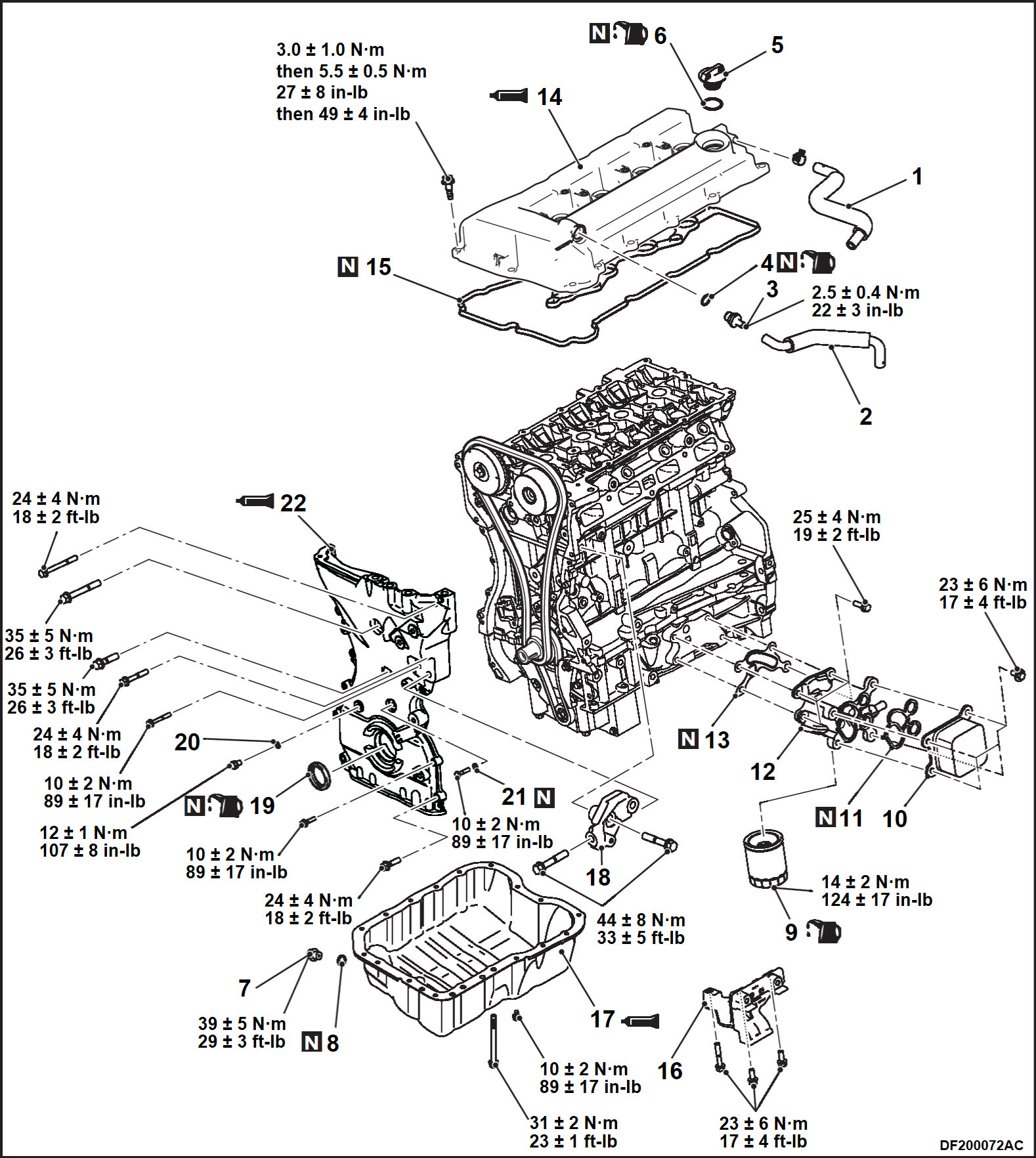

REMOVAL AND INSTALLATION

REMOVAL SERVICE POINTS

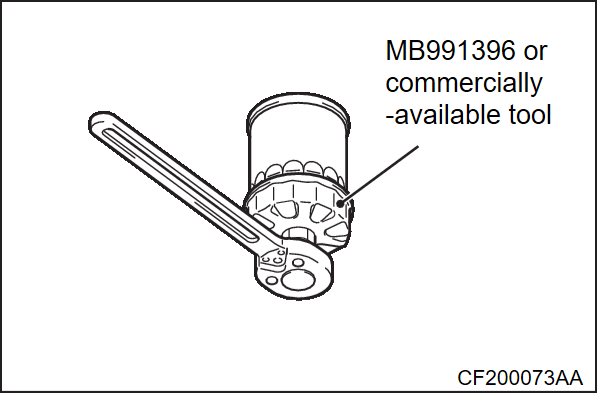

<<A>> ENGINE OIL FILTER REMOVAL

1. Use special tool oil filter wrench (MB991396) or commercially-available tool to remove the engine oil filter.

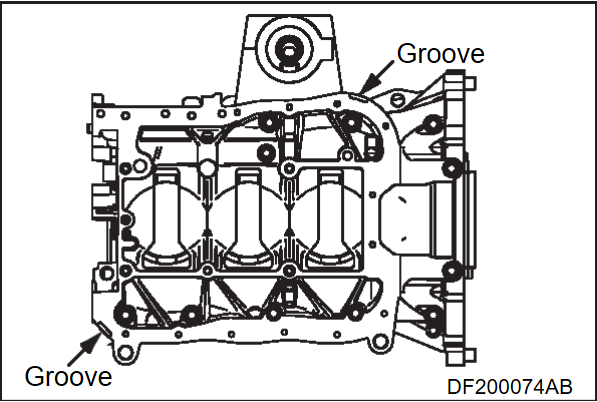

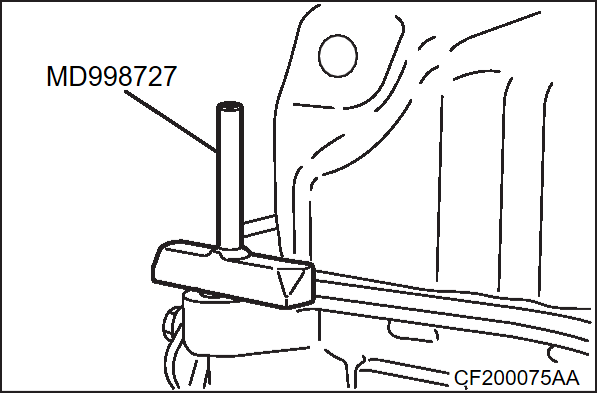

<<B>> ENGINE OIL PAN REMOVAL

1. Remove engine oil pan tightening bolts.

| caution | Lightly tap the engine oil pan FIPG cutter to drive in, taking care not to damage the ladder frame and engine oil pan sealed area. |

2. Lightly tap special tool oil pan FIPG cutter (MD998727) to drive in the illustrated groove of the engine oil pan and ladder frame.

3. Lightly tap and slide special tool oil pan FIPG cutter (MD998727) to remove the oil pan.

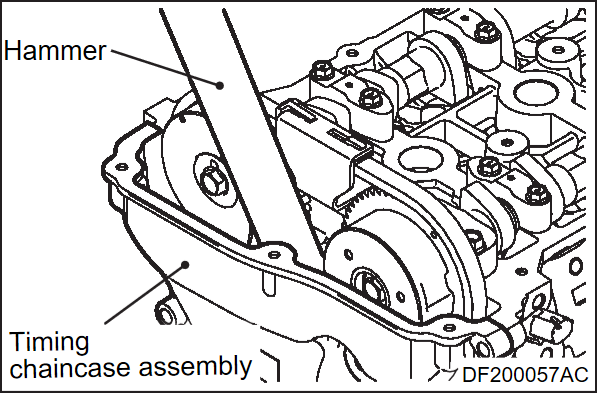

<<C>> TIMING CHAIN CASE ASSEMBLY REMOVAL

1. Remove the timing chain case assembly bolt, and then remove the timing chain case assembly from the cylinder head and cylinder block.

2. If the sealant cannot be peeled off easily, insert a wooden hammer shank into the timing chain case assembly inside as shown in the figure, pry slightly, and remove the timing chain case assembly from the cylinder head and cylinder block.

INSTALLATION SERVICE POINTS

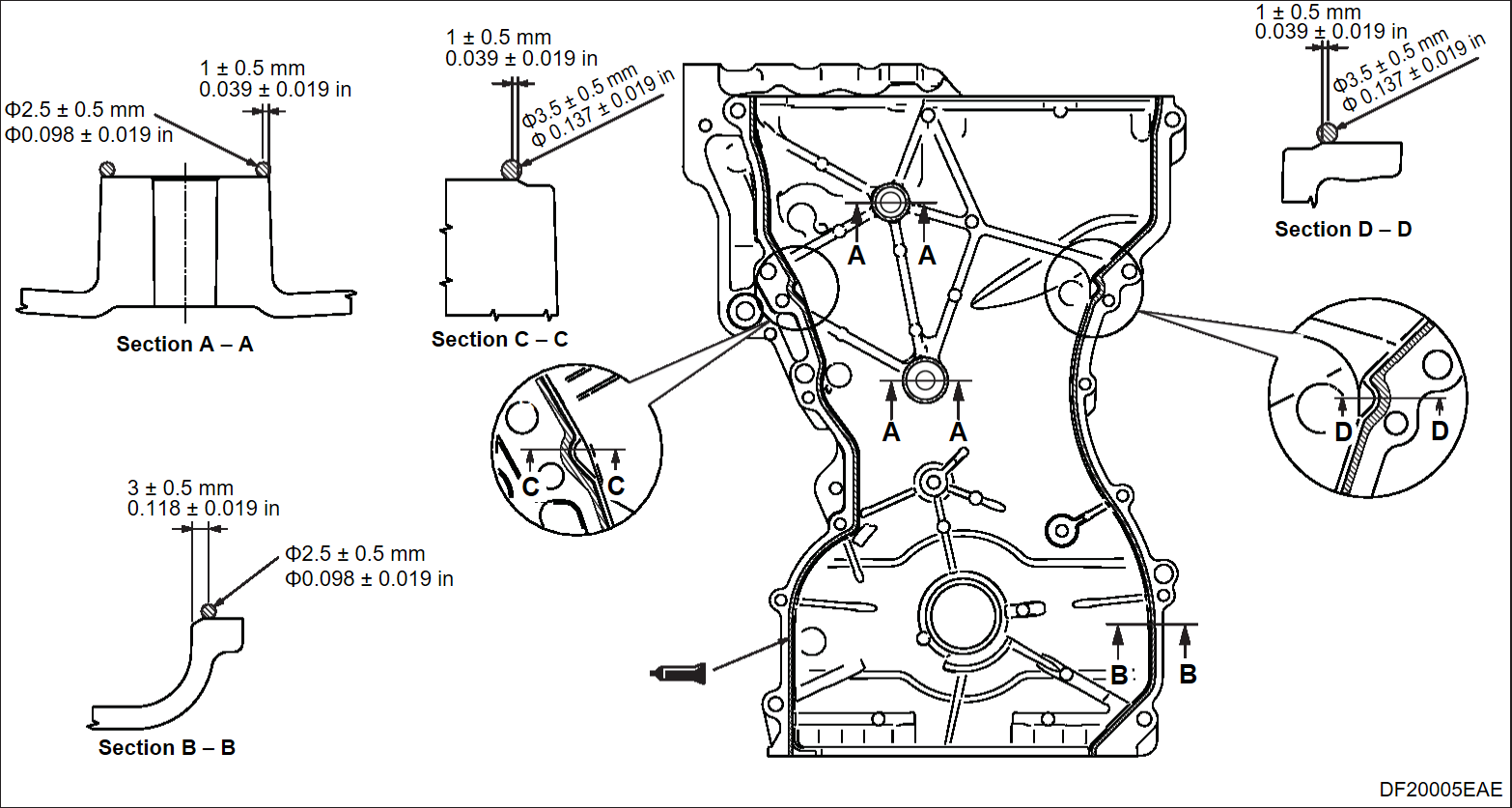

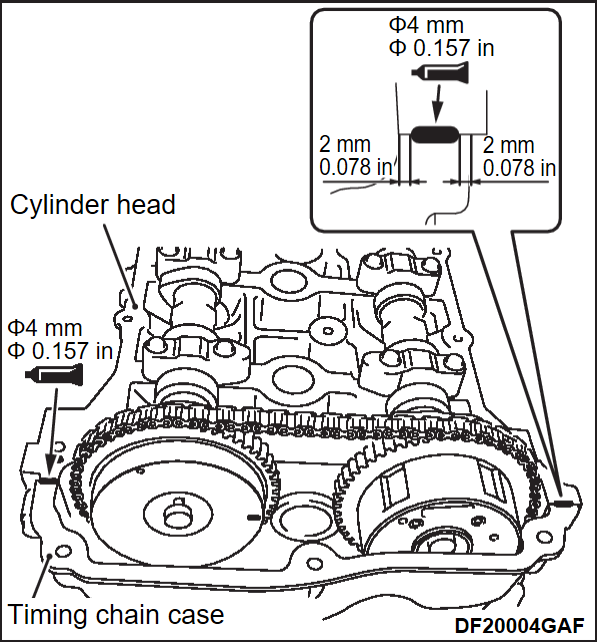

>>A<< TIMING CHAIN CASE ASSEMBLY INSTALLATION

| caution |

|

1. Completely remove sealant adhering to the timing chain case assembly, cylinder block and cylinder head.

2. Apply a layer of sealant 2.5 ± 0.5 mm (0.098 ± 0.019 inch) thick to locations A and B, and a layer 3.5 ± 0.5 mm (0.137 ± 0.019 inch) thick to locations C and D on the timing chain case assembly as shown in the figure.

Specified sealant: ThreeBond 1217G or equivalent

3. Degrease the surface where the sealant is applied and the contact surface between the cylinder block and the cylinder head.

4. The engine oil staying at the cylinder gasket oozes to the 3-plane contact surface described in Step 2 and 3. Swiftly apply the sealant to this area after degreasing.

Specified sealant: ThreeBond 1217G or equivalent

| note | Install the timing chain case assembly immediately after applying sealant. |

| caution | If the sealant contacts any other part during installation of the timing chain case assembly, apply sealant again before installing the timing chain case assembly. |

5. Install the timing chain case assembly to the cylinder block and cylinder head so that the sealant does not contact other parts.

| caution | After the installation, until a sufficient period of time (one hour or more) elapses, do not apply the engine oil or water to the sealant application area or start the engine. |

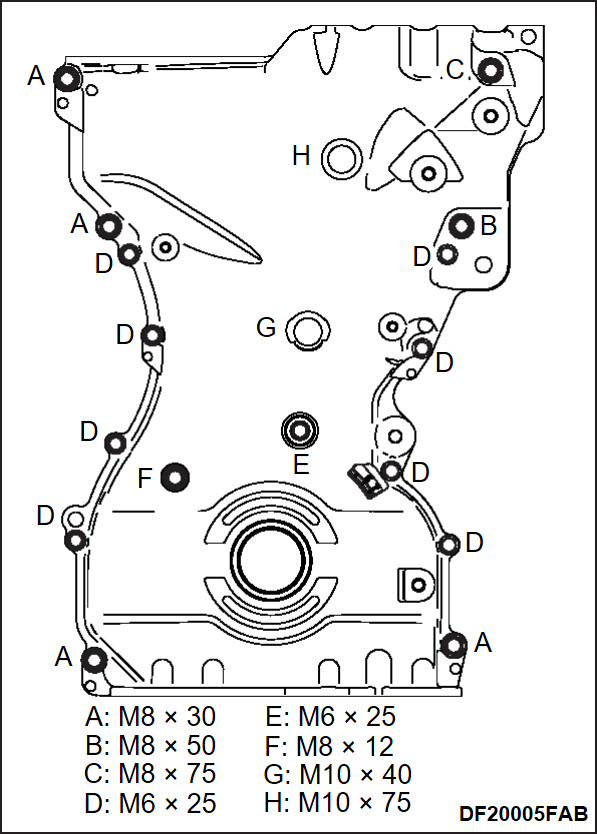

6. Tighten timing chain case assembly mounting bolts to the specified torque.

Tightening torque:

- A: 24 ± 4 N·m (18 ± 2 ft-lb)

- B: 24 ± 4 N·m (18 ± 2 ft-lb)

- C: 24 ± 4 N·m (18 ± 2 ft-lb)

- D: 10 ± 2 N·m (89 ± 17 in-lb)

- E: 10 ± 2 N·m (89 ± 17 in-lb)

- F: 12 ± 1 N·m (107 ± 8 in-lb)

- G: 35 ± 5 N·m (26 ± 3 ft-lb)

- H: 35 ± 5 N·m (26 ± 3 ft-lb)

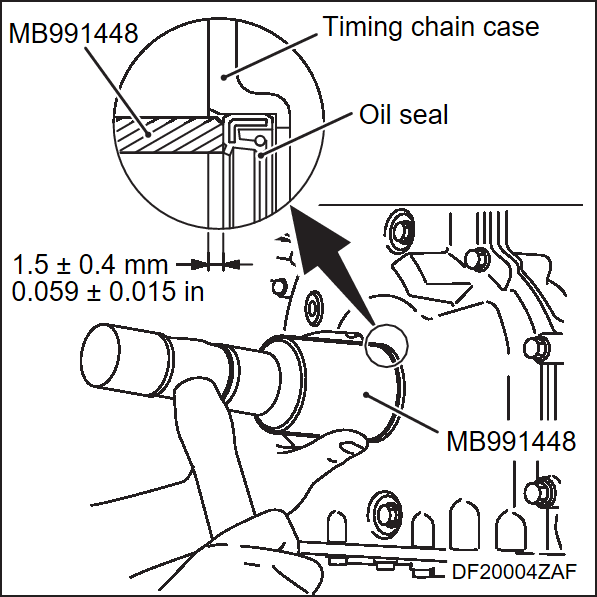

>>B<< CRANKSHAFT FRONT OIL SEAL INSTALLATION

| caution | The front oil seal must not be a strong press fit. The strong press fit can possibly cause the oil leakage, damaging the crankshaft front oil seal. |

1. Apply a small amount of engine oil to the entire inner diameter of the crankshaft front oil seal lip.

2. Use special tool bush remover and installer base (MB991448) in order to press-fit the crankshaft front oil seal into the timing chain case as shown in the illustration.

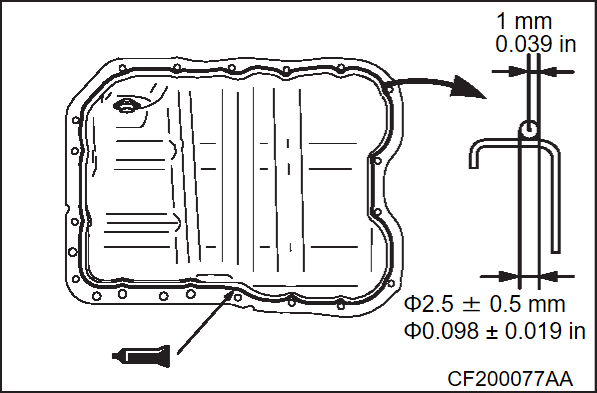

>>C<< ENGINE OIL PAN INSTALLATION

| caution | Sufficiently check that there is no residual oil on the place where degreasing is performed. If fingerprints are left, do not touch it with bare hands after the degreasing, since the oils from your fingers will harm the seal ability. |

1. Remove all the traces of sealant adhering to the engine oil pan and cylinder block assembly using a remover or others. Then, degrease them.

2. Apply the sealant 2.5 ± 0.5 mm (0.098 ± 0.019 inch) in diameter to the engine oil pan as shown in the illustration.

Specified sealant: ThreeBond 1217G or equivalent

| note | Install the engine oil pan immediately after applying sealant. |

| caution | After the installation, until a sufficient period of time (one hour or more) elapses, do not apply the oil or water to the sealant application area or start the engine. |

3. Tighten the engine oil pan mounting bolts to the specified torque.

Tightening torque:

- M6: 10 ± 2 N·m (89 ± 17 in-lb)

- M8: 31 ± 2 N·m (23 ± 1 ft-lb)

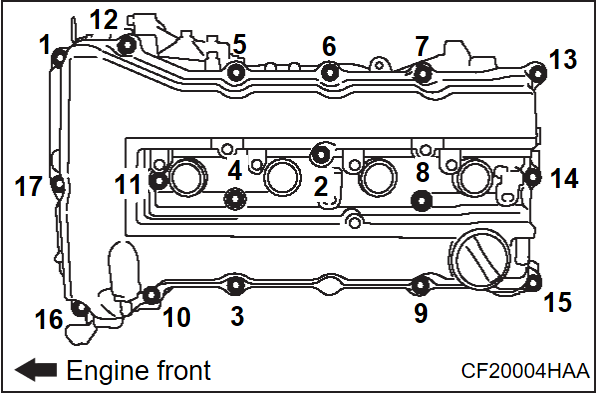

>>D<< ROCKER COVER INSTALLATION

| caution | Sufficiently check that there is no residual oil on the place where degreasing is performed. If fingerprints are left, do not touch it with bare hands after the degreasing, since the oils from your fingers will harm the seal ability. |

1. Completely remove sealant adhering to the rocker cover, timing chain case assembly and cylinder head, and degrease the surface.

2. Use a minimum amount of the sealant appropriately. Make sure that the sealant does not stick out from the application area.

Apply the sealant 4 mm (0.157 inch) in diameter.

Specified sealant: ThreeBond 1217G or equivalent

| note | Install the cylinder head cover assembly immediately after the application of sealant. |

3. Tighten the rocker cover mounting bolts to the specified torque in the order shown in the illustration.

Tightening torque: 3.0 ± 1.0 N·m (27 ± 8 in-lb)

| caution | After the installation, until a sufficient period of time (one hour or more) elapses, do not apply the oil or water to the sealant application area or start the engine. |

4. Tighten again the rocker cover mounting bolts to the specified torque in the order shown in the illustration.

Tightening torque: 5.5 ± 0.5 N·m (49 ± 4 in-lb)

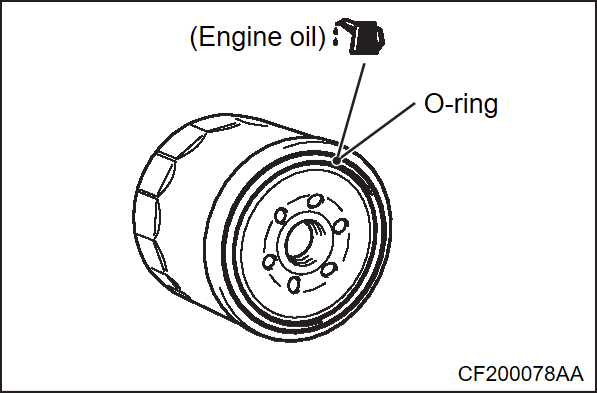

>>E<< ENGINE OIL FILTER INSTALLATION

1. Clean the engine oil filter installing surface on the ladder frame side.

2. Apply a small amount of engine oil to the new engine oil filter O-ring.

3. Tighten the engine oil filter until the O-ring contacts with the installation surface.

4. In the same manner as removal, use special tool oil filter wrench (MB991396) or commercially-available tool to tighten the engine oil filter to the specified torque.

Tightening torque: Approximately 1 turn [14 ± 2 N·m (124 ± 17 in-lb)]

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)