FRONT WHEEL ALIGNMENT CHECK AND ADJUSTMENT

Required Special Tool:

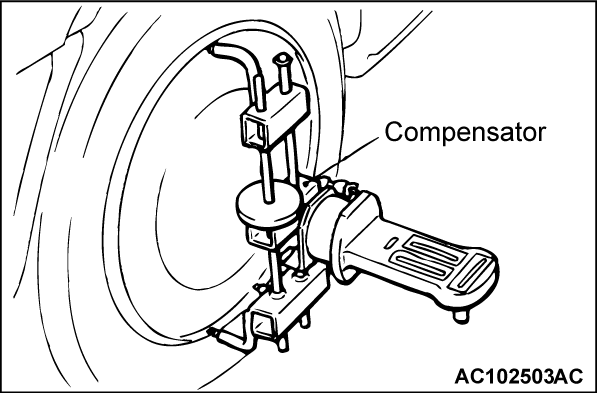

- MB991004: Wheel alignment gauge attachment

Measure wheel alignment with alignment equipment on a level surface. The front suspension, steering system, wheels, and tires should be serviced to normal condition before measuring wheel alignment.

TOE-IN

Standard value:

- At the center of tire tread: 0 ± 3 mm (0.0 ± 0.1 inch)

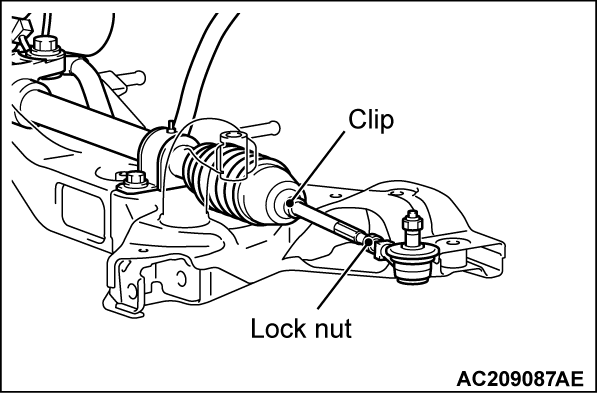

1. Adjust the toe-in by undoing the clip and lock nut, and turning the left and right tie rod turnbuckles by the same amount (in opposite directions).

| note | The toe will move out as the left turnbuckle is turned toward the front of the vehicle and the right turnbuckle is turned toward the rear of the vehicle. |

2. Install the clip and tighten the lock nut to the specified torque.

Tightening torque: 34 ± 5 N·m (25 ± 4 ft-lb)

3. Confirm that the toe-in is at the standard value.

CAMBER, CASTER AND KINGPIN INCLINATION

Standard value:

| Item | Specification |

| Camber | 0°05' ± 0°45'* |

| Caster | 4°00' ± 0°45'* |

| Kingpin inclination | 11°35' ± 1°30' |

| note |

|

| caution | Do not apply the vehicle weight to the wheel bearing while loosening the driveshaft nut. |

| note |

|

Tightening torque: 250 ± 25 N·m (184 ± 18 ft-lb)

| note |

|

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)