Diagnosis Procedure

1.CHECK DTC PRIORITY

If DTC P0365 is displayed with DTC P06B0, first perform the trouble diagnosis for DTC P06B0. Perform diagnosis of applicable. Refer to DTC Description

Perform diagnosis of applicable. Refer to DTC Description .

.

Is applicable DTC detected?

Perform diagnosis of applicable. Refer to DTC Description

Perform diagnosis of applicable. Refer to DTC Description .

.2.CHECK STARTING SYSTEM

Turn ignition switch to START position. Check starting system. Refer to Work Flow

Check starting system. Refer to Work Flow .

.

Does the engine turn over? Does the starter motor operate?

Check starting system. Refer to Work Flow

Check starting system. Refer to Work Flow .

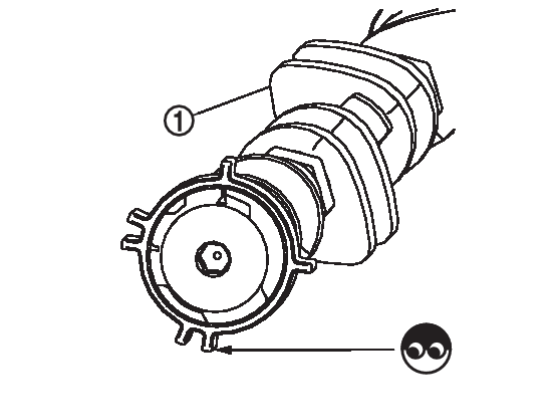

. 3.CHECK EXHAUST CAMSHAFT POSITION SENSOR POWER SUPPLY CIRCUIT-1

- Turn ignition switch OFF.

- Disconnect exhaust camshaft position sensor harness connector.

- Turn ignition switch ON.

- Check the voltage between exhaust camshaft position sensor harness connector terminals.

Exhaust camshaft position sensor Voltage (Approx.)Connector + − Terminals F45 1 2 5 V

Is the inspection result normal?

4.CHECK EXHAUST CAMSHAFT POSITION SENSOR POWER SUPPLY CIRCUIT-2

Check the voltage between exhaust camshaft position sensor harness connector and ground.

| + | − | Voltage (Approx.) | |

| Exhaust camshaft position sensor | |||

| Connector | Terminal | ||

| F45 | 1 | Ground | 5 V |

Is the inspection result normal?

5.CHECK EXHAUST CAMSHAFT POSITION SENSOR POWER SUPPLY CIRCUIT-3

- Turn ignition switch OFF.

- Disconnect ECM harness connector.

- Check the continuity between exhaust camshaft position sensor harness connector and ECM harness connector.

+ − Continuity Exhaust camshaft position sensor ECM Connector Terminal Connector Terminal F45 1 F52 94 Existed

Is the inspection result normal?

Repair or replace error-detected parts.

Repair or replace error-detected parts.6.CHECK EXHAUST CAMSHAFT POSITION SENSOR GROUND CIRCUIT

- Turn ignition switch OFF.

- Disconnect ECM harness connector.

- Check the continuity between exhaust camshaft position sensor harness connector and ECM harness connector.

+ − Continuity Exhaust camshaft position sensor ECM Connector Terminal Connector Terminal F45 2 F52 110 Existed - Also check harness for short to power.

Is the inspection result normal?

Repair or replace error-detected parts.

Repair or replace error-detected parts.7.CHECK ECM GROUND CIRCUIT

Check the continuity between ECM harness connector and ground.

INSPECTION END

INSPECTION END Repair or replace error-detected parts.

Repair or replace error-detected parts.

| ECM | Ground | Continuity | |

| Connector | Terminal | ||

| F51 | 4 | Ground | Existed |

| E16 | 156 | ||

| 157 | |||

| 160 | |||

Is the inspection result normal?

INSPECTION END

INSPECTION END Repair or replace error-detected parts.

Repair or replace error-detected parts.8.CHECK EXHAUST CAMSHAFT POSITION SENSOR INPUT SIGNAL CIRCUIT

- Check the continuity between exhaust camshaft position sensor harness connector and ECM harness connector.

+ − Continuity Exhaust camshaft position sensor ECM Connector Terminal Connector Terminal F45 3 F52 90 Existed - Also check harness for short to power.

Is the inspection result normal?

Repair or replace error-detected parts.

Repair or replace error-detected parts.9.CHECK EXHAUST CAMSHAFT POSITION SENSOR

Refer to Component Inspection .

.  Replace exhaust camshaft position sensor. Refer to Exploded View

Replace exhaust camshaft position sensor. Refer to Exploded View .

.

.

. Is the inspection result normal?

Replace exhaust camshaft position sensor. Refer to Exploded View

Replace exhaust camshaft position sensor. Refer to Exploded View .

. 10.CHECK CAMSHAFT (EXT)

Check the following. INSPECTION END

INSPECTION END Remove debris and clean the signal plate of camshaft rear end or replace camshaft. Refer to Exploded View

Remove debris and clean the signal plate of camshaft rear end or replace camshaft. Refer to Exploded View .

.

- Accumulation of debris to the signal plate of camshaft

rear end

rear end - Chipping signal plate of camshaft rear end

Is the inspection result normal?

INSPECTION END

INSPECTION END Remove debris and clean the signal plate of camshaft rear end or replace camshaft. Refer to Exploded View

Remove debris and clean the signal plate of camshaft rear end or replace camshaft. Refer to Exploded View .

. ![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)