Work Procedure

Always perform the radar alignment after removing and installing or replacing the distance sensor.

Application Notice

TYPE 1

Description

OUTLINE OF RADAR ALIGNMENT PROCEDURE

- A 4-wheel vehicle alignment must be performed before proceeding with radar alignment procedure.

- Always perform the radar alignment after removing and installing or replacing the distance sensor.

| warning | Radio waves could adversely affect electric medical equipment. Those who use a pacemaker should contact the electric medical equipment manufacturer for the possible influences before use. |

| caution | The system does not operate normally unless the radar alignment is performed. Always perform it. |

- Set the target board (SST: KV99112700) to the correct position in front of the vehicle.

- Set the radar alignment mode (“MILLIWAVE RADAR ADJUST” on “Work support”) with M.U.T.-III SE, and then perform the adjustment according to the display. (Distance sensor automatically adjusts.)

CAUTIONARY POINT FOR RADAR ALIGNMENT PROCEDURE

| caution |

|

Preparation

1.ADVANCE PREPARATION FOR RADAR ALIGNMENT

- Adjust all tire pressure to the specified value.

- Empty the vehicle. (Remove any luggage from the passenger compartment, trunk room, etc.)

- Shift the selector lever to “P” position, and release the parking brake.

- Fully fill the fuel tank, and then check that the coolant and oils are filled up to correct level.

- Clean the distance sensor area

of the front bumper grille.

of the front bumper grille.

Setting The Target Board

Accurate adjustment of the radar alignment requires that the target board be accurately positioned.

| caution | If the radar alignment is adjusted with the target board in the incorrect position, the AEB/PFCW systems do not function normally. |

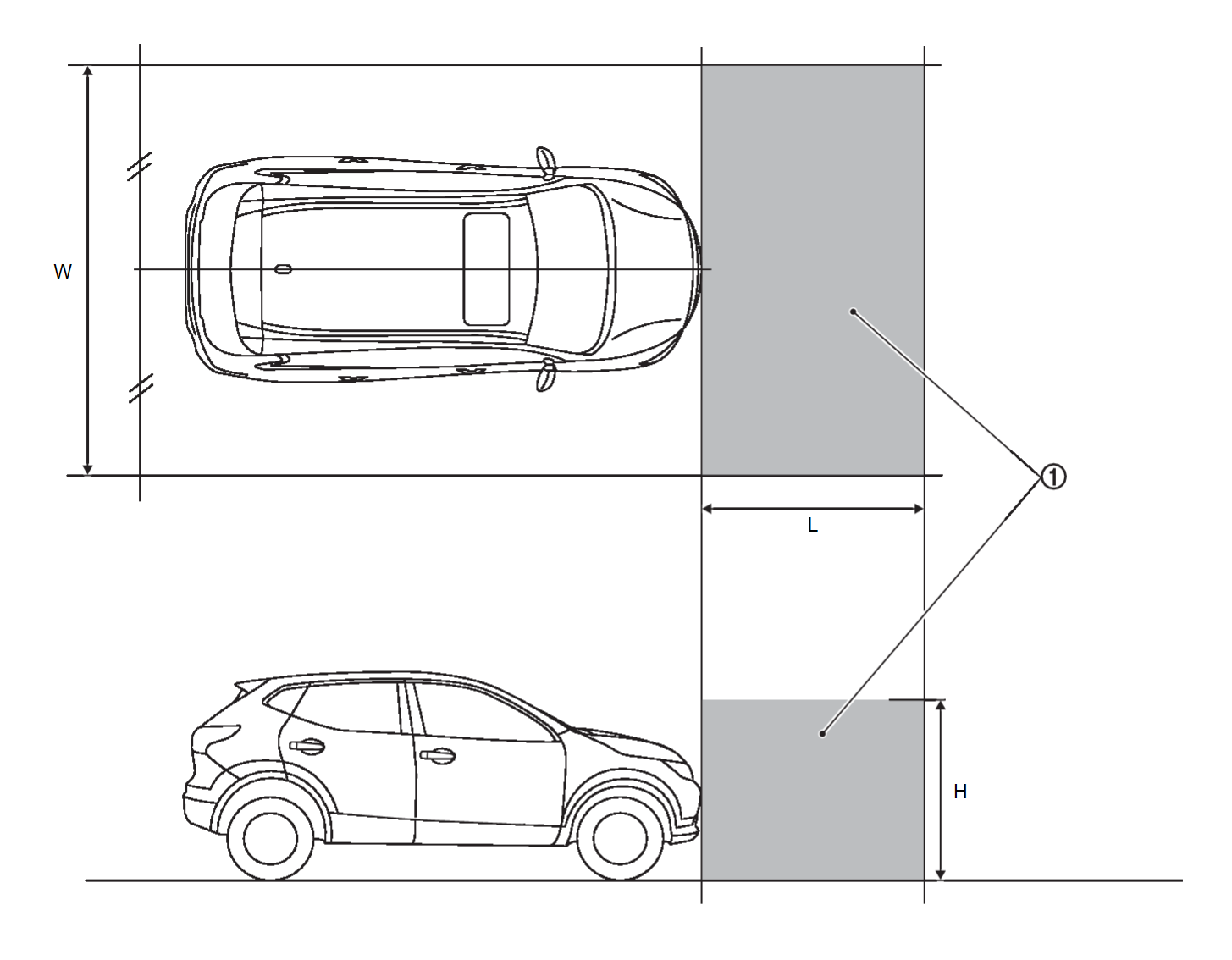

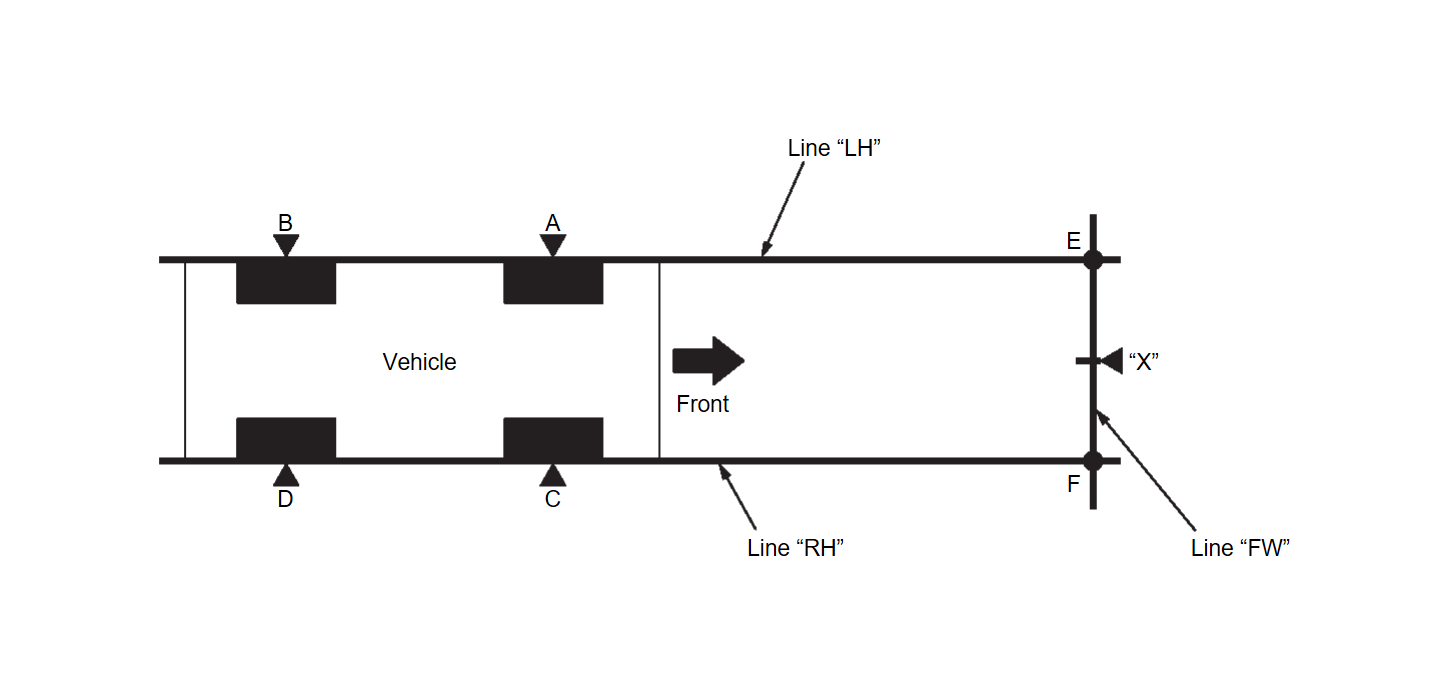

2.PREPARATION OF SETTING TARGET BOARD (1)

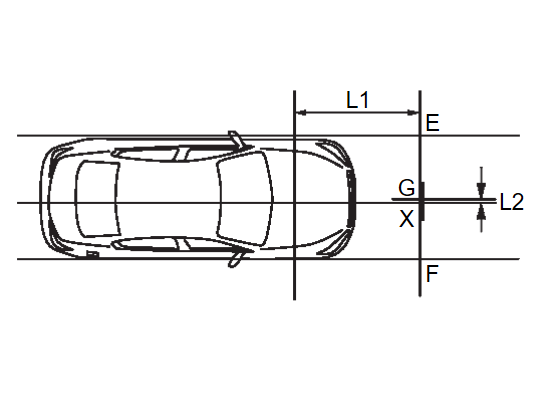

| “A”–“E” (“C”–“F”) | : 2000 mm (78.7 in) |

- Mark points “A”, “B”, “C” and “D”at the center of the lateral surface of each wheels.

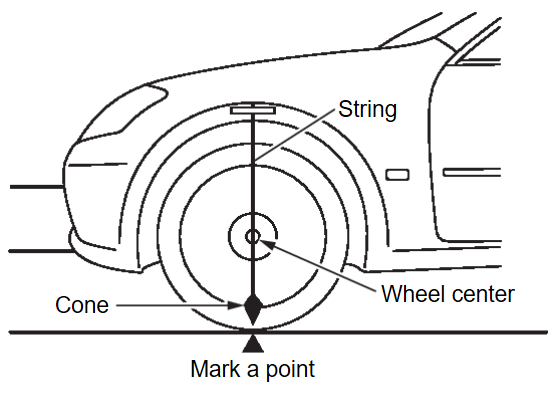

note Hang a string with a cone from the fender so as to pass through the center of wheel, and then mark a point at the center of the lateral surface of the wheel. - Draw line “LH” passing through points “A” and “B” on the left side of vehicle.

note Approximately 2 m (6.56 ft) or more from the front end of vehicle. - Mark point “E” on the line “LH” at the positions 2000 mm (78.7 in) from point “A”.

- Draw line “RH” passing through points “C” and “D” on the right side of vehicle in the same way as step 2.

note Approximately 2 m (6.56 ft) or more from the front end of vehicle. - Mark point “F” on the line “RH” at the positions 2000 mm (78.7 in) from point “C”.

- Draw line “FW” passing through the points “E” and “F” on the front side of vehicle.

- Mark point “X” at the center of point “E” and “F” on the line “FW”.

caution Make sure that “E” to “X” is equal to “F” to “X”.

3.SETTING TARGET BOARD

Place the center of target board on point “G” at line “E-F” and install the target board.

| caution | For performing the radar alignment correctly, securely install (target board) to be parallel with the “E-F” line. |

| L1 | : 2000 mm (78.7 in) |

| L2 | : 0 mm (0 in) |

Radar Alignment

The radar alignment is performed automatically with M.U.T.-III SE.

| caution | Perform all necessary work for radar alignment until the adjustment completes as shown in the procedure. If the procedure does not complete, the AEB/MI-PILOT Assist/PFCW systems are inoperable. |

1.PERFORM RADAR ALIGNMENT

- Start the engine.

- Connect M.U.T.-III SE and select “Work support” of “LASER/RADAR”.

- Select “MILLIWAVE RADAR ADJUST”.

note Confirm the following items; - The target should be accurately placed.

- The vehicle should be stopped.

- Select “Start” after the conditions displayed on M.U.T.-III SE are satisfied.

caution Never select “Start” when the target is not accurately placed. - Select “Next” after the “Radar alignment conditions are ready.” screen is displayed.

note If the radar is in alignment at this time, “In progress” is displayed. It may take several 10s of seconds until the result is displayed. - Confirm the displayed item.

- “Completed.”: Go to 7.

- Except “Completed.”: Perform the following services.

Displayed item Possible cause Service procedure Alignment result is over threshold. - DTC is detected

- The position of the target board is incorrect

- Vehicle is moving

Check the vehicle alignment condition and perform radar alignment again Horizontal value is over threshold. Check the condition.Perform the adjust again.- DTC is detected

- The position of the target board is shifted horizontally

- Vehicle is moving

Check the vehicle alignment condition and perform radar alignment again Vertical value is over threshold. Check the condition.Perform the adjust again.- DTC is detected

- The position of the target board is shifted vertically

- Vehicle is moving

Check the vehicle alignment condition and perform radar alignment again Horizontal value and Vertical value are over threshold. Check the condition.Perform the adjust again.- DTC is detected

- The position of the target board is shifted horizontally and vertically

- Vehicle is moving

Check the vehicle alignment condition and perform radar alignment again This display direction is looking from driver seat side. note This is not an error message, so service procedures are not required. Target is not detected. (Reflection radio waves is weak.) Reconfirm the placing condition, and then re-perform adjustment.- A target is not-yet -placed

- The position of the target board is incorrect

- The position of the distance sensor is incorrect

Check the vehicle alignment condition and perform radar alignment again Target setting is offset in horizontal direction. Reconfirm the placing condition. And then re-perform adjustment or re-install the radar.- The position of the target board is shifted horizontally

- The position of the distance sensor is shifted horizontally

Check the vehicle alignment condition and perform radar alignment again Target setting is offset in vertical direction. Reconfirm the placing condition. And then re-perform adjustment or re-install the radar.- The position of the target board is shifted vertically

- The position of the distance sensor is shifted vertically

Check the vehicle alignment condition and perform radar alignment again EEPROM writing is error. Re-perform adjustment or replace the ECU.- The condition of the alignment is incorrect

- Distance sensor malfunction

- Check the vehicle alignment condition and perform radar alignment again

- If same massage displays again, replace the distance sensor

Hardware is imperfect. Replace the ECU.Distance sensor hardware has trouble for alignment Replace the distance sensor Signal of vehicle side is imperfect or combination of ECU is incorrect. Diagnose the other ECU.Other ECU except distance sensor have trouble for alignment - Check if any DTC is detected in “Self Diagnostic Result” of other ECU except distance sensor

- If any DTC is not detected, replace the distance sensor

Software is incorrect. Replace the ECU.Distance sensor software is incorrect Replace the distance sensor

- Confirm displayed value.

Displayed item Monitor item Reference value Completed Vertical Angle Radar angle “DownW” or “UpW” Vertical Angle Radar measurement result (- 2.50) - (+ 3.00) Horizontal Angle Radar angle “LeftW” or “RightW” Horizontal Angle Radar measurement result Less than 0 ± 4.00 deg Alignment status Alignment complete - Within reference value: Go to 8.

- Outside of reference value: Check the target board condition and perform radar alignment again.

note - Check the condition of the distance sensor installation.

- Check the vehicle for damage.

- Replace distance sensor if it is outside the reference value, even when distance sensor installation is installed normally and the vehicle is not damaged.

- Select “End”.

caution Once “MILLIWAVE RADAR ADJUST” is started with M.U.T.-III SE, always continue the work until the horizontal radar alignment is completed successfully. If the job is stopped midway, the radar alignment is not adjusted and the AEB/MI-PILOT Assist/PFCW systems cannot operate.

: RADAR ALIGNMENT END

TYPE 2

Description

OUTLINE OF RADAR ALIGNMENT PROCEDURE

- A 4-wheel vehicle alignment must be performed before proceeding with radar alignment procedure.

- Always perform the radar alignment after removing and installing or replacing the distance sensor.

- Always perform the radar alignment if rear axle toe settings have been made.

| warning | Radio waves could adversely affect electric medical equipment. Those who use a pacemaker should contact the electric medical equipment manufacturer for the possible influences before use. |

| caution | The system does not operate normally unless the distance sensor is aligned properly. |

CAUTIONARY POINT FOR RADAR ALIGNMENT PROCEDURE

| caution |

|

Required Tools

The following tools are necessary to perform distance sensor alignment:

- Radar Sensor Aiming Kit 1–20–2851–1 Kit includes the following:

a) Target Board (Fixture)

b) Laser assembly

c) Rear Stand

Use kit 1–20–2851–1 with a self-centering wheel adapter (e.g. 1–20–2722–1–IF, Hunter 20–3339–1 or equivalent).

| note | Tools 1–20–2721–1–IF, 1–20–2722–1–IF and J-50808 have been superseded and are no longer available, but may still be used for distance sensor alignment. |

- Target board.

: Position 1, with top tilted 2° toward vehicle (Not used).

: Position 1, with top tilted 2° toward vehicle (Not used). : Position 2, vertical.

: Position 2, vertical. : Position 3, with top tilted 2° away from vehicle (Not used).

: Position 3, with top tilted 2° away from vehicle (Not used).

- Hunter self-centering wheel adapter

[shown with laser assembly

[shown with laser assembly  installed] (Hunter alignment rack head may be substituted).

installed] (Hunter alignment rack head may be substituted). note Directional arrows  and

and  are shown to illustrate the direction of the laser assembly beams.

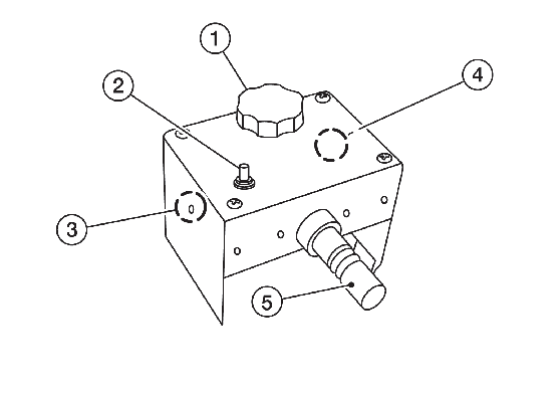

are shown to illustrate the direction of the laser assembly beams. - Laser assembly (with bi-directional laser beam) as shown in the illustration.

- Tightening knob

- Power ON/OFF button

- Front laser beam opening

- Rear laser beam opening

- Attaching shaft

- Tightening knob

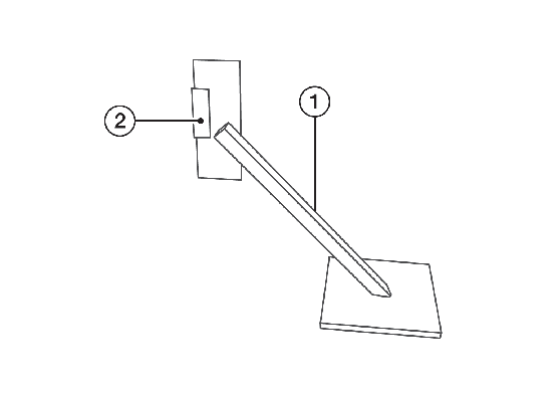

- Rear stand as shown in the illustration.

- Rear stand

- Laser signal reception plate

- Rear stand

- Distance chain (not shown)

Preparation

1.ADVANCE PREPARATION FOR RADAR ALIGNMENT PROCEDURE

- Adjust all tire pressure to the specified value.

- Empty the vehicle. (Remove any luggage from the passenger compartment, luggage room, etc.)

- Shift the selector lever to “P” position, and release the parking brake.

- Fully fill the fuel tank, and then check that the coolant and oils are filled up to correct level.

- Clean the distance sensor area

of the front bumper grille.

of the front bumper grille.

Vehicle Set Up

Accurate adjustment of the radar alignment requires that the target board, wheel adapter, laser assembly, and rear stand be properly positioned.

| caution | If the radar alignment is adjusted with the target board, wheel adapter, laser assembly, or rear stand in the incorrect position, the AEB/PFCW systems will not function properly or the alignment procedure may not be completed successfully. |

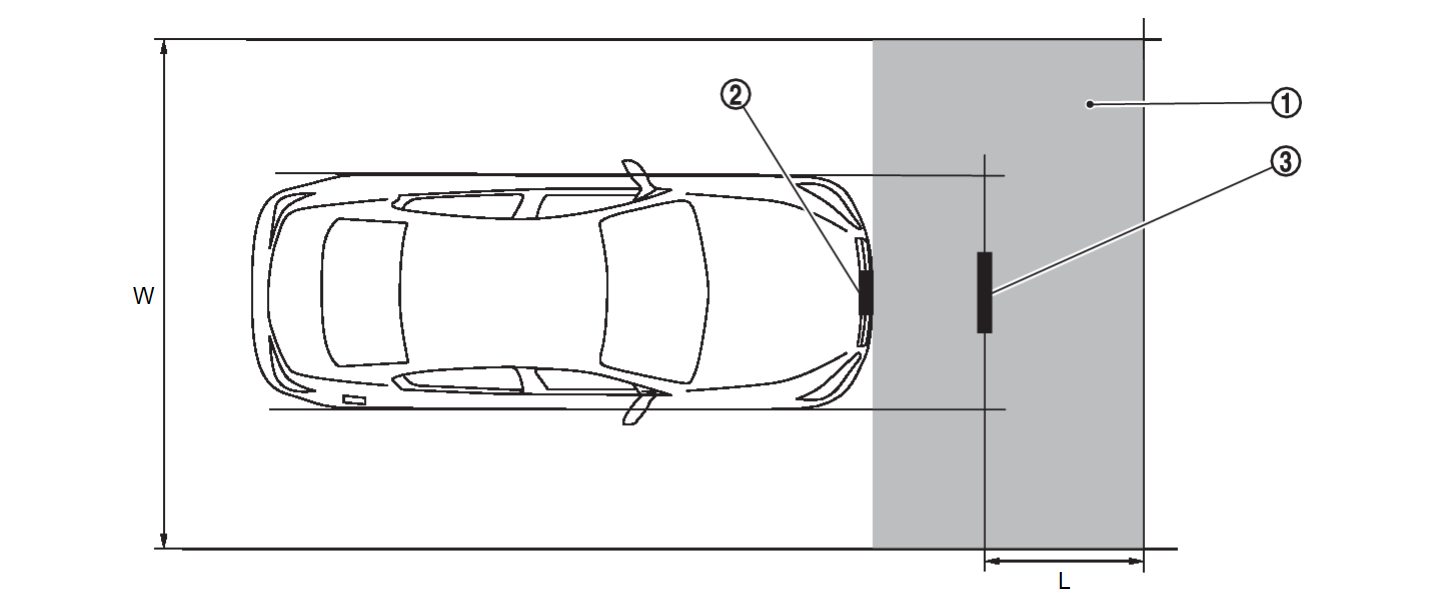

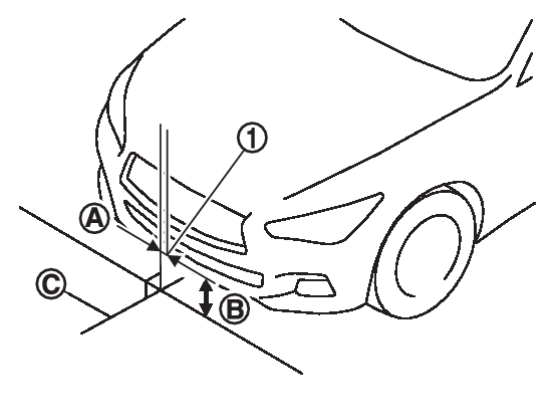

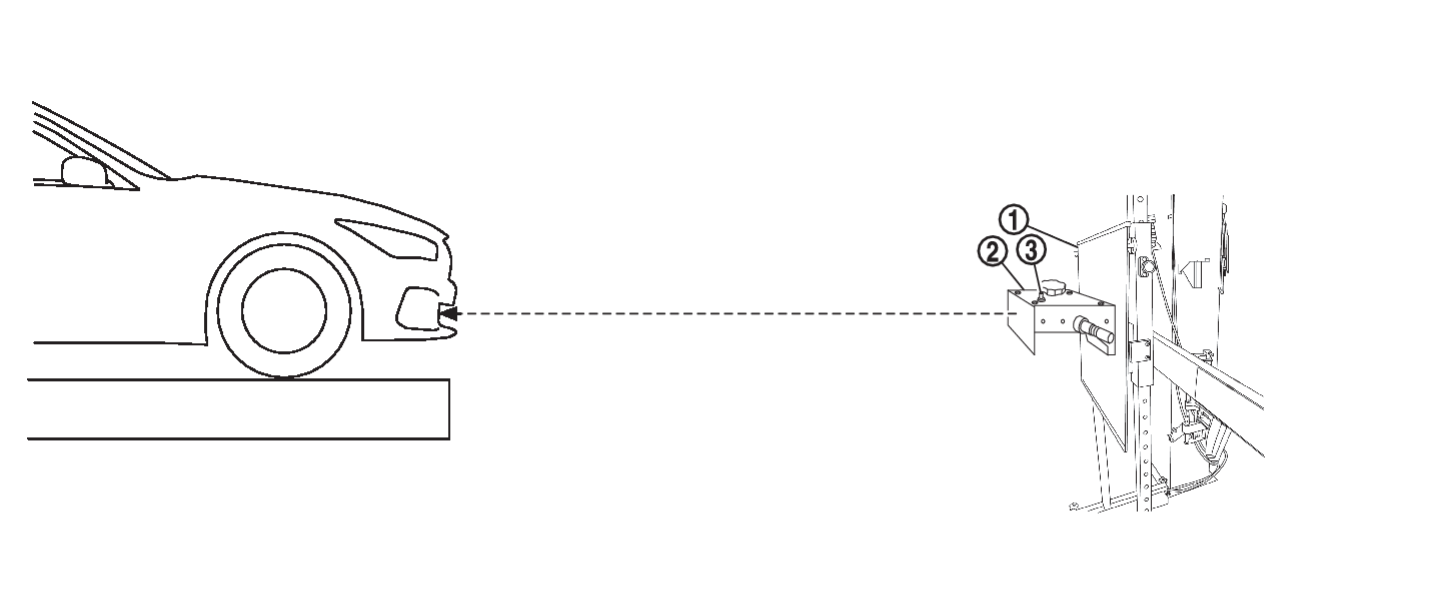

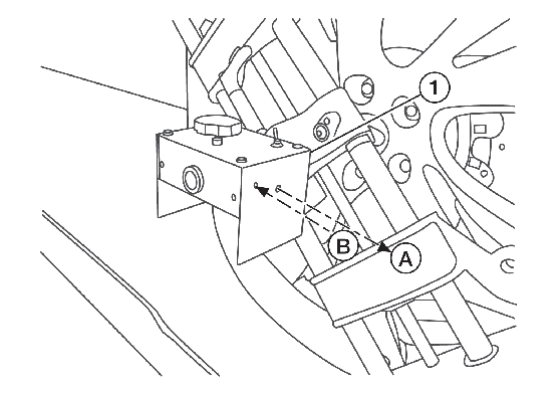

1.PREPOSITION TARGET BOARD

| note |

- Position the target board in front facing the right front side of the vehicle:

- Place the marked center of the target board

813.6 mm (32.03 in) ± 50 mm (1.97 in) facing the distance sensor.

813.6 mm (32.03 in) ± 50 mm (1.97 in) facing the distance sensor. - Adjust the height of the target board using the adjustable nut

to achieve the proper height. The up/down tolerance is ± 30 mm (1.18 in).

to achieve the proper height. The up/down tolerance is ± 30 mm (1.18 in). - Adjust the target board lateral position aligning the marked center of the board horizontally with the center of the distance sensor. The right/left tolerance is ± 80 mm (3.15 in).

- Place the marked center of the target board

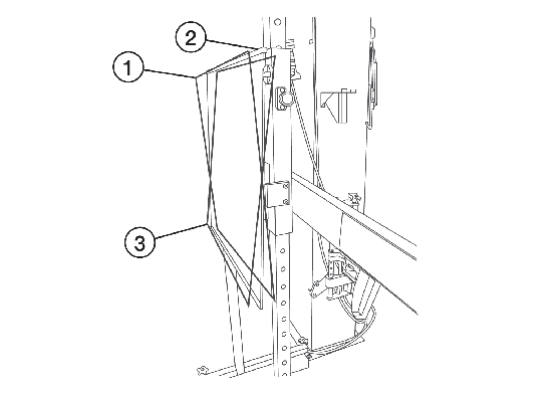

- Extend the machined arm of the target board exposing the reflective surface

to the right front side of the vehicle.

to the right front side of the vehicle. - Place one side of the laser assembly

flush against the center of the target board

flush against the center of the target board  to assist in the positioning.

to assist in the positioning. - Turn the laser assembly ON

allowing the laser beam to emit through the opening of the laser assembly toward the center of the distance sensor.

allowing the laser beam to emit through the opening of the laser assembly toward the center of the distance sensor. - Move the target board

as necessary so that center of target board aligns with center of distance sensor.

as necessary so that center of target board aligns with center of distance sensor. - Turn the laser assembly OFF when done.

Are using Hunter alignment equipment?

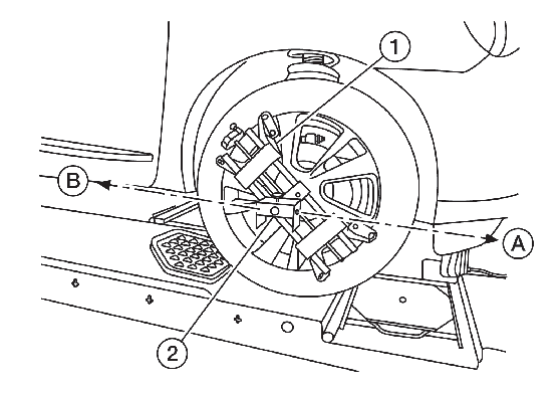

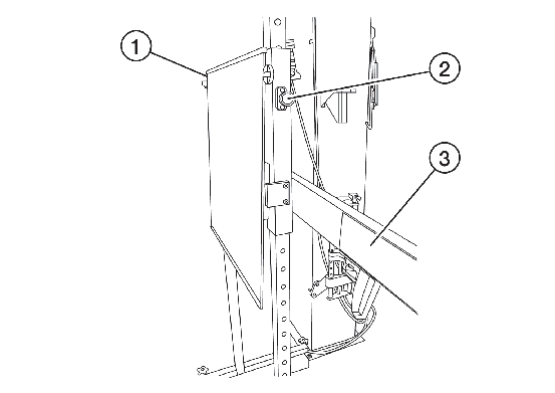

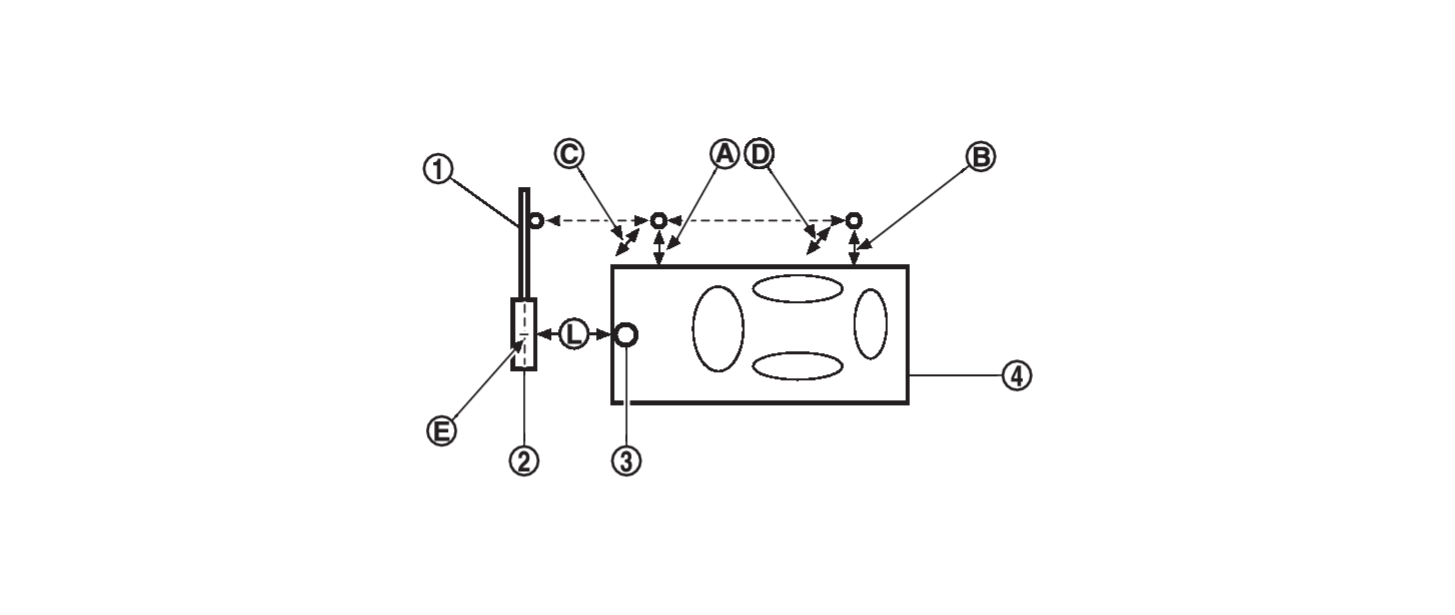

2.INSTALLING LASER ASSEMBLY

| note |

|

- Install the wheel adapter

on the right front wheel.

on the right front wheel. - Mount the laser assembly

to the wheel adapter

to the wheel adapter  as shown in the figure.

as shown in the figure.note When the power switch is turned ON, the front laser signal  will be emitted toward the front target board, and the rear laser signal

will be emitted toward the front target board, and the rear laser signal  will be emitted toward the rear of the vehicle.

will be emitted toward the rear of the vehicle.

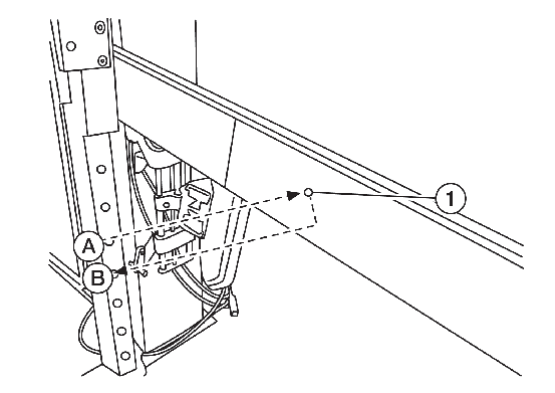

3.SETTING UP REAR STAND

- Place the rear stand next to the right rear tire as shown in the figure.

- Turn the laser assembly ON allowing the laser beam to be emitted through the front and rear laser assembly openings.

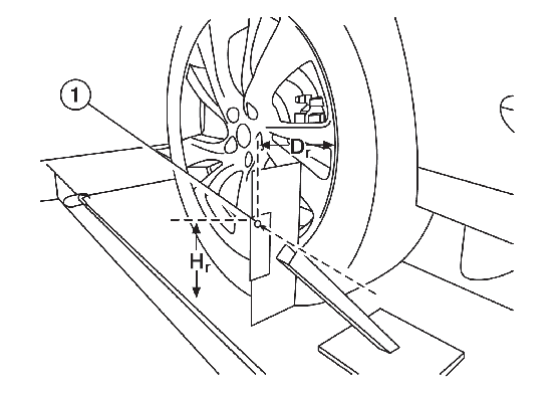

- Measure and record the distance (Dr) between the edge of the right rear wheel and the laser beam

on the rear stand (horizontal line).

on the rear stand (horizontal line). - Measure and record the height (Hr) between the laser beam

on the rear stand and ground level (vertical line).

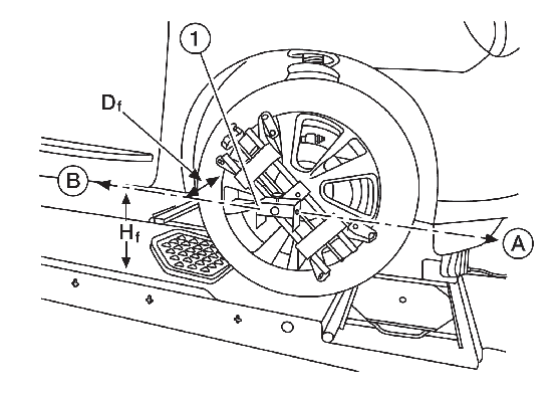

on the rear stand and ground level (vertical line). - Measure and record the distance (Df) between the edge of the right front wheel and the laser beam signal/opening

on the laser assembly (horizontal line).

on the laser assembly (horizontal line). - Measure and record the height (Hf) between the laser beam signal/opening

on the laser assembly and ground level (vertical line).

on the laser assembly and ground level (vertical line).note - Horizontal adjustment [front distance (Df) and rear distance (Dr)] is accomplished by slowly turning the steering wheel until the 2 distances are the same.

- Vertical adjustment [front height (Hf) and rear height (Hr)] is accomplished by rotating the laser assembly around its axis until the two heights are the same.

- Directional arrows

and

and  are shown to illustrate the direction of the laser assembly beams.

are shown to illustrate the direction of the laser assembly beams.

- Adjust laser beam as necessary until the two distances match and the two heights match.

note Must be verify both horizontal and vertical adjustments anytime one adjustment is made.

Setting The Target Board

Accurate adjustment of the radar alignment requires that the target board be accurately positioned.

| caution | If the radar alignment is adjusted with the target board in the incorrect position, the AEB/PFCW systems will not function properly or the alignment procedure may not be completed successfully. |

1.TARGET BOARD FINAL SETTING

- With the target board arm extended, the laser beam

emitted by the laser assembly

emitted by the laser assembly  will be reflected back

will be reflected back  toward the laser assembly.

toward the laser assembly.note When adjusted properly, reflected laser beam  must align with emitted laser beam

must align with emitted laser beam  and the two laser beams will be seen as one.

and the two laser beams will be seen as one. - Rotate the target board to achieve the necessary horizontal adjustment.

- Adjust the target board leveling screws to achieve the necessary vertical adjustment.

- The figure shown illustrates the laser beam

emitted by the laser assembly

emitted by the laser assembly  and its reflection

and its reflection  off of the target board arm.

off of the target board arm.

2.CHECK THE POSITION OF THE TARGET BOARD

Do not place anything other than the target board in the space shown in front of the vehicle (view from top).

| Target board arm |  | Target board |  | Distance sensor |

| Vehicle | ||||

| Distance between front wheel and laser beam (Df) |  | Distance between rear wheel and laser beam (Dr) |  | Height between front laser beam and ground (Hf) |

| Height between rear laser beam and ground (Hr) |  | Target board center position |  | 1010 - 1110 mm (39.76 - 43.7 in) |

Distance Sensor Adjustment

The radar alignment is performed automatically with M.U.T.-III SE.

| caution | Perform all necessary work for radar alignment until the adjustment completes as shown in the procedure. If the procedure does not complete, the AEB/MI-PILOT Assist/PFCW systems are inoperable. |

1.PERFORM RADAR ALIGNMENT

- Start the engine.

- Connect M.U.T.-III SE and select “Work support” of “LASER/RADAR”.

- Select “MILLIWAVE RADAR ADJUST”.

note Confirm the following items; - The target should be accurately placed.

- The vehicle should be stopped.

- Select “Start” after the conditions displayed on M.U.T.-III SE are satisfied.

caution Never select “Start” when the target is not accurately placed. - Select “Next” after the “Radar alignment conditions are ready.” screen is displayed.

note If the radar is in alignment at this time, “In progress” is displayed. It may take several 10s of seconds until the result is displayed. - Confirm the displayed item.

- “Completed.”: Go to 7.

- Except “Completed.”: Perform the following services.

Displayed item Possible cause Service procedure Alignment result is over threshold. - DTC is detected

- The position of the target board is incorrect

- Vehicle is moving

Check the vehicle alignment condition and perform radar alignment again Horizontal value is over threshold. Check the condition.Perform the adjust again.- DTC is detected

- The position of the target board is shifted horizontally

- Vehicle is moving

Check the vehicle alignment condition and perform radar alignment again Vertical value is over threshold. Check the condition.Perform the adjust again.- DTC is detected

- The position of the target board is shifted vertically

- Vehicle is moving

Check the vehicle alignment condition and perform radar alignment again Horizontal value and Vertical value are over threshold. Check the condition.Perform the adjust again.- DTC is detected

- The position of the target board is shifted horizontally and vertically

- Vehicle is moving

Check the vehicle alignment condition and perform radar alignment again This display direction is looking from driver seat side. note This is not an error message, so service procedures are not required. Target is not detected. (Reflection radio waves is weak.) Reconfirm the placing condition, and then re-perform adjustment.- A target is not-yet -placed

- The position of the target board is incorrect

- The position of the distance sensor is incorrect

Check the vehicle alignment condition and perform radar alignment again Target setting is offset in horizontal direction. Reconfirm the placing condition. And then re-perform adjustment or re-install the radar.- The position of the target board is shifted horizontally

- The position of the distance sensor is shifted horizontally

Check the vehicle alignment condition and perform radar alignment again Target setting is offset in vertical direction. Reconfirm the placing condition. And then re-perform adjustment or re-install the radar.- The position of the target board is shifted vertically

- The position of the distance sensor is shifted vertically

Check the vehicle alignment condition and perform radar alignment again EEPROM writing is error. Re-perform adjustment or replace the ECU.- The condition of the alignment is incorrect

- Distance sensor malfunction

- Check the vehicle alignment condition and perform radar alignment again

- If same massage displays again, replace the distance sensor

Hardware is imperfect. Replace the ECU.Distance sensor hardware has trouble for alignment Replace the distance sensor Signal of vehicle side is imperfect or combination of ECU is incorrect. Diagnose the other ECU.Other ECU except distance sensor have trouble for alignment - Check if any DTC is detected in “Self Diagnostic Result” of other ECU except distance sensor

- If any DTC is not detected, replace the distance sensor

Software is incorrect. Replace the ECU.Distance sensor software is incorrect Replace the distance sensor

- Confirm displayed value.

Displayed item Monitor item Reference value Completed Vertical Angle Radar angle “DownW” or “UpW” Vertical Angle Radar measurement result (- 2.50) - (+ 3.00) Horizontal Angle Radar angle “LeftW” or “RightW” Horizontal Angle Radar measurement result Less than 0 ± 4.00 deg Alignment status Alignment complete - Within reference value: Go to 8.

- Outside of reference value: Check the target board condition and perform radar alignment again.

note - Check the condition of the distance sensor installation.

- Check the vehicle for damage.

- Replace distance sensor if it is outside the reference value, even when distance sensor installation is installed normally and the vehicle is not damaged.

- Select “End”.

caution Once “MILLIWAVE RADAR ADJUST” is started with M.U.T.-III SE, always continue the work until the horizontal radar alignment is completed successfully. If the job is stopped midway, the radar alignment is not adjusted and the AEB/MI-PILOT Assist/PFCW systems cannot operate.

: RADAR ALIGNMENT END

![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)