REMOVAL AND INSTALLATION

Pre-removal operation | Post-installation operation |

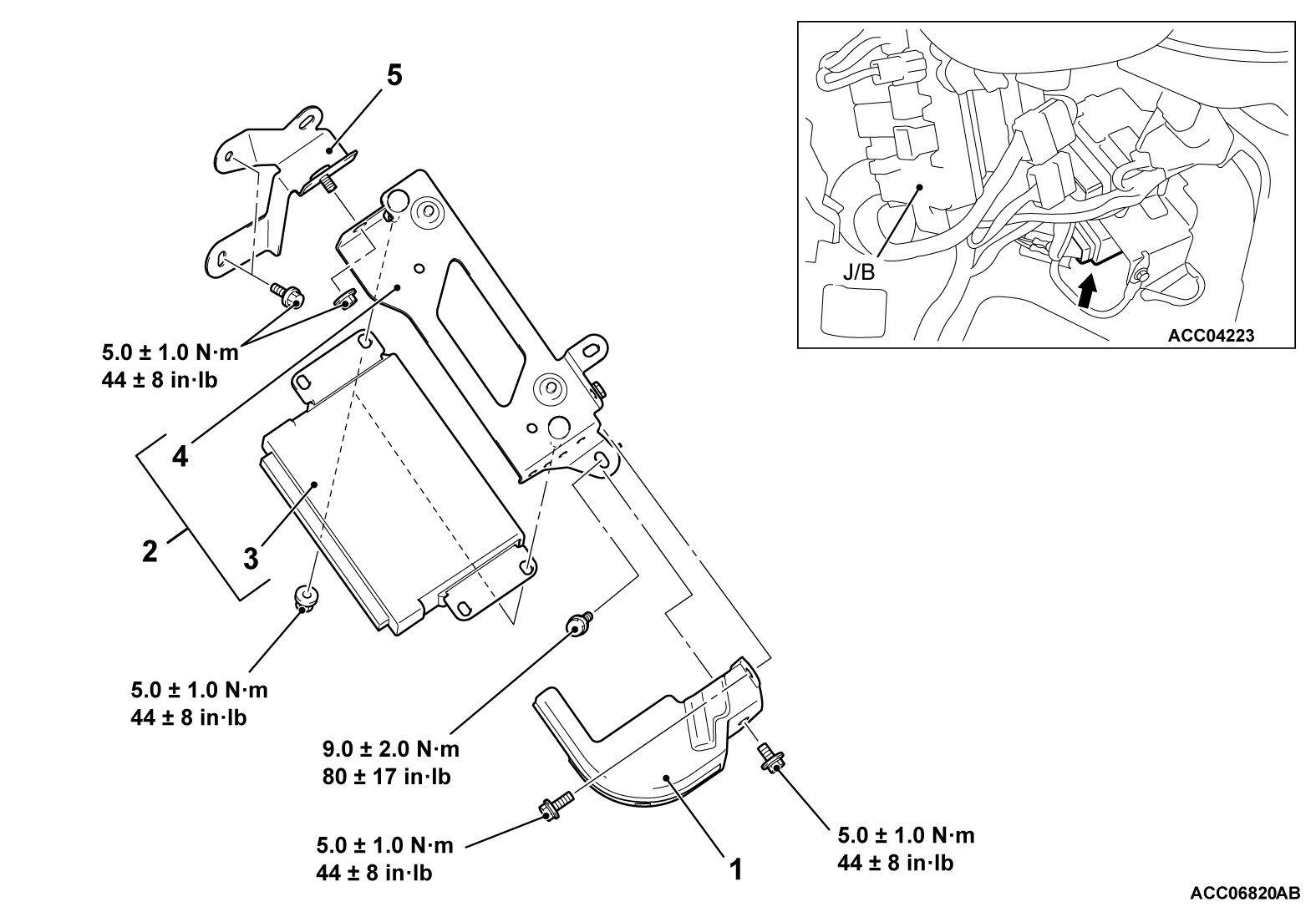

<Except vehicles for Canada> |

REMOVAL SERVICE POINT

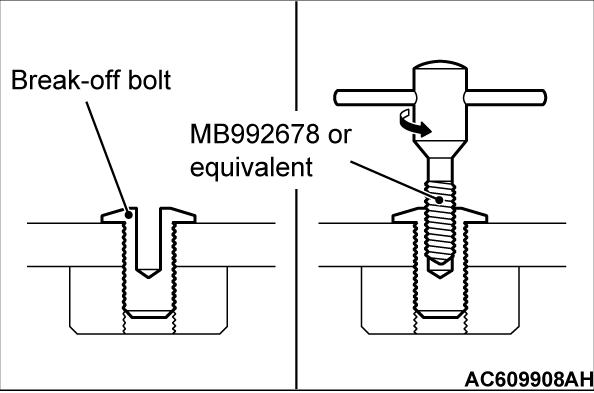

<<A>> BREAK-OFF BOLT REMOVAL

1. <When using recommended tool screw extractor set (MB992678) or equivalent>

(1) Drill in the break-off bolt a hole deep enough for the tap to stand.

(2) Use recommended tool screw extractor set (MB992678) or equivalent to remove the break-off bolt.

2. <When using the flat-tipped screwdriver>

(1) Apply force towards the direction to loose the bolt by a flat-tipped screwdriver.

(2) Remove the break-off bolt.

INSTALLATION SERVICE POINTS

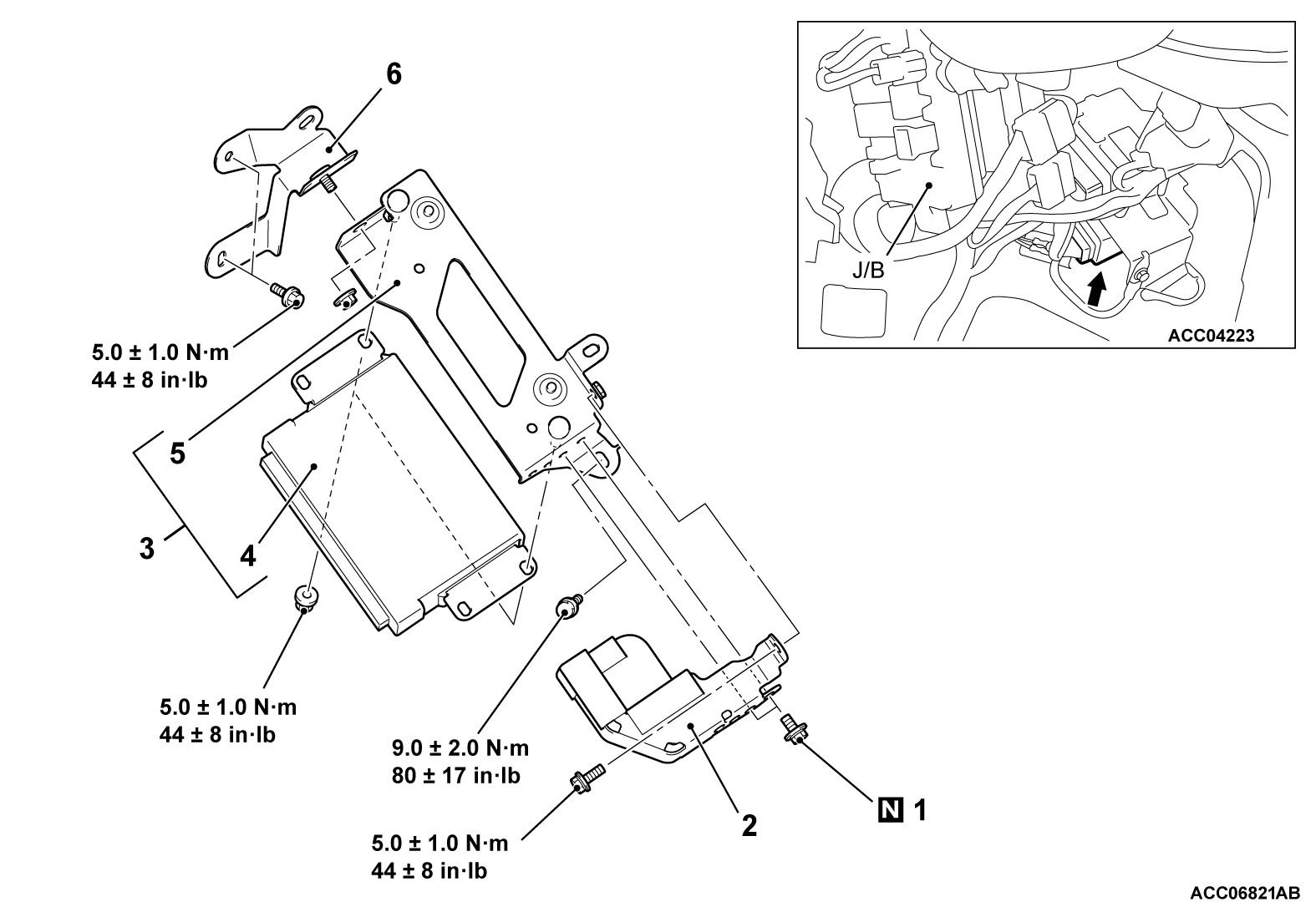

>>A<< ECM AND BRACKET ASSEMBLY INSTALLATION

1. Tighten the ECM and bracket assembly mounting bolt temporarily.

2. Tighten the mounting nut to the specified torque.

Tightening torque: 5.0 ± 1.0 N·m (44 ± 8 in-lb)

3. Tighten the mounting bolt to the specified torque.

Tightening torque: 9.0 ± 2.0 N·m (80 ± 17 in-lb)

>>B<< BREAK-OFF BOLT INSTALLATION

Tighten until the head of break-off bolt is broken off.

>>C<< INITIALIZATION OPERATION

Turn the ignition switch to the "ON" position and then to "LOCK" (OFF) position and hold it for at least 10 seconds.

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)