INITIALIZATION PROCEDURE FOR CVT LEARNED VALUE

Required Special Tools:

- MB992744: Vehicle communication interface-Lite (V.C.I.-Lite)

- MB992745: V.C.I.-Lite main harness A

- MB992747: V.C.I.-Lite USB cable short

- MB992748: V.C.I.-Lite USB cable long

- MB991958 Scan Tool (M.U.T.-III Sub Assembly)

- MB991824: Vehicles Communication Interface (V.C.I.)

- MB991827 M.U.T.-III USB Cable

- MB991910 M.U.T.-III Main Harness A (Vehicles with CAN communication system)

AIM

After the Transaxle assembly or valve body assembly is replaced, learned values must be initialized. The initialization procedure is as below.

INITIALIZATION PROCEDURE

1. Move the selector lever to the P range and turn the ignition switch to the LOCK (OFF) position. Then, connect scan tool (M.U.T.-III) to the data link connector.

2. Turn the ignition switch to the ON position, and then move the selector lever to the R range.

3. Depress the accelerator pedal while depressing the brake pedal. (Engine stops.) Use the scan tool (M.U.T.-III) special function to execute "reset (item No.3: C/V initial & learned value)" while holding them in applied position.

4. Set the selector lever to the P range.

5. Turn the ignition switch to the LOCK (OFF) position, and then wait for ten seconds.

6.

| caution | Do not start the engine. |

Turn the ignition switch to the ON position, and then wait for ten seconds.

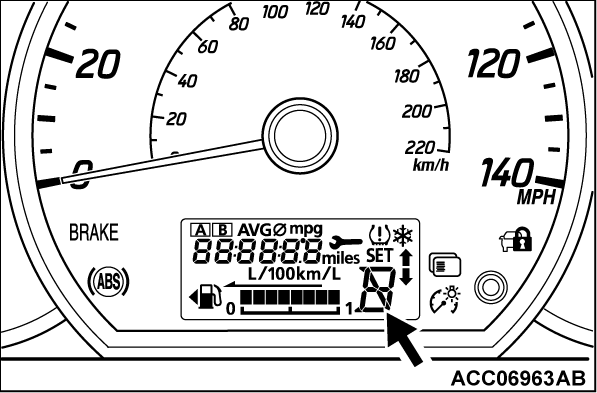

7. Check that "P" is displayed on the selector lever position indicator on the multi-information display.

| note | "P" will disappear while the data is being read. "P" will appear when the data reading is complete. |

8. Turn the ignition switch to the LOCK (OFF) position and then to the ON position. Then use the scan tool (M.U.T.-III) to erase the transmission fluid degradation level.

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)