Heated Oxygen Sensor 2

FUNCTIONS WITHIN THE SYSTEM

Heated oxygen sensor 2 detects the oxygen concentration in the exhaust gases, converts it to a voltage signal, and transmits the signal to the ECM. Heated oxygen sensor 2 contains a heater for maintaining its activation.

INDIVIDUAL FUNCTION WITHIN THE SYSTEM

Heated Oxygen Sensor 2

Under normal conditions, heated oxygen sensor 2 is not used for engine control. When A/F sensor 1 is malfunctioning, the signal from heated oxygen sensor 2 is used to control the A/F ratio to the stoichiometric ratio.

Heated Oxygen Sensor 2 Heater

The heated oxygen sensor 2 heater activates heated oxygen sensor 2.

INDIVIDUAL OPERATION

Heated Oxygen Sensor 2

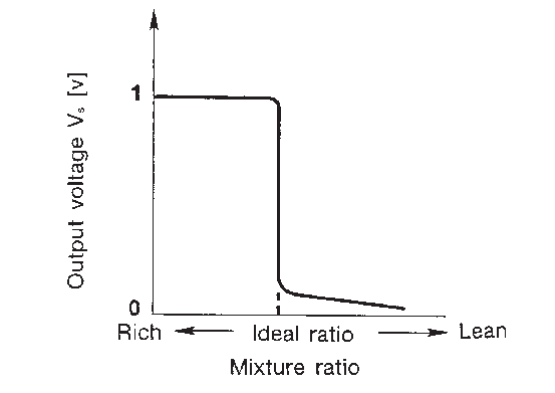

Heated oxygen sensor 2 is composed of a zirconia element in a test tube shape, and is exposed to the atmosphere on the inside and the exhaust gases on the outside. When there is a difference in the oxygen concentration between the inside and outside, electromotive force is generated. When the A/F ratio is leaner than the stoichiometric ratio, the voltage is approximately 0 V. When it is richer, the voltage is approximately 1 V.

Heated Oxygen Sensor 2 Heater

The ECM performs ON/OFF control of the heated oxygen sensor 2 heater corresponding to the engine speed, amount of intake air and engine coolant temperature.

| Engine speed | Heated oxygen sensor 2 heater |

| Above 3,600 rpm | OFF |

Below 3,600 rpm after the following conditions are met.

| ON |

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)