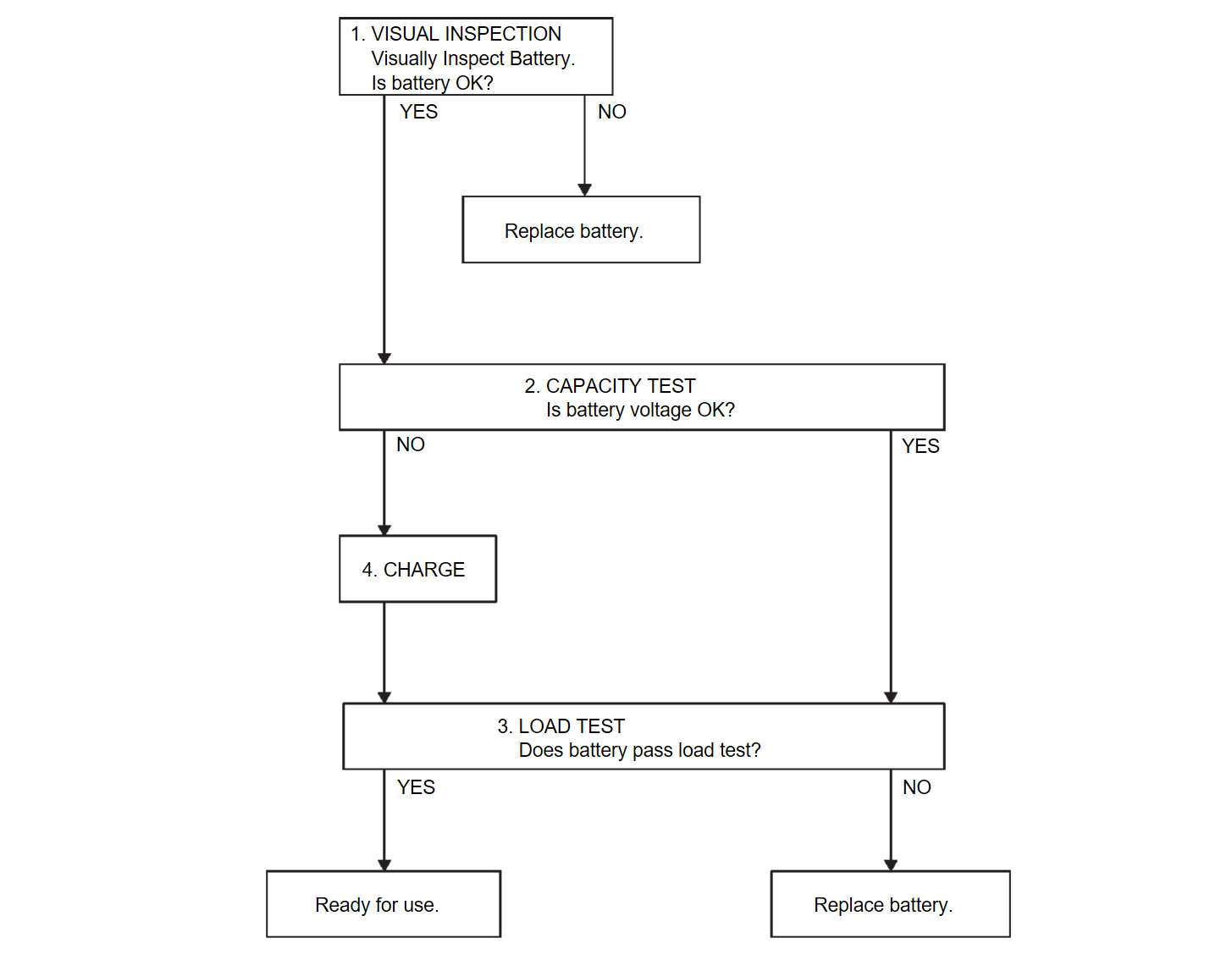

Work Flow

BATTERY DIAGNOSIS WITH EXP-800 NI OR GR8-1200 NI

To diagnose and confirm the condition of the battery, use the following special service tools:

- EXP-800 NI Battery and electrical diagnostic analyzer

- GR8-1200 NI Multitasking battery and electrical diagnostic station

| note | Refer to the applicable instruction manual for proper battery diagnosis procedures. |

BATTERY DIAGNOSIS WITHOUT EXP-800 NI OR GR8-1200 NI

DETAILED FLOW

1.VISUAL INSPECTION

- Check battery case for cracks or bends.

- Check battery terminals for damage.

Are these inspection results normal?

Replace battery. Refer to Removal and Installation

Replace battery. Refer to Removal and Installation .

.3.LOAD TEST

- Check battery type and determine the specified current using the table.

Type Current (A) L3–EFB 300 - Read load tester voltage when specified discharging current flows through battery for 15 seconds.

note Follow tool manufacturers operating instructions when performing load test.

Is the voltage 10 V or more?

Ready for use.

Ready for use. Replace battery. Refer to Removal and Installation

Replace battery. Refer to Removal and Installation .

.![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)