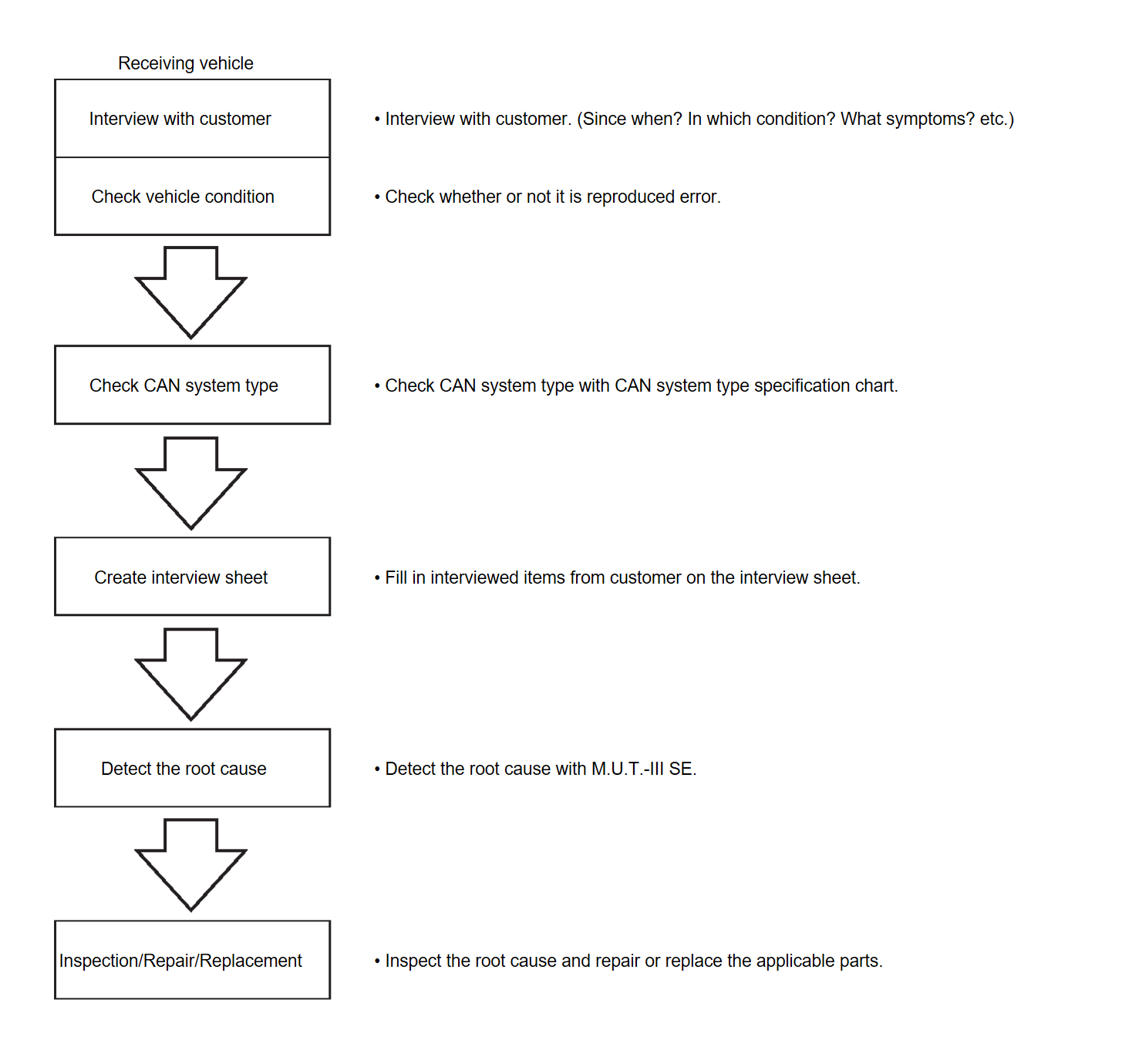

Trouble Diagnosis Flow Chart

DETAIL OF TROUBLE DIAGNOSIS FLOW CHART

1.INTERVIEW WITH CUSTOMER

Interview with the customer is important to detect the root cause of CAN communication system errors and to understand vehicle condition and symptoms for proper trouble diagnosis.

Points in interview

- What: Parts name, system name

- When: Date, Frequency

- Where: Road condition, Place

- In what condition: Driving condition/environment

- Result: Symptom

Notes for checking error symptoms:

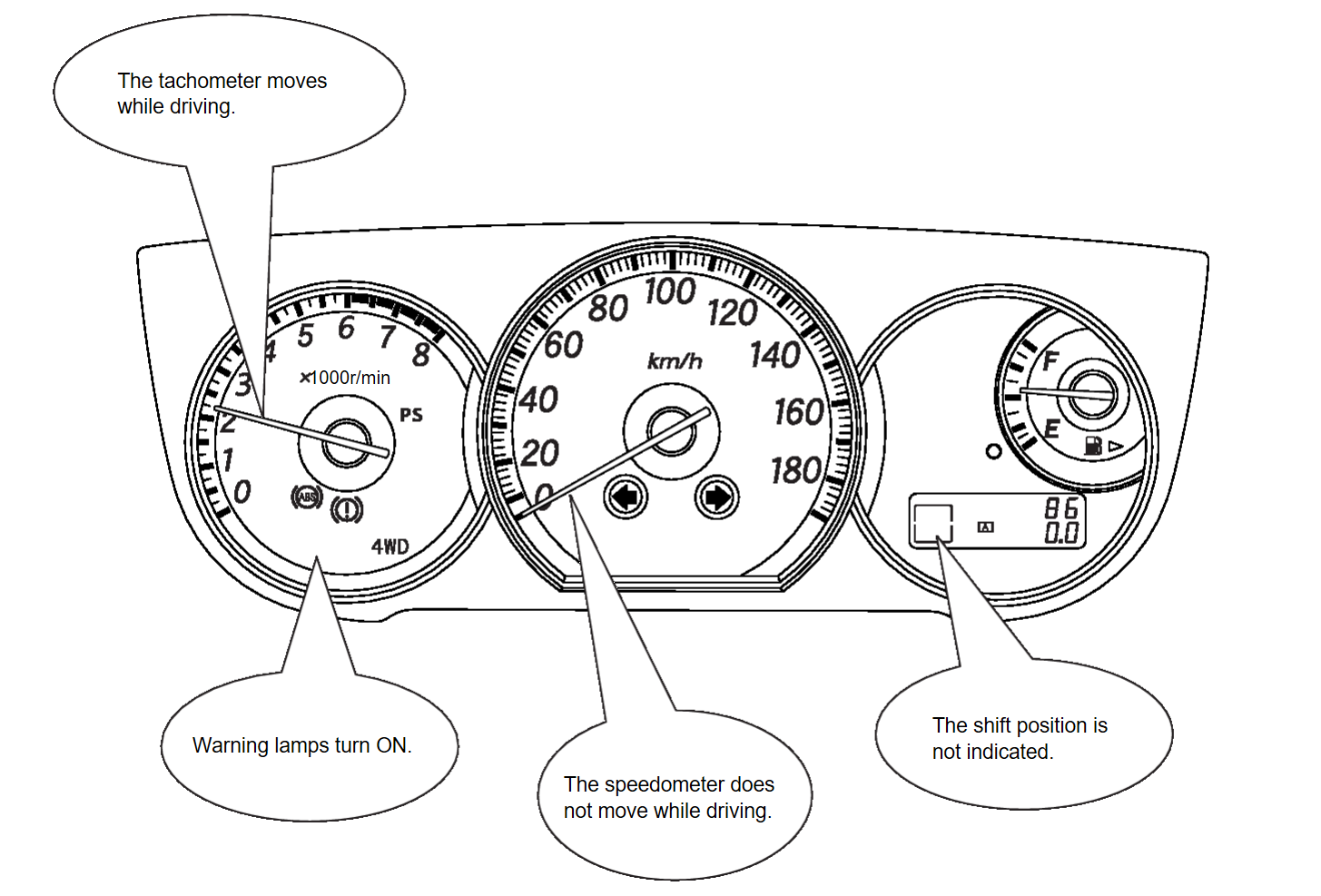

- Check normal units as well as error symptoms.

- Example: Circuit between ECM and the combination meter is judged normal if the customer indicates tachometer functions normally.

- When a CAN communication system error is present, multiple control units may malfunction or go into fail-safe mode.

- Indication of the combination meter is important to detect the root cause because it is the most obvious to the customer, and it performs CAN communication with many units.

2.INSPECTION OF VEHICLE CONDITION

Check whether the symptom is reproduced or not.

| note | Do not turn the ignition switch OFF or disconnect the 12V battery cable while reproducing the error. The error may temporarily correct itself, making it difficult to determine the root cause. |

3.CHECK OF CAN SYSTEM TYPE (HOW TO USE CAN SYSTEM TYPE SPECIFICATION CHART)

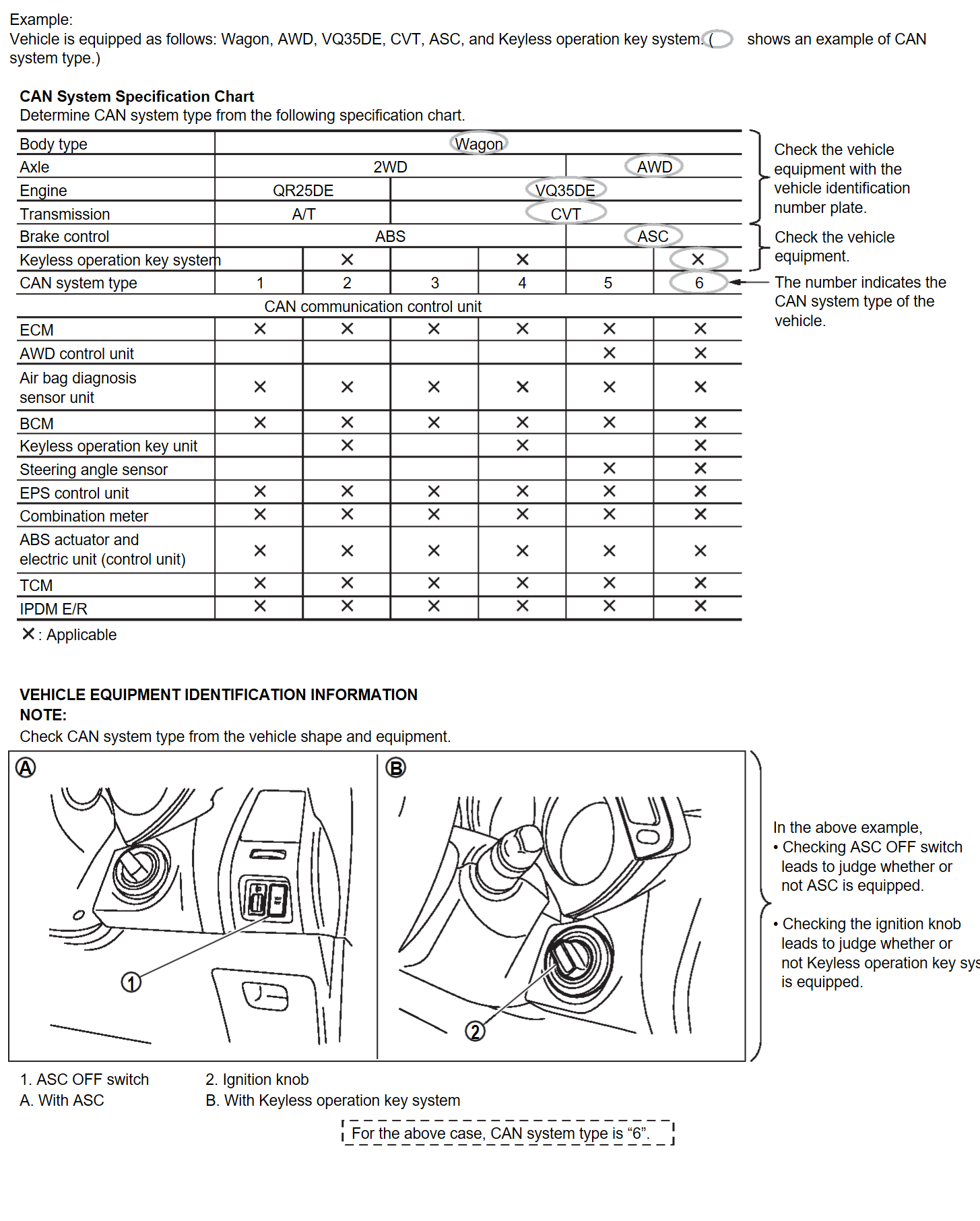

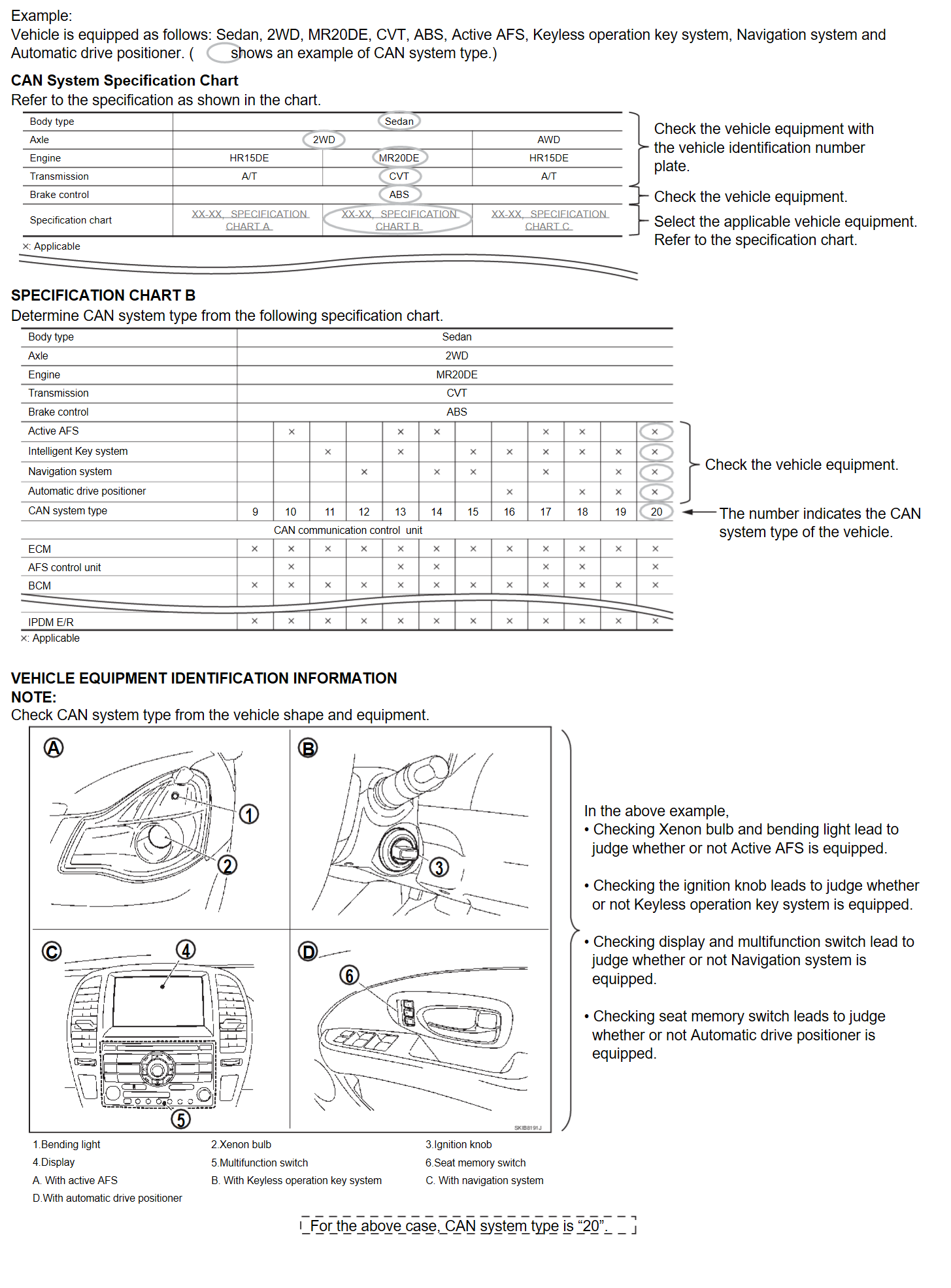

Determine CAN system type based on vehicle equipment.

| note |

|

- CAN System Type Specification Chart (Style A)

note CAN system type is easily checked with the vehicle equipment identification information shown in the chart.

- CAN System Type Specification Chart (Style B)

note CAN system type is easily checked with the vehicle equipment identification information shown in the chart.

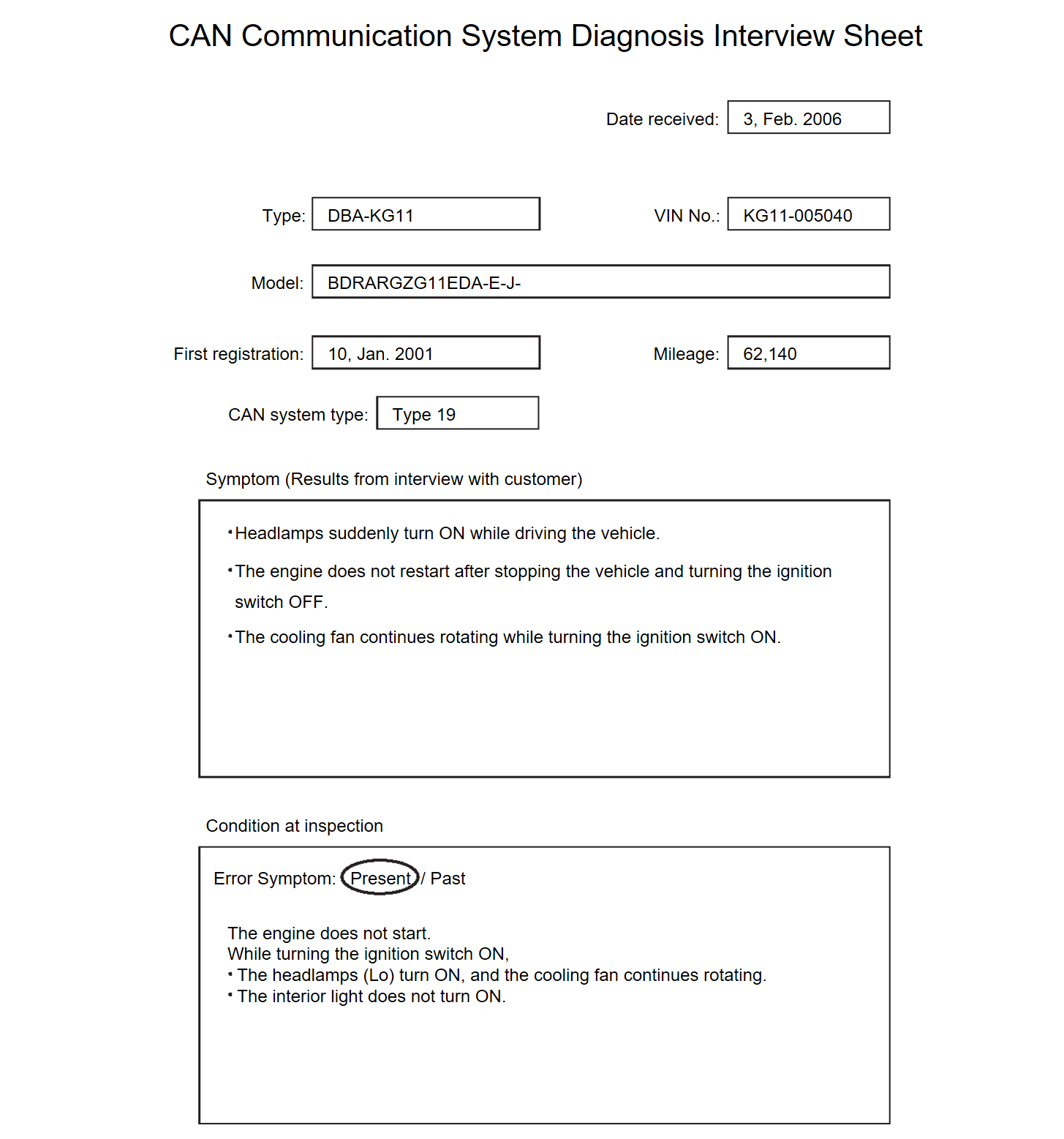

4.CREATE INTERVIEW SHEET

Fill out the symptom described by the customer, vehicle condition, and CAN system type on the interview sheet.

| note | Interview Sheet (Example) |

6.REPAIR OR REPLACE MALFUNCTIONING PART

Repair or replace malfunctioning parts identified by CAN diagnosis function of M.U.T.-III SE.

: Refer to Vehicle CAN Communication Circuit .

.

.

. : Refer to ITS CAN Communication Circuit .

.

.

. : Refer to Chassis Communication CircuitChassis CAN Communication Circuit .

.

.

. : Refer to Drivetrain CAN Communication Circuit .

.

.

. : Refer to IT CAN Communication Circuit .

.

.

. : Refer to Engine CAN Communication CircuitENGINE CAN Communication Circuit .

.

.

. : Refer to Diagnostic CAN Communication Circuit .

.

.

.![[Previous]](../../../buttons/fprev.png)

![[Next]](../../../buttons/fnext.png)