DISASSEMBLY AND ASSEMBLY

Required Special Tools:

- MB992249: Variable Spanner

- MB992209: Bellows Band Clipping Tool

- MB992208: Bellows Band Clipping Tool

DISASSEMBLY SERVICE POINT

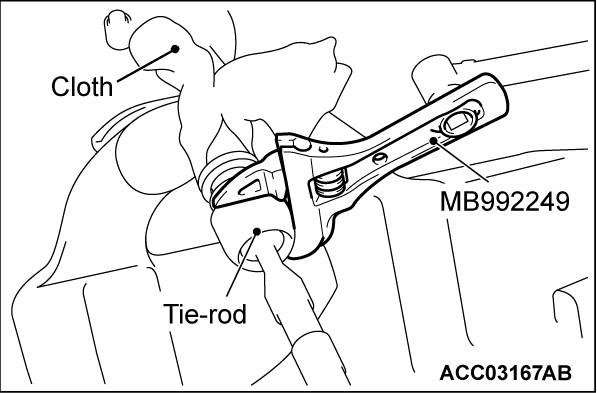

<<A>> TIE-ROD REMOVAL

1. Move the bellows and pull the rack bar toward arrow direction.

2.

Wrap rack bar with cloth in order not to damage, and fix the rack bar with a vise.

| caution | Do not tighten the vise strongly in order not to damage the rack bar. |

3. Use the special tool MB992249 to remove the tie-rod.

ASSEMBLY SERVICE POINTS

>>A<< TIE-ROD INSTALLATION

1.

Wrap rack bar with cloth in order not to damage, and fix the rack bar with a vise.

| caution | Do not tighten the vise strongly in order not to damage the rack bar. |

2. Use the special tool MB992249 to tighten the tie-rod to the specified torque.

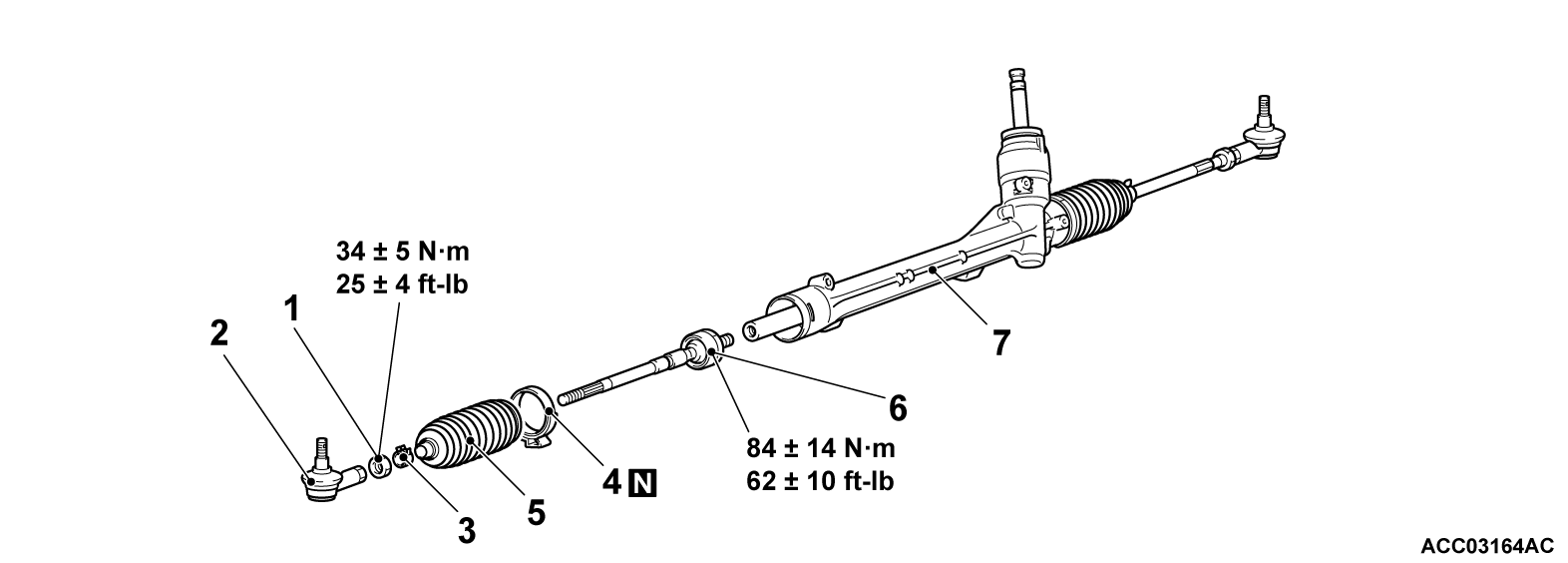

Tightening torque: 84 ± 14 N·m (62 ± 10 ft-lb)

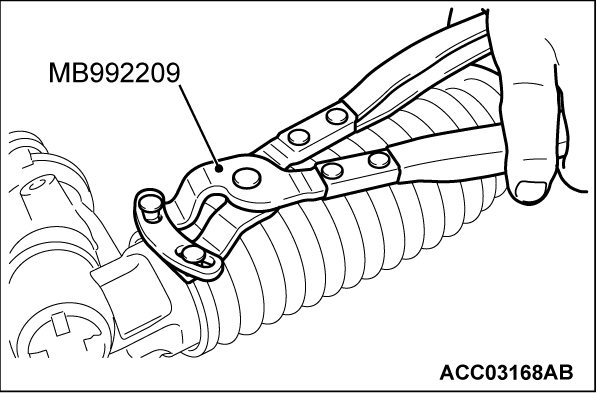

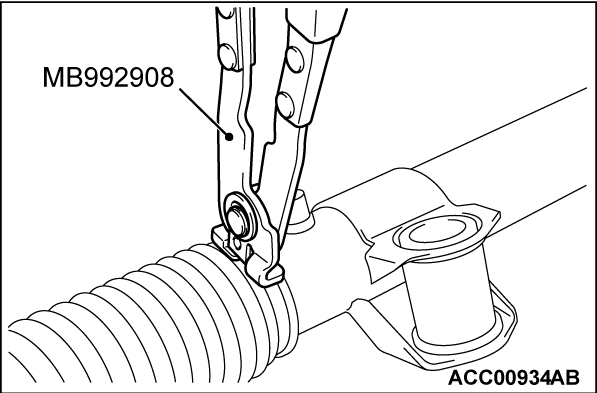

>>B<< BAND INSTALLATION

1.

Use the special tool MB992209 or MB992908 crimping tool to crimp the bellows band.

| caution |

|

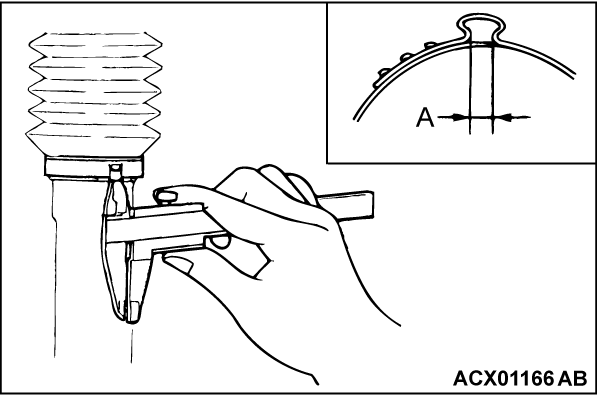

2. Check that crimped width (A) is within the standard value.

Standard value (A): 2.4 - 2.8 mm (0.09 - 0.11 inch)

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)