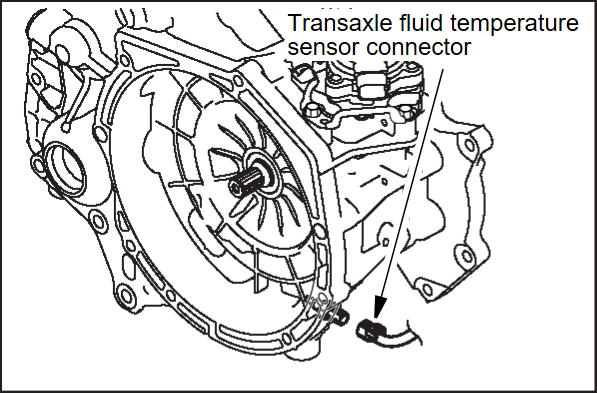

TRANSAXLE FLUID TEMPERATURE SENSOR CHECK

1. Remove the engine room under cover. Refer to Removal and Installation .

.

.

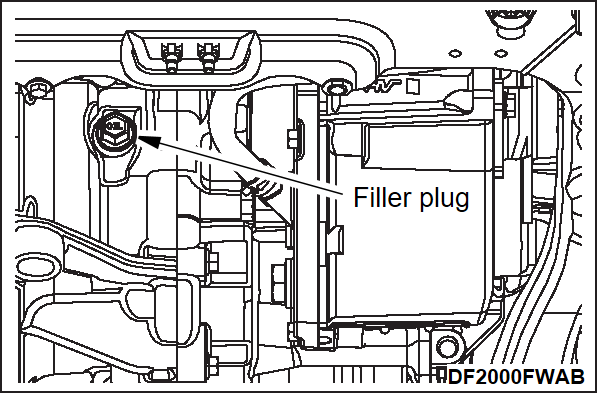

.4. Insert a thermometer into the filler plug hole of the transaxle.

| note | Insert a thermometer which is made of metal or is put in a metal case [overall length: approximately 150 – 200 mm (5.9 – 7.9 inches)] into the transaxle case hole approximately 80 mm (3.1 inches). |

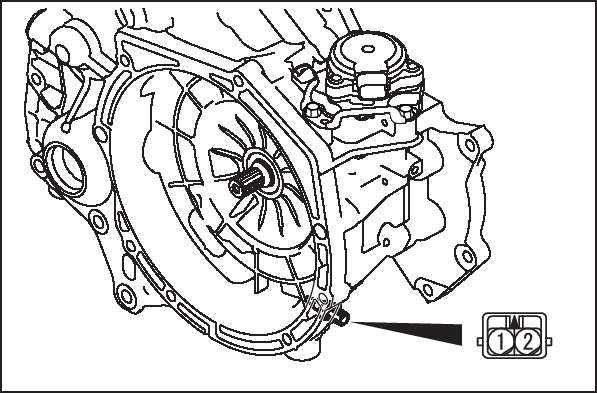

5. Measure the resistance between the sensor-side connector terminal No. 1 and terminal No. 2.

Standard value:

| Fluid temperature °C (°F) | Resistance kΩ |

| –20 (–4) | 13.92 – 16.34 |

| 20 (68) | 2.513 – 2.777 |

| 100 (212) | 0.210 – 0.221 |

| 200 (392) | 0.0263 – 0.0303 |

6. If the resistance deviates from the standard value greatly, replace the sensor.

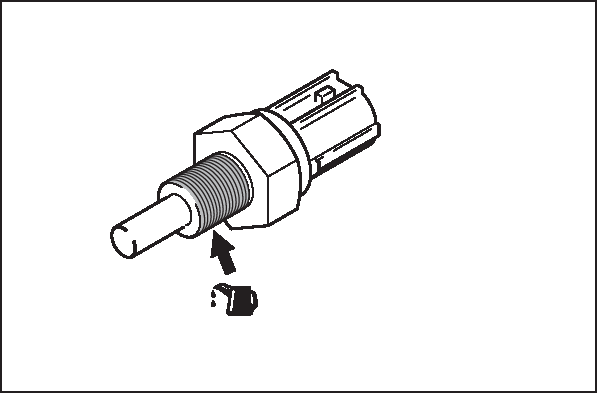

7. When installing a new sensor and gasket, apply ATF to the threaded portion of the transaxle fluid temperature sensor.

8. Tighten the transaxle fluid temperature sensor to the specified torque.

Tightening torque: 14 ± 1 N·m (124 ± 8 in-lb)

9. Install the filler plug and new gasket, and tighten to the specified torque.

Tightening torque: 32 ± 2 N·m (24 ± 1 ft-lb)

10. Install the engine room under cover. Refer to Removal and Installation .

.

.

.![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)