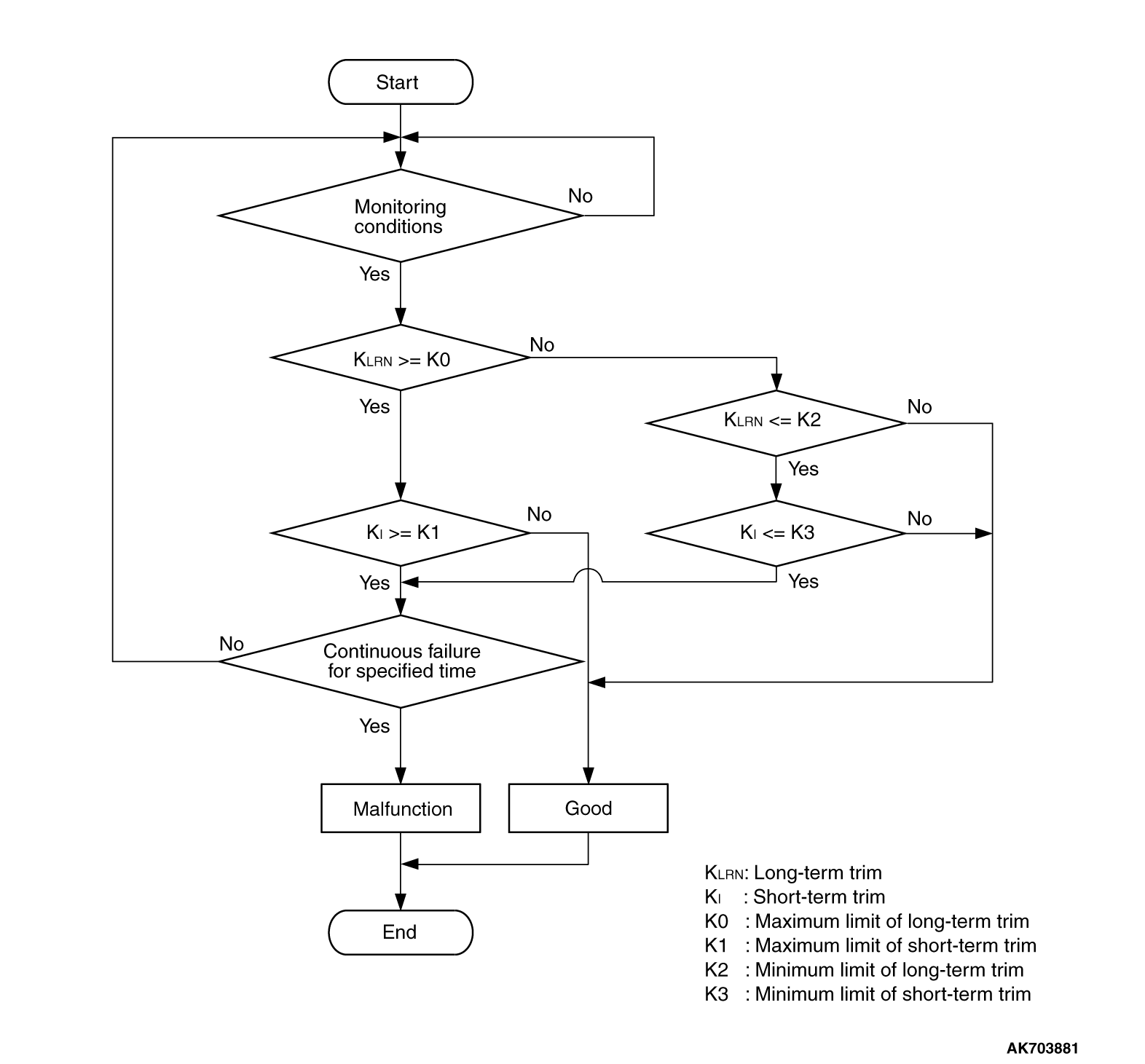

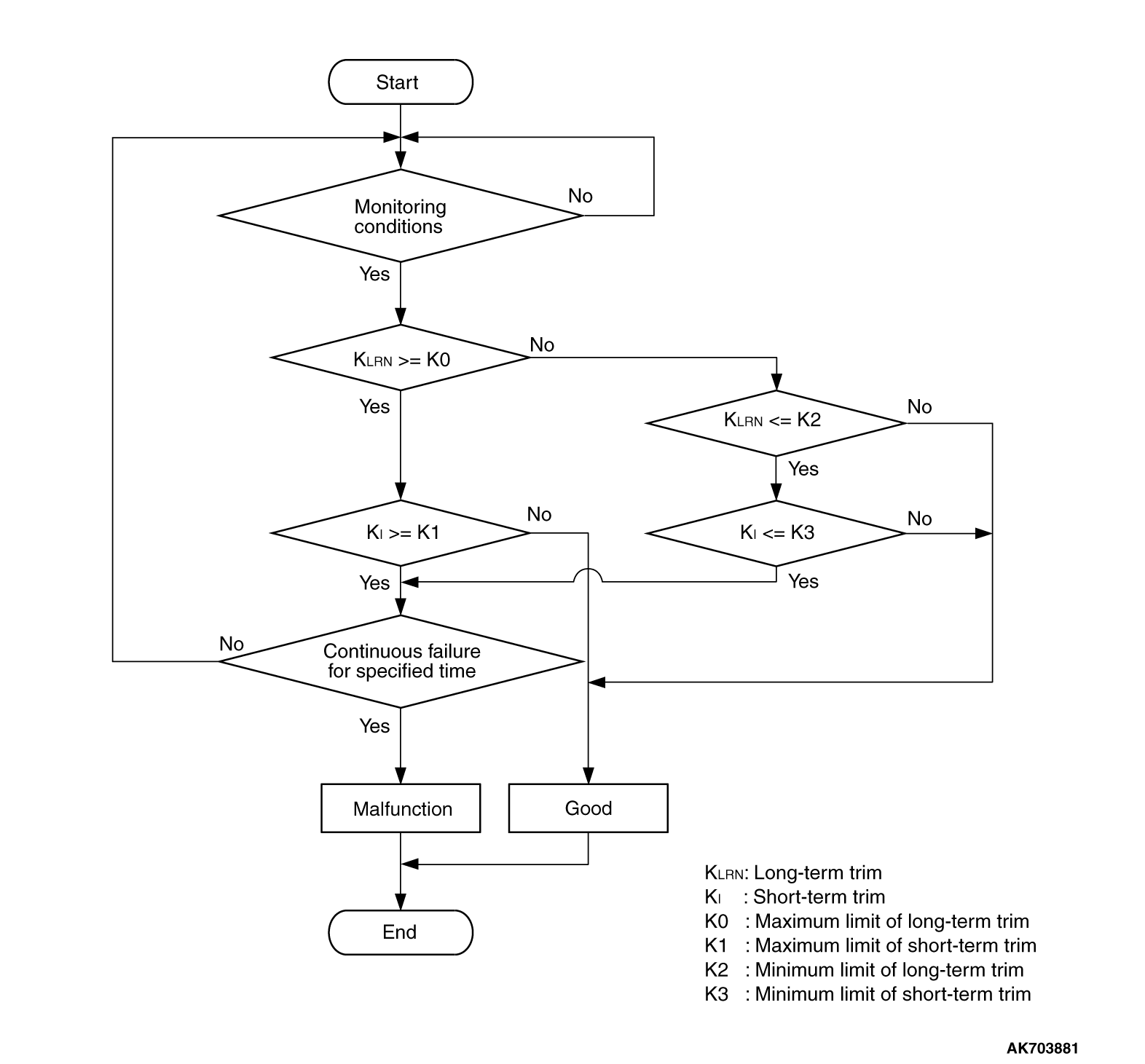

DESCRIPTIONS OF MONITOR METHODS

Air/fuel learning value (long time fuel trim) and

air/fuel feedback integral value (short time fuel trim) are too lean.

MONITOR EXECUTION

MONITOR EXECUTION CONDITIONS (Other monitor and Sensor)

Other Monitor (There is no temporary DTC stored in memory

for the item monitored below)

Sensor (The sensor below is determined to be normal)

- Mass airflow sensor

- Engine coolant temperature sensor

- Intake air temperature sensor

- Barometric pressure sensor

- Throttle position sensor

DTC SET CONDITIONS

Logic Flow Chart

Check Conditions

- Engine coolant temperature is lower than 100°C (212°F) when the engine

is started.

- Intake air temperature is lower than 60°C (140°F) when the engine

is started.

- Under the closed loop air/fuel ratio control.

- Engine coolant temperature is higher than 76°C (169°F).

- Mass airflow sensor output is 10 g/sec <M/T> or 6 g/sec <CVT> or more.

Judgement Criterion

- Long-term fuel trim has continued to be higher than +12.5 percent for 5 seconds.

or

- Short-term fuel trim has continued to be higher than +7.0

percent <Except for California> or +5.5 percent <California> for 5 seconds.

Check Conditions

- Engine coolant temperature is lower than 100°C (212°F) when the engine

is started.

- Intake air temperature is lower than 60°C (140°F) when the engine

is started.

- Under the closed loop air/fuel ratio control.

- Engine coolant temperature is higher than 76°C (169°F).

- Mass airflow sensor output is 10 g/sec <M/T> or 6 g/sec <CVT> or less.

Judgement Criterion

- Long-term fuel trim has continued to be higher than +12.5 percent for 5 seconds.

or

- Short-term fuel trim has continued to be higher than +12.1

percent <Except for California> or +10.5 percent <California> for 5 seconds.

Check Conditions

- Engine coolant temperature is higher than 100°C (212°F) when the engine

is started.

- Intake air temperature is higher than 60°C (140°F) when the engine

is started.

- Under the closed loop air/fuel ratio control.

- Engine coolant temperature is higher than 76°C (169°F).

- Mass airflow sensor output is 10 g/sec <M/T> or 6 g/sec <CVT> or more.

Judgement Criteria

- Long-term fuel trim has continued to be higher than +12.5 percent for 5 seconds.

or

- Short-term fuel trim has continued to be higher than +17.2

percent <Except for California> or +15.6 percent <California> for 5 seconds.

Check Conditions

- Engine coolant temperature is higher than 100°C (212°F) when the engine

is started.

- Intake air temperature is higher than 60°C (140°F) when the engine

is started.

- Under the closed loop air/fuel ratio control.

- Engine coolant temperature is higher than 76°C (169°F).

- Mass airflow sensor output is 10 g/sec <M/T> or 6 g/sec <CVT> or less.

Judgement Criterion

- Long-term fuel trim has continued to be higher than +12.5 percent for 5 seconds.

or

- Short-term fuel trim has continued to be higher than +22.3

percent <Except for California> or +20.7 percent <California> for 5 seconds.

Check Conditions

- Engine coolant temperature is higher than 76°C (169°F).

- Under the closed loop air/fuel ratio control.

Judgement Criterion

- Long-term fuel trim has continued to be +12.5 percent for 2 seconds.

or

- Short-term fuel trim has continued to be +25.0

percent for 2 seconds.

OBD-II DRIVE CYCLE PATTERN

Refer to Diagnostic Function - OBD-II Drive

Cycle - Pattern 21  .

.

TROUBLESHOOTING HINTS (The most likely causes for this code

to be set are:)

- Mass airflow sensor failed.

- Injector failed.

- Incorrect fuel pressure.

- Air drawn in from gaps in gasket, seals, etc.

- Engine coolant temperature sensor failed.

- Intake air temperature sensor failed.

- Barometric pressure sensor failed.

- Manifold absolute pressure sensor failed.

- Exhaust leak.

- Use of incorrect or contaminated fuel.

- Harness damage in injector circuit or connector damage.

- ECM failed.

|

|

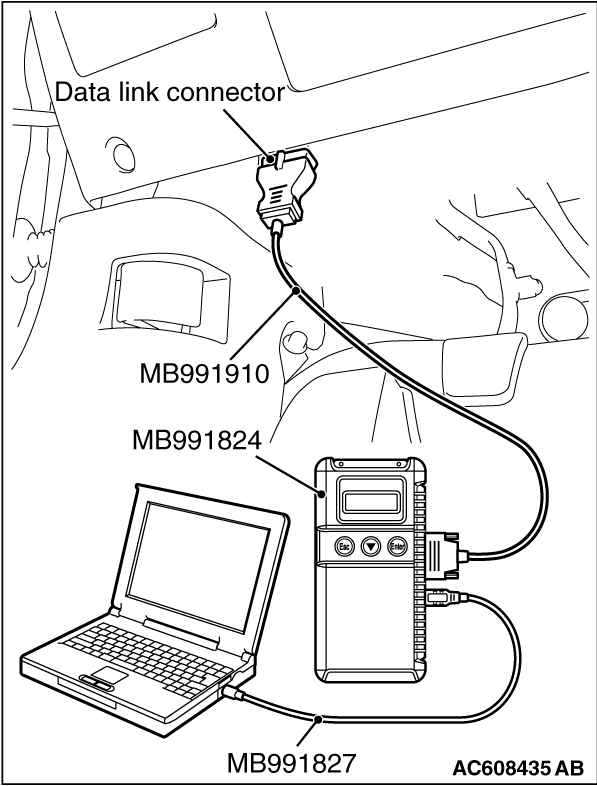

Required Special Tools:

- MB991958: Scan Tool (M.U.T.-III Sub Assembly)

- MB991824: V.C.I.

- MB991827: USB Cable

- MB991910: Main Harness A

|

|

|

STEP 1. Check for exhaust leak.

|

|

|

Q.

Are there any abnormalities?

|

|

|

Repair it. Then go to Step 14. Repair it. Then go to Step 14.

|

|

|

|

|

|

Go to Step 2. Go to Step 2.

|

|

|

|

|

|

STEP 2. Check for intake system vacuum leak.

|

|

|

Q.

Are there any abnormalities?

|

|

|

Repair it. Then go to Step 14. Repair it. Then go to Step 14.

|

|

|

|

|

|

Go to Step 3. Go to Step 3.

|

|

|

|

|

|

STEP 3. Using scan tool MB991958, check data list item 10: Mass Airflow

Sensor.

|

|

| caution |

To prevent damage to scan tool MB991958, always turn the ignition switch to the "LOCK"

(OFF) position before connecting or disconnecting scan tool MB991958.

|

(1)Connect scan tool MB991958 to the data link connector.

(2)Start the engine and run at idle.

(3)Set scan tool MB991958 to the data reading mode for item 10, Mass Airflow Sensor.

(4)Warm up the engine to normal operating temperature: 80°C to 95°C

(176°F to 203°F).

- When idling, between 1,350 and 1,670 mV.

- When 2,500 r/min, between 1,620 and 2,020 millivolts.

(5)Turn the ignition switch to the "LOCK" (OFF) position.

Q.

Is the sensor operating properly?

Go to Step 4. Go to Step 4.

Refer to DTC P0101 - Mass Airflow Circuit Range/Performance

Problem Refer to DTC P0101 - Mass Airflow Circuit Range/Performance

Problem  , DTC P0102 - Mass Airflow Circuit Low Input , DTC P0102 - Mass Airflow Circuit Low Input  ,

DTC P0103 - Mass Airflow Circuit High Input ,

DTC P0103 - Mass Airflow Circuit High Input  . .

|

|

|

STEP 4. Using scan tool MB991958, check data list item 5: Intake Air

Temperature Sensor.

|

|

|

(1)Turn the ignition switch to the "ON" position.

|

|

|

(2)Set scan tool MB991958 to the data reading mode for item 5, Intake Air Temperature

Sensor.

- The intake air temperature and temperature shown with

the scan tool should approximately match.

|

|

|

(3)Turn the ignition switch to the "LOCK" (OFF) position.

|

|

|

Q.

Is the sensor operating properly?

|

|

|

Go to Step 5. Go to Step 5.

|

|

|

|

|

|

Refer to DTC P0111 - Intake Air Temperature Circuit Range/Performance

Problem Refer to DTC P0111 - Intake Air Temperature Circuit Range/Performance

Problem  , DTC P0112 - Intake Air Temperature Circuit

Low Input , DTC P0112 - Intake Air Temperature Circuit

Low Input  , DTC P0113 - Intake Air Temperature Circuit

High Input , DTC P0113 - Intake Air Temperature Circuit

High Input  . .

|

|

|

|

|

|

STEP 5. Using scan tool MB991958, check data list item 6: Engine Coolant

Temperature Sensor.

|

|

|

(1)Turn the ignition switch to the "ON" position.

|

|

|

(2)Set scan tool MB991958 to the data reading mode for item 6, Engine Coolant Temperature Sensor.

- The engine coolant temperature and temperature shown

with the scan tool should approximately match.

|

|

|

(3)Turn the ignition switch to the "LOCK" (OFF) position.

|

|

|

Q.

Is the sensor operating properly?

|

|

|

Go to Step 6. Go to Step 6.

|

|

|

|

|

|

Refer to DTC P0116 - Engine Coolant Temperature Circuit Range/Performance Problem Refer to DTC P0116 - Engine Coolant Temperature Circuit Range/Performance Problem ,

DTC P0117 - Engine Coolant Temperature Circuit Low Input ,

DTC P0117 - Engine Coolant Temperature Circuit Low Input  ,

DTC P0118 - Engine Coolant Temperature Circuit High Input ,

DTC P0118 - Engine Coolant Temperature Circuit High Input  . .

|

|

|

|

|

|

STEP 6. Using scan tool MB991958, check data list item 8: Manifold

Absolute Pressure Sensor.

|

|

|

(1)Turn the ignition switch the "ON" position.

|

|

|

(2)Set scan tool MB991958 to the data reading mode for item 8, Manifold Absolute Pressure Sensor.

- When altitude is 0 m (0 foot), 101 kPa (29.8 in.Hg).

- When altitude is 600 m (1,969 feet), 95 kPa (28.1 in.Hg).

- When altitude is 1,200 m (3,937 feet), 88 kPa (26.0 in.Hg).

- When altitude is 1,800 m (5,906 feet), 81 kPa (23.9 in.Hg).

|

|

|

(3)Start the engine.

- When the engine is idling, 16 - 36 kPa (4.7 - 10.6 in.Hg).

- When the engine is suddenly revved, manifold absolute pressure varies.

|

|

|

(4)Turn the ignition switch to the "LOCK" (OFF) position.

|

|

|

Q.

Is the sensor operating properly?

|

|

|

Go to Step 7. Go to Step 7.

|

|

|

|

|

|

Refer to DTC P0106 - Manifold Absolute Pressure Circuit Range/Performance

Problem Refer to DTC P0106 - Manifold Absolute Pressure Circuit Range/Performance

Problem  , DTC P0107 - Manifold Absolute Pressure Circuit

Low Input , DTC P0107 - Manifold Absolute Pressure Circuit

Low Input  , DTC P0108 - Manifold Absolute Pressure

Circuit High Input , DTC P0108 - Manifold Absolute Pressure

Circuit High Input  . .

|

|

|

|

|

|

STEP 7. Check harness connector B-101, B-102, B-103 and B104 at injector

for damage.

|

|

|

Q.

Is the harness connector in good condition?

|

|

|

Go to Step 8. Go to Step 8.

|

|

|

|

|

|

Repair or replace it. Refer to GROUP 00E, Harness Connector Inspection Repair or replace it. Refer to GROUP 00E, Harness Connector Inspection  .

Then go to Step 14. .

Then go to Step 14.

|

|

|

|

|

|

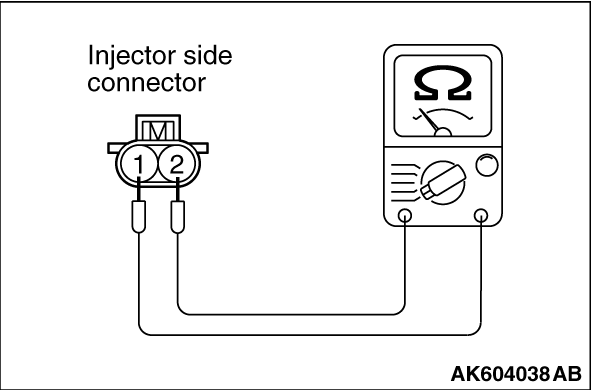

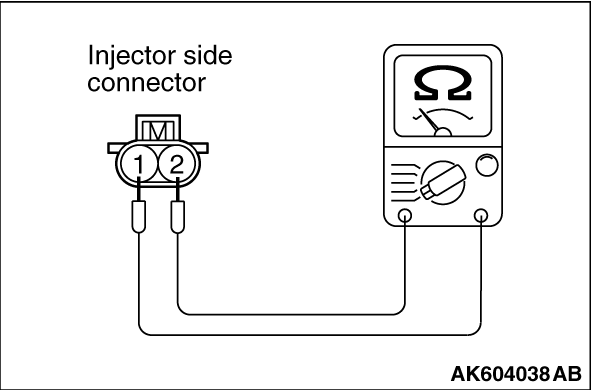

STEP 8. Check the injector.

|

|

|

(1)Disconnect the injector connector B-101, B-102, B-103 and B104.

|

|

(2)Measure the resistance between each injector side connector terminal No. 1 and No. 2.

Standard value: 10.5 - 13.5 Ω [at 20°C (68°F)]

Q.

Is the measured resistance between 10.5 and 13.5 Ω [at 20°C

(68°F)]?

Go to Step 9. Go to Step 9.

Replace the injector. Then go to Step 14. Replace the injector. Then go to Step 14.

|

|

|

STEP 9. Check harness connector B-108 at ECM for damage.

|

|

|

Q.

Is the harness connector in good condition?

|

|

|

Go to Step10. Go to Step10.

|

|

|

|

|

|

Repair or replace it. Refer to GROUP 00E, Harness Connector Inspection Repair or replace it. Refer to GROUP 00E, Harness Connector Inspection  .

Then go to Step 14. .

Then go to Step 14.

|

|

|

|

|

|

STEP 10. Check for harness damage between injector connector and ECM

connector.

|

|

|

- Check the harness wire between injector connector

B-101 (terminal No. 2) and ECM connector B-108 (terminal No. 2) at No. 1 cylinder injector.

- Check the harness wire between injector connector B-102 (terminal No. 2) and ECM

connector B-108 (terminal No.3) at No. 2 cylinder injector.

- Check the harness wire between injector connector B-103 (terminal No. 2) and ECM

connector B-108 (terminal No. 18) at No. 3 cylinder injector.

- Check the harness wire between injector connector B-104 (terminal No. 2) and ECM

connector B-108 (terminal No. 19) at No. 4 cylinder injector.

|

|

|

Q.

Is the harness wire in good condition?

|

|

|

Go to Step 11. Go to Step 11.

|

|

|

|

|

|

Repair it. Then go to Step 14. Repair it. Then go to Step 14.

|

|

|

|

|

|

STEP 11. Check the fuel pressure.

|

|

|

Refer to On-vehicle Service - Fuel Pressure Test  . .

|

|

|

Q.

Is the fuel pressure normal?

|

|

|

Go to Step 12. Go to Step 12.

|

|

|

|

|

|

Repair it. Then go to Step 14. Repair it. Then go to Step 14.

|

|

|

|

|

|

STEP 12. Check for entry of foreign matter (water, kerosene, etc.)

into fuel.

|

|

|

Q.

Are there any abnormalities?

|

|

|

Replace the fuel. Then go to Step 14. Replace the fuel. Then go to Step 14.

|

|

|

|

|

|

Go to Step 13. Go to Step 13.

|

|

|

|

|

|

STEP 13. Replace the injector.

|

|

|

(2)Carry out a test drive with the drive cycle pattern. Refer to Diagnostic Function - OBD-II

Drive Cycle - Pattern 21  . .

|

|

|

(3)Check the diagnostic trouble code (DTC).

|

|

|

Replace the ECM. When the ECM is replaced, register the ID code. Refer to GROUP

42B, Diagnosis - ID Code Registration Judgment Table <Vehicles with KOS> Replace the ECM. When the ECM is replaced, register the ID code. Refer to GROUP

42B, Diagnosis - ID Code Registration Judgment Table <Vehicles with KOS>  or

GROUP 42C, Diagnosis - ID Codes Registration Judgment Table <Vehicles with WCM> or

GROUP 42C, Diagnosis - ID Codes Registration Judgment Table <Vehicles with WCM>  .

Then go to Step 14. .

Then go to Step 14.

|

|

|

|

|

|

The inspection is complete. The inspection is complete.

|

|

|

|

|

|

STEP 14. Test the OBD-II drive cycle.

|

|

|

(1)Carry out a test drive with the drive cycle pattern. Refer to Diagnostic Function - OBD-II

Drive Cycle - Pattern 21  . .

|

|

|

(2)Check the diagnostic trouble code (DTC).

|

|

|

Retry the troubleshooting. Retry the troubleshooting.

|

|

|

|

|

|

The inspection is complete. The inspection is complete.

|

|

|

|

,

DTC P0202 - Injector Circuit-Cylinder 2

,

DTC P0202 - Injector Circuit-Cylinder 2  , DTC P0203 - Injector

Circuit-Cylinder 3

, DTC P0203 - Injector

Circuit-Cylinder 3  , DTC P0204 - Injector Circuit-Cylinder

4

, DTC P0204 - Injector Circuit-Cylinder

4  .

.![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)

,

DTC P0202 - Injector Circuit-Cylinder 2

,

DTC P0202 - Injector Circuit-Cylinder 2  , DTC P0203 - Injector

Circuit-Cylinder 3

, DTC P0203 - Injector

Circuit-Cylinder 3  , DTC P0204 - Injector Circuit-Cylinder

4

, DTC P0204 - Injector Circuit-Cylinder

4  .

. ,

DTC P0202 - Injector Circuit-Cylinder 2

,

DTC P0202 - Injector Circuit-Cylinder 2  , DTC P0203 - Injector

Circuit-Cylinder 3

, DTC P0203 - Injector

Circuit-Cylinder 3  , DTC P0204 - Injector Circuit-Cylinder

4

, DTC P0204 - Injector Circuit-Cylinder

4  .

.

.

. Repair it. Then go to Step 14.

Repair it. Then go to Step 14. Go to Step 2.

Go to Step 2. Repair it. Then go to Step 14.

Repair it. Then go to Step 14. Go to Step 3.

Go to Step 3. Go to Step 5.

Go to Step 5. Refer to DTC P0111 - Intake Air Temperature Circuit Range/Performance

Problem

Refer to DTC P0111 - Intake Air Temperature Circuit Range/Performance

Problem  , DTC P0112 - Intake Air Temperature Circuit

Low Input

, DTC P0112 - Intake Air Temperature Circuit

Low Input  , DTC P0113 - Intake Air Temperature Circuit

High Input

, DTC P0113 - Intake Air Temperature Circuit

High Input  .

. Go to Step 6.

Go to Step 6. Refer to DTC P0116 - Engine Coolant Temperature Circuit Range/Performance Problem

Refer to DTC P0116 - Engine Coolant Temperature Circuit Range/Performance Problem ,

DTC P0117 - Engine Coolant Temperature Circuit Low Input

,

DTC P0117 - Engine Coolant Temperature Circuit Low Input  ,

DTC P0118 - Engine Coolant Temperature Circuit High Input

,

DTC P0118 - Engine Coolant Temperature Circuit High Input  .

. Go to Step 7.

Go to Step 7. Refer to DTC P0106 - Manifold Absolute Pressure Circuit Range/Performance

Problem

Refer to DTC P0106 - Manifold Absolute Pressure Circuit Range/Performance

Problem  , DTC P0107 - Manifold Absolute Pressure Circuit

Low Input

, DTC P0107 - Manifold Absolute Pressure Circuit

Low Input  , DTC P0108 - Manifold Absolute Pressure

Circuit High Input

, DTC P0108 - Manifold Absolute Pressure

Circuit High Input  .

. Go to Step 8.

Go to Step 8. Repair or replace it. Refer to GROUP 00E, Harness Connector Inspection

Repair or replace it. Refer to GROUP 00E, Harness Connector Inspection  .

Then go to Step 14.

.

Then go to Step 14.

Go to Step 9.

Go to Step 9. Replace the injector. Then go to Step 14.

Replace the injector. Then go to Step 14. Go to Step10.

Go to Step10. Repair or replace it. Refer to GROUP 00E, Harness Connector Inspection

Repair or replace it. Refer to GROUP 00E, Harness Connector Inspection  .

Then go to Step 14.

.

Then go to Step 14. Go to Step 11.

Go to Step 11. Repair it. Then go to Step 14.

Repair it. Then go to Step 14. .

.  Go to Step 12.

Go to Step 12. Repair it. Then go to Step 14.

Repair it. Then go to Step 14. Replace the fuel. Then go to Step 14.

Replace the fuel. Then go to Step 14. Go to Step 13.

Go to Step 13. .

. Replace the ECM. When the ECM is replaced, register the ID code. Refer to GROUP

42B, Diagnosis - ID Code Registration Judgment Table <Vehicles with KOS>

Replace the ECM. When the ECM is replaced, register the ID code. Refer to GROUP

42B, Diagnosis - ID Code Registration Judgment Table <Vehicles with KOS>  or

GROUP 42C, Diagnosis - ID Codes Registration Judgment Table <Vehicles with WCM>

or

GROUP 42C, Diagnosis - ID Codes Registration Judgment Table <Vehicles with WCM>  .

Then go to Step 14.

.

Then go to Step 14. The inspection is complete.

The inspection is complete. .

. Retry the troubleshooting.

Retry the troubleshooting. The inspection is complete.

The inspection is complete.