DTC No. P1B1A-1B Internal resistance difference diagnosis (stack4)

MONITOR EXECUTION

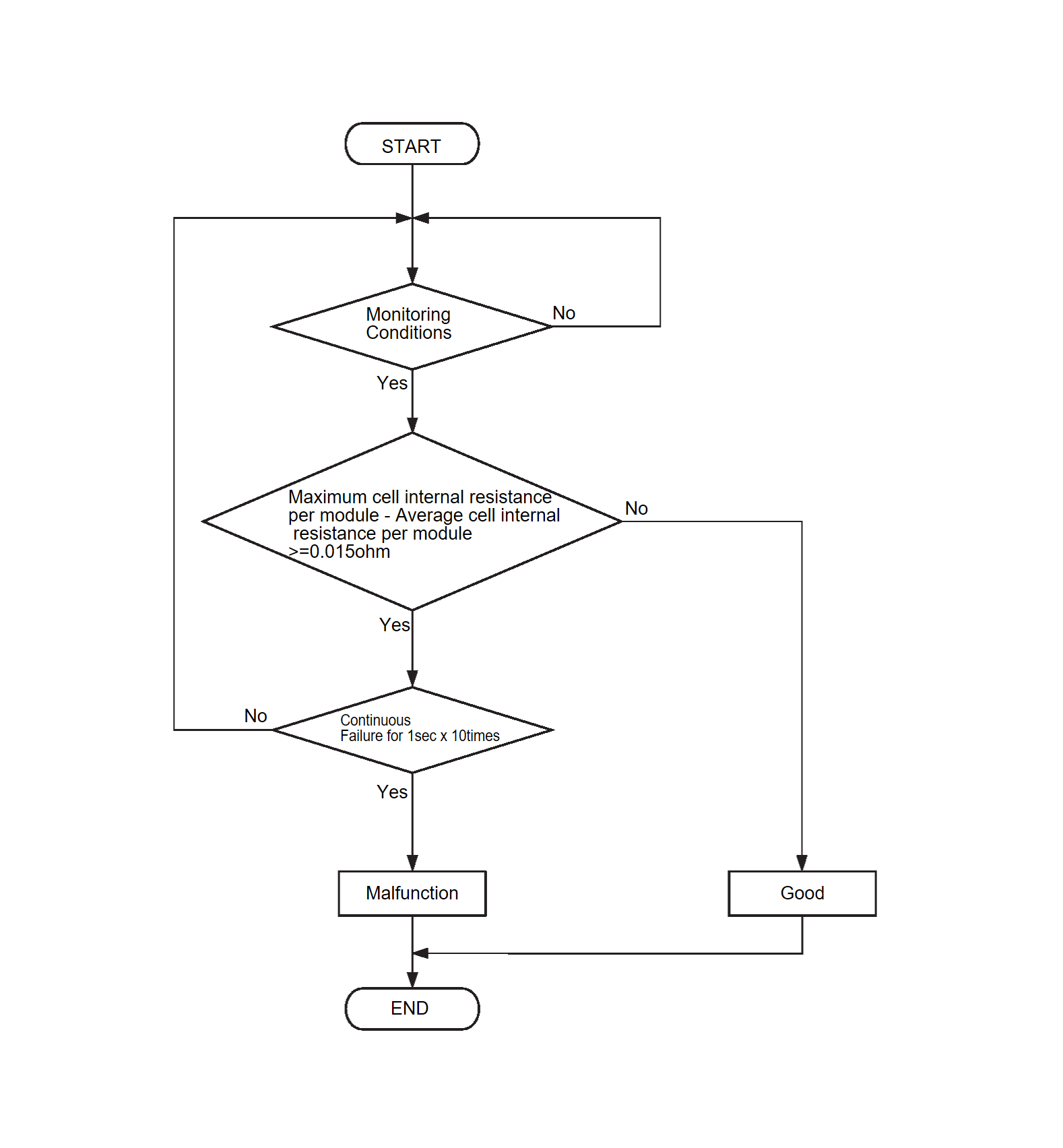

Continuous

MONITOR EXECUTION CONDITIONS (Other monitor and Sensor)

Other Monitor (There is no temporary DTC set in memory for the item monitored below)

- BMU monitor

- Drive battery voltage sensor circuit monitor

- EV CAN monitor

Sensor (The sensor below is determined to be normal)

- Drive battery current sensor

- Drive battery temperature sensor

DTC SET CONDITIONS

Check Condition

- BMU power supply voltage is more than 7.578 volts

- The vehicle status is in propulsion system active condition.

- The minimum drive battery temperature is -10°C (14°F) or less.

- The change of the battery current is 30 amperes or more.

- The SOC is less than 90% and more than 15%.

Judgment Criterion

- The value subtracting the average cell internal resistance of the battery module No. 4 from the maximum cell internal resistance of the battery module No. 4 is 0.015 ohms or more for 1 second or more ten times.

OBD-II DRIVE CYCLE PATTERN

- Refer to OBD-II Drive Cycle OBD-II DRIVE CYCLE

.

.

TROUBLESHOOTING HINTS

- Malfunction of the cell voltage wiring harness

- Malfunction of the drive battery (battery module No. 4)

- Looseness or foreign material attached on the bus bar

- Malfunction of the BMU

DIAGNOSIS

Required Special Tools:

- MB992744: Vehicle communication interface-Lite (V.C.I.-Lite)

- MB992745: V.C.I.-Lite main harness A

- MB992747: V.C.I.-Lite USB cable short

- MB992748: V.C.I.-Lite USB cable long

1.Check of other DTC

Check whether the BMU and BMU2 set the following DTC. Troubleshoot the set DTCs (Refer to DIAGNOSTIC TROUBLE CODE CHART

Troubleshoot the set DTCs (Refer to DIAGNOSTIC TROUBLE CODE CHART ). Then,

). Then,

- DTC No. P0A1F-00 ECU Internal Failure

Is the DTC set?

Troubleshoot the set DTCs (Refer to DIAGNOSTIC TROUBLE CODE CHART

Troubleshoot the set DTCs (Refer to DIAGNOSTIC TROUBLE CODE CHART ). Then,

). Then,

2.Check the looseness or foreign material attached on the bus bar

(1) Disassemble the drive battery (Refer to SERVICE PROCEDURE ).

).

).

).(2) Check that there is no looseness or foreign material attached on the bus bar of the battery module No. 4.

Is the check result normal?

3.Cell voltage harness check

Check the cell voltage wiring harness of the battery module No. 4 (Refer to CELL VOLTAGE HARNESS CHECK ).

). Replace the drive battery (Refer to DRIVE BATTERY REMOVAL AND INSTALLATION

Replace the drive battery (Refer to DRIVE BATTERY REMOVAL AND INSTALLATION ). Then,

). Then,

Repalce the cell voltage harness (Refer to SERVICE PROCEDURE

Repalce the cell voltage harness (Refer to SERVICE PROCEDURE ). Then,

). Then,

).

).Is the check result normal?

Replace the drive battery (Refer to DRIVE BATTERY REMOVAL AND INSTALLATION

Replace the drive battery (Refer to DRIVE BATTERY REMOVAL AND INSTALLATION ). Then,

). Then,

Repalce the cell voltage harness (Refer to SERVICE PROCEDURE

Repalce the cell voltage harness (Refer to SERVICE PROCEDURE ). Then,

). Then,

4.Test the OBD-II drive cycle.

(1) Carry out a test drive with the drive cycle pattern. Refer to OBD-II Drive Cycle OBD-II DRIVE CYCLE .

.

.

.(2) Check the DTC.

Is the DTC set?

Retry the troubleshooting.

Retry the troubleshooting. The procedure is complete.

The procedure is complete.![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)