DTC P0133: Linear Air-Fuel Ratio Sensor Circuit Slow Response

TECHNICAL DESCRIPTION

- The ECM effects air/fuel ratio feedback control in accordance with the signals from the linear air-fuel ratio sensor.

- If the linear air-fuel ratio sensor has deteriorated, corrections will be made by the heated oxygen sensor (rear).

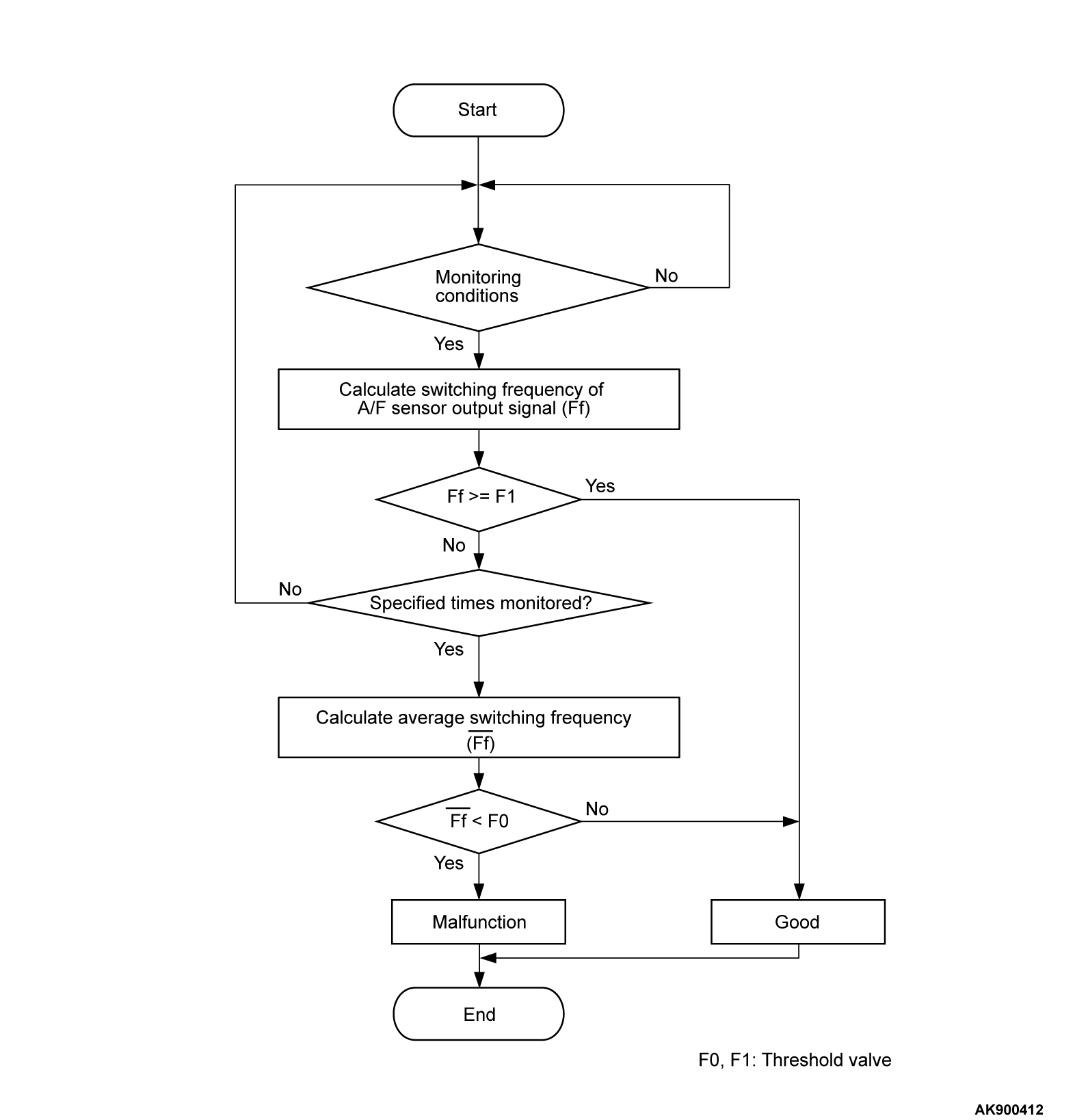

DESCRIPTIONS OF MONITOR METHODS

- If the response speed of the linear air-fuel ratio sensor to the change in the air-fuel ratio is too slow, the DTC is stored as the linear air-fuel ratio sensor deterioration.

MONITOR EXECUTION

- Continuous

MONITOR EXECUTION CONDITIONS (Other monitor and Sensor)

Other Monitor (There is no temporary DTC stored in memory for the item monitored below)

- Linear air-fuel ratio sensor heater monitor

- Misfire monitor

- Fuel system monitor

Sensor (The sensor below is determined to be normal)

- Mass airflow sensor

- Engine coolant temperature sensor

- Intake air temperature sensor

- Barometric pressure sensor

- Throttle position sensor

- Accelerator pedal position sensor

Check Conditions

- Engine speed is between 2,000 and 4,000 r/min <M/T> or 1,250 and 3,000 r/min <CVT>.

- Volumetric efficiency is between 22 and 65 percent.

- Engine coolant temperature is more than 60°C (140°F).

- Under the closed loop air/fuel control.

- The accelerator pedal is depressed.

- Short-term fuel trim is between -25 and +25 percent.

- More than 3 seconds have passed after the above mentioned conditions have been met.

- During the drive cycle, the ECM performs monitoring with the accumulated total time of 10 seconds, 5 times.

Judgment Criteria

- The average frequency is less than 8 times.

- The frequency is less than 16 times.

FAIL-SAFE AND BACKUP FUNCTION

- None

TROUBLESHOOTING HINTS (The most likely causes for this code to be stored are:)

- Linear air-fuel ratio sensor failed.

- Connector damage.

DIAGNOSIS

Required Special Tools:

- MB992744: Vehicle communication interface-Lite (V.C.I.-Lite)

- MB992745: V.C.I.-Lite main harness A

- MB992747: V.C.I.-Lite USB cable short

- MB992748: V.C.I.-Lite USB cable long

- MB991958: Scan Tool (M.U.T.-III Sub Assembly)

- MB991824: Vehicles Communication Interface (V.C.I.)

- MB991827: M.U.T.-III USB Cable

- MB991910: M.U.T.-III Main Harness A (Vehicles with CAN communication system)

STEP 1. Check harness connector at linear air-fuel ratio sensor and harness connector at ECM for damage.

Is the harness connector in good condition?

STEP 2. Test the OBD-II drive cycle.

| caution | To prevent damage to scan tool (M.U.T.-III), always turn the ignition switch to the "LOCK" (OFF) position before connecting or disconnecting scan tool (M.U.T.-III). |

(2) Turn the ignition switch to the "ON" position and delete the DTC.

(3) Carry out the test drive with the drive cycle pattern. Refer to Diagnostic Function - OBD-II Drive Cycle - Pattern 1  .

.

.

.(4) Check the diagnostic trouble code (DTC).

Is DTC P0133 stored?

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)