INSPECTION PROCEDURE USING AN OSCILLOSCOPE

CAMSHAFT POSITION SENSOR AND CRANKSHAFT POSITION SENSOR

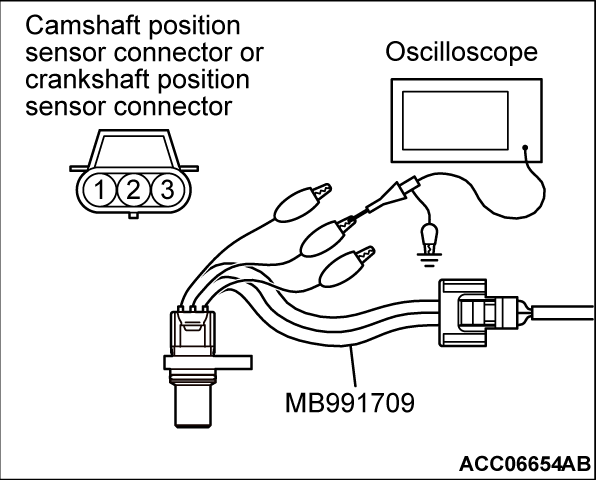

Required Special Tool:

- MB991709: Test Harness

Measurement Method

1. Disconnect the camshaft position sensor connector, and connect the test harness special tool (MB991709) between the separated connector (All terminals should be connected).

2. Connect the oscilloscope probe to camshaft position sensor connector terminal No. 2.

3. Disconnect the crankshaft position sensor connector, and connect the test harness special tool (MB991709) between the separated connector (All terminals should be connected).

4. Connect the oscilloscope probe to crankshaft position sensor connector terminal No. 2.

Alternate Method (Test harness not available)

1. Connect the oscilloscope special patterns pickup to ECM terminal SGC (When checking the camshaft position sensor signal wave pattern).

2. Connect the oscilloscope special patterns pickup to ECM terminal SGT (When checking the crank angle sensor signal wave pattern).

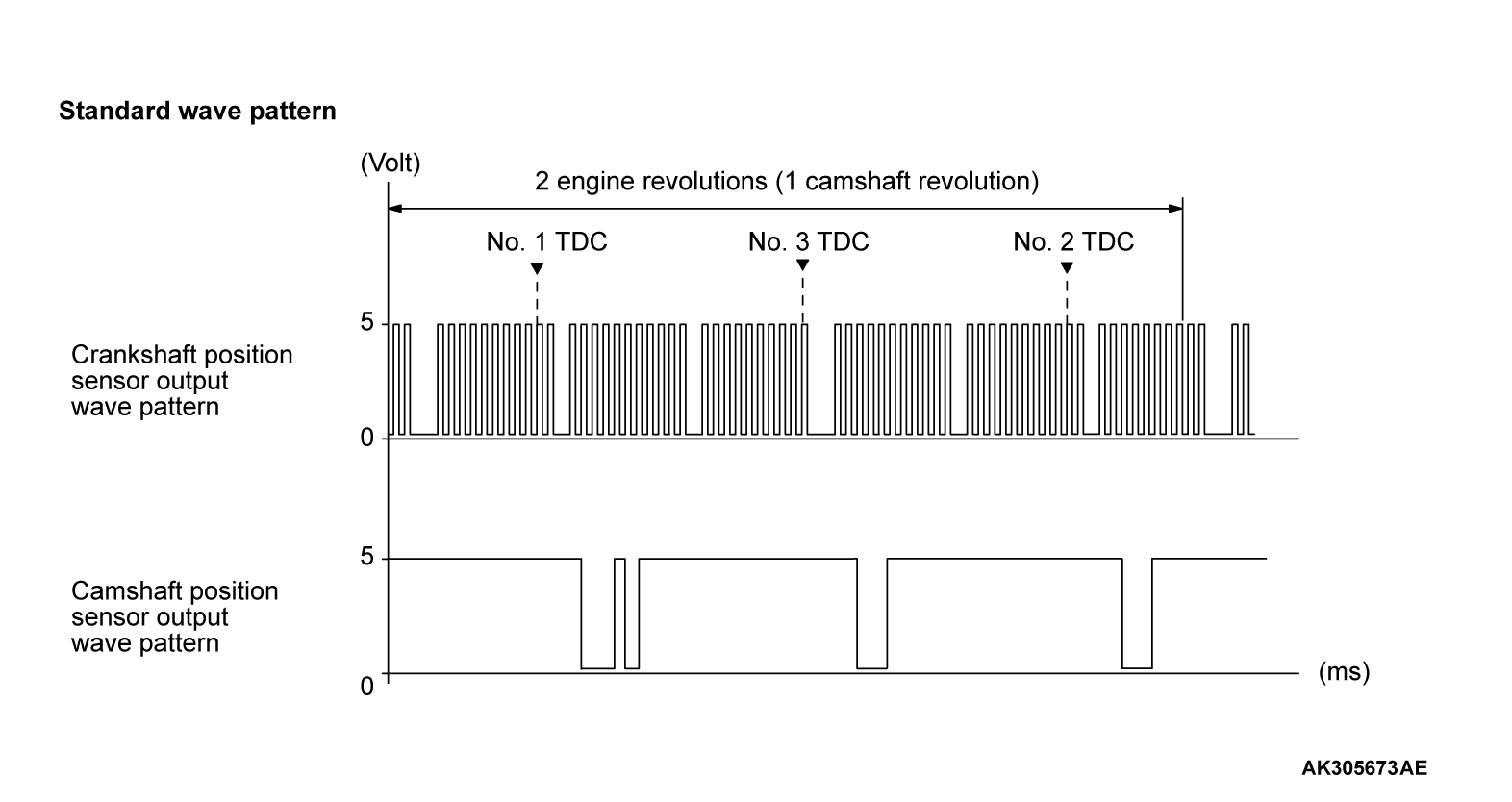

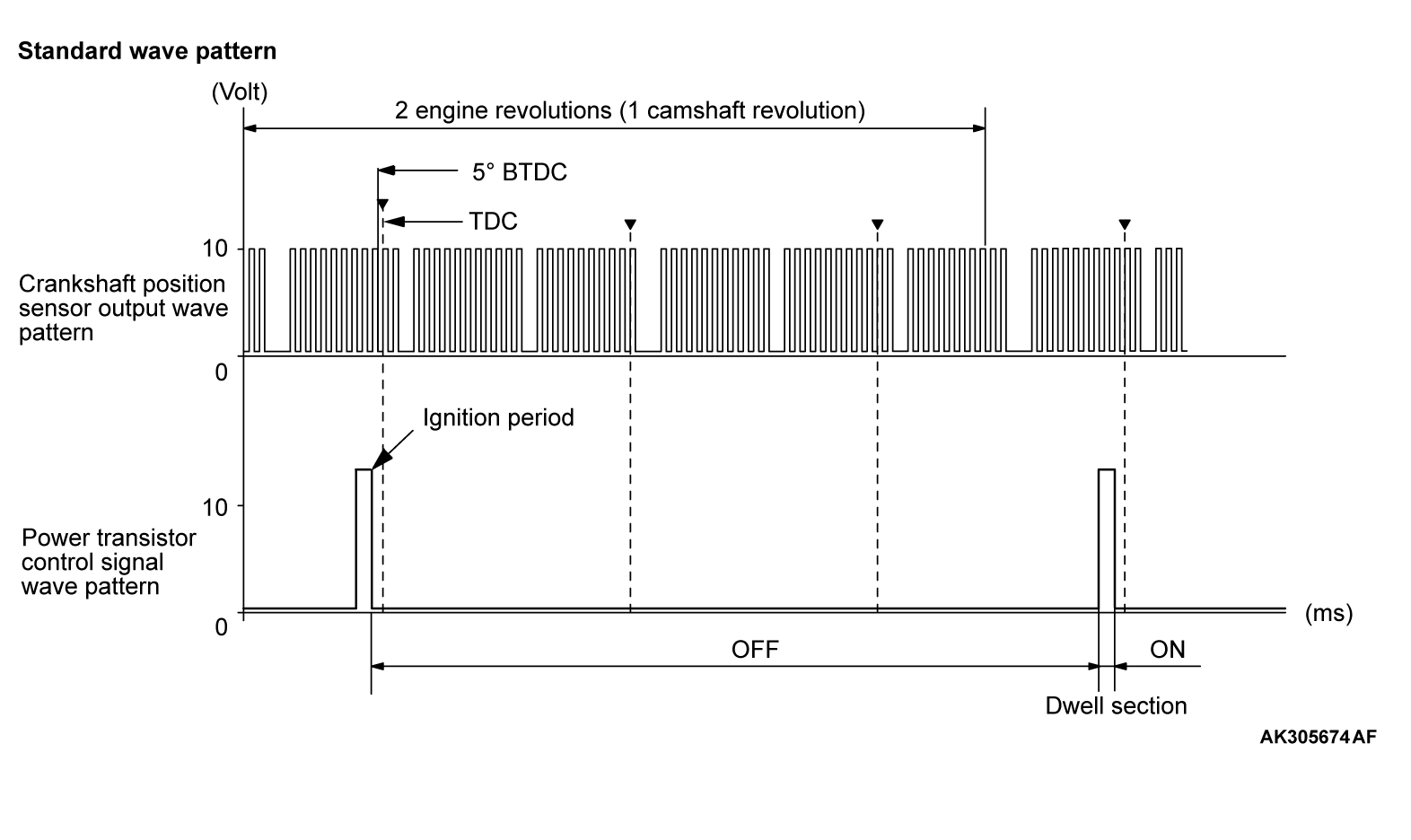

Standard Wave Pattern

| Observation condition | |

| Function | Special pattern |

| Pattern height | Low |

| Pattern selector | Display |

| Engine condition | Idle |

Wave Pattern Observation Points

- Verify that the sensor signal frequency increase as the engine speed rises.

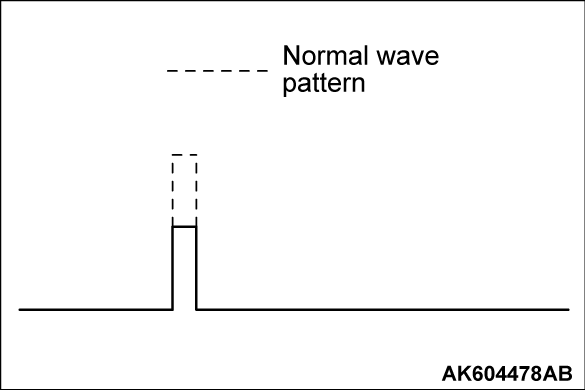

Examples of Abnormal Wave Patterns

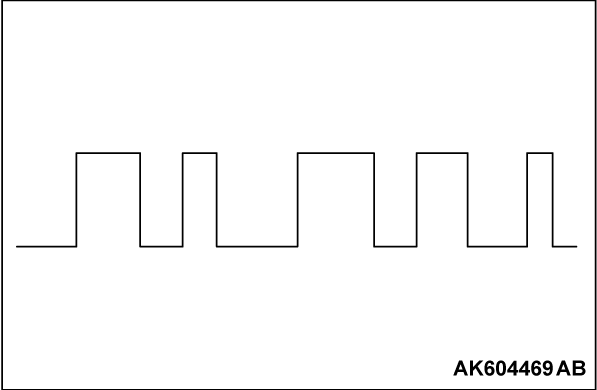

Example 1

- Cause of problem

- Sensor interface malfunction.

- Wave pattern characteristics

- Rectangular wave pattern is output even when the engine is not started.

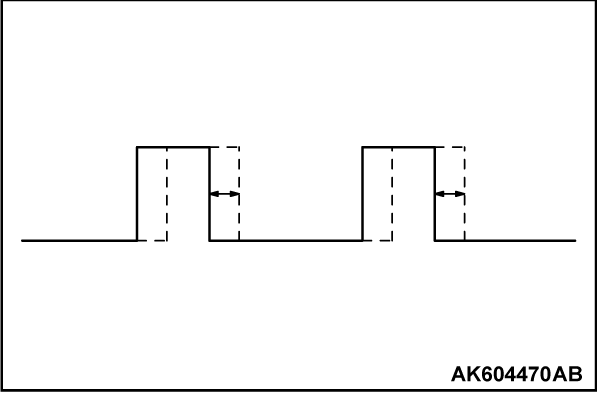

Example 2

- Cause of problem

- Loose timing chain.

- Abnormality in sensor disc.

- Wave pattern characteristics

- Wave pattern is displaced to the left or right.

INJECTOR

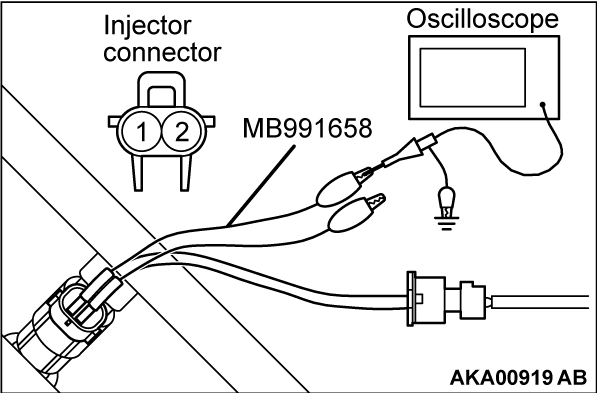

Required Special Tool:

- MB991658: Test Harness

Measurement Method

- Disconnect the injector connector, and connect the test harness special tool (MB991658) between the separated connector. (All terminals should be connected.)

- Connect the oscilloscope probe to injector connector terminal No. 2.

Alternate method (Test harness not available)

- Connect the oscilloscope special patterns pickup to ECM terminal INJ1 (When checking the No. 1 cylinder).

- Connect the oscilloscope special patterns pickup to ECM terminal INJ2 (When checking the No. 2 cylinder).

- Connect the oscilloscope special patterns pickup to ECM terminal INJ3 (When checking the No. 3 cylinder).

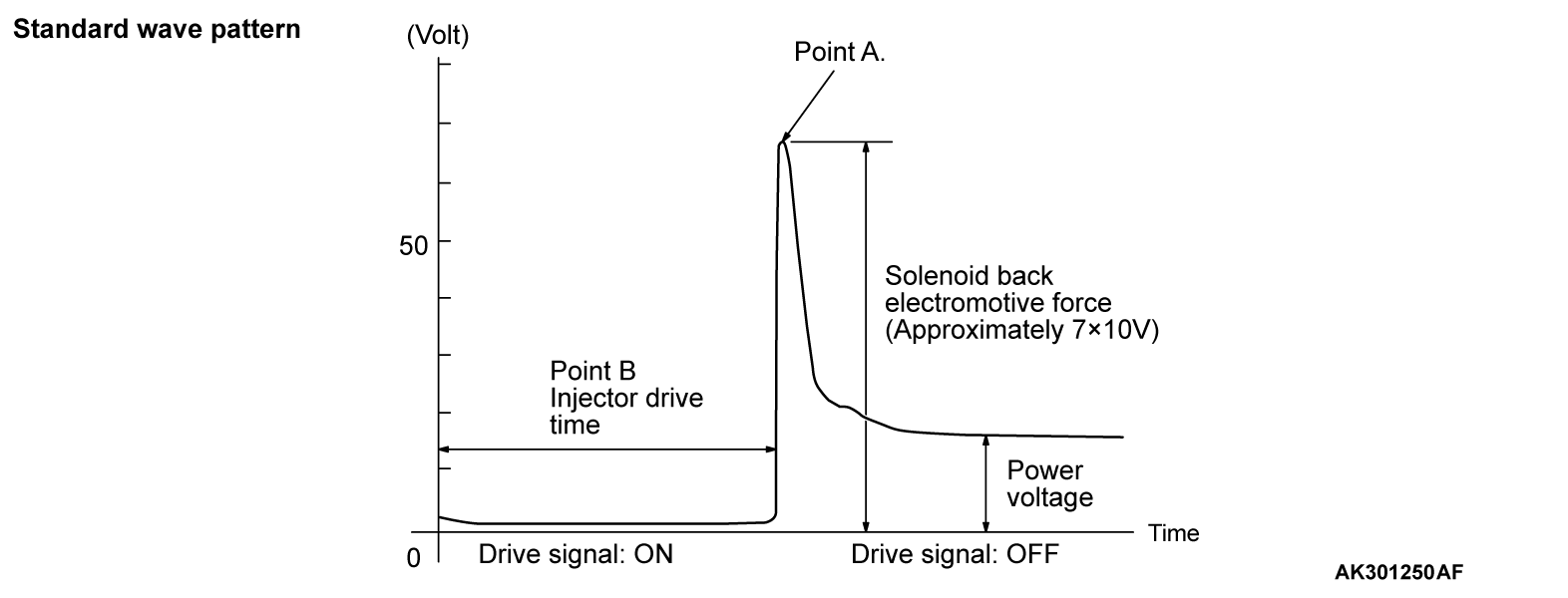

Standard Wave Pattern

| Observation conditions | |

| Function | Special pattern |

| Pattern height | Variable |

| Variable knob | Adjust while viewing the wave pattern |

| Pattern selector | Display |

| Engine condition | Idle |

Wave Pattern Observation Points

- Point A: Height of injector coil induced voltage.

| CONTRAST WITH STANDARD WAVE PATTERN | PROBABLE CAUSE |

| Injector coil induced voltage is low or doesn't appear at all | Short in the injector solenoid |

Point B: Injector drive time

- The injector drive time should be synchronized with the scan tool tester display.

- When the engine is suddenly revved, the drive time will be greatly extended at first, but the drive time will soon return to original length.

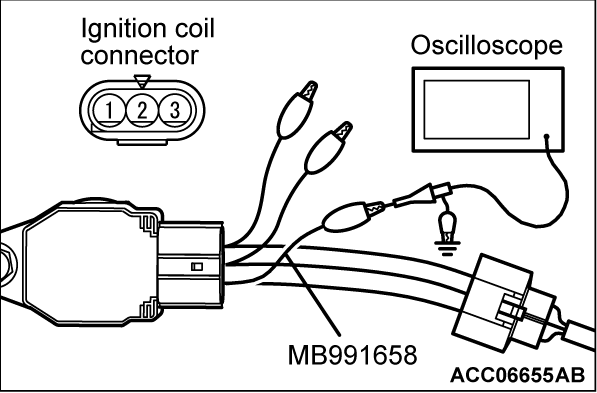

IGNITION COIL AND IGNITION POWER TRANSISTOR

Required Special Tool:

- MB991658: Test Harness

Measurement Method

- Disconnect the ignition coil connector, and connect test harness special tool (MB991658) between the separated connector. (All terminals should be connected.)

- Connect the oscilloscope probe to ignition coil connector terminal No. 1.

Alternate method

1. Connect the oscilloscope special patterns pickup to ECM terminal CIL1. (When checking the No. 1 cylinder.)

2. Connect the oscilloscope special patterns pickup to ECM terminal CIL2. (When checking the No. 2 cylinder.)

3. Connect the oscilloscope special patterns pickup to ECM terminal CIL3. (When checking the No. 3 cylinder.)

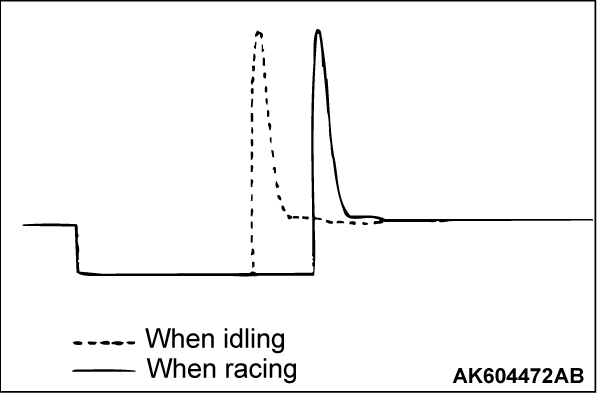

Standard Wave Pattern

| Observation condition | |

| Function | Special pattern |

| Pattern height | Low |

| Pattern selector | Display |

| Engine condition | Idle |

Wave Pattern Observation Points

- Point: The power transistor control signal (ignition timing) is advanced when the engine speed is increased.

| CONDITION OF WAVE PATTERN BUILD-UP SECTION AND MAXIMUM VOLTAGE | PROBABLE CAUSE |

| Voltage value is too low | Open-circuit in ignition primary circuit |

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)