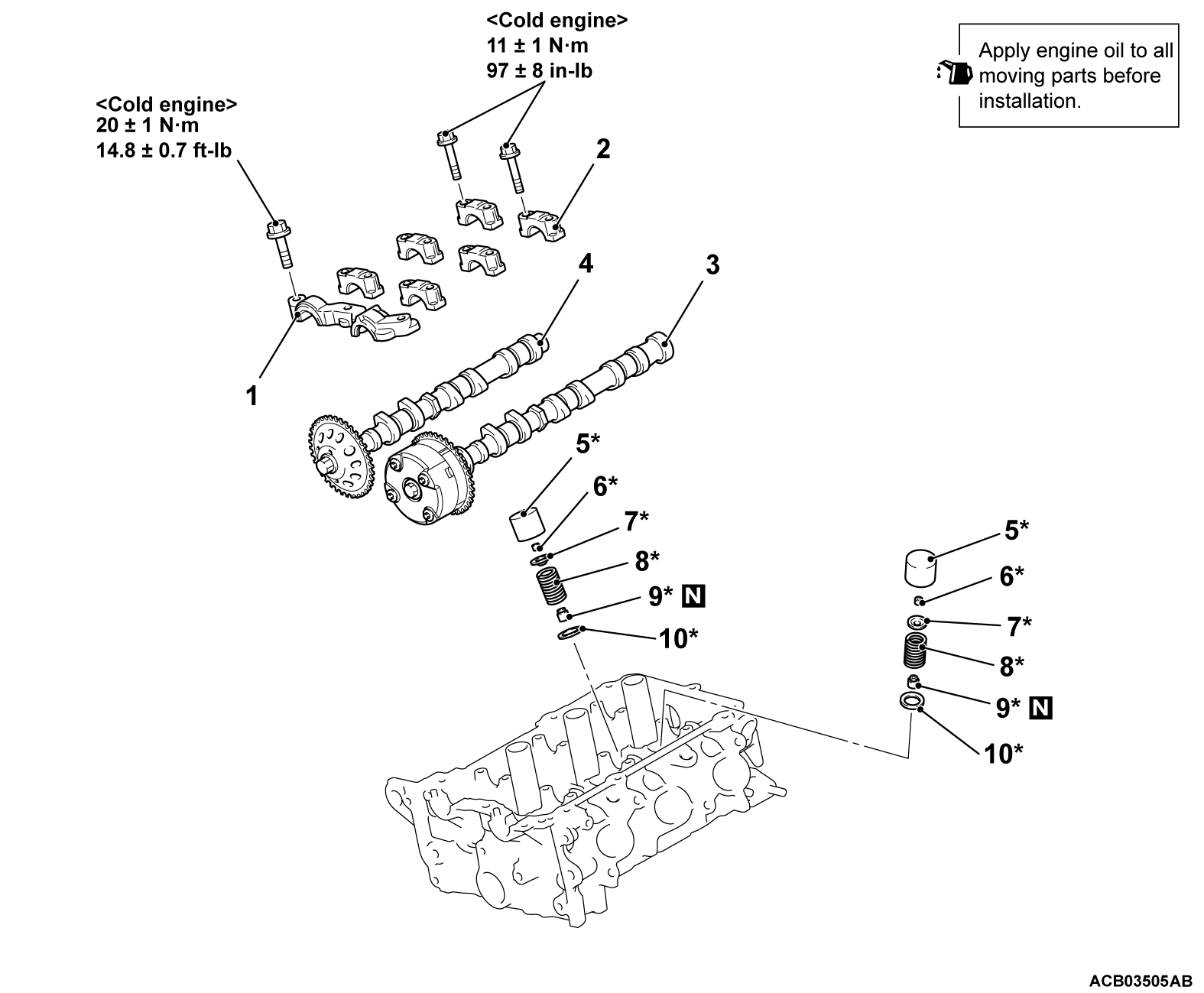

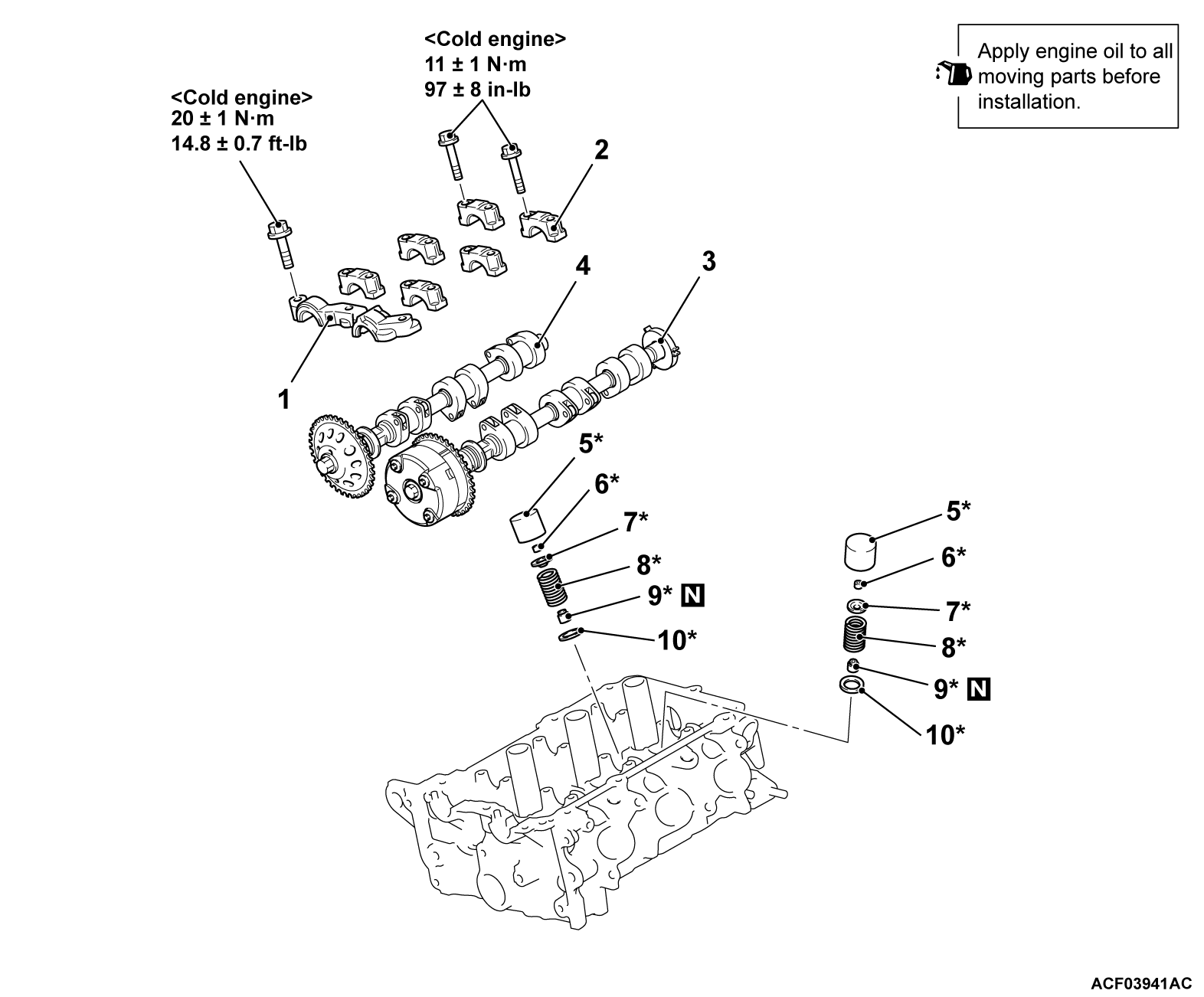

REMOVAL AND INSTALLATION

| caution | *Remove and assemble the marked parts in each cylinder unit. |

Pre-removal and post-installation operation |

<CVT>

|

Required Special Tools:

- MB991928: Engine Hanger

- Slide Bracket (HI)

- MB991932: Foot (standard)

- MB991929: Joint (50)

- MB991895: Engine Hanger

- MB992906: Engine Hanger Attachment

- MB990772: Valve Spring Compressor

- MB992090: Retainer Holder Attachment

- MB992089: Retainer Holder C

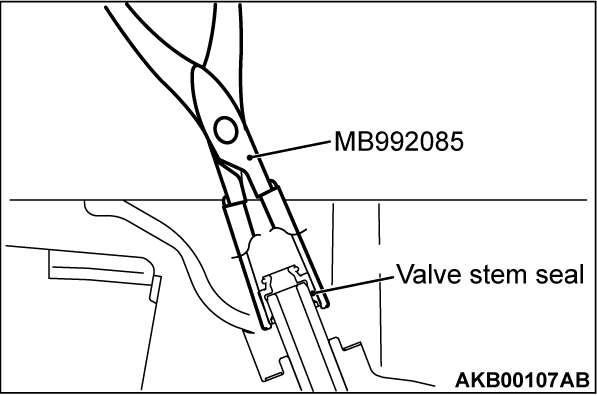

- MB992085: Valve Stem Seal Pliers

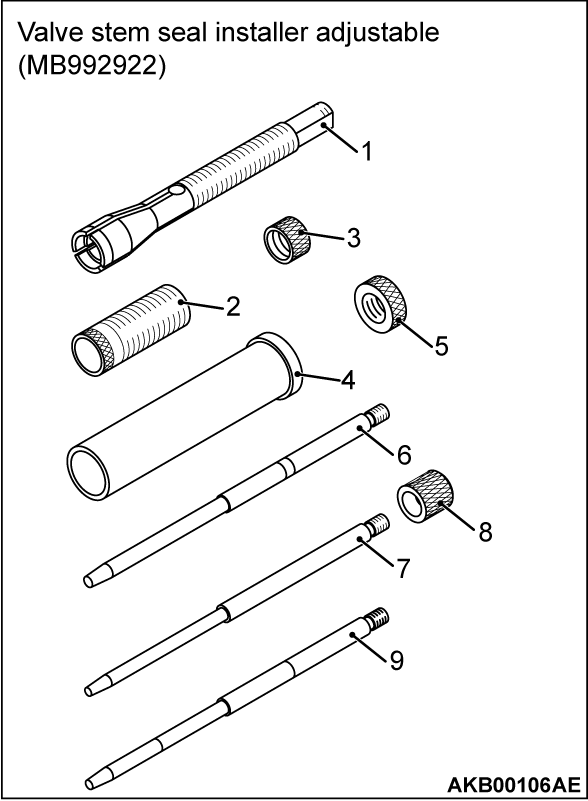

- MB992922: Valve Stem Seal Installer Adjustable

REMOVAL SERVICE POINTS

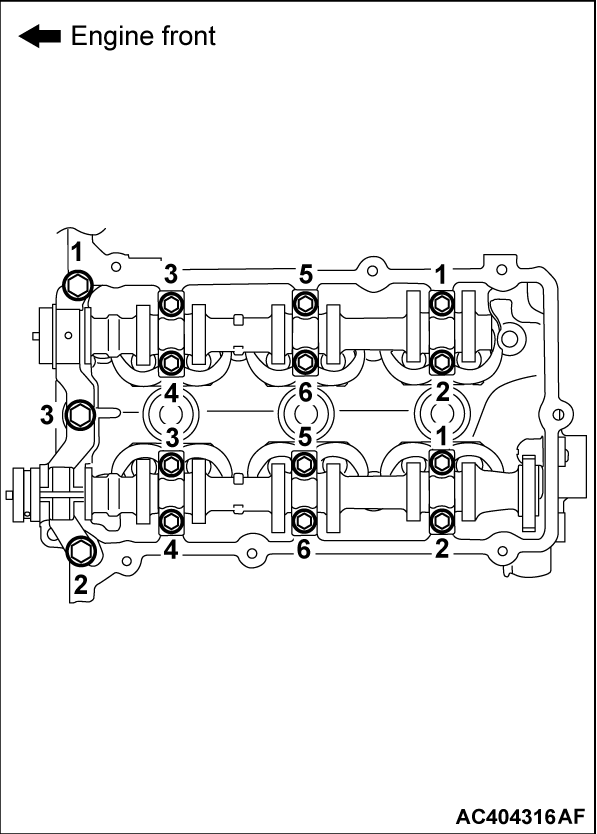

<<A>> FRONT CAMSHAFT BEARING CAP/CAMSHAFT BEARING CAP REMOVAL

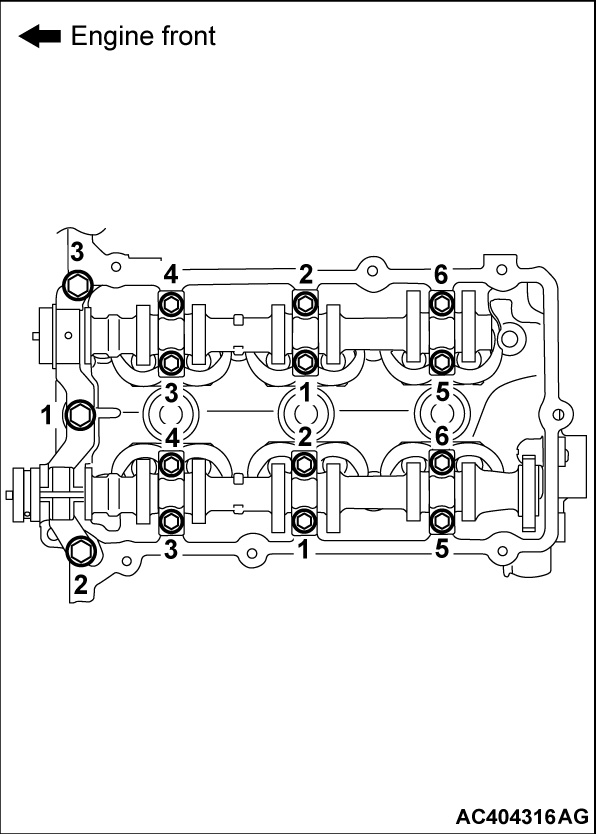

Loosen the front camshaft bearing cap mounting bolts in the order shown, and then loosen each camshaft bearing cap mounting bolts as well. Remove the front camshaft bearing cap and each camshaft bearing cap.

<<B>> VALVE TAPPET REMOVAL

To facilitate reassembly, attach a tag to each valve tappet removed that shows where it has been assembled.

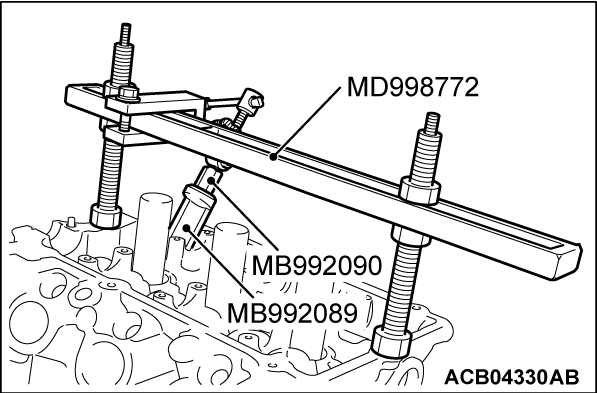

<<C>> VALVE SPRING RETAINER LOCK REMOVAL

1. Temporarily install the oil pan which was removed at the timing chain case removal.

2.

| caution | When supporting the engine assembly with a garage jack, be careful not to deform the oil pan. |

Place a garage jack against the oil pan with a piece of wood in between to support the engine assembly.

3. Remove the engine hanger special tool (MB991928 or MB991895) for holding the engine assembly, which have been attached when the timing chain case was removed.

4. Remove the brake booster vacuum pipe (Refer to GROUP 35A, Master Cylinder Assembly and Brake Booster Assembly  ).

).

).

).6. Screw in special tool MB992090 to special tool MD998772 and assemble special tool MB992089.

7.

| caution | When removing the valve spring retainer lock, leave the piston of the cylinder in the top dead center (TDC) position. The valve may fall into the cylinder if the piston is not properly in the TDC position. |

Install special tool MD998772 (with special tools MB992090 and MB992089 attached) to the cylinder head and compress the valve spring. Then, remove the valve spring retainer lock.

INSTALLATION SERVICE POINTS

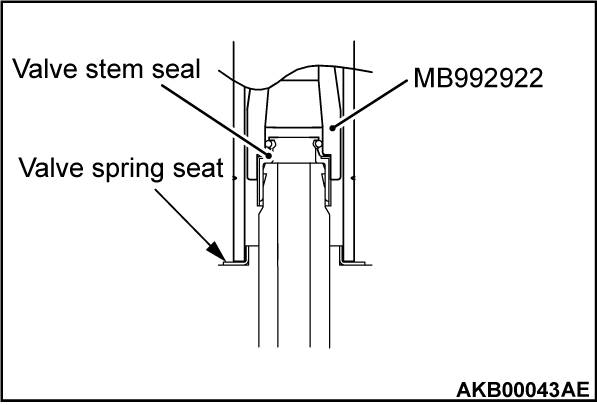

>>A<< VALVE SPRING SEAT/VALVE STEM SEAL INSTALLATION

1.

| caution |

|

Apply a small amount of engine oil to the press-fit part and lip part of the new valve stem seal.

2. Use a special tool to install the valve stem seal, obeying the following procedures.

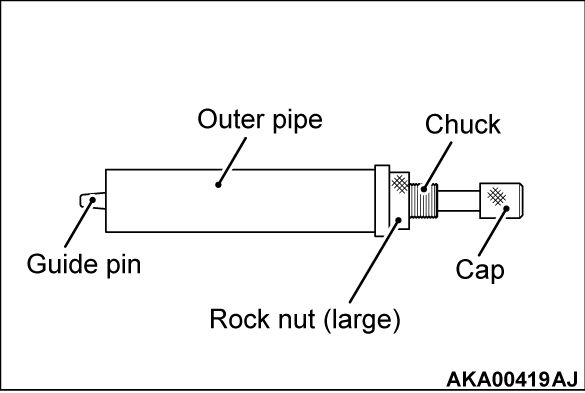

3. Special tool MB992922 is composed of the components shown in the illustration.1: Chuck

2: Sleeve

3: Rock nut (small)

4: Outer pipe

5: Rock nut (large)

6: Guide pin (5.9)

7: Guide pin (4.9)

8: Cap

9: Guide pin (5.4)

4. Adjust the inside chuck diameter, obeying the following procedures.

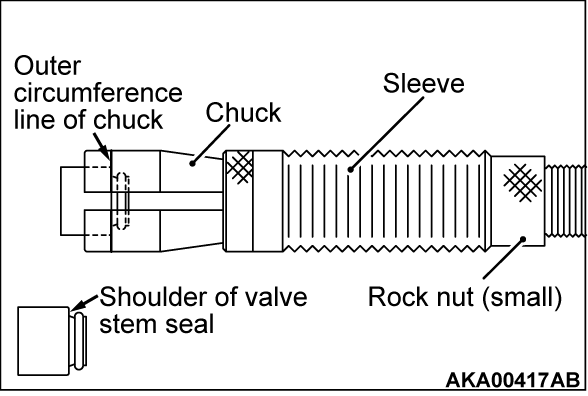

(1) Install the sleeve to the chuck as shown in the illustration.

(2) Install the shoulder of the valve stem seal to the chuck, aligning with the outer circumference line of the chuck as shown in the illustration.

(3) Turn the sleeve to wring the chuck.

(4) Stop the sleeve at the position where you can easily remove the valve stem seal by hand.

(5) Use the rock nut (small) to fix the sleeve.

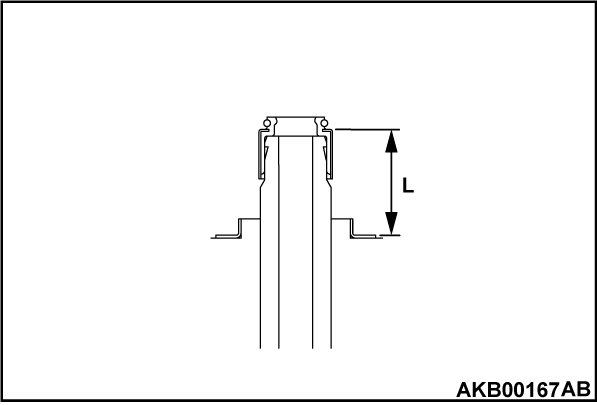

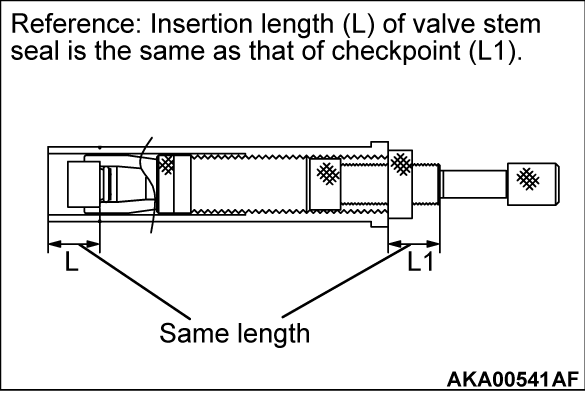

5. Adjust the stem seal insertion length [L (L1)], obeying the following procedures.

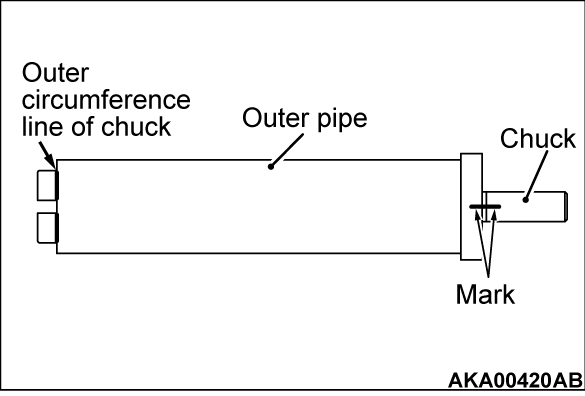

(1) The position, in which the end face of the outer pipe is aligned with the outer circumference line of the chuck, is 0 mm (0 inch) of the insertion length. Insert the chuck and the sleeve into the outer pipe to fit the nut as shown in the illustration.

(2) Turn the chuck to adjust the valve stem seal insertion length.

| note | The insertion length can change by 1 mm (0.04 inch) per the chuck turn. To easily know how many times the chuck is turned, put the mark at the position shown in the illustration. |

(3) Use a vernier caliper to measure the checkpoint (L1) of the insertion length shown in the illustration. Check the insertion length.

L1: 14.4 mm (0.57 inch)

(4) Use the rock nut (large) to fix the sleeve.

6. Install the cap to the guide pin (4.9).

7. Install the guide pin (4.9) as shown in the illustration.

8. Apply the engine oil to the valve stem seal to set the chuck.

9. Install the valve spring seat.

10. Use the plastic hammer to insert the valve stem seal.

>>B<< VALVE SPRING RETAINER LOCK INSTALLATION

In the same manner as removal, use the valve spring compressor special tool (MD998772) attached to compress the valve spring, and install the valve spring retainer lock.

>>C<< VALVE TAPPET INSTALLATION

1. Assemble each valve tappet to the correct location shown on the tag.

3. Install the brake booster vacuum pipe (Refer to GROUP 35A, Master Cylinder Assembly and Brake Booster Assembly  ).

).

).

).4. Install the engine hanger special tool (MB991928 or MB991895) for holding the engine assembly.

5. Remove the oil pan.

>>D<< CAMSHAFT BEARING CAP/FRONT CAMSHAFT BEARING CAP INSTALLATION

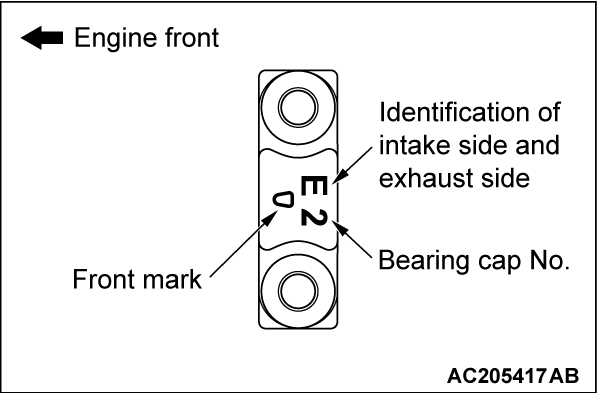

1. Camshaft bearing caps (number 2 to 4) are identical. To avoid confusion (bearing cap number and intake/exhaust side), confirm each identification mark and face the front mark towards the direction shown before installing them.

Identification mark (engraved on the front and bearing caps number 2 to 4)

- I: Intake side

- E: Exhaust side

2. Tighten each camshaft bearing cap mounting bolts to the specified torque in the order shown, and then tighten the front camshaft bearing cap mounting bolts as well.

Tightening torque:

- Camshaft bearing cap mounting bolts: 11 ± 1 N·m (97 ± 8 in-lb)

- Front camshaft bearing cap mounting bolts: 20 ± 1 N·m (14.8 ± 0.7 ft-lb)

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)