DISASSEMBLY AND ASSEMBLY

Required Special Tools:

- MB991017: Front Hub Remover and Installer

- MB991355: Knuckle Arm Bridge

- MB992250: Knuckle Arm Bridge attachment

- MB992867: Front Hub Remover and Installer Spacer

- MB991618: Hub Bolt Remover

- MB991019: Spacer

- MD998801: Remover

- MB992254: Base

- MD999547: Oil Seal Installer

- MB990799: Ball Joint A Remover and Installer

- MD998812: Installer Cap

- MD998813: Installer 100

- MD998815: Installer Adapter

- MB990767: Front Hub and Flange Yoke Holder

- MB990800: Ball Joint B Remover and Installer

- MB991199: Oil Seal Installer

- MB991000: Spacer

- MB990326: Preload Socket

- MB990685: Torque Wrench

DISASSEMBLY SERVICE POINTS

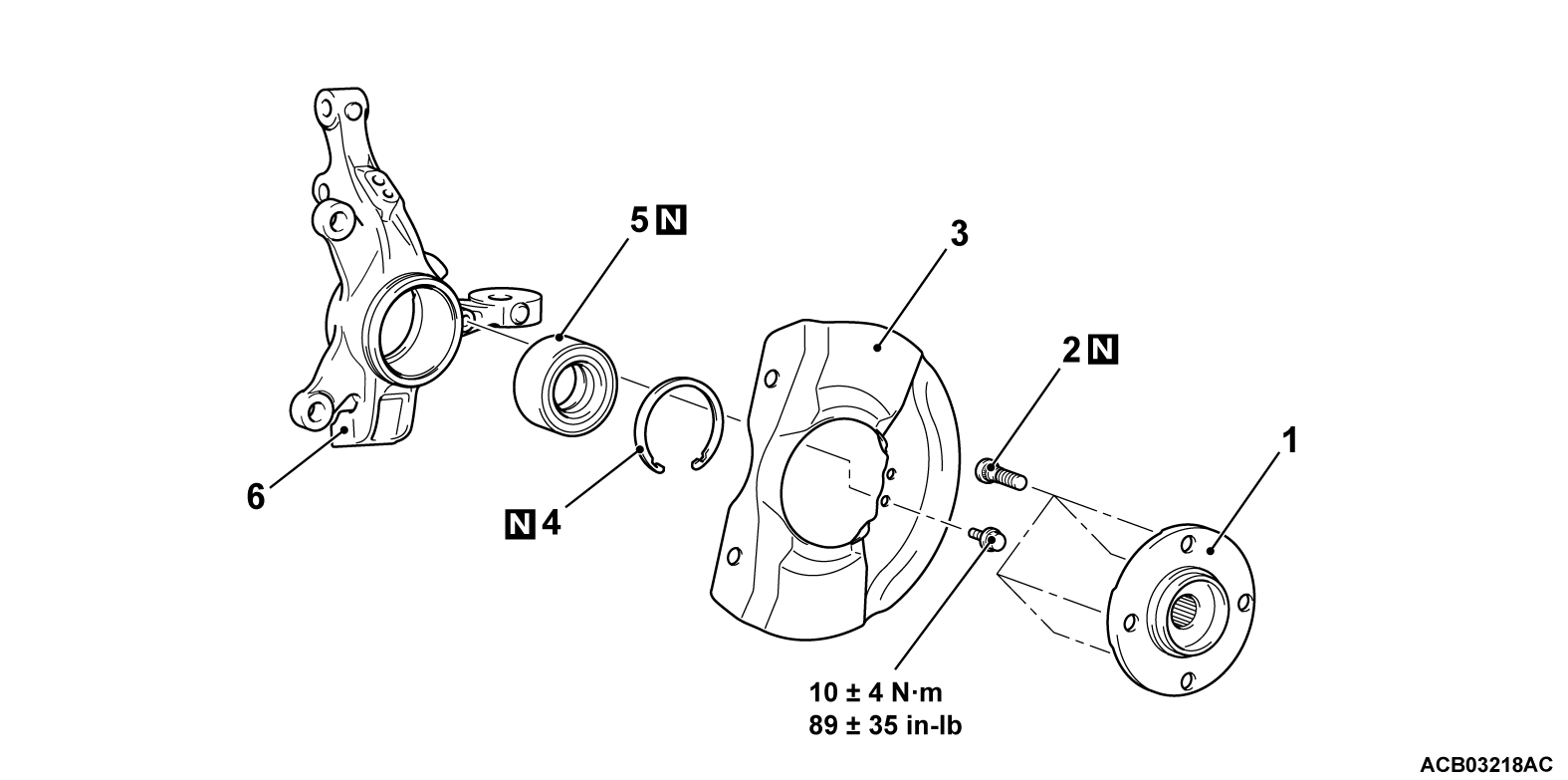

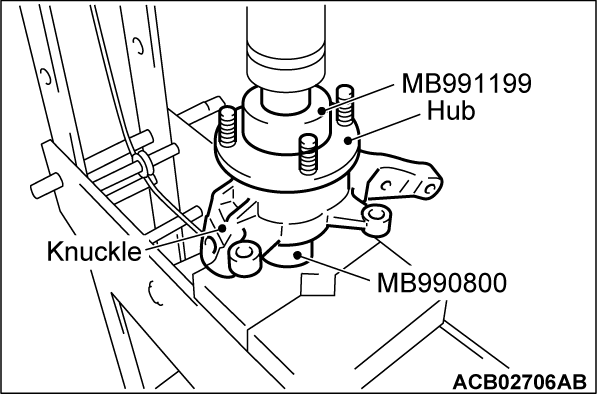

<<A>> HUB REMOVAL

| caution | When the hub has been removed, always replace the wheel bearing with a new part because wheel bearing frictional surface will be damaged when removing the hub. |

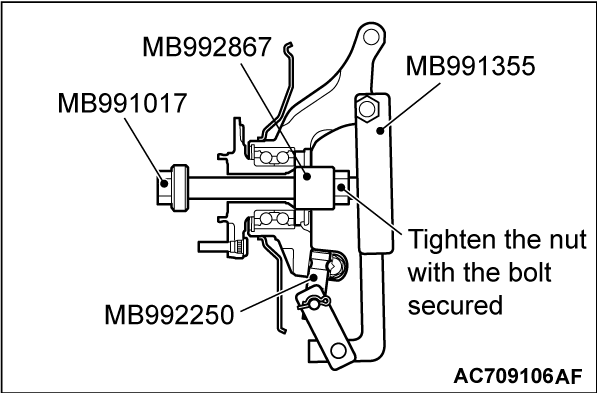

Use the following special tools to pull out the front wheel hub assembly from the knuckle.

- MB991017: Front hub remover and installer

note Except spacer (MB991019). - MB991355: Knuckle arm bridge

- MB992250: Knuckle Arm Bridge attachment

- MB992867: Front hub remover and installer spacer

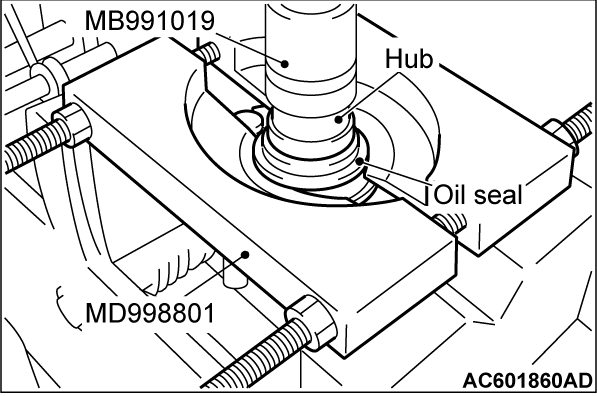

<<C>> SNAP RING/WHEEL BEARING REMOVAL

1. From the inner race of the wheel bearing outer side, remove the ball bearing.

2. Using following special tools, remove the oil seal from the hub.

- MB991019: Spacer

- MD998801: Remover

3.

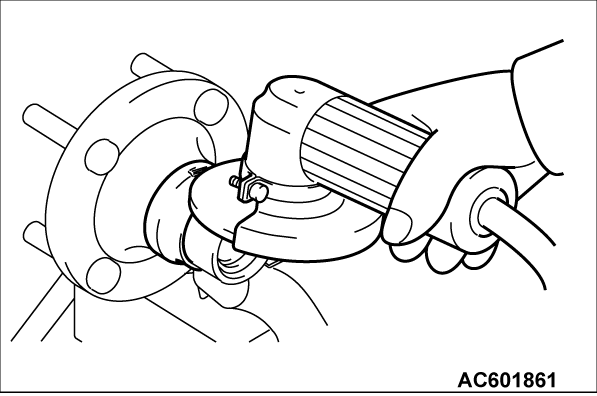

Fix the hub, then grind off the inner race of wheel bearing outer side.

| caution |

|

4. Wedge a chisel or a similar tool into the ground section, and remove the inner race of wheel bearing outer side.

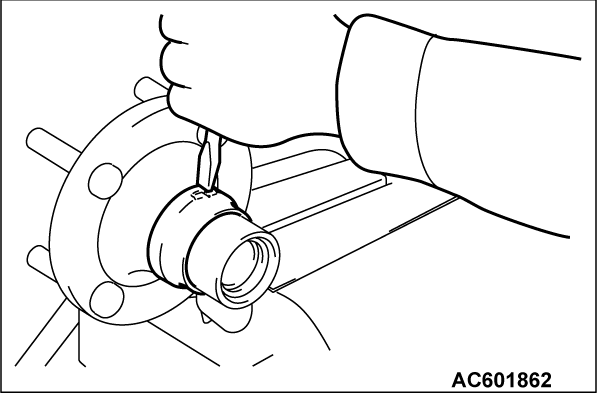

5. Using snap ring pliers, remove the snap ring from the knuckle.

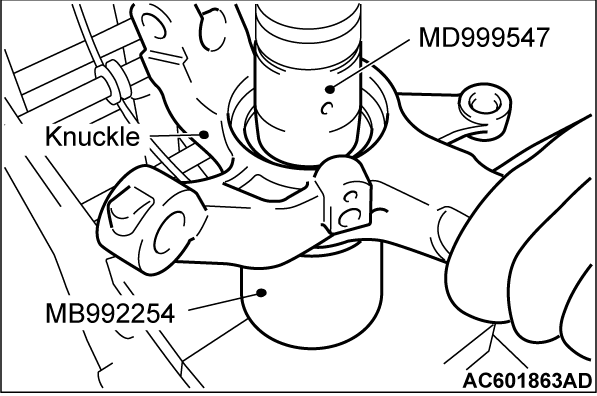

6. Use the following special tools to remove the wheel bearing outer race from the knuckle.

- MB992254: Base

- MD999547: Oil seal installer

ASSEMBLY SERVICE POINTS

>>A<< KNUCKLE/WHEEL BEARING INSTALLATION

1. Remove the remaining grease, anti-corrosion oil and foreign material from the inner circumference of the knuckle.

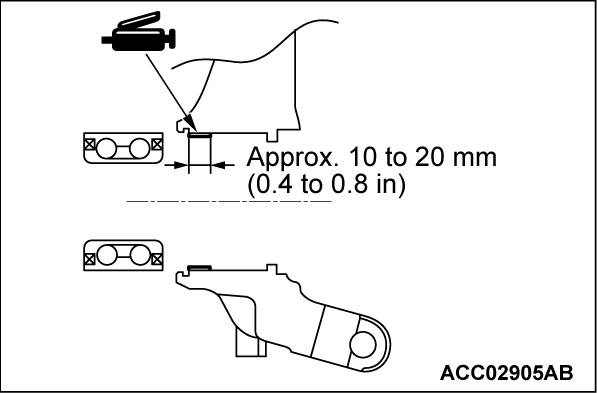

2. Apply the specified grease to the inner circumference of the knuckle evenly as shown {The application width should be approximately 10 to 20 mm (0.4 to 0.8 inch)}.

Specified grease: Dowcorning/Molykote BR2 Plus

Amount to use: as required {0.5 - 1.5 g (0.02 - 0.05 oz)}

3.

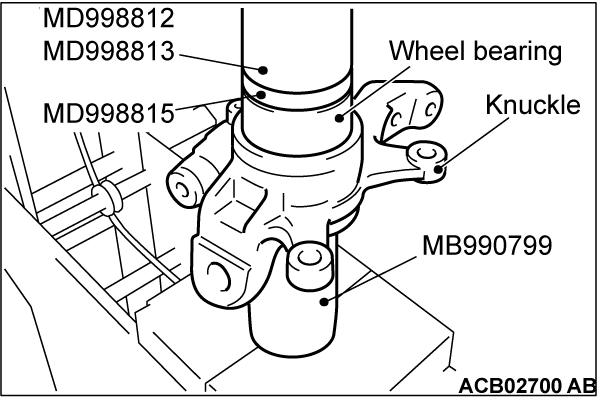

Use the following special tools to press-fit the wheel bearing to the knuckle.

| caution |

|

- MB990799: Ball joint A remover and installer

- MD998812: Installer cap

- MD998813: Installer

- MD998815: Installer adapter

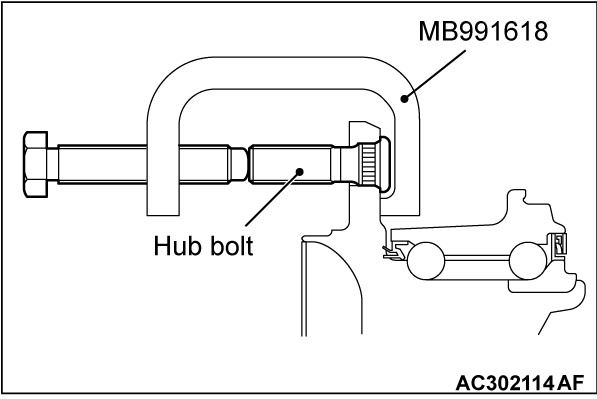

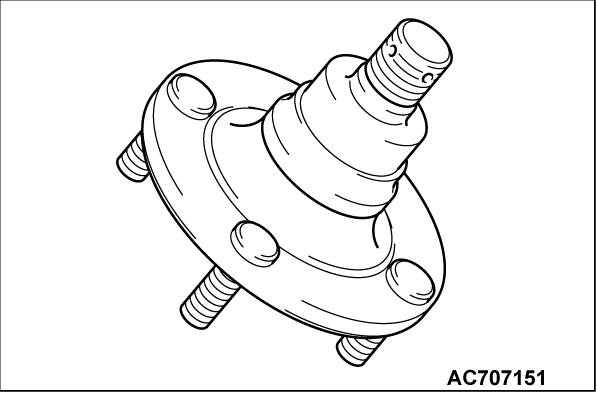

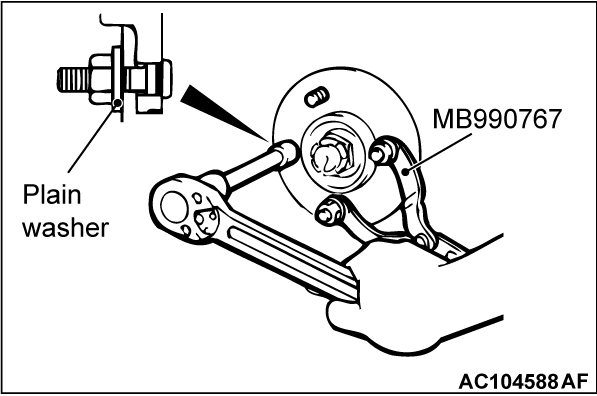

>>B<< HUB BOLT INSTALLATION

After fixing the hub using the special tool MB990767, install the plain washer to the new hub bolt, and tighten the bolt with a nut.

>>C<< HUB INSTALLATION

Use the following special tools to press-fit the hub to the knuckle wheel bearing.

- MB990800: Ball joint B remover and installer

- MB991199: Oil seal installer

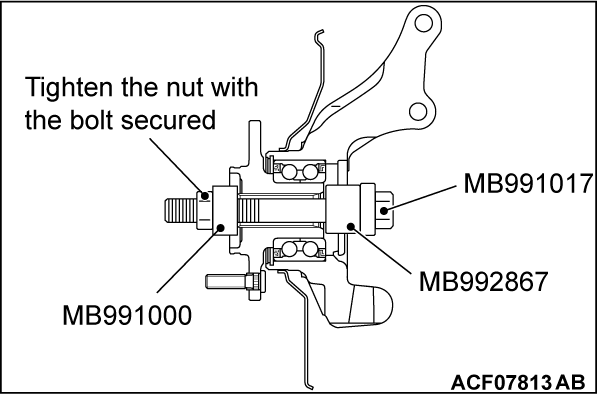

>>D<< WHEEL BEARING STARTING TORQUE CHECK

1. Set the following special tools as shown in the figure, tighten the nut to the specified torque, and press-fit the hub into the knuckle:

- MB991000: Spacer

- MB991017: Front hub remover and installer

note Except spacer (MB991019). - MB992867: Front hub remover and installer spacer

Tightening torque: 250 ± 25 N·m (184 ± 18 ft-lb)

2. Rotate the hub to make the bearing well-greased.

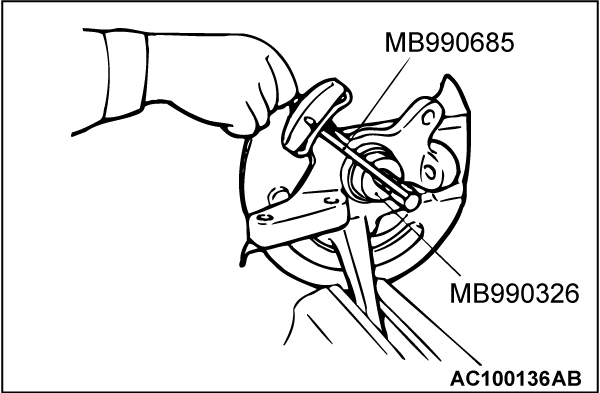

3. Use the following special tools to measure the hub rotation starting torque.

- MB990326: Preload socket

- MB990685: Torque wrench

Limit: 1.5 N·m (13 in-lb)

4. Hub rotation starting torque should be within the limit value, and there should be no roughness and gritty feeling in rotation.

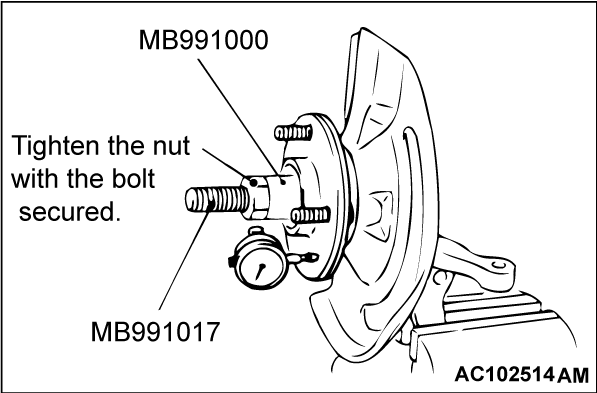

>>E<< WHEEL BEARING END PLAY CHECK

1. Use the following special tools to measure the wheel bearing end play:

- MB991000: Spacer

- MB991017: Front hub remover and installer

note Except spacer (MB991019). - MB992867: Front hub remover and installer

Limit: 0.05 mm (0.002 inch)

2. If the end play is not within the limit range while the nut is tightened to the specified torque, the bearing, hub and/or knuckle have probably not been installed correctly. Replace the bearing and re-install.

Tightening torque: 250 ± 25 N·m (184 ± 18 ft-lb)

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)