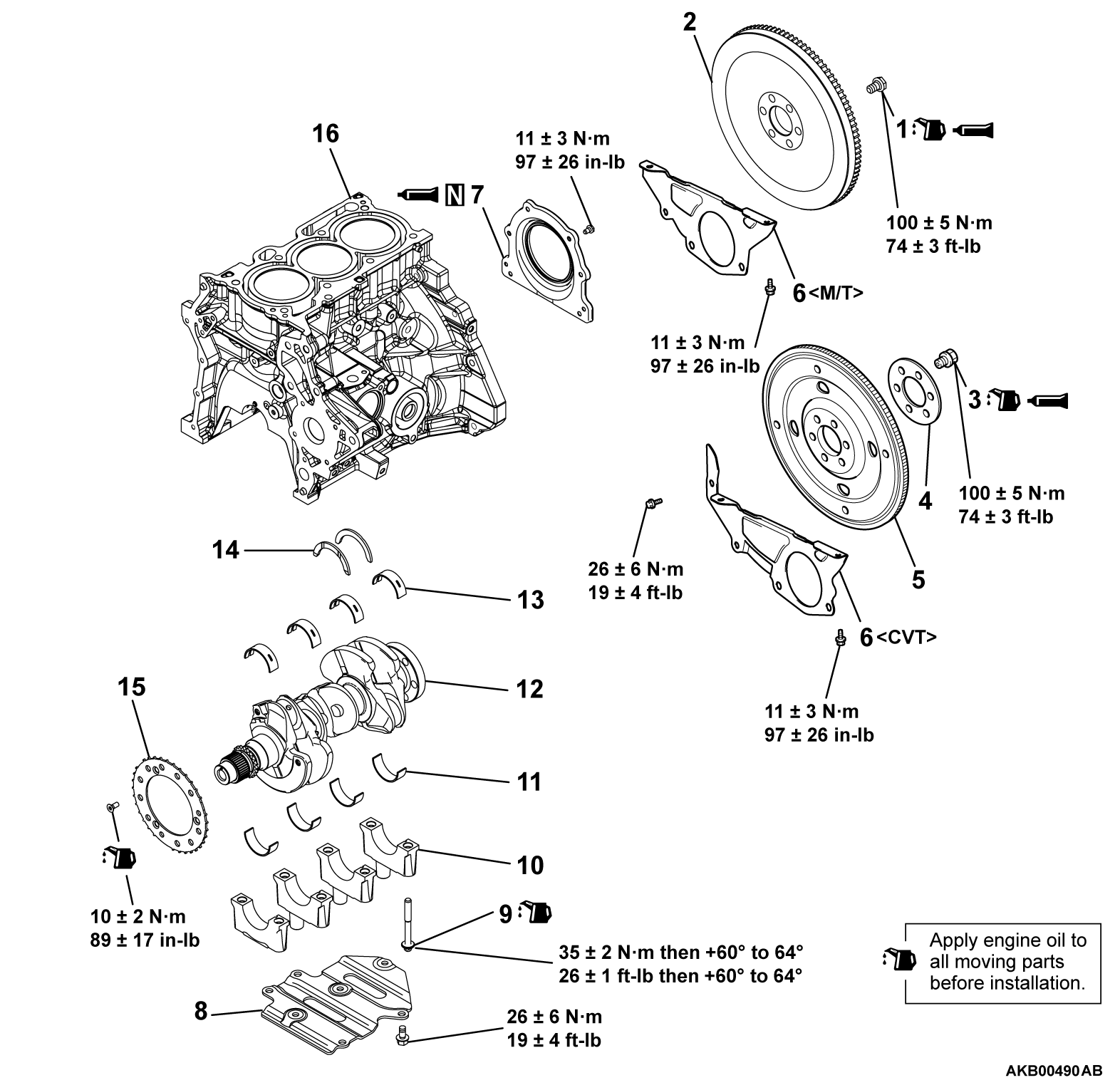

REMOVAL AND INSTALLATION

Required Special Tools:

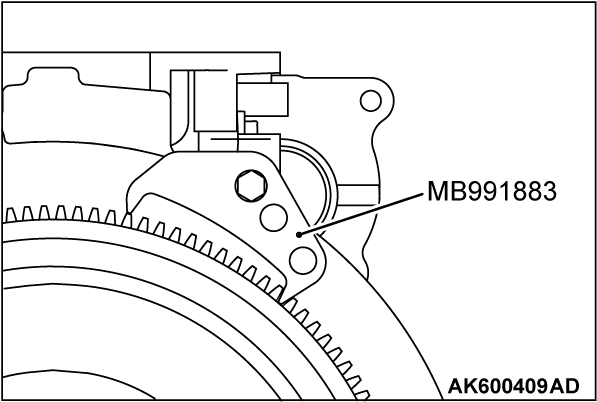

- MB991883: Flywheel Stopper

- MB991614: Angle Gauge

REMOVAL SERVICE POINT

INSTALLATION SERVICE POINTS

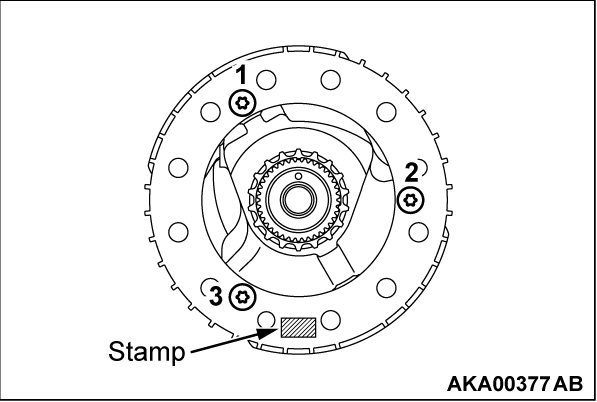

>>A<< CRANKSHAFT SENSING RING INSTALLATION

1. Install the crankshaft sensing ring to the crankshaft after aligning a stamp to the position as shown in the illustration when the crankshaft is at number 1 TOP.

2. Apply engine oil to the crankshaft sensing ring bolt.

3. Tighten the crankshaft sensing ring bolts to specified torque in the order shown in the illustration.

Tightening torque: 10 ± 2 N·m (89 ± 17 in-lb)

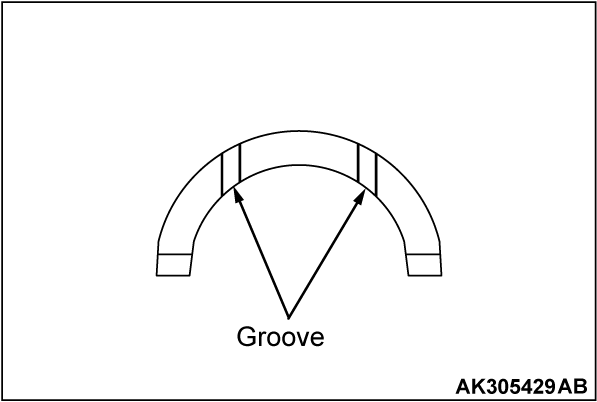

>>B<< THRUST BEARING INSTALLATION

1. Install the thrust bearing onto the cylinder block side of the number 3 bearing. Apply engine oil to the thrust bearing to facilitate installation.

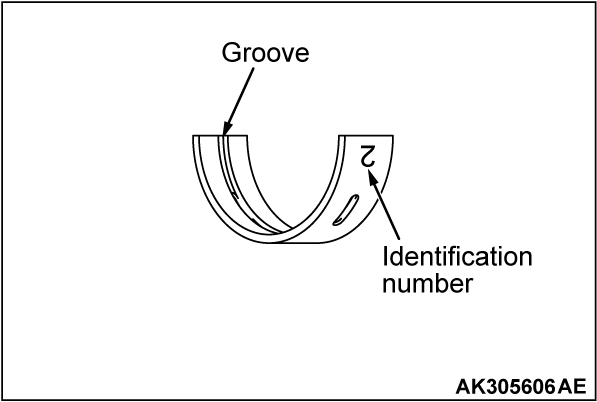

2. The thrust bearing should be installed such that its groove faces the crankshaft weight.

>>C<< CRANKSHAFT BEARING UPPER INSTALLATION

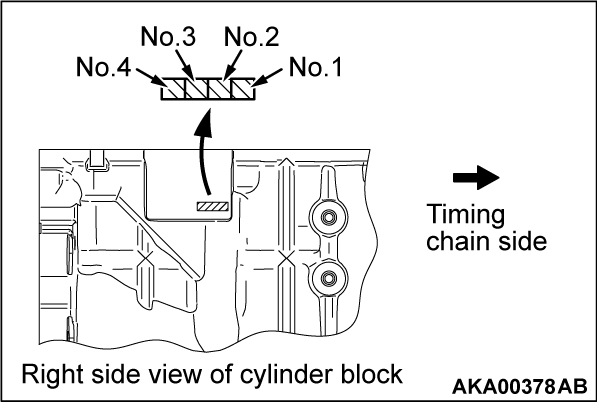

1. The crankshaft bearing upper should be selected based on the identification mark on the right side face of the cylinder block (illustrated) and the table shown below.The crankshaft bearing upper has the identification mark at the illustrated position.

| |||||||||||||||

2. Select and install the crankshaft bearing upper.

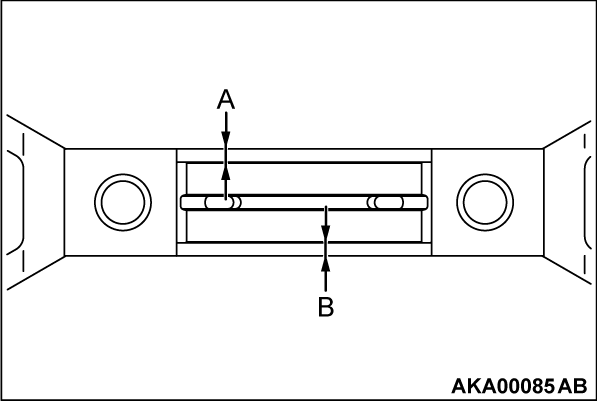

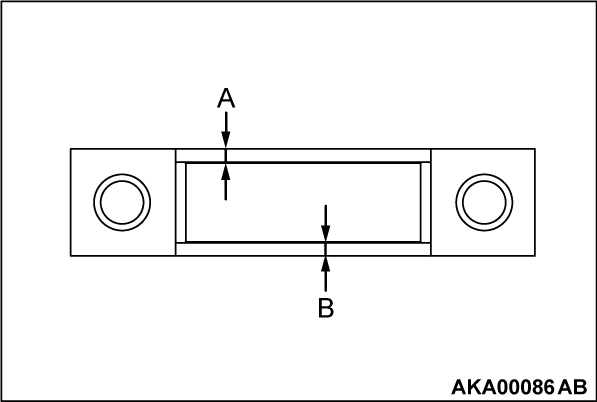

3. Measure the illustrated location. (A - B) be within 0.5 mm (0.02 inch).

>>D<< CRANKSHAFT BEARING LOWER INSTALLATION

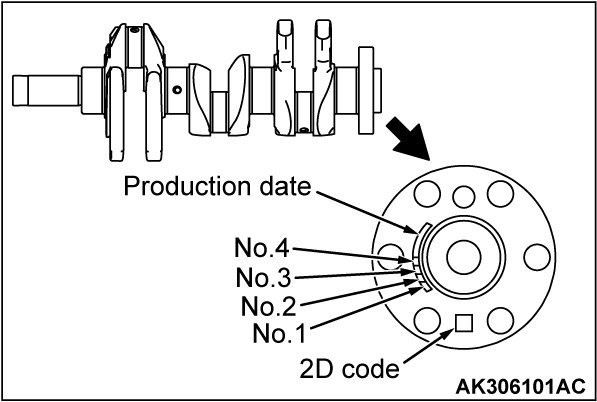

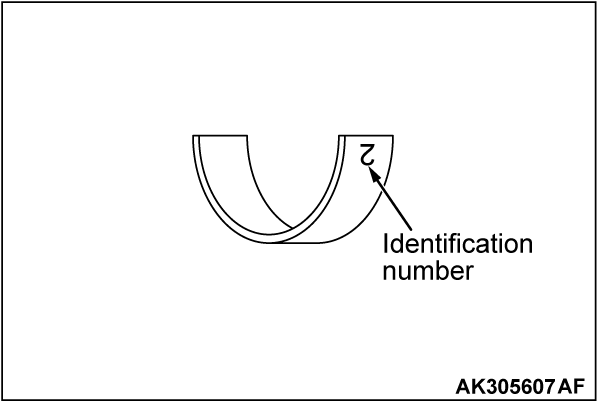

1. The crankshaft bearing lower should be selected based on the identification mark on the crankshaft rear flange (illustrated) and the table shown below.The crankshaft bearing lower has the identification mark at illustrated position.

| ||||||||||||||||||

2. Select and install the crankshaft bearing lower.

3. Measure the illustrated location. (A - B) should be within 0.5 mm (0.02 inch).

>>E<< CRANKSHAFT BEARING CAP/CRANKSHAFT BEARING CAP BOLT INSTALLATION

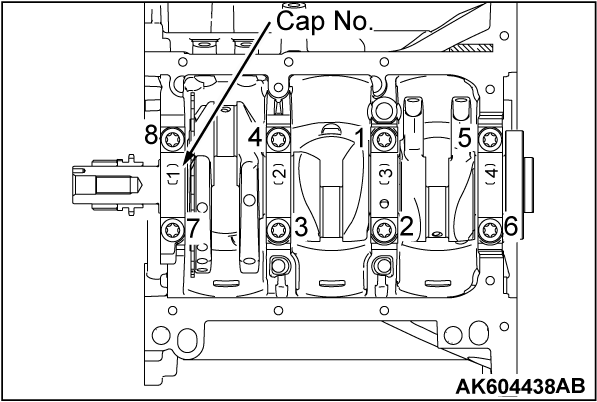

1. Install the bearing cap, based on the identification mark at the illustrated location.

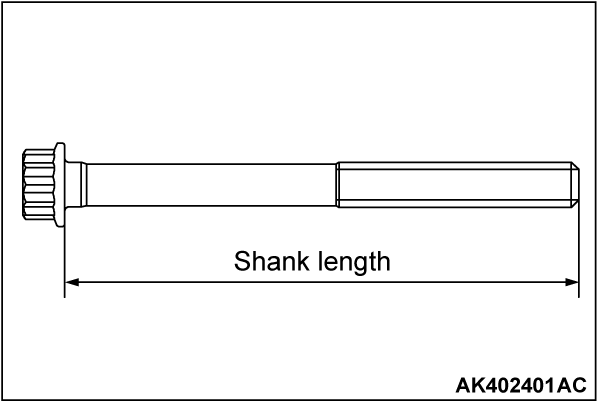

2. Before the bearing cap bolt is installed, make sure the nominal length of the bolt is below the limit. If above the limit, replace the bolt with the new one.

Standard value: 74.15 - 74.85 mm (2.920 - 2.946 inches)

3. Apply engine oil to the threaded portion and seating face of the bolt.

4. Tighten the bearing cap bolts in the illustrated sequence to specified torque.

Tightening torque: 35 ± 2 N·m (26 ± 1 ft-lb)

5.

Using the special tool MB991614, tighten the bearing cap bolts in the illustrated sequence by a further 60 degree angle to 64 degree angle.

| caution |

|

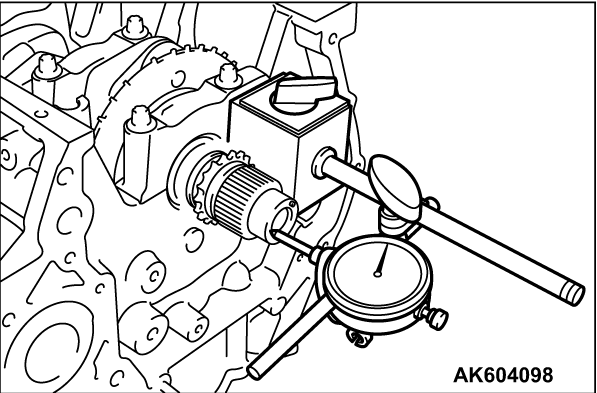

6. With the bearing caps installed, check the crankshaft end play. If the measured value exceeds the limit, replace the crankshaft bearings.

Standard value: 0.09 - 0.27 mm (0.004 - 0.010 inch)

Limit: 0.30 mm (0.012 inch)

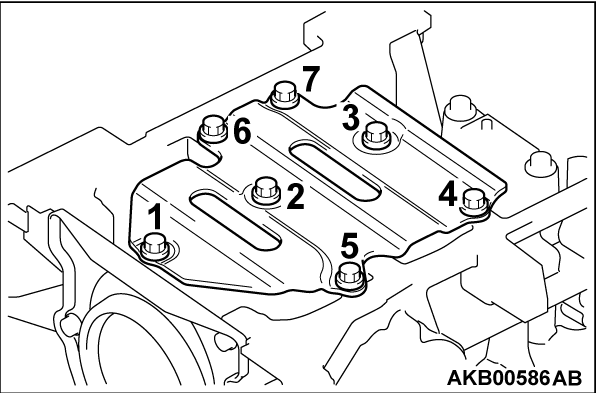

>>F<< STIFFENER INSTALLATION

In accordance with the installation order, tighten them to the specified torque.

Tightening torque: 26 ± 6 N·m (19 ± 4 ft-lb)

>>G<< OIL SEAL CASE INSTALLATION

1. Remove sealant from the oil seal case mounting surface of the cylinder block.

2. Apply a bead of specified sealant to the oil seal case mating surface of the cylinder block as shown.

Specified sealant:

- Three bond 1217G or equivalent

3.

| caution | Install the oil seal case not to damage the oil seal. |

Within 10 minutes after applying the specified sealant, install the oil seal case to the cylinder block.

4. Tighten the oil seal case mounting bolts to the specified torque.

Tightening torque: 11 ± 3 N·m (97 ± 26 in-lb)

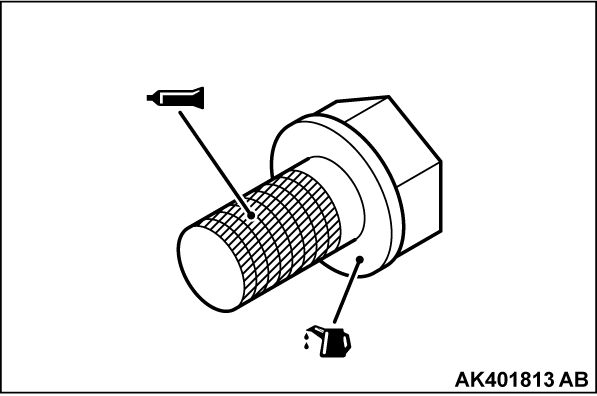

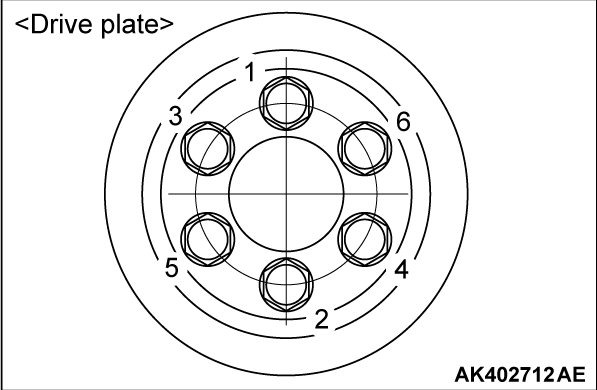

>>H<< DRIVE PLATE BOLT <CVT>/FLYWHEEL BOLT <M/T> INSTALLATION

1. Remove any sealant remaining on the threaded hole in the crankshaft.

2. Apply a small amount of engine oil to the installation face of the drive plate bolt <CVT> or flywheel bolt <M/T> and the thread portion of the crankshaft.

3.

| caution | Apply sealant correctly so that it will not be squeezed out onto the end of the threaded portion upon assembly. |

Apply sealant to the threaded portion of the drive plate bolt <CVT> or flywheel bolt <M/T> as illustrated.

Specified sealant:

- LOCTITE 2701 or equivalent

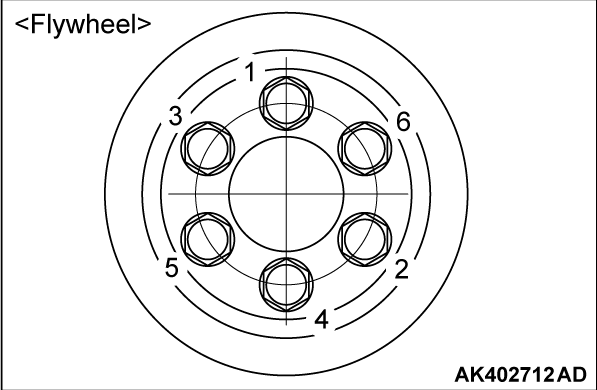

4. Fix the drive plate <CVT> or flywheel <M/T> in place using special tool MB991883.

5. In accordance with the numerical order shown in the illustration, tighten the drive plate bolt <CVT> or flywheel bolt <M/T> to the specified torque in several steps.

Tightening torque: 100 ± 5 N·m (74 ± 3 ft-lb)

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)