DTC P1797: G Sensor/Brake Pressure Sensor Malfunction

DIAGNOSTIC FUNCTION

The TCM determines that the system is defective when it receives a "G sensor" or "brake fluid pressure" abnormality signal from the ASC-ECU.

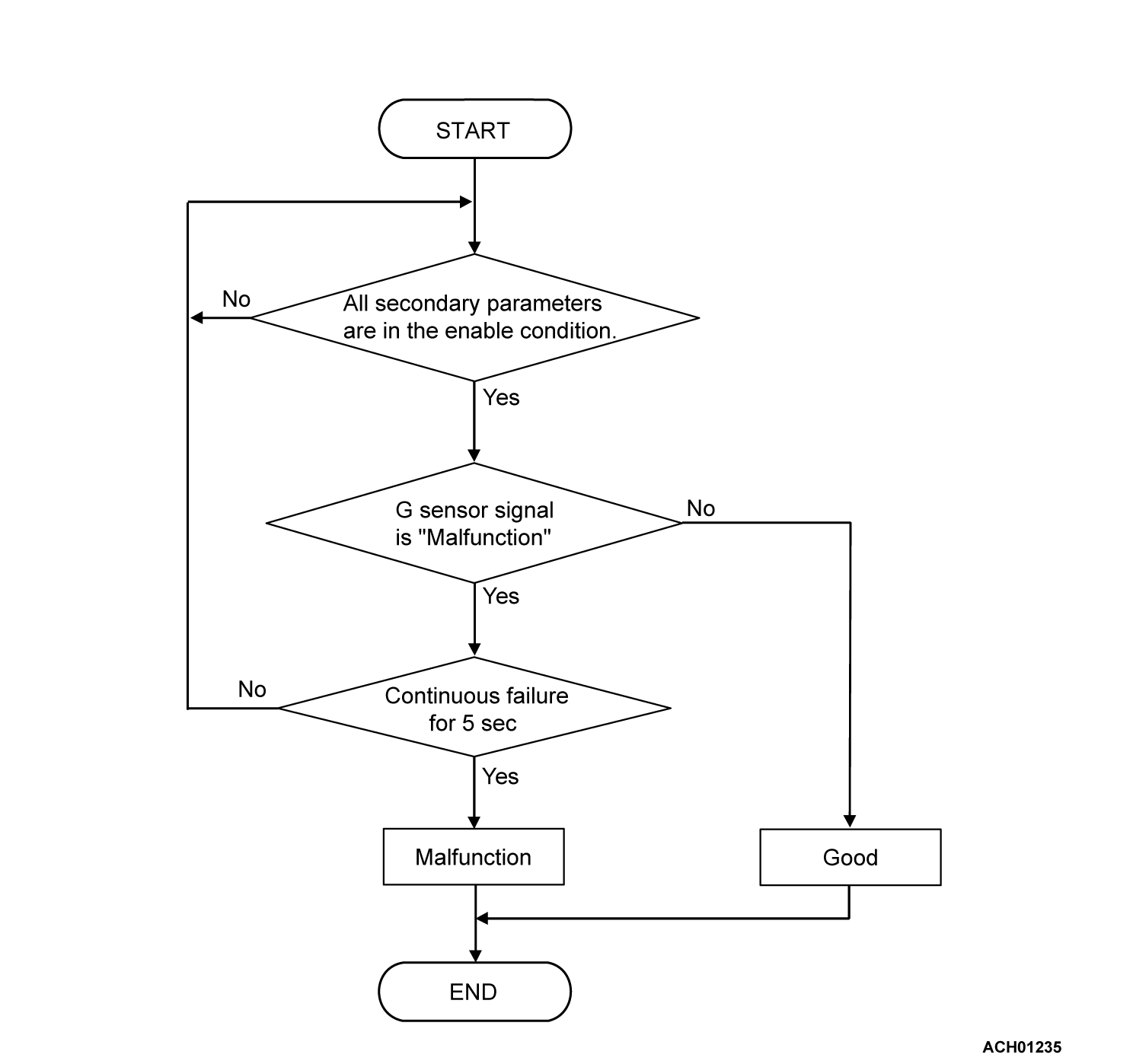

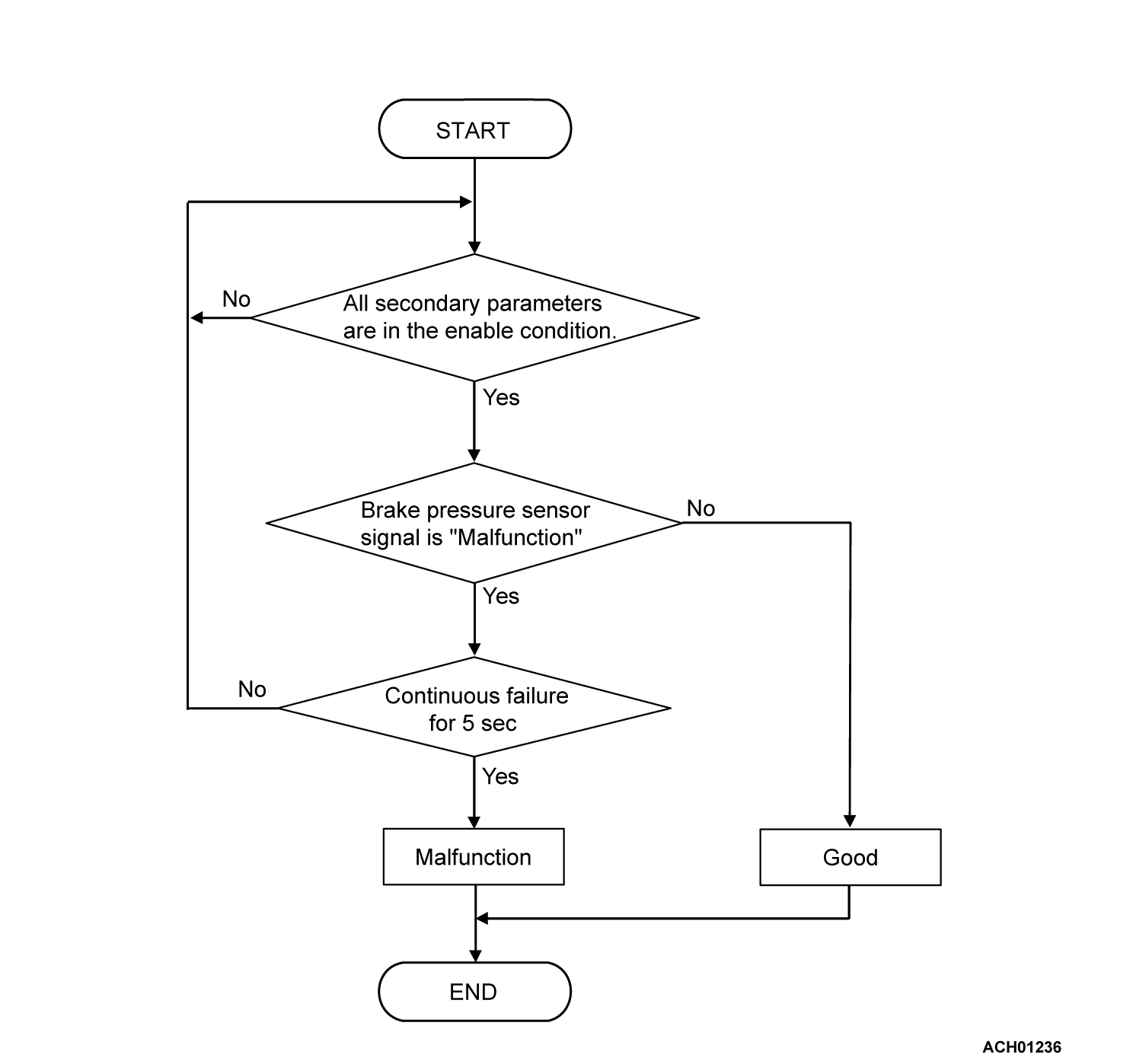

DESCRIPTIONS OF MONITOR METHODS

- The brake fluid pressure sensor error signal reception continues.

- The front/rear G sensor error signal reception continues.

MONITOR EXECUTION

- Engine speed: 450 r/min or more

- Vehicle speed: 5 km/h (3.1 mph) or more

MONITOR EXECUTION CONDITIONS (OTHER MONITOR AND SENSOR)

Other Monitor (There is no temporary DTC stored in memory for the item monitored below)

- U0121: CAN time-out error (ASC)

Sensor (The sensor below is determined to be normal)

- Not applicable

DTC SET CONDITIONS

Check Conditions

- Voltage of battery: 10 volts or more

- Voltage of battery: 16.5 volts or less

- Engine speed: 450 r/min or more

- Vehicle speed: 5 km/h (3.1 mph) or more

Judgment Criteria

- The G sensor error signal reception continues for five seconds.

- The brake fluid pressure sensor error signal reception continues for five seconds.

OBD-II DRIVE CYCLE PATTERN

The vehicle is driven for at least 10 seconds at 10 km/h (6.2 mph) or more while the selector lever is at "D" range.

PROBABLE CAUSES

- Malfunction of the CAN bus line

- Malfunction of ASC-ECU

- Malfunction of TCM

DIAGNOSIS

Required Special Tools:

- MB992744: Vehicle communication interface-Lite (V.C.I.-Lite)

- MB992745: V.C.I.-Lite main harness A

- MB992747: V.C.I.-Lite USB cable short

- MB992748: V.C.I.-Lite USB cable long

- MB991958: Scan Tool (M.U.T.-III Sub Assembly)

- MB991824: Vehicles Communication Interface (V.C.I.)

- MB991827: M.U.T.-III USB Cable

- MB991910: M.U.T.-III Main Harness A (Vehicles with CAN communication system)

| caution |

|

STEP 1. Using scan tool (M.U.T.-III), diagnose the CAN bus lines.

| caution | To prevent damage to scan tool (M.U.T.-III), always turn the ignition switch to the "LOCK" (OFF) position before connecting or disconnecting scan tool (M.U.T.-III). |

Using scan tool (M.U.T.-III), perform CAN bus diagnosis [Refer to GROUP 54C, Explanation About The Scan Tool (M.U.T.-III) Can Bus Diagnostics  ].

].

].

].Is the check result normal?

STEP 2. Using scan tool (M.U.T.-III), DTC recheck after repairing CAN bus lines.

Check again if the DTC is stored. This diagnosis is complete.

This diagnosis is complete.

(1) Erase the DTC.

(2) Turn the ignition switch to the "LOCK" (OFF) position.

(3) Carry out a test drive with the OBD-II drive cycle pattern.

(4) Recheck the DTC.

Is DTC P1797 stored?

This diagnosis is complete.

This diagnosis is complete.STEP 3. Using scan tool (M.U.T.-III), check the DTC.

Using scan tool (M.U.T.-III), check if the DTC other than P1797 is stored.

Is any DTC other than P1797 stored?

STEP 4. Using scan tool (M.U.T.-III), check the DTC of other system.

Using scan tool (M.U.T.-III), check if the DTC is stored in ASC-ECU (Refer to GROUP 35C, Diagnosis - Diagnostic Function - How to Read and Erase Diagnostic Trouble Codes  ).

).

).

).Is any DTC stored?

STEP 5. Using scan tool (M.U.T.-III), recheck the DTC.

Check again if the DTC is stored.

(1) Erase the DTC.

(2) Turn the ignition switch to the "LOCK" (OFF) position.

(3) Carry out a test drive with the OBD-II drive cycle pattern.

(4) Recheck the DTC.

Is DTC P1797 stored?

STEP 6. Using scan tool (M.U.T.-III), recheck the DTC.

Check again if the DTC is stored. This diagnosis is complete.

This diagnosis is complete.

(1) Erase the DTC.

(2) Turn the ignition switch to the "LOCK" (OFF) position.

(3) Carry out a test drive with the OBD-II drive cycle pattern.

(4) Recheck the DTC.

Is DTC P1797 stored?

This diagnosis is complete.

This diagnosis is complete.![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)