Lubricant Adjusting Procedure for A/C compressor Replacement

1. Drain lubricant from removed A/C compressor and measure lubricant amount.

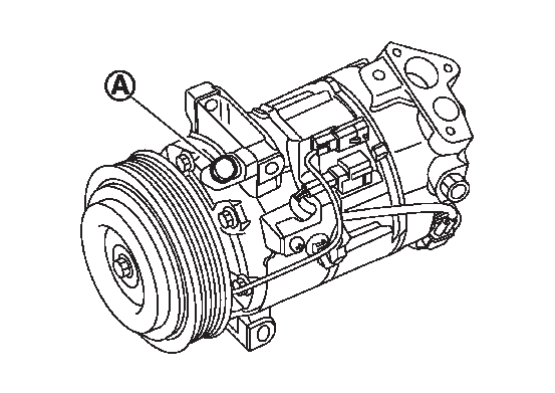

- Remove drain bolt

, and then drain lubricant from drain port.

, and then drain lubricant from drain port. - Measure total amount of lubricant that is drained from removed A/C compressor.

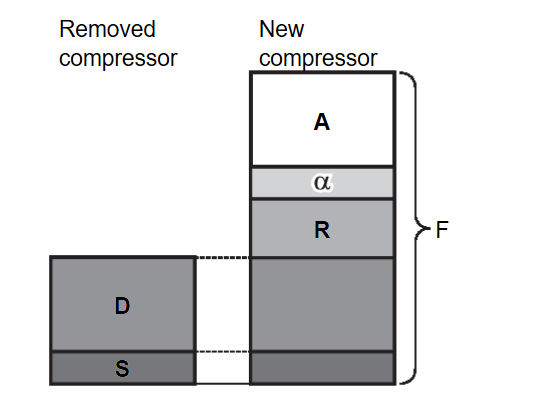

2. Drain lubricant from a new A/C compressor that is calculated according to the following conditions.

Amount to be drained (A) [m (Imp fl oz)] = F − (D + S + R + α) (Imp fl oz)] = F − (D + S + R + α) | |

| F | : Lubricant amount that a new A/C compressor contains [110 (3.9)] |

| D | : Lubricant amount that is drained from removed A/C compressor |

| S | : Lubricant amount that remains inside of removed A/C compressor [20 (0.7)] |

| R | : Lubricant amount to be added according to components that are removed except A/C compressor |

| α | : Lubricant amount that is recycled together with refrigerant during recycle operation |

| caution | If lubricant amount that is drained from removed A/C compressor is less than 60 m (2.1 Imp fl oz), perform calculation by setting “D” as 40 m (2.1 Imp fl oz), perform calculation by setting “D” as 40 m (1.4 Imp fl oz). (1.4 Imp fl oz). |

| Conditions | Lubricant amount to be added to A/C system m  (Imp fl oz) (Imp fl oz) |

| Replace evaporator | 35 (1.2) |

| Replace condenser & liquid tank | 20 (0.7) |

Example: Lubricant amount to be drained from a new A/C compressor when replacing A/C compressor and condenser & liquid tank [m (Imp fl oz)] [D = 60 (2.1), α = 5 (0.2)]

(Imp fl oz)] [D = 60 (2.1), α = 5 (0.2)]

(Imp fl oz)] [D = 60 (2.1), α = 5 (0.2)]

(Imp fl oz)] [D = 60 (2.1), α = 5 (0.2)]110 (3.9) − [60 (1.6) + 20 (0.7) + 5 (0.2)] = 15 (−0.9)

3. Tighten drain bolt to the specified torque

| Specified torque | : 30 N·m (3.1 kg-m, 22 ft-lb) |

4. Install A/C compressor and check the operation.

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)