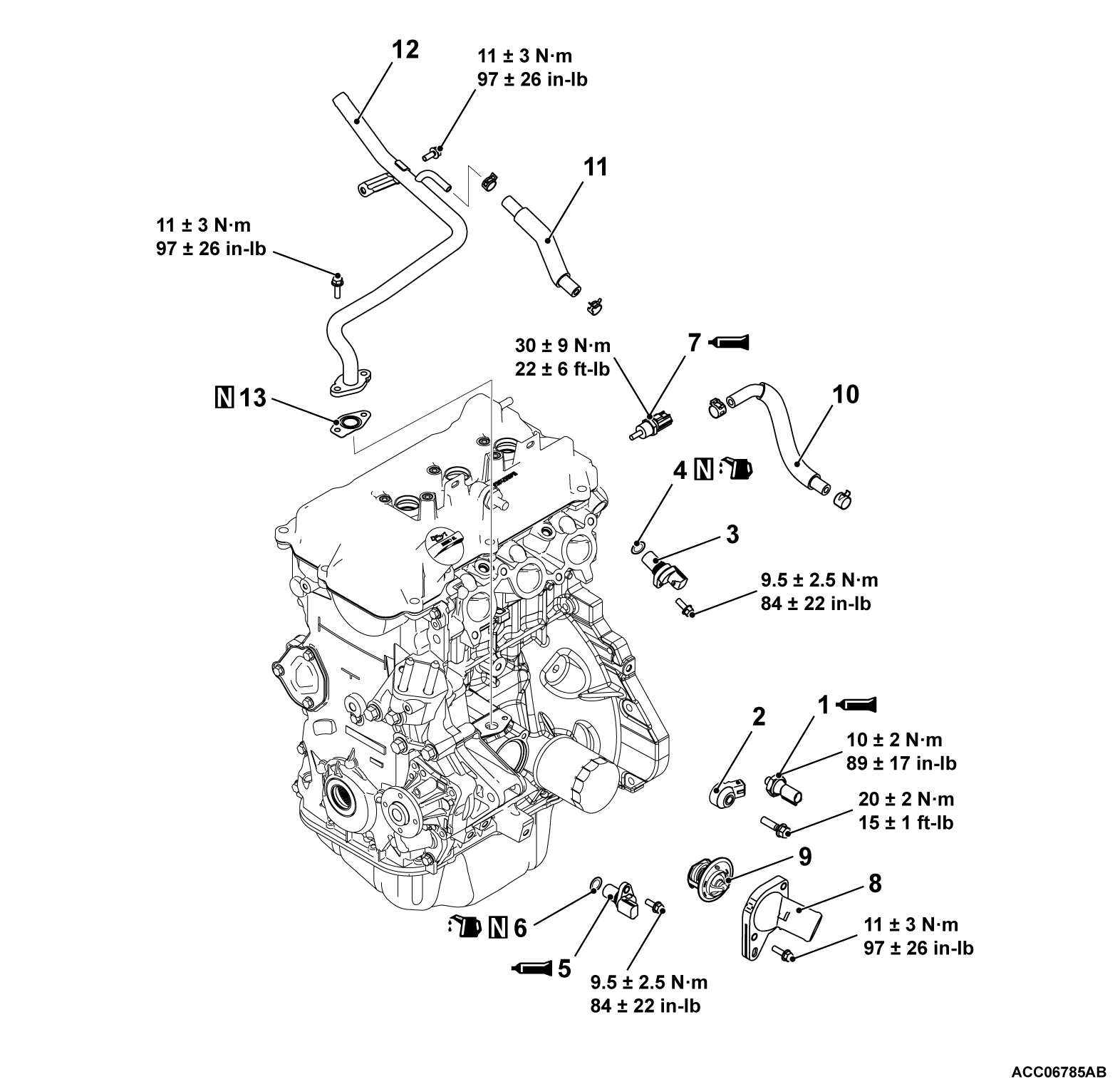

REMOVAL AND INSTALLATION

| caution |

|

Required Special Tool:

- MB992118: Oil pressure switch wrench

REMOVAL SERVICE POINT

INSTALLATION SERVICE POINTS

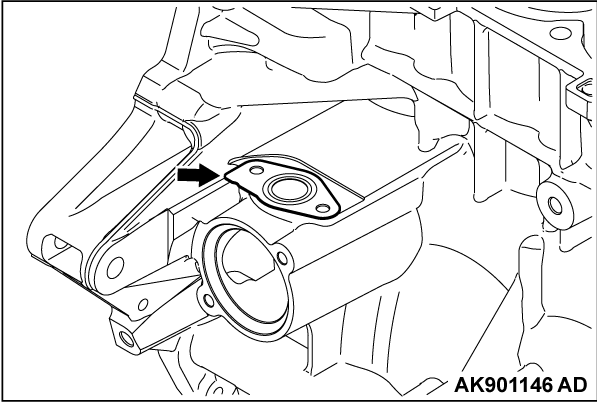

>>A<< WATER PIPE GASKET INSTALLATION

Install the water pipe gasket as its protrusion is in the direction shown.

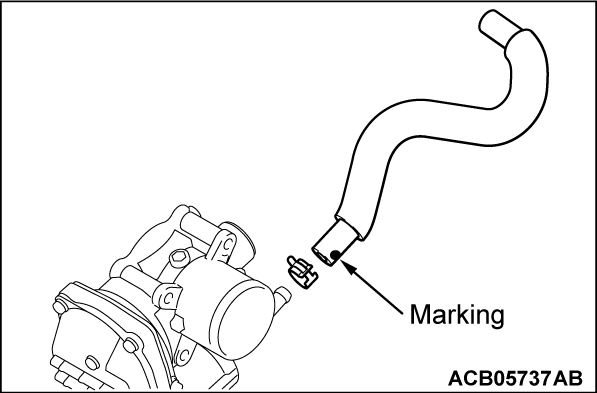

>>B<< WATER HOSE A INSTALLATION

Make sure that the marking on the hose should face towards the transaxle.

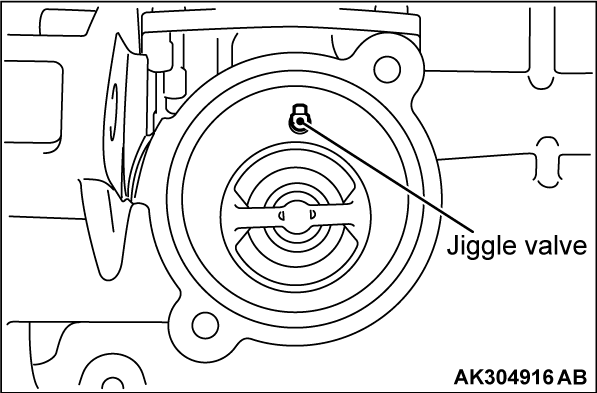

>>C<< THERMOSTAT INSTALLATION

Install the thermostat onto the cylinder block such that the jiggle valve is positioned on top of the thermostat housing.

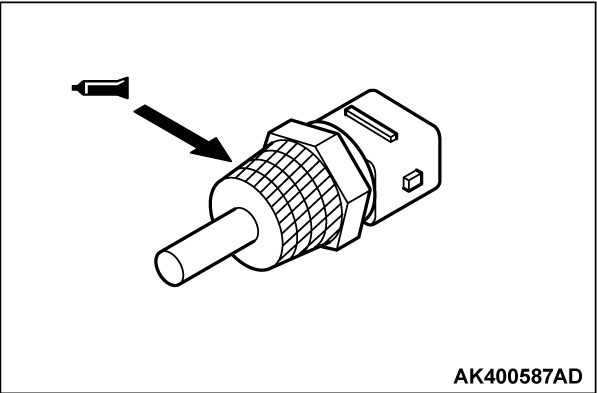

>>D<< ENGINE COOLANT TEMPERATURE SENSOR INSTALLATION

| caution | Be careful not to damage the connector portion (made of resin) of the sensor with the tool. |

1. Remove any sealant that may be remaining on the engine coolant temperature sensor or the threaded hole in the cylinder head.

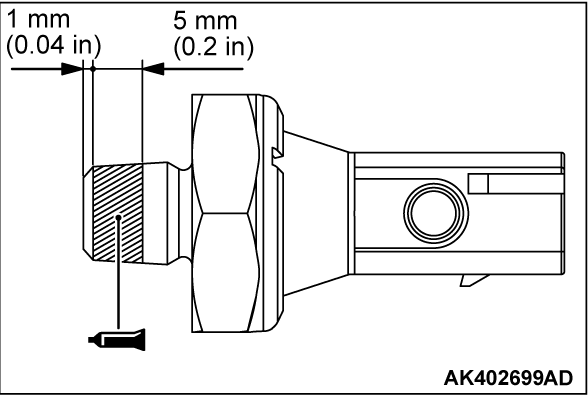

2. Apply sealant onto the threaded portion (illustrated) of the sensor.

Specified sealant: LOCTITE® 262 or equivalent

3. Install the engine coolant temperature sensor onto the cylinder block by tightening it to the specified torque.

Tightening torque: 30 ± 9 N·m (22 ± 6 ft-lb)

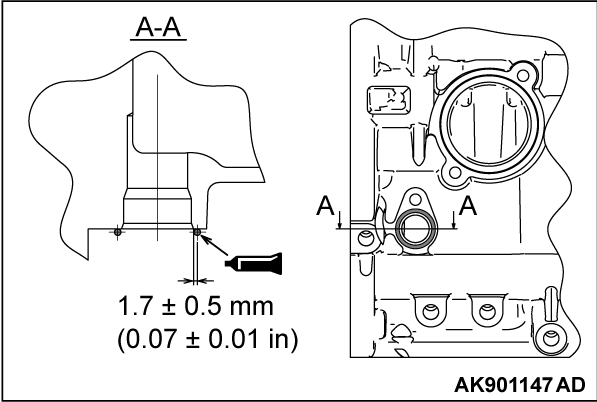

>>E<< CRANKSHAFT POSITION SENSOR INSTALLATION

| caution | Apply sealant correctly so that it will not be squeezed out onto the end of the threaded portion upon assembly. |

1. Remove any sealant that may be remaining on the angle sensor or the mounting face on the cylinder block.

2. Apply a bead of sealant with a diameter of 1.7 ± 0.5 mm (0.07 ± 0.01 inch) on the cylinder block as illustrated.

Specified sealant: MITSUBISHI GENUINE PART NUMBER MZ100191 or equivalent

3. Install the crankshaft position sensor onto the cylinder block by tightening it to the specified torque.

Tightening torque: 9.5 ± 2.5 N·m (84 ± 22 in-lb)

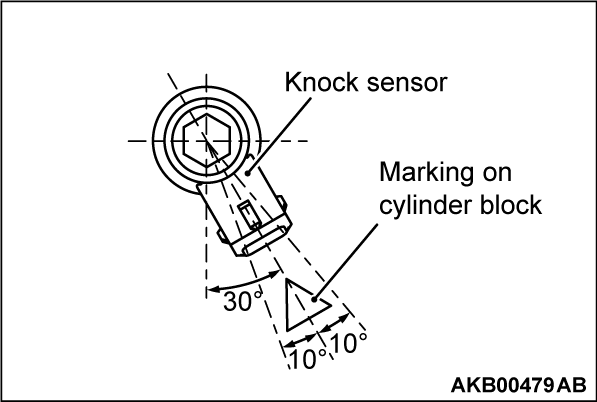

>>F<< KNOCK SENSOR INSTALLATION

Align the knock sensor connector with the position shown in the illustration, and then tighten it to the specified torque.

Tightening torque: 20 ± 2 N·m (15 ± 1 ft-lb)

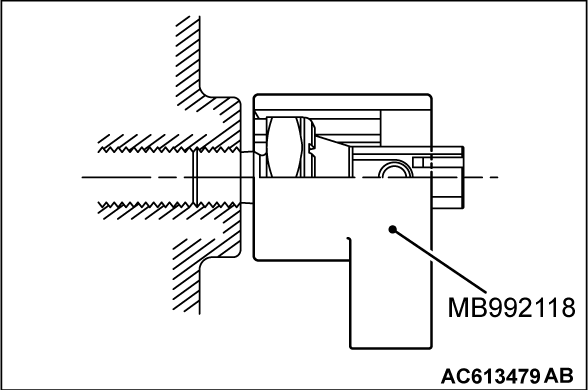

>>G<< ENGINE OIL PRESSURE SWITCH INSTALLATION

| caution | Apply sealant correctly so that it will not be squeezed out onto the end of the threaded portion upon assembly. |

1. Remove any sealant that may be remaining on the engine oil pressure switch or the threaded hole in the cylinder block.

2. Apply sealant to the threaded portion of the engine oil pressure switch as illustrated.

Specified sealant: MITSUBISHI GENUINE PART NUMBER MZ100077 or equivalent

| note | Install the engine oil pressure switch immediately after applying sealant. |

3.

In the same manner as removal, use special tool MB992118 to tighten the engine oil pressure switch to the specified torque.

| caution | After the installation, until a sufficient period of time (one hour or more) elapses, do not apply the engine oil or water to the sealant application area or start the engine. |

Tightening torque: 10 ± 2 N·m (89 ± 17 in-lb)

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)