Inspection

INSPECTION AFTER REMOVAL

Appearance

Check propeller shaft tube surface for dents or cracks. If malfunction is detected, replace propeller shaft assembly.

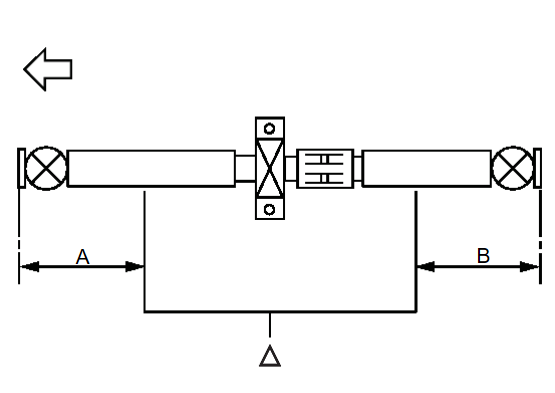

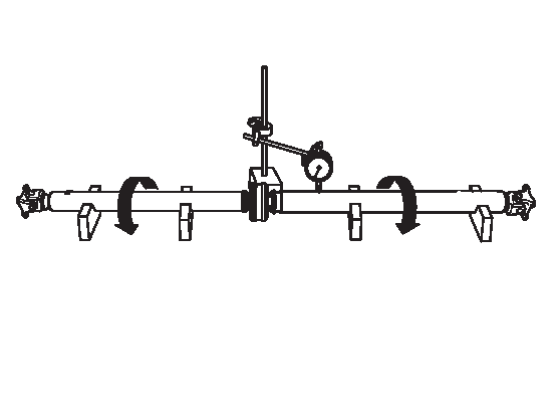

Propeller Shaft Runout

Check propeller shaft runout at measuring points with a dial indicator. If runout exceeds specifications, replace propeller shaft assembly.

| Propeller shaft runout | : Refer to Propeller Shaft Tube . . |

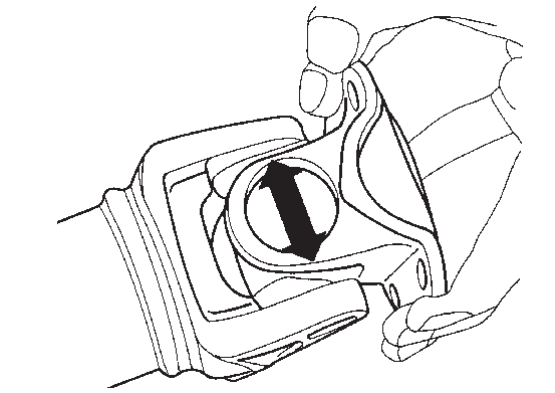

Journal Axial Play

As shown in the figure, while fixing yoke on one side, check axial play of joint. If it is outside the standard, replace propeller shaft assembly.

| Journal axial play | : Refer to Journal . . |

| caution | Never disassemble joints. |

Center Bearing

Check center bearing for noise and damage. If malfunction is detected, replace propeller shaft assembly.

| caution | Never disassemble center bearing. |

INSPECTION AFTER INSTALLATION

After assembly, perform a driving test to check propeller shaft vibration. If vibration occurred, separate propeller shaft from final drive. Reinstall propeller shaft by changing the phase between companion flange and propeller shaft by the one bolt hole at a time. Then perform driving test and check propeller shaft vibration again at each point.

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)

”).

”).