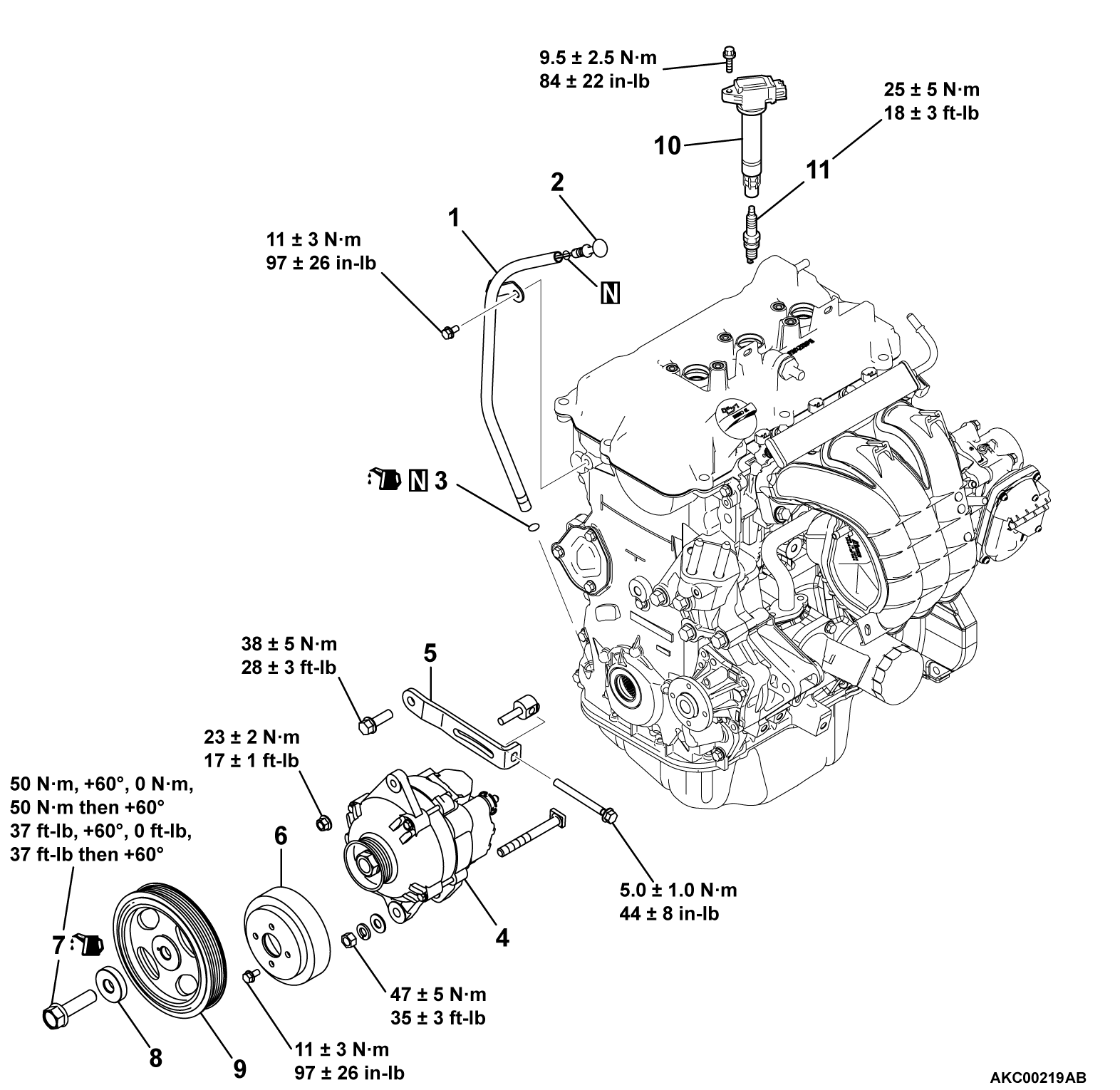

REMOVAL AND INSTALLATION

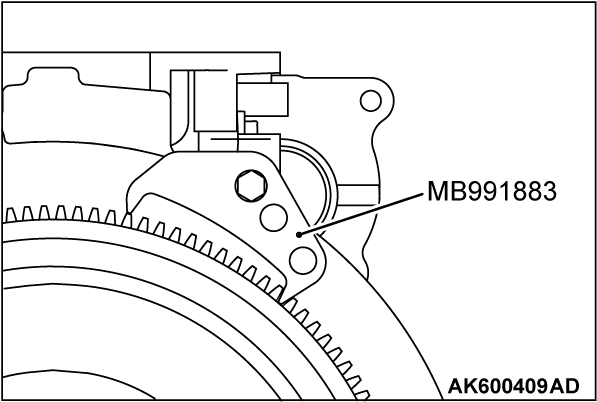

Required Special Tool:

- MB991883: Flywheel Stopper

REMOVAL SERVICE POINT

INSTALLATION SERVICE POINT

>>A<< CRANKSHAFT PULLEY/CRANKSHAFT PULLEY WASHER/CRANKSHAFT PULLEY CENTER BOLT INSTALLATION

1. Lock the flywheel or drive plate with special tool flywheel stopper (MB991883).

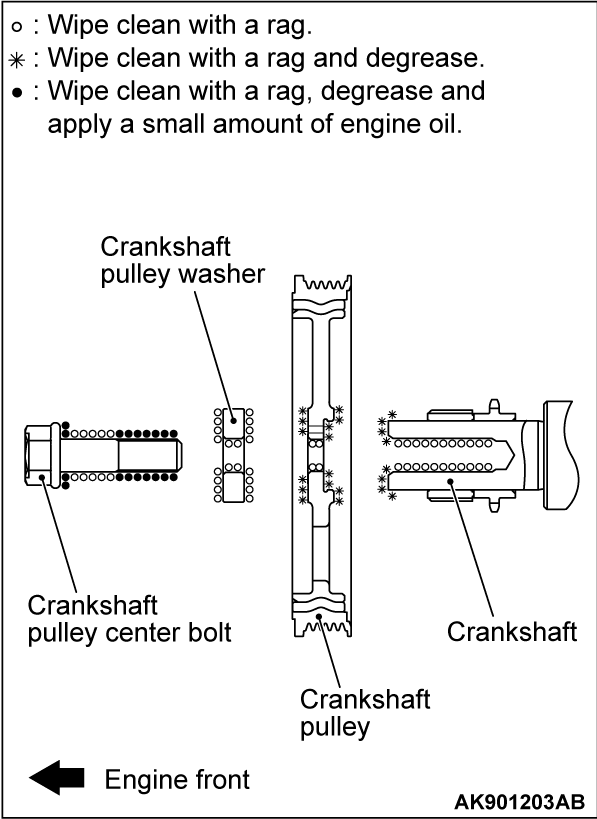

2. Using a rag, wipe dirt on the crankshaft thread hole and the crankshaft pulley washer.

3. Using a rag, wipe dirt on the crankshaft pulley and then degrease the place specified in the illustration.

| note | Perform degreasing to prevent the friction resistance from decreasing in the compressed area due to the residual oil. |

4. Install the crankshaft pulley.

5. Apply the minimum amount of engine oil to the crankshaft pulley center bolt threads and the seating surface.

6. Tighten the crankshaft pulley center bolt to the specified torque.

Tightening torque: 50 N·m (37 ft-lb)

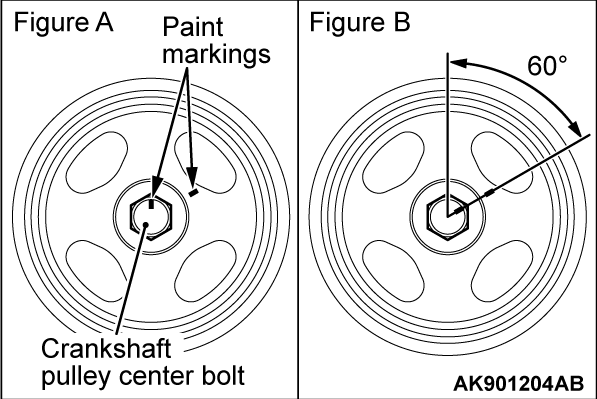

7. As shown in figure A, put a paint mark on one angle of the crankshaft pulley center bolt. Then, put a paint mark on the crankshaft pulley on the extended line of the angle next to the marked angle.

8.

| caution |

|

Tighten the crankshaft pulley center bolt in a 60°, and check that the paint mark on the crankshaft pulley center bolt aligns with the paint mark on the crankshaft pulley as shown in figure B.

9. Loosen the crankshaft pulley center bolt completely after steps 6 to 8, and then repeat steps 6 to 8.

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)