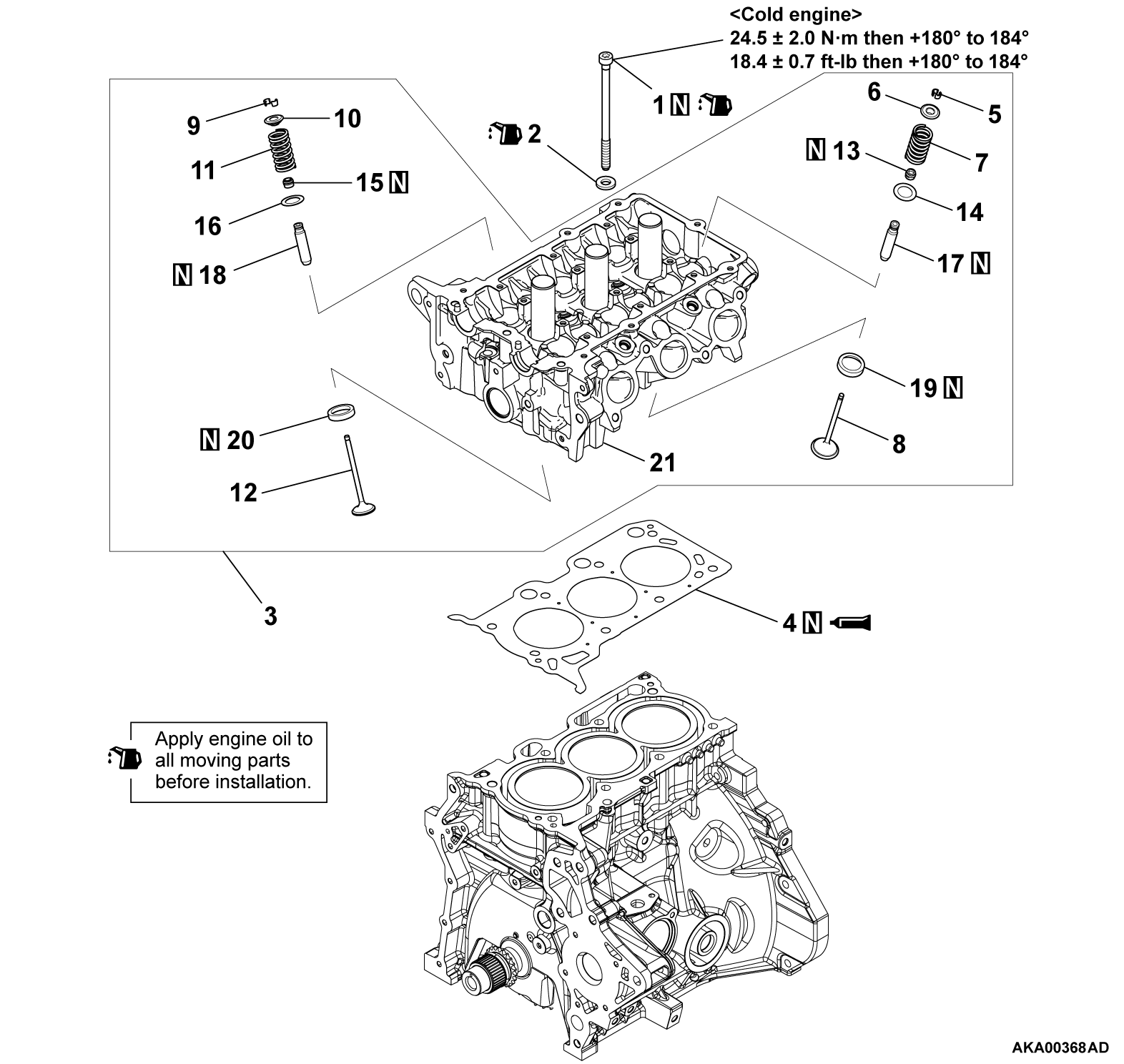

REMOVAL AND INSTALLATION

Required Special Tools:

- MD999597: Valve Spring Compressor

- MB992085: Valve Stem Seal Pliers

- MB992922: Valve Stem Seal Installer Adjustable

REMOVAL SERVICE POINTS

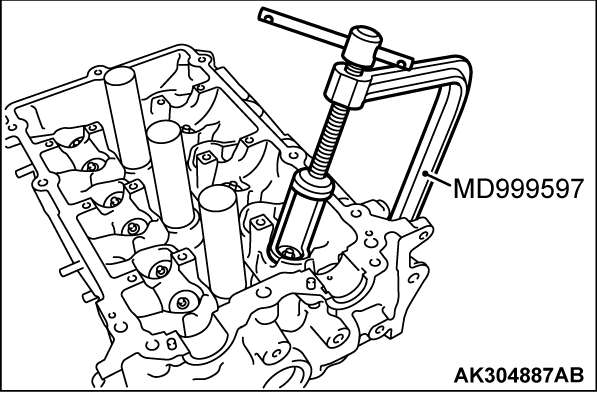

<<A>> RETAINER LOCK REMOVAL

While compressing the valve spring using the special tool MD999597, remove the retainer lock.

| note | To facilitate assembly, the valve, spring and other parts removed should be kept together and attached with a tag showing where it has been assembled including the cylinder number. |

INSTALLATION SERVICE POINTS

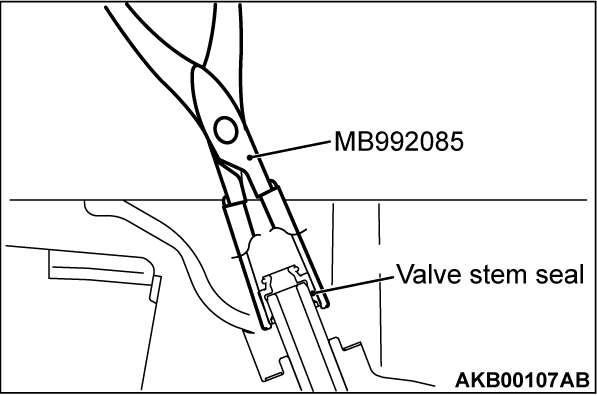

>>A<< VALVE SPRING SEAT/VALVE STEM SEAL INSTALLATION

1.

| caution |

|

Apply a small amount of engine oil to the press-fit part and lip part of the new valve stem seal.

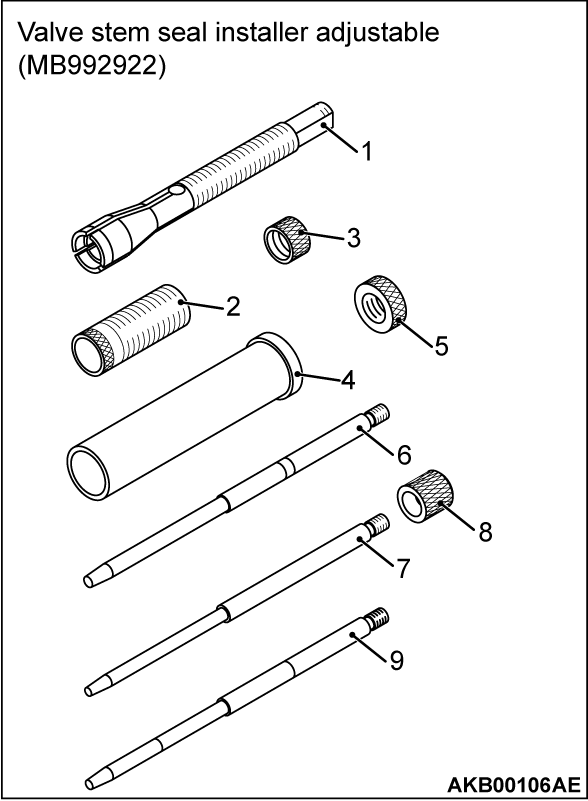

2. Use a special tool MB992922 to install the valve stem seal, obeying the following procedures.

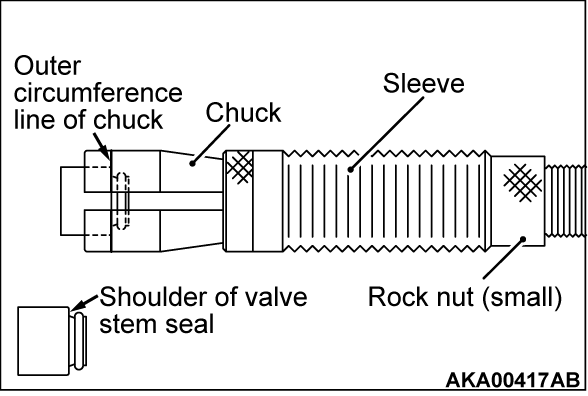

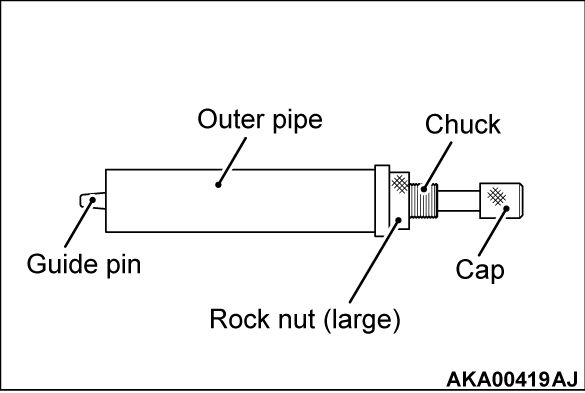

3. Special tool MB992922 is composed of the components shown in the illustration.

1: Chuck

2: Sleeve

3: Rock nut (small)

4: Outer pipe

5: Rock nut (large)

6: Guide pin (5.9)

7: Guide pin (4.9)

8: Cap

9: Guide pin (5.4)

4. Adjust the inside chuck diameter, obeying the following procedures.

(1) Install the sleeve to the chuck as shown in the illustration.

(2) Install the shoulder of the valve stem seal to the chuck, aligning with the outer circumference line of the chuck as shown in the illustration.

(3) Turn the sleeve to wring the chuck.

(4) Stop the sleeve at the position where you can easily remove the valve stem seal by hand.

(5) Use the rock nut (small) to fix the sleeve.

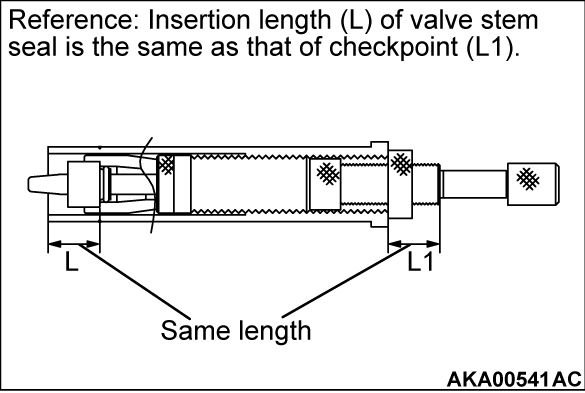

5. Adjust the stem seal insertion length [L (L1)], obeying the following procedures.

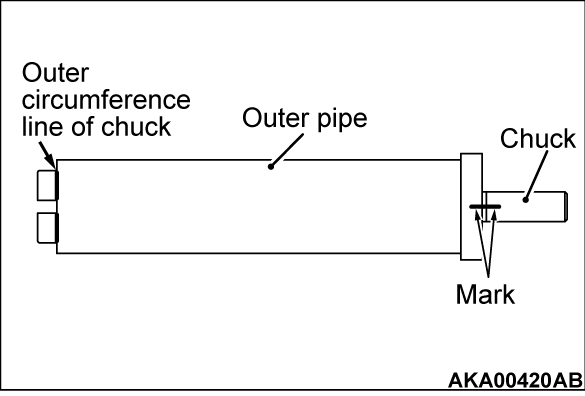

(1) The position, in which the end face of the outer pipe is aligned with the outer circumference line of the chuck, is 0 mm (0 inch) of the insertion length. Insert the chuck and the sleeve into the outer pipe to fit the nut as shown in the illustration.

(2) Turn the chuck to adjust the valve stem seal insertion length.

| note | The insertion length can change by 1 mm (0.04 inch) per the chuck turn. To easily know how many times the chuck is turned, put the mark at the position shown in the illustration. |

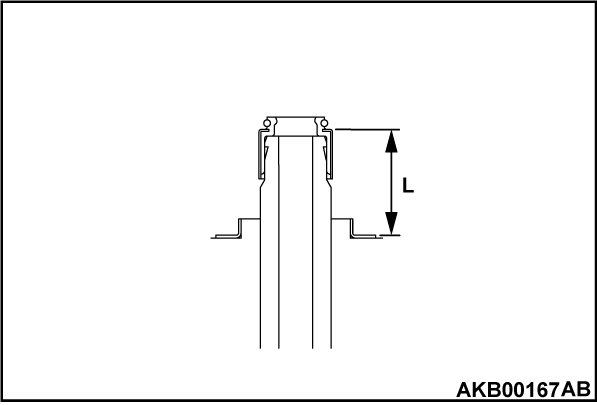

(3) Use a vernier caliper to measure the checkpoint (L1) of the insertion length shown in the illustration. Check the insertion length.

L1: 14.4 mm (0.57 inch)

(4) Use the rock nut (large) to fix the sleeve.

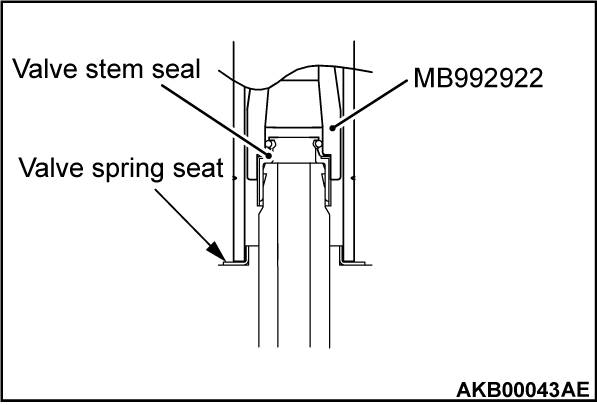

6. Install the cap to the guide pin (4.9).

7. Install the guide pin (4.9) as shown in the illustration.

8. Apply the engine oil to the valve stem seal to set the chuck.

9. Install the valve spring seat.

10. Use the plastic hammer to insert the valve stem seal.

>>B<< RETAINER LOCK INSTALLATION

While compressing the valve spring using the special tool MD999597, install the retainer lock.

>>C<< CYLINDER HEAD GASKET INSTALLATION

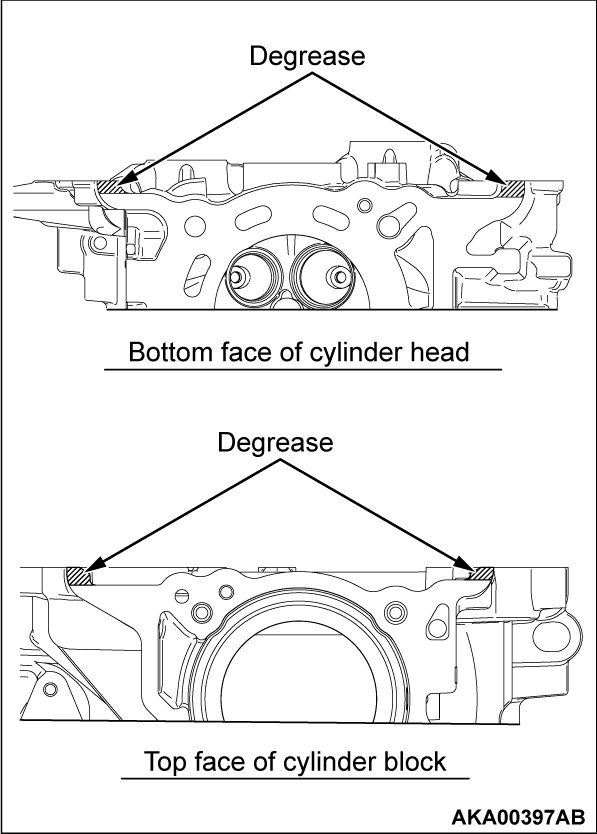

1. Completely remove the sealant on the upper plane of the cylinder block and the lower plane of the cylinder head.

2.

Degrease the place specified in the illustration.

| caution | Sufficiently check that there is no residual oil on the place where degreasing is performed. If fingerprints are left, do not touch it with bare hands after the degreasing, since the oils from your fingers will harm the seal ability. |

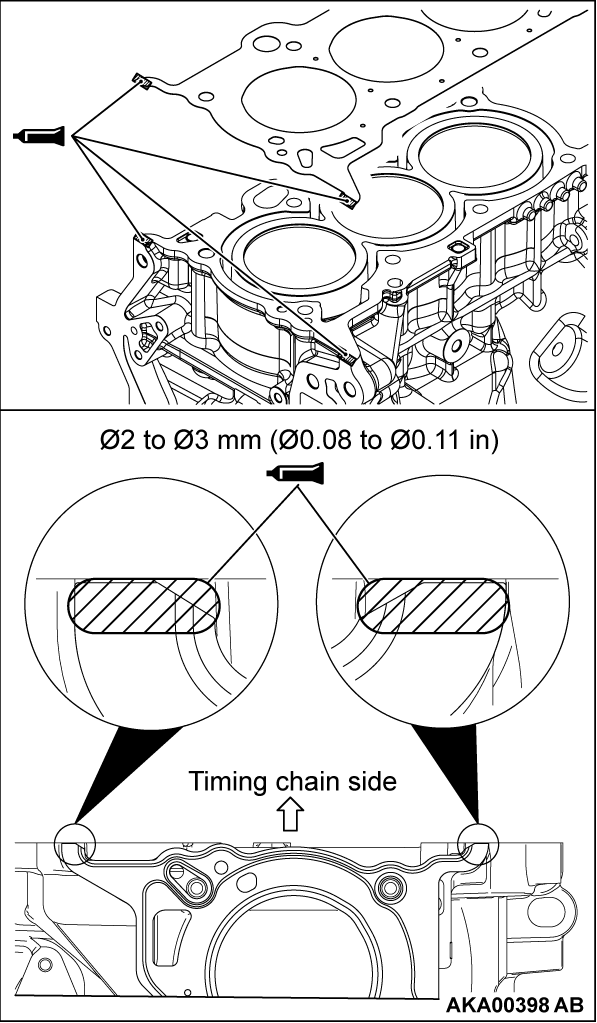

3. As shown in the illustration, apply a bead of sealant with a diameter of 2 to 3 mm (0.08 to 0.11 inch) to the top face of cylinder block.

Specified sealant: ThreeBond 1217G or equivalent

4. Install the cylinder head gasket.

| note | Check that the center of the sealant is located toward the cylinder gasket in the position specified in the illustration. |

5. As shown in the illustration, apply a bead of sealant with a diameter of 2 to 3 mm (0.08 to 0.11 inch) to the top face of cylinder head gasket.

Specified sealant: ThreeBond 1217G or equivalent

6. Install the cylinder head assembly.

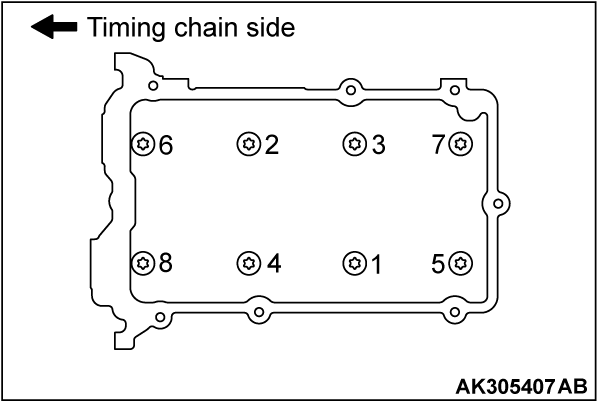

>>D<< CYLINDER HEAD BOLT INSTALLATION

1. Install the cylinder head bolt and washer assembly onto the cylinder head.

2. In accordance with the installation order, tighten them to the specified torque in several steps.

Tightening torque: 24.5 ± 2.0 N·m (18.4 ± 0.7 ft-lb)

3. Make sure all bolts reach the specified torque.

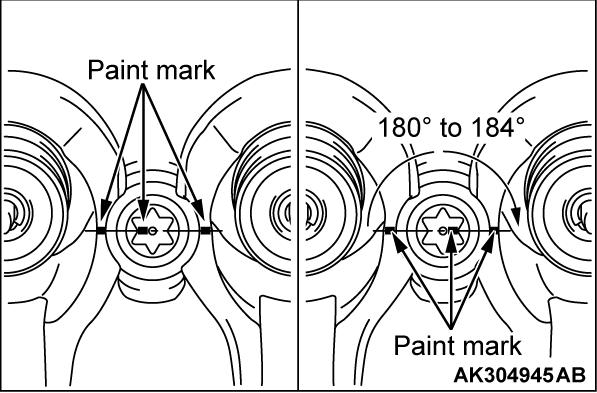

4. Put paint marks on the bolt heads and the cylinder as illustrated.

5.

| caution |

|

Tighten the bolts in the correct sequence by 180 to 184 degree angle.

Ensure that the paint marks on the bolt heads and the cylinder are aligned in a straight line.

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)