Component Inspection

2.CHECK HEATED OXYGEN SENSOR 2

With M.U.T.-III SE

With M.U.T.-III SE- Turn ignition switch ON and select “DATA MONITOR” mode of “ENGINE” using M.U.T.-III SE.

- Start engine and warm it up to normal operating temperature.

- Turn ignition switch OFF and wait at least 10 seconds.

- Start engine and keep the engine speed between 3,500 and 4,000 rpm for at least 1 minute under no load.

- Let engine idle for 1 minute.

- Select "FUEL INJECTION" in "Actuator Test" (in "Special Function") mode of "ENGINE" using M.U.T.-III SE, and select "HO2S2 (B1)” as the monitor item with M.U.T.-III SE.

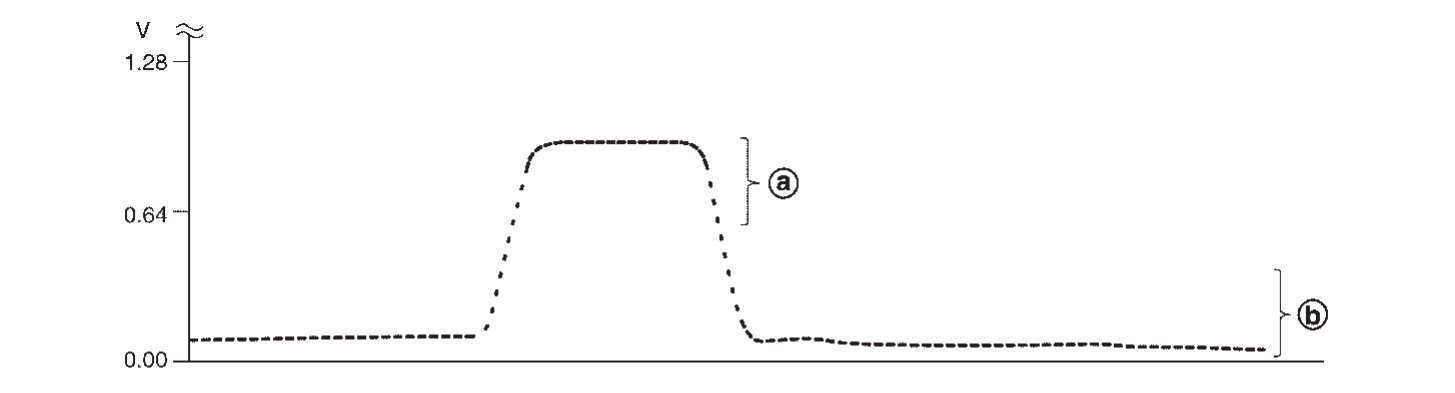

- Check “HO2S2 (B1)” at idle speed when adjusting “FUEL INJECTION” to ± 25%.“HO2S2 (B1)” should be above

0.71 V at least once when the “FUEL INJECTION” is + 25%.“HO2S2 (B1)” should be below

0.71 V at least once when the “FUEL INJECTION” is + 25%.“HO2S2 (B1)” should be below 0.18 V at least once when the “FUEL INJECTION” is − 25%.

0.18 V at least once when the “FUEL INJECTION” is − 25%.

Is the inspection result normal?

INSPECTION END

INSPECTION END3.CHECK HEATED OXYGEN SENSOR 2-1

Without M.U.T.-III SE

Without M.U.T.-III SE- Start engine and warm it up to normal operating temperature.

- Turn ignition switch OFF and wait at least 10 seconds.

- Start engine and keep the engine speed between 3,500 and 4,000 rpm for at least 1 minute under no load.

- Let engine idle for 1 minute.

- Check the voltage between ECM harness connector and ground as per the following condition.

ECM Condition Voltage Connector + − Terminal F52 92 97 Revving up to 4,000 rpm under no load at least 10 times The voltage should be above 0.71 V at least once during this procedure. The voltage should be below 0.18 V at least once during this procedure.

Is the inspection result normal?

INSPECTION END

INSPECTION END4.CHECK HEATED OXYGEN SENSOR 2-2

Check the voltage between ECM harness connector and ground as per the following condition.

INSPECTION END

INSPECTION END

| ECM | Condition | Voltage | ||

| Connector | + | − | ||

| Terminal | ||||

| F52 | 92 | 97 | Keeping engine speed at idle for 10 minutes | The voltage should be above 0.71 V at least once during this procedure. The voltage should be below 0.18 V at least once during this procedure. |

Is the inspection result normal?

INSPECTION END

INSPECTION END5.CHECK HEATED OXYGEN SENSOR 2-3

Check the voltage between ECM harness connector and ground as per the following condition.

INSPECTION END

INSPECTION END

| ECM | Condition | Voltage | ||

| Connector | + | − | ||

| Terminal | ||||

| F52 | 92 | 97 | Coasting from 80 km/h (50 MPH) in D position | The voltage should be above 0.71 V at least once during this procedure. The voltage should be below 0.18 V at least once during this procedure. |

Is the inspection result normal?

INSPECTION END

INSPECTION END6.REPLACE HEATED OXYGEN SENSOR 2

Replace heated oxygen sensor 2. Refer to Exploded View .

.

.

.| caution |

|

: INSPECTION END

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)