|

|

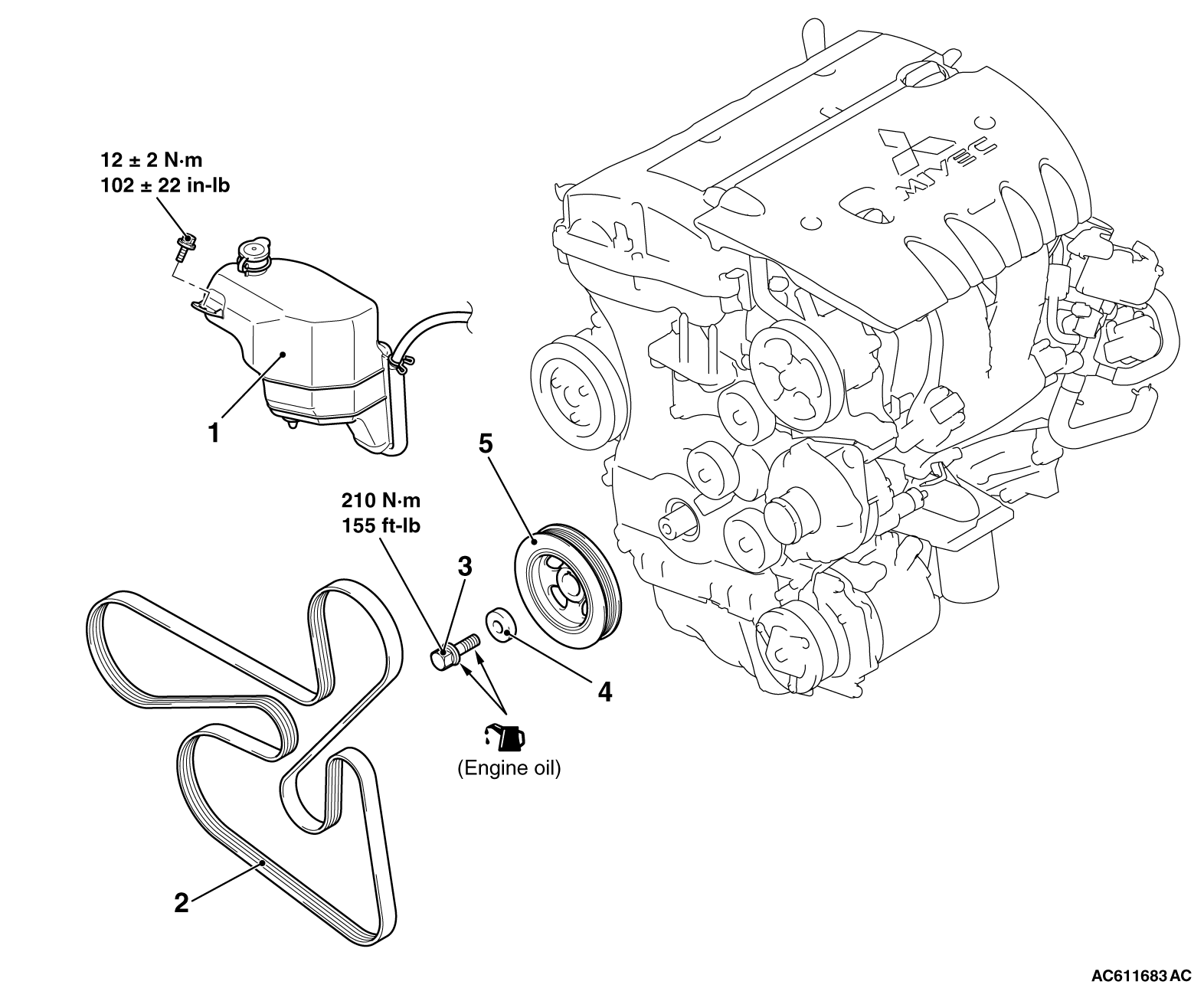

Remove the radiator condenser tank assembly mounting bolt, and move the radiator condenser

tank assembly to a place where it does not interfere with the drive belt removal and installation.

|

|

|

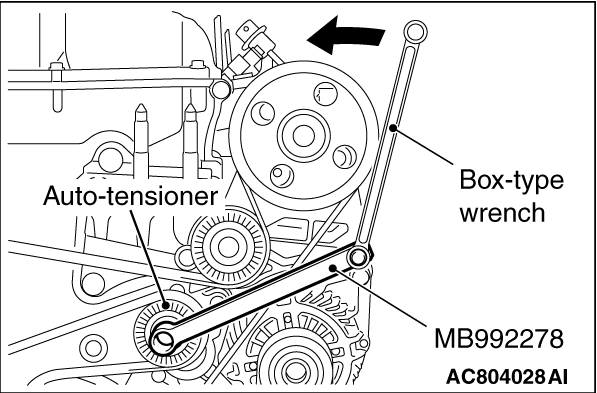

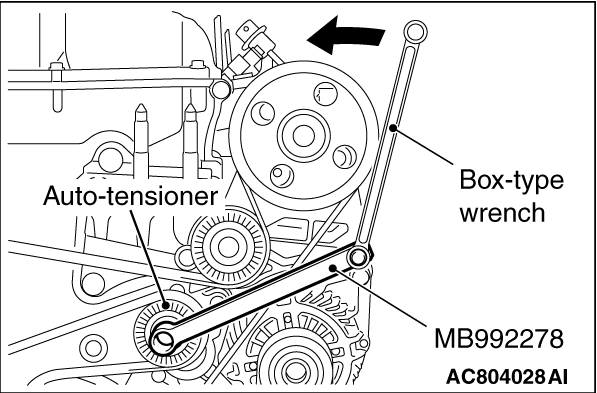

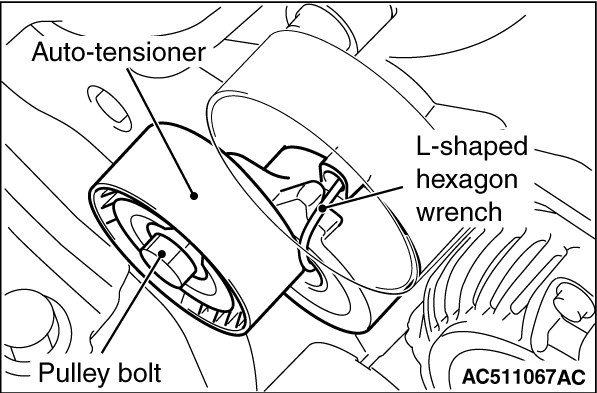

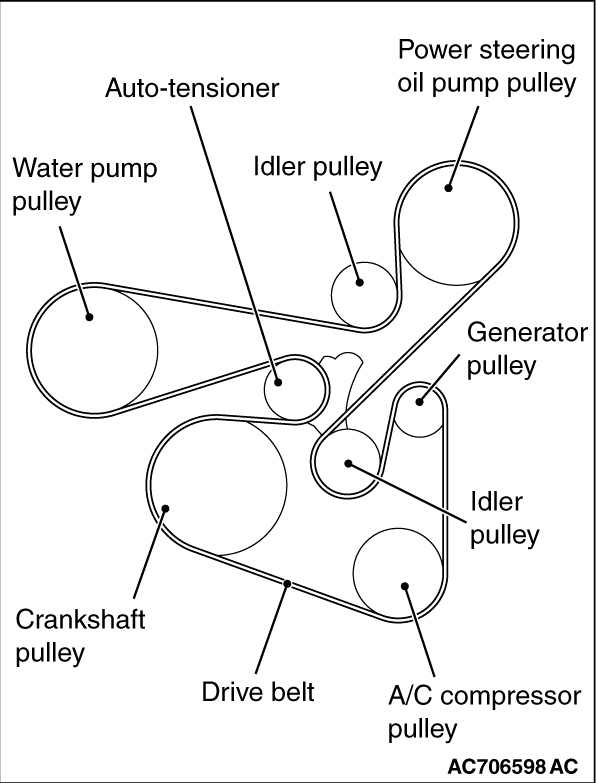

Since the serpentine drive system with the auto-tensioner is used, the following operations

will be required.

|

|

1.

| caution |

To reuse the drive belt, draw an arrow indicating the rotating

direction on the back of the belt using chalk to install the same direction.

|

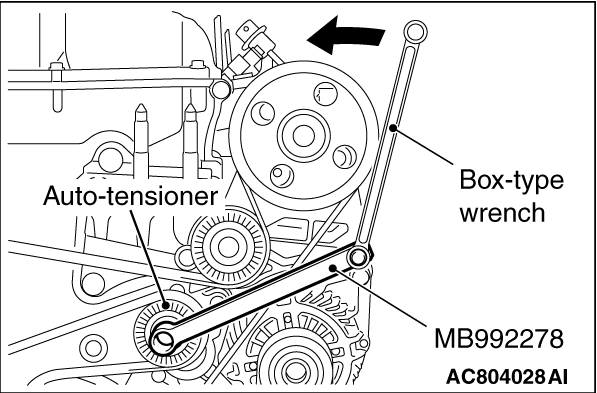

| warning |

Always work from above when releasing the tension of the

auto-tensioner. When you try to gain access from underneath the vehicle, you will experience difficulty,

thus causing the tool to be dropped off.

|

| caution |

To work at the optimum angle, you must choose a most suitable

box-type wrench is applied to the special tool.

|

| warning |

Be sure to set the box-type wrench and the special tool MB992278

to the hexagonal parts securely to prevent the tool from falling off because the tension of

the auto-tensioner is high.

|

Install special tool MB992278 and a box-type wrench at the optimum angle.

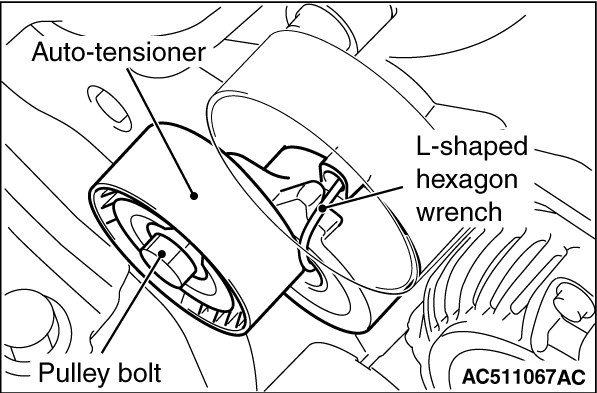

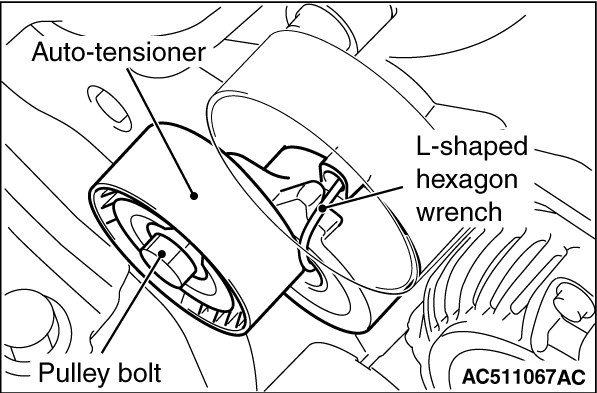

2.Rotate the pulley bolt of the auto-tensioner counterclockwise.

3.Insert the L-shaped hexagon wrench into the auto-tensioner hole to fix the auto-tensioner.

4.Remove the drive belt.

|

|

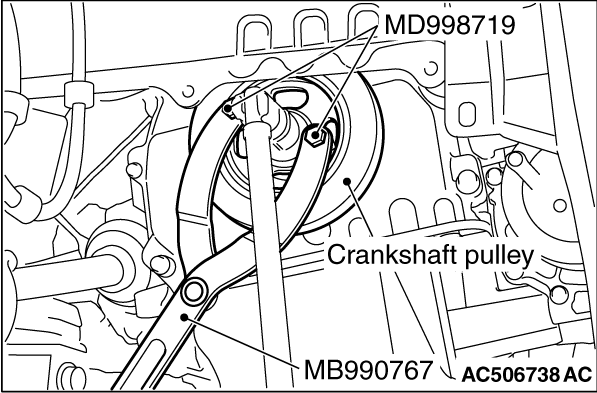

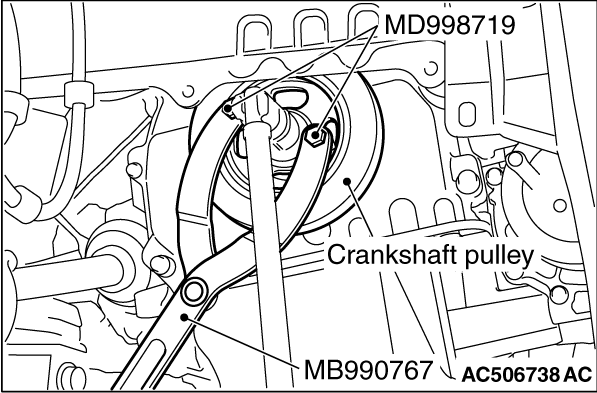

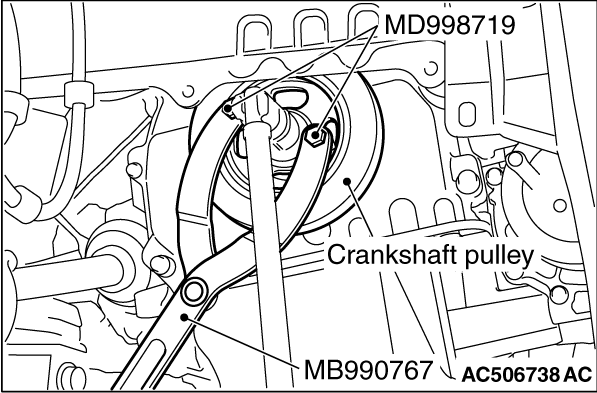

1.Hold the crankshaft pulley with special tools MB990767 and MD998719.

2.Loosen the crankshaft pulley center bolt and remove the crankshaft pulley center bolt,

crankshaft pulley washer and crankshaft pulley.

|

|

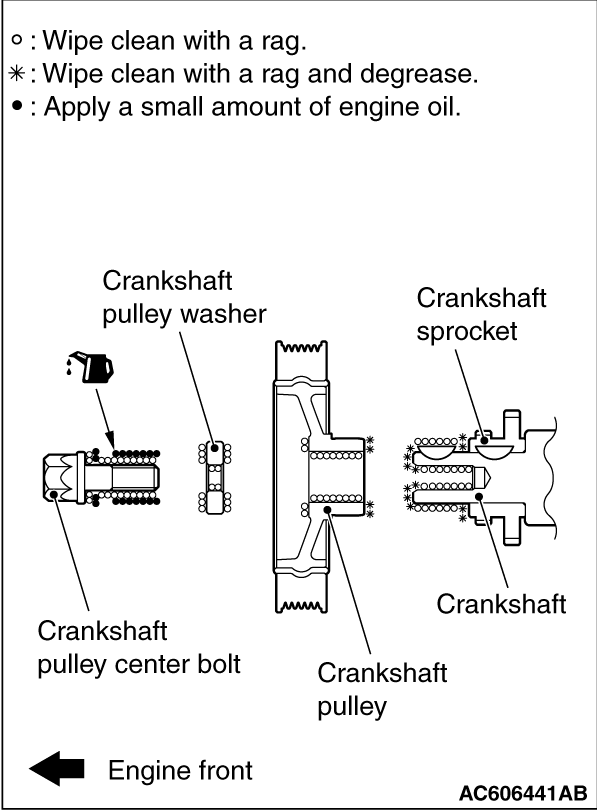

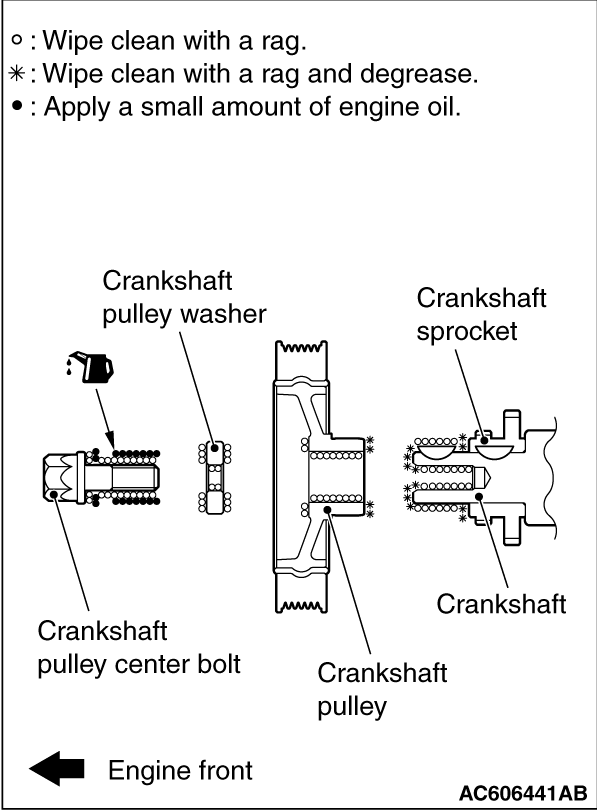

1.Wipe off the dirt on the crankshaft and crankshaft pulley as shown in the figure using

a rag.

2.Wipe off the dirt on the crankshaft sprocket, crankshaft and crankshaft pulley as

shown in the figure using a rag, and then degrease them.

| note |

Degrease them to prevent drop in the friction coefficient of the pressed area, which is

caused by oil adhesion.

|

3.Install the crankshaft pulley.

4.Wipe off the dirt on the crankshaft pulley washer and crankshaft pulley center bolt

as shown in the figure using a rag.

5.Apply an adequate and minimum amount of engine oil to the threads

of the crankshaft pulley center bolt and lower area of the flange.

|

|

6.Hold the crankshaft pulley with special tools MB990767 and MD998719 in the same manner

as removal.

7.Tighten the crankshaft pulley center bolt to the specified torque.

Tightening torque: 210 N·m (155 ft-lb)

|

|

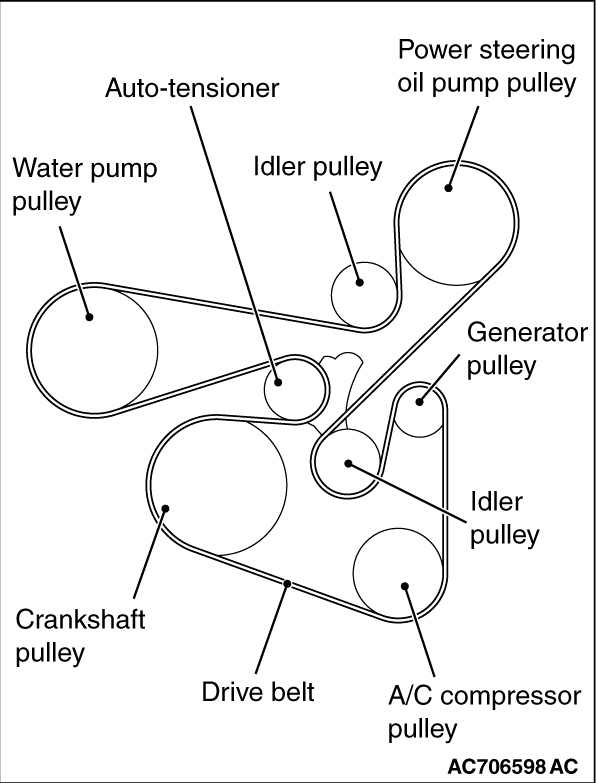

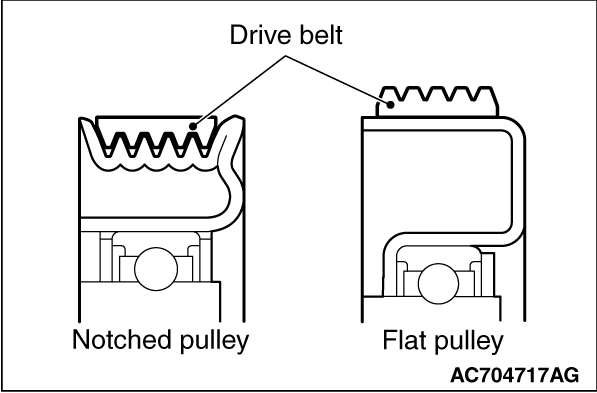

1.

| caution |

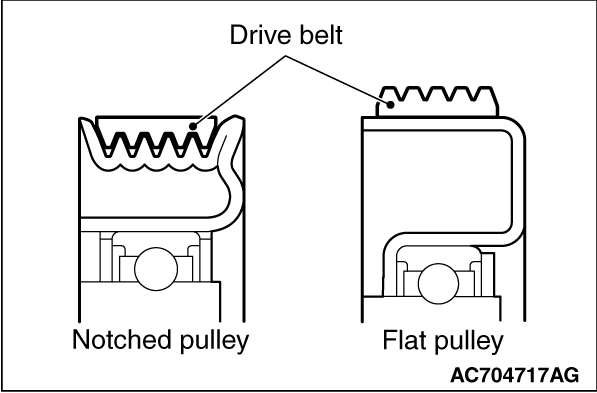

- To reuse the drive belt, install it by aligning

the arrow mark on the backside of belt marked at the removal with the rotating direction.

- Check that the notches of the notched pulley and the notches of the drive belt are fit

correctly.

- Check that the drive belt is installed in the center of the flat surface of the

flat pulley.

|

Install the drive belt to each pulleys as shown in the figure.

|

|

2.

| warning |

Always work from above when releasing the tension of

the auto-tensioner. When you try to gain access from underneath the vehicle, you will experience difficulty,

thus causing the tool to be dropped off.

|

| caution |

To work at the optimum angle, you must choose a most suitable

box-type wrench is applied to the special tool.

|

| warning |

Be sure to set the box-type wrench and the special tool MB992278

to the hexagonal parts securely to prevent the tool from falling off because the tension of

the auto-tensioner is high.

|

Install special tool MB992278 and a box-type wrench at the optimum angle.

3.Rotate the auto-tensioner counterclockwise and remove the L-shaped hexagon wrench

fixing the auto-tensioner.

4.Apply tension to the drive belt while slowly turning the auto-tensioner clockwise.

|

.)

.) .)

.) .)

.)![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)