Disassembly and Assembly

DISASSEMBLY

| caution | Never drop parts to remove. |

| note | Never remove the torque member, brake pad and pad retainers when disassembling and assembling the cylinder body. |

1. Remove the sliding pin bolt, and remove the cylinder body from the torque member. Refer to Removal and Installation .

.

.

.| caution | Fix the brake pad at suitable tape so that the brake pad will not drop. |

2. Remove sliding pins and sliding pin boots from torque member.

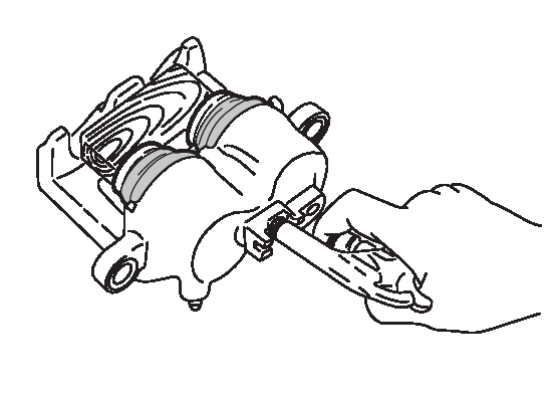

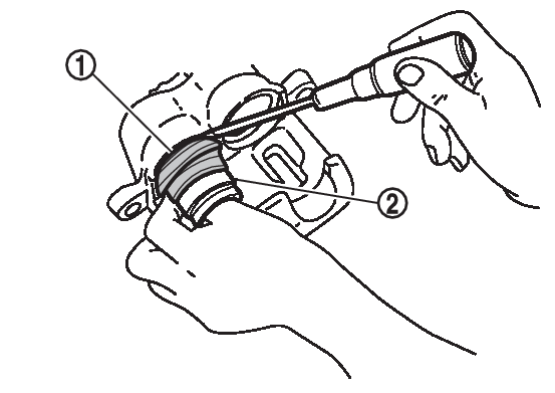

4. Place a wooden block as shown in the figure, and blow air from union bolt mounting hole to remove pistons and piston boots.

| caution | Never get fingers caught in the pistons. |

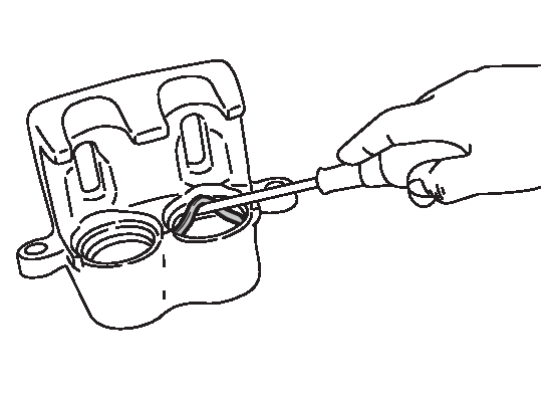

5. Remove piston seals from cylinder body using seal pick tool.

| caution | Be careful not to damage a cylinder inner wall. |

6. Remove bleeder valve and cap.

7. Perform inspection after disassembly. Refer to InspectionInspection .

.

.

.ASSEMBLY

| caution | Never drop when installing. |

1. Install bleeder valve and cap.

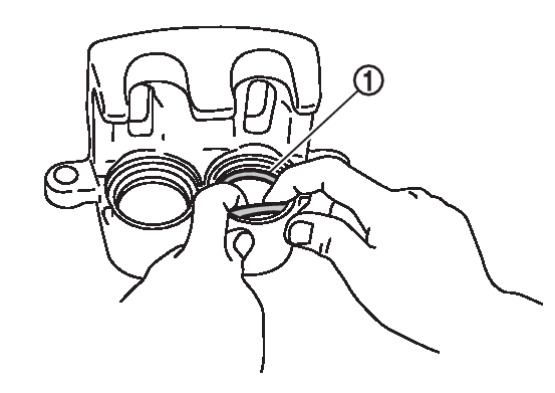

2. Apply new brake fluid to piston seals  , and install them to cylinder body.

, and install them to cylinder body.

, and install them to cylinder body.

, and install them to cylinder body.| caution | Never reuse piston seals. |

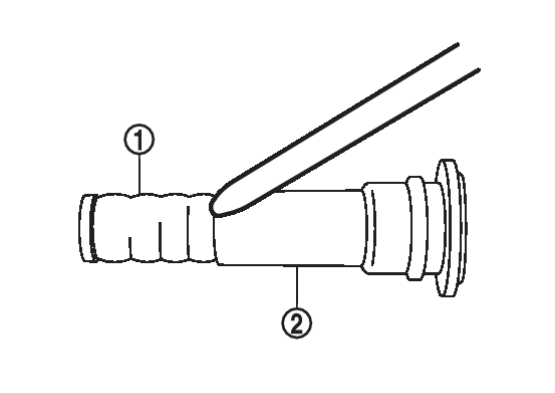

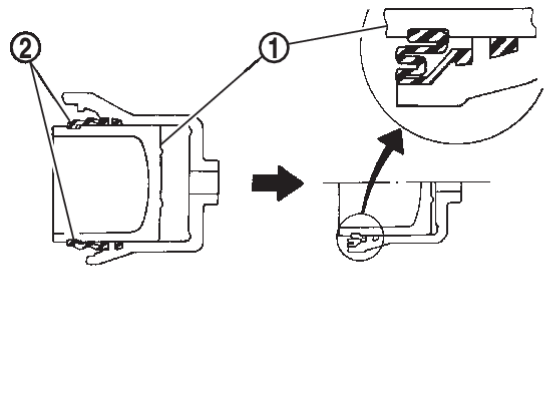

3. Apply rubber grease to piston boots  . Cover the piston

. Cover the piston  end with piston boot, and then install cylinder side lip on piston boot securely into a groove on cylinder body.

end with piston boot, and then install cylinder side lip on piston boot securely into a groove on cylinder body.

. Cover the piston

. Cover the piston  end with piston boot, and then install cylinder side lip on piston boot securely into a groove on cylinder body.

end with piston boot, and then install cylinder side lip on piston boot securely into a groove on cylinder body.| caution | Never reuse piston boots. |

4. Apply new brake fluid to pistons  . Push piston into cylinder body by hand and push piston boot

. Push piston into cylinder body by hand and push piston boot  piston-side lip into the piston groove.

piston-side lip into the piston groove.

. Push piston into cylinder body by hand and push piston boot

. Push piston into cylinder body by hand and push piston boot  piston-side lip into the piston groove.

piston-side lip into the piston groove.| caution | Press the pistons evenly and vary the pressing point to prevent cylinder inner wall from being rubbed. |

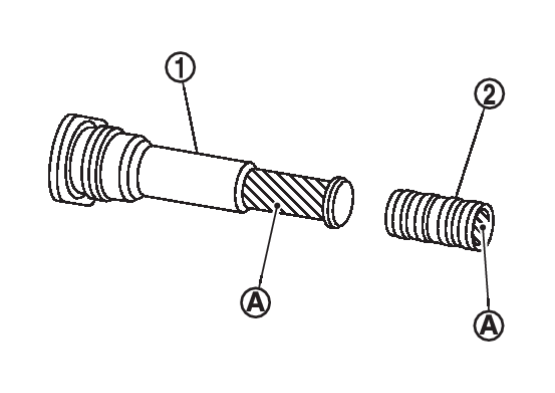

5. Apply rubber grease to mating faces  between sliding pin

between sliding pin  and bushing

and bushing  , and install bushing to sliding pin.

, and install bushing to sliding pin.

between sliding pin

between sliding pin  and bushing

and bushing  , and install bushing to sliding pin.

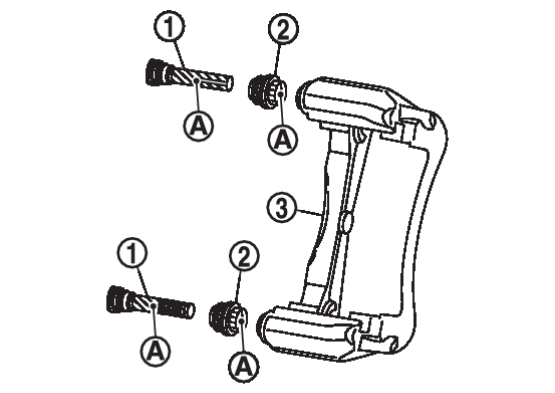

, and install bushing to sliding pin.6. Apply rubber grease to mating faces  between sliding pins

between sliding pins  and sliding pin boots

and sliding pin boots  , and install sliding pins and sliding pin boots to torque member

, and install sliding pins and sliding pin boots to torque member  .

.

between sliding pins

between sliding pins  and sliding pin boots

and sliding pin boots  , and install sliding pins and sliding pin boots to torque member

, and install sliding pins and sliding pin boots to torque member  .

.7. Install the cylinder body to tighten sliding pin bolts to the specified torque.

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)